- Offer Profile

-

HERMLE is all about milling and achieving outstanding results.

This is clearly demonstrated by the slogan "milling at its best". It stands for high-performance, highly innovative machining centres which have risen to a leading position nationally and internationally. It stands for a far-reaching and closely meshed sales and service network and for a worldwide presence.Globally there are more than 27000 machines in use, mainly at suppliers of medical technology, in the optical industry, in aviation, in the automotive industry and in motor sport.

HERMLE produces small to medium-sized three to five-axis milling centres for a wide range of applications.

Even machines for applications with increased demands on precision or machining volumes are manufactured. The different machine models are available with magazine extensions and a pallet changer. Furthermore, various handling systems are offered directly from the manufacturer.

Our highlights

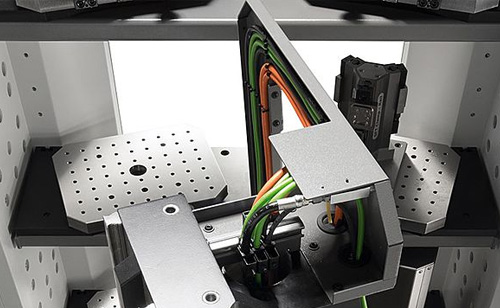

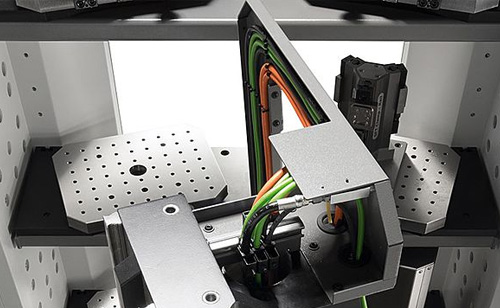

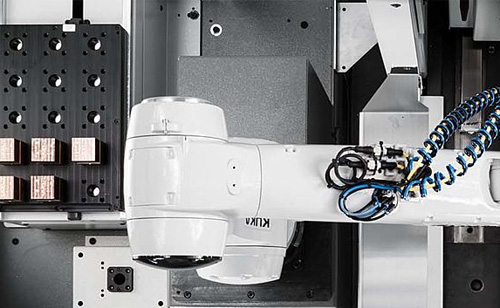

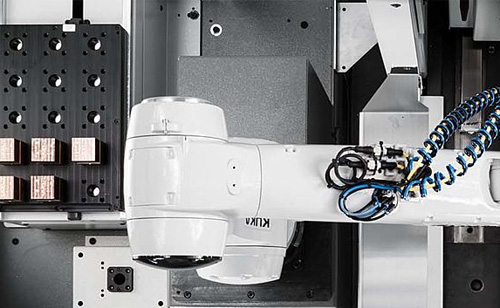

RS 1 ROBOT SYSTEM

-

MINIMUM SPACE, MAXIMUM PRODUCTIVITY

This is where the unique adaptation concept of the RS 1 comes into its own: with an installation area of just 12 m², the robot system always offers free access to the machine, regardless of whether one or two machining centres are docked – and with up to three rack storage modules that can be integrated.

HS FLEX / HS FLEX HEAVY

-

PERFECT OPERATION - KEEP IT SIMPLE

The integrated touch panel reduces buttons to the ones most needed, forming the basis for the greatest possible reduction to the essential. This concept is also evident in the easy-to-operate scanner for the simplest order recording imaginable.

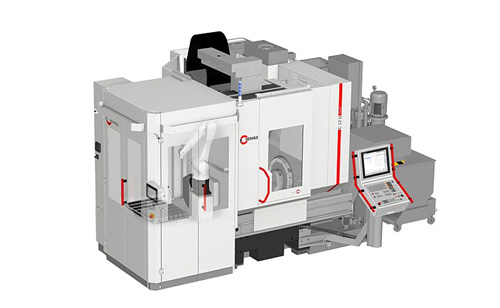

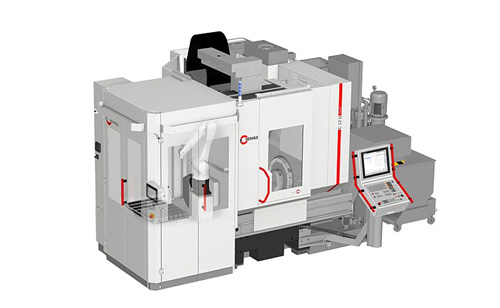

RS 05-2 ROBOT SYSTEM

-

SMALL FOOTPRINT - BIG PERFORMANCE

Machine and robot system merge into one compact unit

Product overview

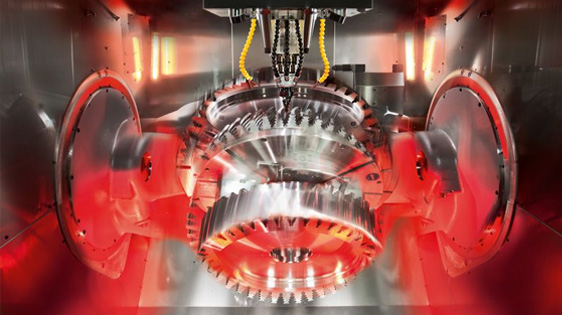

Top speed! With 2.5 t in 5 axes for all sectors.

Milling at its best: HERMLE machines are often at the forefront when it comes to optimized results. The proverbial HERMLE precision in combination with process consulting and project management has made us the most important machine partner in nearly all key sectors – ranging from large-sized complex components to microcomponents in the high-tech field. Versatile use, uncompromising results – simply HERMLE.

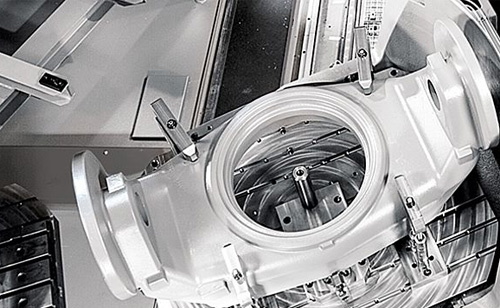

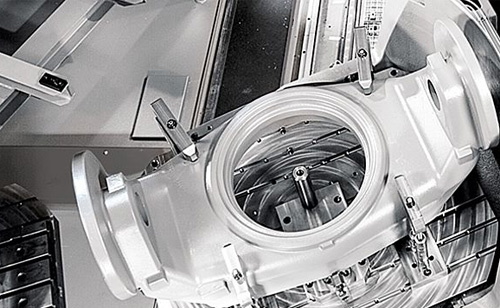

HERMLE machining centers have a very large round component diameter thanks to their axis design and the way that the NC swivelling rotary table is integrated into the machine.

