- Offer Profile

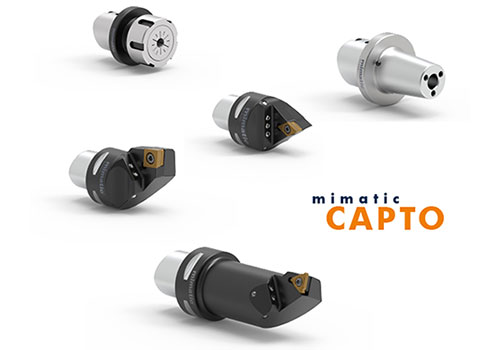

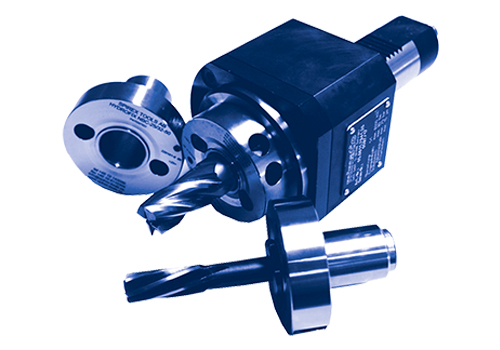

- mimatic Tool System products

are utilised between the machine spindle and the workpiece. Cutting tools,

driven toolholders, angle heads as well as precision drill chucks are

important elements of our range of products.

Cutting tools cover circular milling of slots and grooves, circular thread milling with multiple inserts or a single insert, solid carbide thread millers as well as reaming with system tools (shank plus carbide metal head).

Complete Solutions

Component Part Specific Complete Solutions

-

of driven tool holder and cutting edge

Ask us – we gladly accept the challenge and develop together with you a solution in the areas of:- Multi spindle solutions

- Saw blade holders

- Fixed angle

- Plunge milling in cavities of larger components

- Complete solutions with cutting tools

mimaticDTF

-

Turn Cut Milling instead of parting off:

Faster parting off than anybody else!

Turn Cut Milling with PolySAW- Short process times

- Process reliability

- Material saving

- Surface quality

- Absence of burrs

- Short chips

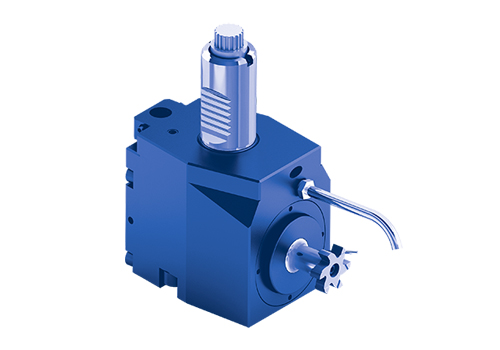

agMILL

-

Compact Driven Toolholders with Interface for Carbide Inserts

Thanks to mimatic‘s cross-system expertise in the fields of driven tool holders and precision carbide steel cutting tools, mimatic has developed a compact new cutting solution.

The interfaces and holders that are usually located between the powered tool and circular milling insert are eliminated. Directly on the main shaft of the powered tool there is now the polygonal insert fixture for the cutting of threads, grooves and cut-ins.

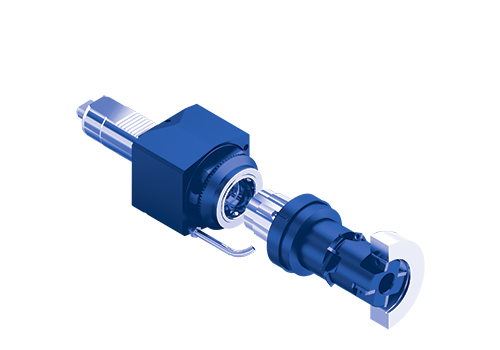

mimaticMi

-

The Integrated Tool Solution

For more efficient machining on turning machines, mimatic applies its expertise in integrated and complex cuttting tools and its expertise in driven tool holders. The result is a cross-system tool solution for series production.

The central part of this solution is the modular quick-change interface mi, which connects the driven tool holder directly and without additional work to e.g. shell-type milling tools for combined machining (turning, planing, chamfering).

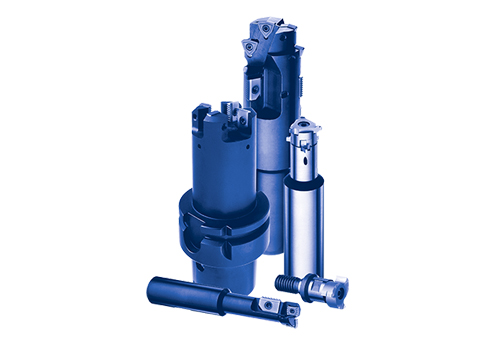

Cutting Tools

Special- and Combination Tools

-

Do you have a special application or a production problem?