They can process very large workpieces relative to the installation area. Some models can even considerably exceed the 0° to 90° swivelling range.

The C axes use either worm gears or torque drives, depending on the machining process. The A axes can be fitted with one-sided or tandem drives, depending on workpiece weight and the required dynamics. Our MT models can even mill or turn in 5 axes simultaneously.HIGH-PERFORMANCE-LINE

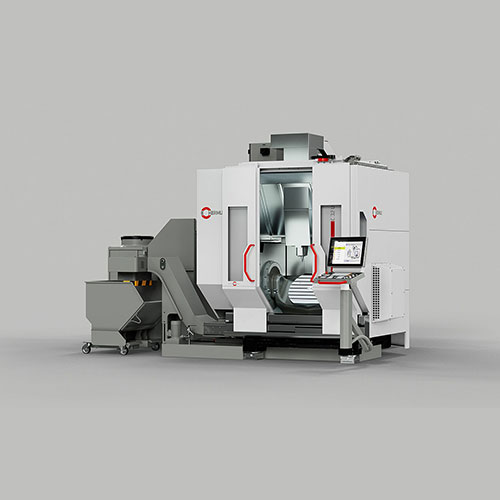

The C 12

5-axis machining centre-

The C 12 High-Performance-Line machining centre is hugely popular due to its particularly compact footprint.

Maximum efficiency combined with a installation area: The C 12is the most compact HERMLE machining centre in the High-Performance-Line. Designed for machining cubic parts up to 100 kg in weight, the

C 12 works in the most diverse applications compactly, precisely and dynamically. As the following application areas show, the right RPM rating is available for practically any application.The especially compact and space-saving C 12 machining centre meets the ever increasing demands placed on speed and precision thanks to the corresponding HERMLE setups. It goes without saying that there are also many options available for more complex situations.

The especially compact and space-saving C 12 machining centre meets the ever increasing demands placed on speed and precision thanks to the corresponding HERMLE setups. It goes without saying that there are also many options available for more complex situations.

- Traverse path: 350x440x330 mm

- Body: dia. 320/ H 265

- Collision circle: dia. 610 mm

- Max. vertical table clearance: 430 mm

- Speed: 12000/15000/18000/25000/30000/42000 1/min

- Rapid traverse linaer: 30 (50) m/min.

- Swivelling rotary table: dia. 320 mm

- Table loading max.: 100 kg

The C 22

3/4/5-axis machining centre-

As the C 12’s bigger brother, the C 22 High-Performance-Line machining centre has the same collision circle but longer traverse paths and enables larger component dimensions.

As the C 12’s bigger brother, the C 22 High-Performance-Line machining centre has the same collision circle with longer traverse paths and larger component dimensions – and that means a huge degree of flexibility.. The C 22 impresses with a large number of features. This predestines the C 22 for an especially wide range of applications, as the following examples show.

Short process cycles, quick workflows and the highest possible machine dynamics:: The flexible C 22 machining centre is ideal for machining high-value parts with excellent accuracy and small tolerances. As with most HERMLE machining centres, the height-adjustable control panel can be altered to suit the operator’s working height.

- Traverse path: 450 x 600 x 330 mm

- Body: dia. 450 / H 370

- Collision circle: dia. 610 mm

- Max. vertical table clearance: max. 470 mm

- Speed: 15000/18000/25000/30000/42000 1/min

- Rapid traverse linear X-Y-Z: 30 (50) m/min.

- Swivelling rotary table: dia. 320 mm

- Max. table load: 300 kg

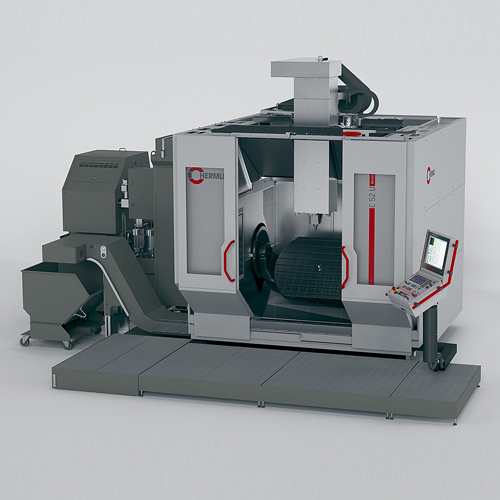

The C 32

3/4/5-axis machining centre-

The C 32 machining centre machines up to 1000 kg workpieces at five axes simultaneously: from delicate wings for aeroplane models to robust bearing blocks.

The C 32 machining centre can machine workpieces weighing up to 1000 kg in five axes simultaneously. The machining centre can even deal with difficult-to-machine materials in record time and perfect precision – even fully automated and always with unbeatable operating comfort! The scope of usage for the C 32 is very wide.

The C 32 machining centre uses two axes in the workpiece and three axes in the tool. Dynamic positioning, short non-productive periods and secure holding in the desired machining position all go without saying. As does the very large working area in relation to the installation space.

- Traverse path: 650 x 650 x 500 mm

- Body: dia. 650 / H 420

- Collision circle: dia. 840 mm

- Max. vertical table clearance: 600 / 635 mm

- Speed: 15000/18000/25000/42000 1/min

- Rapid traverse linear X-Y-Z: (60)–45 (60)–40 (60) m/min.

- Swivelling rotary table: dia. 650 x 540 mm

- Max. table load: 1000 kg

The C 42 / C42 U MT

3/4/5-axis machining centre-

The C 42 High-Performance-Line machining centre offers ideal entry into MT technology.

The C 42 machining centre from the High-Performance-Line makes for an effective entry into MT technology – and it becomes a high-performance milling and turning centre. This includes various applications in the tool and mould making, medical, aerospace, motorsport, racing machine sectors and other industries: TheC 42/ C C 42 U MT machining centre is at home in every area.

As a milling/turning centre, the C 42 / C 42 U MT responds to demands for highest precision and very small tolerances through its workpiece-dimension-optimized traverse paths and thought-through 5-axis usage.

- Traverse path: 800 x 800 x 550 mm

- Body: dia. 800 / H 560

- Collision circle: dia.990 mm

- Max. vertical table clearance: max. 700 mm

- Speed: 15000/18000/25000/42000 1/min

- Rapid traverse linear X-Y-Z: 45 (60)–45 (60)–40 (60) m/min.

- Swivelling rotary table: dia. 800 x 630 mm

- Max. table load: 1400 kg

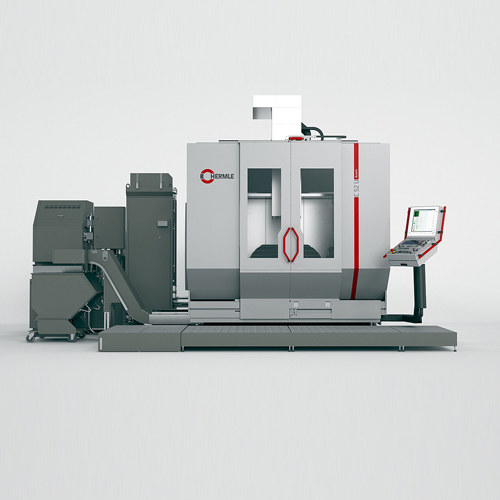

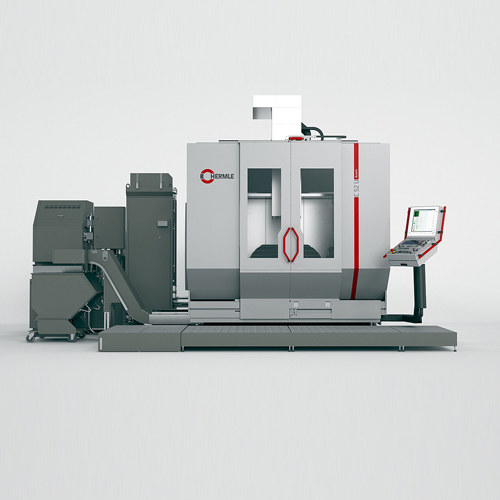

The C 52 / C 52 U MT

5-axis machining centre-

The C 52 enables the 5-axis machining of workpieces weighing up to 2000 kg. The optional MT technology guarantees simultaneous milling and turning.

The C 52 machining centre is a flexible multitalent with an especially large working area on a very small installation area. With the C 52, workpieces weighing up to 2000 kg can be machined in 5 axes simultaneously – with unbeatable precision and accuracy. The C 52 sets new standards: These standards are particularly valued in demanding applications, for instance in the medical, aerospace and automotive industries. In short: wherever the highest precision and maximum efficiency are required.

Ample dimensions, high-performance spindle drives and many useful innovations for practical work turn the C 52 / C 52 U MT machining centre into a top performer.

- Traverse path: 1000 x 1100 x 750 mm

- Body: dia. 1000 / H 810

- Collision circle: dia. 1290 mm

- Max. vertical table clearance: 950 mm

- Speed: 9000/14000/18000 1/min

- Rapid traverse linaer: 60–60–55 m/min.

- Swivelling rotary table: dia. 1150 x 900 mm

- Table loading max.: 2000 kg

The C 62 / C62 U MT

5-axis machining centre-

As the premium model of the High-Performance-Line, the C 62 effortlessly machines components measuring up 1200 mm in diameter.

‘State-of-the-art’ CNC machining – this is what the C 62 / C 62 U MT stands for as HERMLE’s High-Performance-Line flagship at the top of the entire product range. The highly dynamic machining centre represents ultimately consistent design for efficient machining of CNC milled parts and CNC turned parts. The application clips show the details of how this works in practice.

Numerous features ensure high-precision and cost-effective work on workpieces up to 2500 kg in weight. Various optional extras simply add to the capabilities for innovative advanced machining. As with all HERMLE machining centres, the C 62 / C 62 U MT offers various workpiece loading options to guarantee optimum operation.

- Traverse path: 1200 x 1300 x 900 mm

- Body: dia. 1200 / H 900

- Collision circle: dia. 1400 mm

- Max. vertical table clearance: 1100 mm

- Speed: 9000/10000/12000/15000/18000 1/min

- Rapid traverse linear X-Y-Z:50 m/min.

- Swivelling rotary table: dia. 1350 x 1100 mm

- Max. table load: 2500 kg

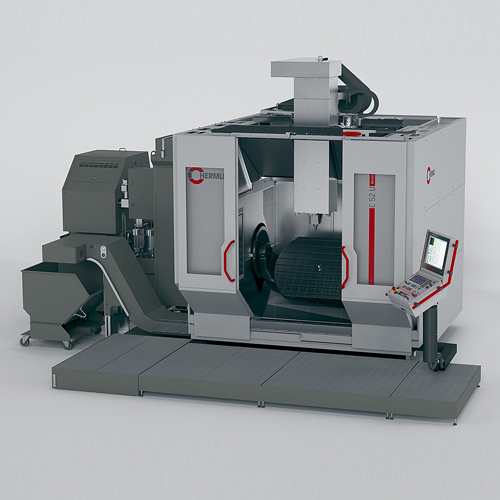

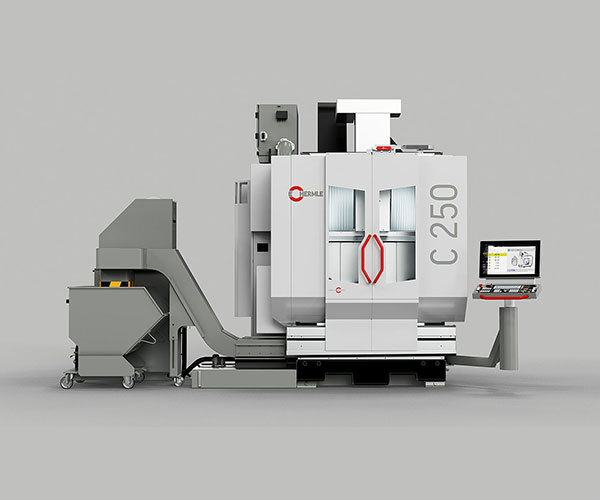

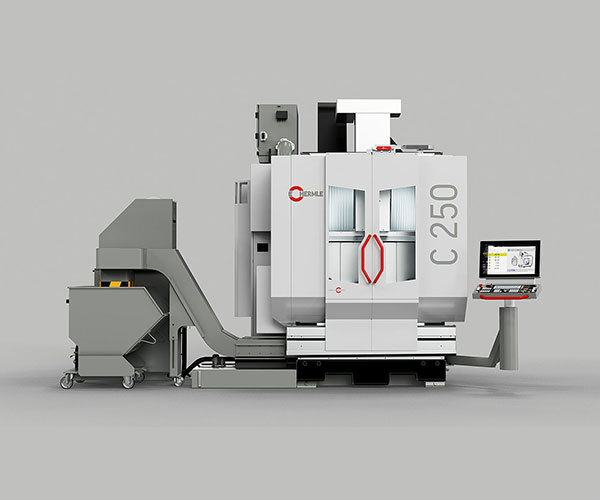

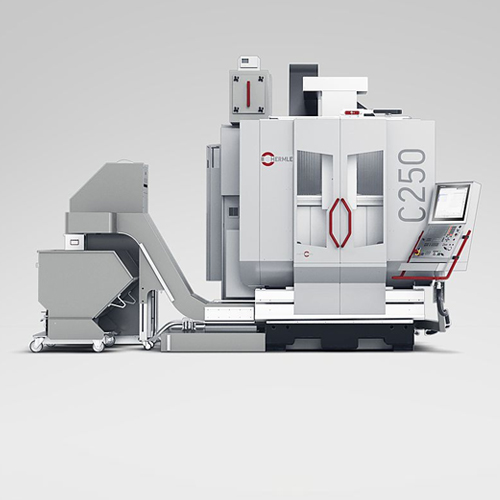

PERFORMANCE-LINE

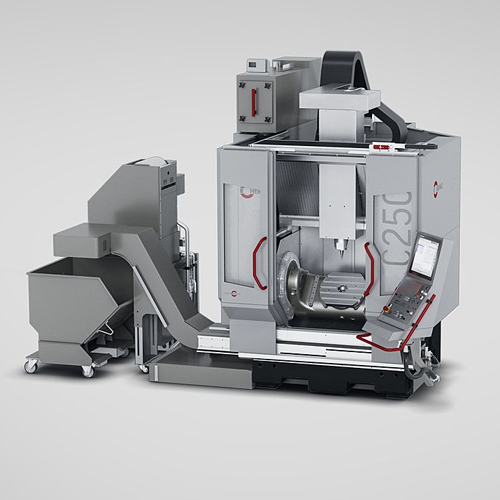

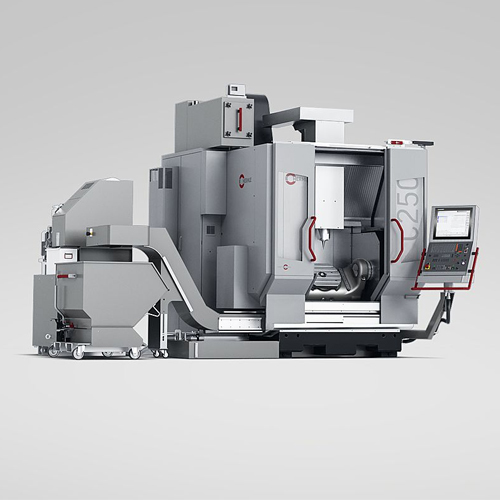

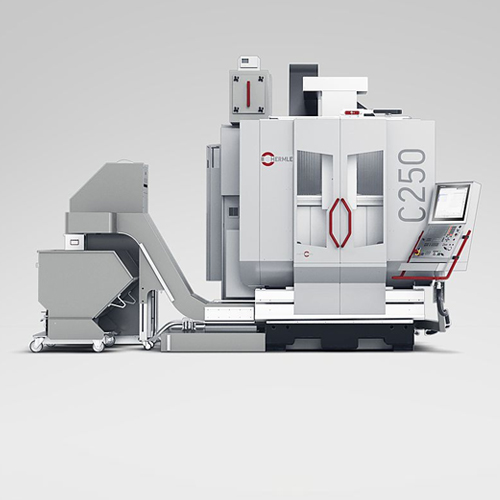

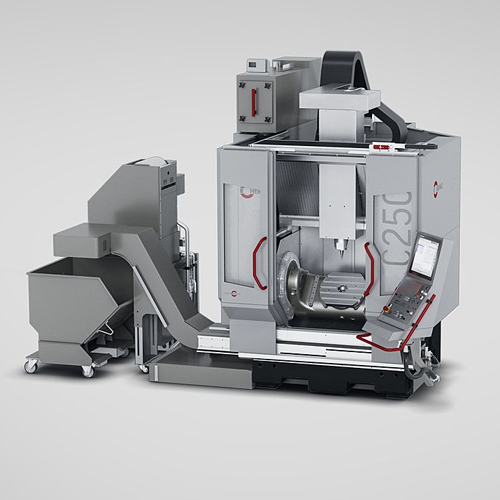

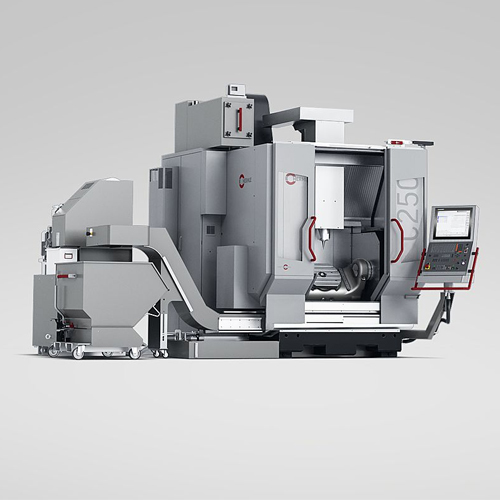

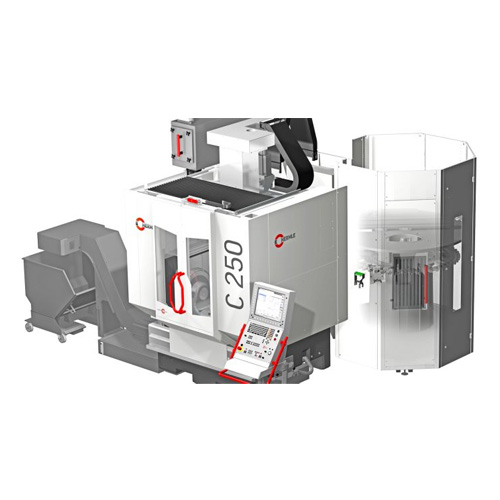

C 250 – Dynamic CNC machining centre for entry into 5-axis / 5-sided machining

-

As the entry-level model in the world of HERMLE, the C 250 Performance-Line machining centre meets the highest standards of quality and durability

Within the model range, the C 250 can be seen as the entry-level model for 5-axis milling – and for the HERMLE Performance-Line. Thanks to the wide-reaching swivelling range of the workpieces in the working area, the exploitation of the full traverse range and the large collision circle between the table sections, the C 250 has the largest working area in relation to the installation area. And it is constructed for everyday use: The application video shows the HERMLE C 250 U in the 5-axis version machining a Rockerbox in Toolox33 for vehicle technology.

Maximum precision thanks to the HERMLE swivelling rotary table concept. The machining table has a large worm drive. On the A axis you can directly access the gearwheel on the table housing.

- Traverse path: 600 x 550 x 450 mm

- Body: dia. 450 / H 355

- Collision circle: dia. 770 mm

- Max. vertical table

- clearance: 550 mm

- Speed: 15000/18000 1/min

- Rapid traverse linear X-Y-Z: 35 m/min

- Rigid clamping table: 800 x 616 mm

- Max. table load: 1100 kg

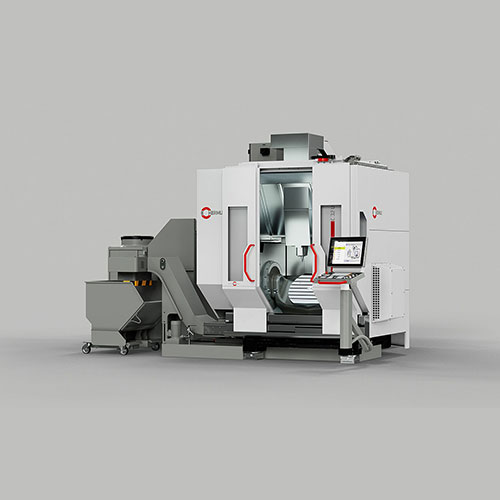

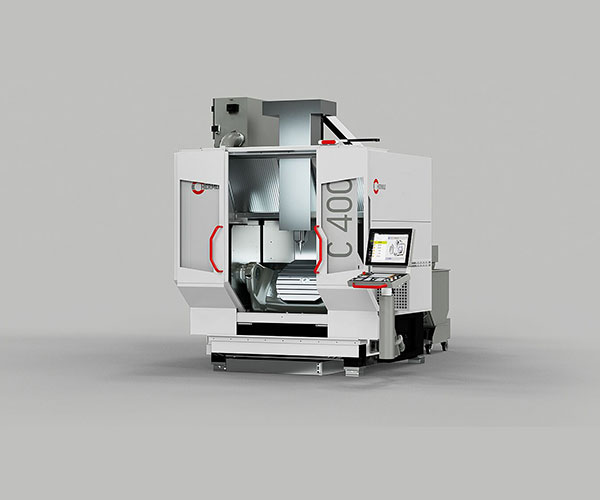

The C 400

3/4/5-axis machining centre-

Compared to the C 250 within the Performance-Line, the C 400 machining centre enables the machining of large components.

The C 400 is a dynamic and economical machining centre designed for 5-axis / 5-side machining. This is where HERMLE’s well-known core competence in 5-axis technology comes into its own. The mineral cast machine bed provides for the C 400'sstable, vibration-free machining. You will find some application examples below from the areas of toolmaking and mould construction as well as machine construction.

Many features combine to make for economical 5-axis / 5-side machining. The C 400 machining centre is intended for high performance, large-scale machining of workpieces to high accuracy and surface quality. The C 400 features a large working area with a small installation area and can be ergonomically adapted to every machine operator - thus ensuring optimum ease of use.

- Traverse path: 850 x 700 x 500 mm

- Body: dia. 650 / H 500

- Colision circle: dia.885 mm

- Max. vertical table clearance: max. 625 mm

- Speed: 15000/18000 1/min

- Rapid traverse linear X-Y-Z:m/min

- Rigid clamping table:1070 x 700 mm

- Max. table load: 2000 kg

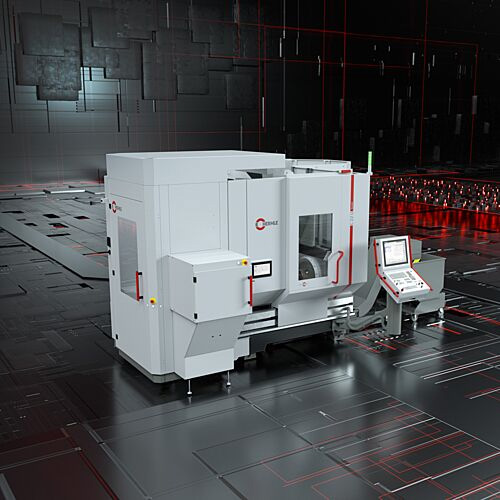

The C 650

3/4/5-axis machining centre-

Setting new standards in the HERMLE Performance-Line: The C 650 is a brand new development offering the highest precision at maximum table load.

From machine construction to precision mechanics, from medical engineering to energy production, from the aerospace and automotive industry to tool and mould construction and the general subcontractor industry: The C 650 is ideal for a vast array of milling operations. Seeing as the new machining centre was launched in 2017, there are as yet no examples of practical applications. Be the first! Use the button below to access examples of good practice with other HERMLE machining centres.

As the youngest member of the HERMLE Performance-Line, the C 650 sets new standards in terms of the traverse path and load performance. Furthermore, the machining centre manages to integrate the entire spectrum of features that have proved hugely popular with users of the smaller C 250 and C 400 models. The top speed of the linear rapid traverses is 35 m/min.

- Traverse path: 1050 x 900 x 600 mm

- Body: Dia. 900 / H 600

- Collision circle: Ø 1100 mm

- Vertical table clearance max. 775 mm

- Rotational speed: 15000/18000 rpm

- Rapid traverse linear X-Y-Z : 35 m/min

- Rigid clamping table: 1250 x 982 mm

- Max. table load: 3000 kg

Automation

-

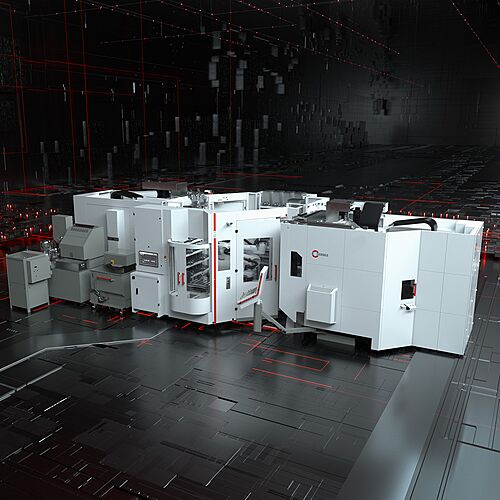

HERMLE automation - pure efficiency! We develop solutions to meet your requirements!

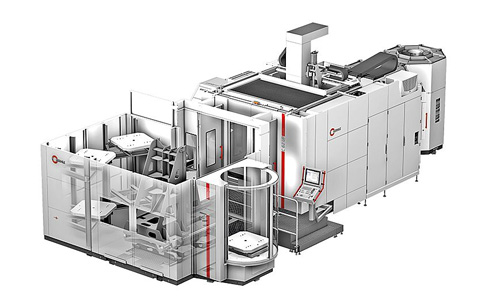

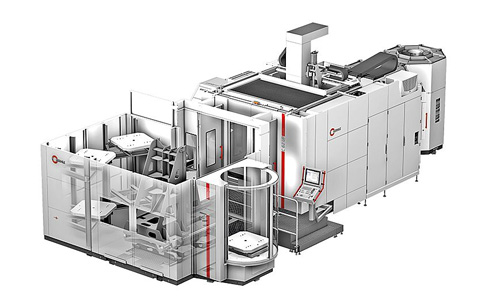

HERMLE has been taking the subject of automation for its machining centres and milling machines seriously for many years now. The beginnings were modest, with simple automation and handling solutions, but as early as the mid nineteen-nineties a specially founded subsidiary HLS HERMLE Systemtechnik GmbH took over the operations.

Whether the problem involves pallet changers, pallet storage, additional magazines, handling systems, robot systems or complex turnkey projects, we provide you with optimal solutions for automating HERMLE products – everything from a single supplier, including servicing.

ASSEMBLY AND PRODUCTION HALL OF HLS HERMLE SYSTEMTECHNIK GMBH

- Assembly and production of automation systems, robot systems, turn-key projects.

WHY AUTOMATION?

-

Why automation? Mankind has alway been very inventive when it comes to making work easier, avoiding hard and monotonous work and improving productivity. Now the main aims are to increase production times and decrease idle times and downtimes.

The better this can be achieved, the lower the machine-hour rate and the lower the personnel costs, meaning altogether lower capital commitment. Especially in times of staff shortages in the high-qualification areas, automation provides an alternative to manned triple-shift operations.

The pallet changers!

- For economical production from the very first batch. Improve the productivity of your HERMLE machining centre.

The handling systems!

- For efficient production.

Handling of workpieces in a wide variety of shapes, sizes and weights can be

largely automated with handling systems to achieve advantages in terms of cost and time.

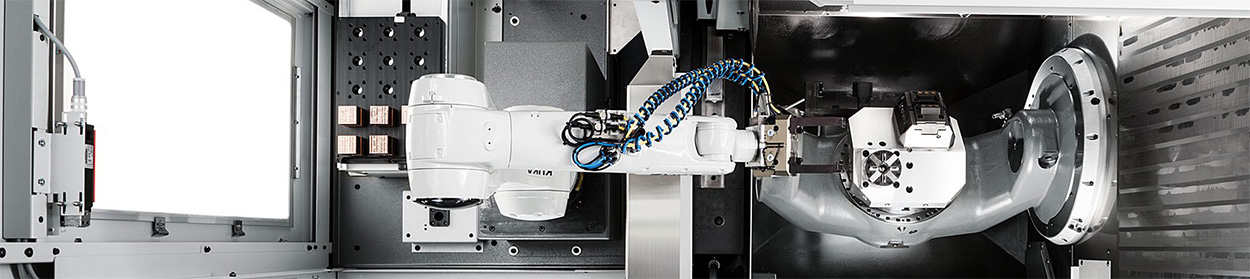

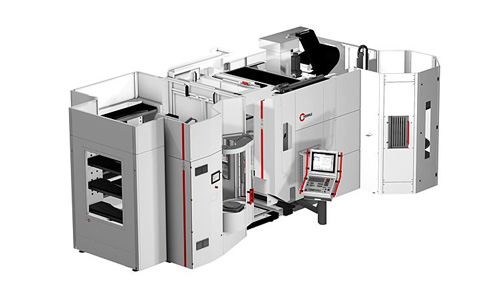

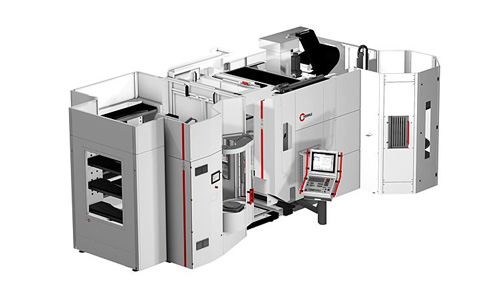

The robot systems!

-

Crème de la crème of HERMLE's automation solutions are its robot systems.

Designed for individual requirements and extremely flexible – for pallet handling or changing workpieces from dies and/or directly.Gripper change from single to double gripper for even more flexibility.

Wide range of magazine configurations to suit individual customer requirements.

The robot systems, which can be adapted to all HERMLE machining centres,

are divided into different designs.From the RS 05-2 robot system for small pallets and components to the RS 3 system with a transport capacity of up to 420 kg.

Additive Manufacturing

-

The Hermle MPA technology - Additive manufacturing using MPA technology

The thermal injection technique that HERMLE has been establishing over more than 10 years of intensive research and development is the only one of its kind on the market, and it opens up completely new dimensions in the field of additive manufacturing. The technique unites the ideas of additive production and better milling, for especially the combination of material augmentation and metal cutting in a single machine creates undreamt-of possibilities for manufacturing even large-sized metal components. From the integration of efficient cooling ducts to sophisticated material combinations – find out about the exceptional features of this new additive production technique for yourself.

This is how the unique MPA technology functions

HERMLE’s additive manufacturing technology: as fascinating as it is ingenious.

Get detailed information about the way it works and the range of new possibilities that it opens up.Perhaps just right for your application?

Additive manufacturing using MPA technology

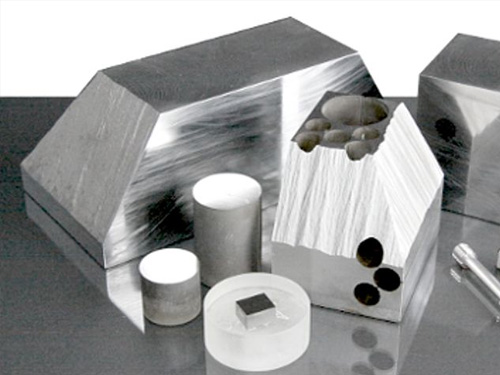

- For more than 10 years now we investigate in the development of new additive manufacturing techniques and processes. The MPA technology developed by HERMLE Maschinenbau GmbH is a versatile tool for generative creation of large-volume components offering a widespread field of applications. It is especially in the field of injection moulding and die casting tools where the MPA technology can play to its strength. One of its prominent features is the possibility to complement precast blanks with additively applied components. The results are hybrid-manufactured components entering new dimensions in additive manufacturing with weights up to several hundred kilos and dimensions larger than 500mm in diameter.

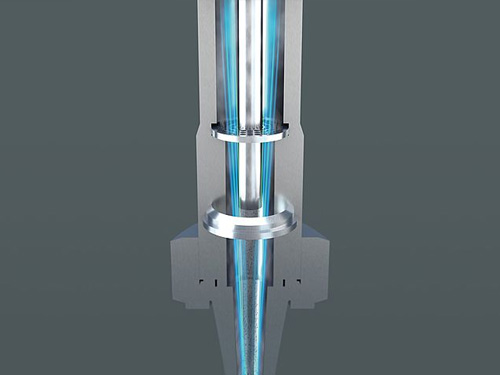

MPA = Metal-Powder-Application

- HERMLE MPA technology stands for a thermal spray process where metal powder particles are compacted layer by layer to massive solids. To do so, the powder particles are accelerated to very high speed by means of a carrier gas and then deposited on the substrate via a laval nozzle. Material build-up rates exceeding 200 cm³ per hour and a powder jet diameter of several millimeters predestine our MPA technology for additive application of comparatively large volumes on rather large component surfaces.

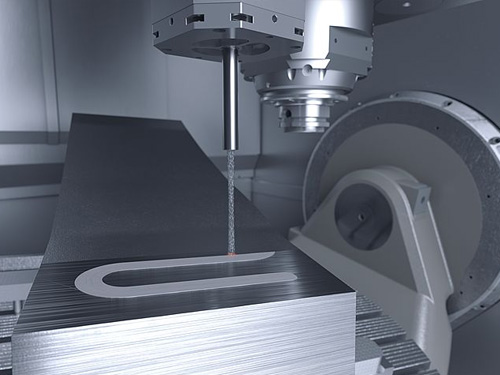

Additive manufacturing and milling combined

-

The MPA material application unit is integrated into a HERMLE 5-axis machining center of type C-40. The combination of MPA material application and milling in just one machine results in a hybrid additive manufacturing process. The machine's workspace allows for part dimensions exceeding 500mm in diameter.

Layer-based alternating material growth

MPA technology is generally designed to grow material on geometrically accessible planes of a component. If additional materials are to be integrated or embedded, the materials are applied in layers as far as the relevant contours of the other material components are accessible for machining. The contour accuracy of the components depends on the milling method and can be adapted to individual requirements. Now we start the application of the respective other material onto the prepared component contours and subsequently mill it into shape. With this alternating scheme, massive components made of two or more materials can be created.Filling material for channels and cavities

A special filling material allows for the creation of inner hollow areas, channels and undercut contours. This material is water soluble and flushed out at the end of the manufacturing process to expose the inner geometry. Subsequent heat treatment optimizes the component's microstructure and ensures the component has the desired hardness.

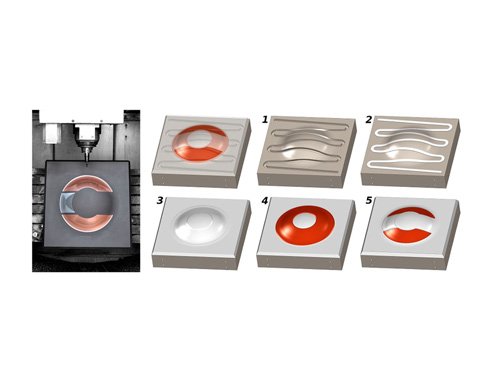

Manufacturing process scheme

-

The part shown in the upper left image was created for demonstrational purposes. It contains a 3.4m long channel (18x18mm) serving as a marble run as well as an embedded copper component which, by milled out openings, shows HERMLE's company logo.

Part dimensions: 520 x 520 x 140 mm, total weight approx. 270kg, of which about 40kg where applied with MPA technology.

The image sequence illustrates the main steps of the manufacturing process: - Milling of the marble run channel into the prepared blank.

- Filling of the channel with a water-soluble filling material.

- Application of a layer of 1.2344 hot-working steel. Milling of the copper component contours.

- Application of pure copper onto the pre-milled surface and subsequent milling of the copper part's shape.

- Application of a second layer of 1.2344 steel. Milling of the copper inlay openings and dissolving of the remaining filling material in the channel.

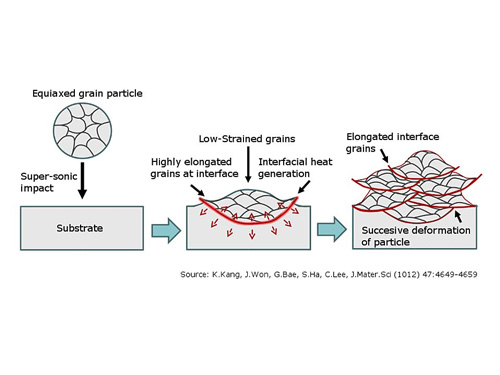

Layer formation

- Powder particles from the nozzle as well as the substrate surface undergo heavy plastic deformation on particle impact. In particular the impacting surface grains are getting highly stretched by local pressures exceeding 10 GPa and temperatures up to 1000°C. Within this process, a binding contact surface is created between powder particle and the subtrate. The subsequent plasticity of colliding particles during kinetic spraying leads to an isothermal heating of the whole component.

Base material: metal powders

- Metal powders are the base material for additive manufacturing with HERMLE MPA technology. The physical properties of the applied metal layers and the transitions between materials must meet the high mechanical and thermal requirements defined by the operational environment of the manufactured component. Precise adjustment of the process parameters is therefore essential for each metal powder used. The properties of the resulting material microstructure are determined in extensive test series. In addition to tension and compression tests, information about particle and layer adhesion, porosity and material inclusions is derived from the examination of grindings in an optical microscope.

Currently available materials for MPA technology

-

- hot-working steels 1.2344, 1.2367, 1.2083

- cold-working steel 1.2333, 1.2379

- stainless steels 1.4404, 1.4313

- invar 1.3912

- pure iron, pure copper, bronze…

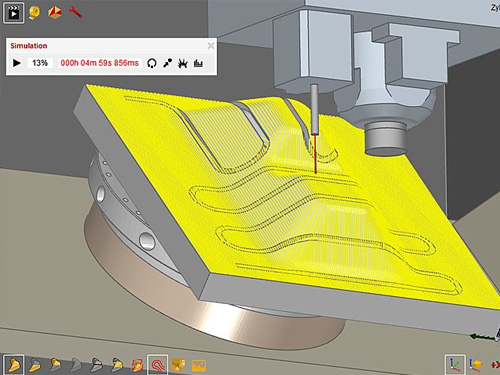

Mpa studio - a cam solution for mpa technology

- For the MPA manufacturing process we designed and developed our own CAD/CAM software named MPA Studio. It is used to create programs integrating both the additive material application and the milling paths into one process. The software allows the customization of the component geometry and the layer-by-layer analysis required for the additive manufacturing. The ability to simulate the complete process as well as quality assurance functions for checking the finished component make the software a flexible and versatile tool for the use of MPA technology.

Application technology

-

We provide comprehensive advice on milling, programming and handling of our products. This is the core competence of HERMLE application technicians,

who are experts in machining processes and who are quick to assist and advise you and provide specialist theoretical and practical support.Innovativ

In our training centres, we feature individual milling demonstrations on innovative milling machines and machining centre.Comprehensive

Comprehensive advice on milling, programming and handling of our productsProfessional

We guarantee professional support concerning tooling, clamping fixtures, mounting devices, data transmission and CAD/CAM.

Features & Highlights

- Impressive!

The basis of our machining centers.

Ergonomics, compact dimensions, workshop suitability, precision, reliability, durability. These are not empty promises for us. Every one of our machines is distinguished by precisely these properties. Even now, after many years of production. Machining centers and automation solutions from a single source with high system expertise during planning, installation and maintenance:

Long-lasting technology and a broad range of sectors provide the basis for this. Universal automation, impressive accuracy and exemplary energy efficiency are further HERMLE machining center constants! Experience the numerous functions and possibilities offered by HERMLE machining centers for yourself, from control units through to information diversity. Technology

- Precision power houses!

From compact to gigantic.

The original is always the first. We are often copied but never equalled. HERMLE remains the original and the best. We have been committed to 5-axis processing from our very beginnings. By the middle of the nineteen-nineties, we recognized that this recipe for success was indeed the future. Since that time, we have continually perfected our technology and expanded our range of machines.

HERMLE offers users comprehensive support to introduce new technologies in every phase with longstanding project experience. We understand our clients’ core business and offer them comprehensive advice on milling, programming and how to handle our machines. And, even more, taking the customer’s requirement and the specific components to be produced as a basis, we develop an overall solution, in which the tool, the controls and automation technologies are perfectly coordinated.

As a process provider, we are able to combine the possibilities of a special machine manufacturer with the expertise of a system integrator. The result is maximum expertise for optimal production processes and a maximum in terms of investment security for our customers. Precision

- Dead-on!

Precision knows no limits.

Precision in every dimension: HERMLE has a thorough understanding of the requirements for manufacturing high-precision machining centers for processing smaller and larger workpieces of up to 2.5 t in weight. For this reason, "The Original" only uses German machines for production and materials from European suppliers. Furthermore, the entire machining production department is fully air conditioned and kept clean by a central swarf disposal system.

HERMLE machining centers are thoroughly tested by means of intensive endurance tests and in manufacture-oriented machining processes in our own machining manufacturing department. Our meticulous manufacturing processes allow HERMLE to set new precision standards which undercut those demanded by the DIN/ISO 10791 standard in every way. Options

- Anything is possible!

Our machining centers with added customisation.

The following options allow your HERMLE machining center to be adapted to your specific needs. It goes without saying that you will receive perfectly integrated systems in which all elements are dovetailed, without friction or interface losses.

- Automatic cabin door

- Rotating inspection window

- Height-adjustable and pivotable control panel with tiltable 19” screen

- Electrical heat compensation

- Electrical hand-held control module

- Preparation of stylus

- Tool breakage monitoring/measuring system

- Swarf flushing nozzle

- External minimum quantity lubrication

- Pallet changer

- Pallet storage and much more

- Visibility improvement unit

- Coolant nozzle

- Sealing air for scales

- Signal lamp

- Preparation of touch probe system

- Tool breakage monitoring/measurement

- Additional magazines

-

Genuine added value!

Small details with a big impact.Comprehensive fluid technology, diverse coolant equipment and optimized swarf management machining centres from HERMLE impress thanks to their intelligent details.

-

Cooling management

- Space-saving arrangement

- Internal cooling lubricant supply

- Temperature control unit

- Emulsion mist extraction system

Additional magazines

- Room for more!

Additional magazines make it possible.

- Increases productivity and system runtimes

- Ideal for automated systems or complex machining with numerous tools

- 8-corner design for space-optimised extension of the tool memory capacity

- Fast adaption and commissioning

- All additional magazines can be retrofitted to a limited extent

Additional magazine ZM 50

- available for C 250, C 400, C 22, C 32, C 42 models

- Magazine pockets: 50

- Max. tool weight: 8 kg

- Max. tool diameter: Ø 80, with empty adjacent pockets Ø 125 mm

- Max. tool length: 300 mm

Additonal magazine ZM 88k

- available for C 250, C 400, C 22, C 32, C 42 models

- Magazine pockets: 88

- Max. tool weight: 8 kg

- Max. tool diameter: Ø 80, with empty adjacent pockets Ø 125 mm

- Max. tool length: 300 mm

Additional magazine single or double

- available for C 22, C 32, C 42, C 52 and C 62 models

- up to 192 (single) odr 462 (double) tool pockets (depending on the interface)

- Max. tool weight: 30 kg

- Max. tool diameter Ø 250 mm

- Max. tool length: 500 mm

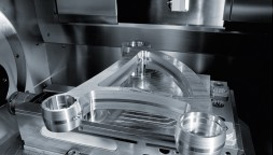

Applications

- Practical examples!

The entire application spectrum.

In theory, the machining centres from HERMLE offer impressive performance data. In practice, they are possibly the best machines in the world. They can do so much and can be used for almost any application! Numerous machining examples are given below. You can either search directly for applications or, alternatively, for the machining spectrums of the individual HERMLE machines. We hope you enjoy discovering the very many interesting details!

Automotive Industry

Aerospace Technology

Machine Construction

Medical Engineering

Motor Sports and Racing

Optical Industry

Tool and Mould Construction

Tool Technology

Subcontractor Industry

Precision Mechanics

Energy Technology