Ask us – we gladly accept the challenge and develop together with you a solution in the areas of:- Milling

- Thread Milling

- Slots

- Chamfering

- Facing

- Grooving

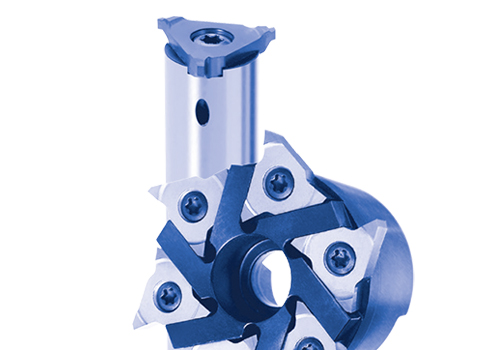

PolyMILL

-

The affordable system with high performance allows threading and / or

circlip grooving in high precision. The polygonal connection of insert and milling body improves the efficiency and precision of the process significantly:

- Longer tool life

- Higher machining volume

- Higher feed rates

- Shorter processing times

- High stability

- High security at interrupted cutting

TriMILL

-

Affordable and flexible system for short processing times and long tool lifes.

- Deep, true to gauge threads

- Accurate free-form contours

- Accurate grooving

Bottom threads can be cut almost to the bottom without undercuts. By using the same pitches, the storage and acquisition costs decrease also.

TrioCUT

-

Smooth cutting and low cutting pressure results in high surface quality and long tool lifes. A

conical position of insert pocket guarantees stability of the tool shaft. Further advantages are a

radially back ground thread profile, extremely high wedge angle, a more stable cutting edge as well as a positive rake angle. The optimum application area are fine threads and/or very short thread lengths.

- Thread milling

- Thread milling with undercut

- Drill milling

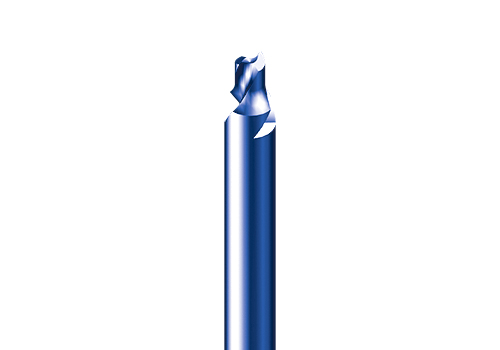

SolidCUT

-

Extensive range of solid carbide thread milling cutters.

- Spiral-grooved grooves

- Soft cut

- Excellent surface qualities

- Also for thin-walled workpieces

- A tool for right- and left-hand threads

14,5 15 21 26

- Multi tooth thread milling cutters, ideal for short thread lengths and very rigid clamping of workpiece and cutter.

mimaticSTC

-

Sectional thread milling for high-quality large threads from M24.

STC-1 with 10 edges

Biggest advantage for any long threads from M24: A shorter process time compared to cutters with inserts and easier assembly.

STC-2 and STC-3

Depending on the thread length (pitch, material) much faster than STC-1.

DeepMILL

-

Slot milling, grooving, milling of cooling fins

with a up to tenfold cutting performance!- Larger range of applications

- Defined tooth and cutting edge geometry

- mimatic core competence:

- Polygon interface Quadrogon interface

- High performance coatings

- Internal coolant direct to the edges

- Clamping with only one center screw

- Special chip space geometry

- With DeepMILL can be milled up to shoulders

- Cutting edges on the face can be used for special machining operations

- On request: Increased cutting depths (S) achievable with reductions in speed/feed

- Re-sharpen-Service 2x

- Minimum distance for operations to shoulders: 0,001 mm

Keyway Slot Milling Cutters

-

- CNC-Turning Machines with Y-Axis

- Increased stiffness, higher precision

- CNC-Turning Machines without Y-Axis

- Optimized straight run-out

- Short Process Times

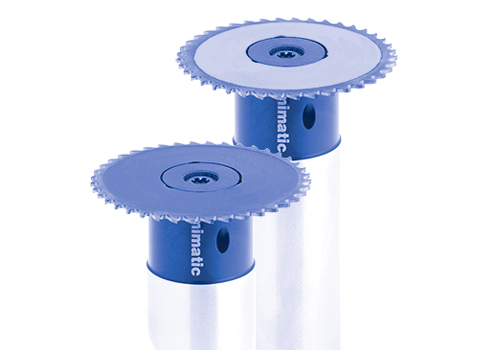

PolySAW

-

Cutting, Sawing, Slitting

with a up to tenfold cutting performance compared to conventional carbide circular saws!- Larger range of applications

- Defined tooth and cutting edge geometry

- mimatic core competence: Polygon interface Quadrogon interface

- High performance coatings

- Internal coolant direct to the edges

- Clamping with only one center screw

- Special chip space geometry

- With PolySAW-G profiles can be machined up to the shoulder

- On request: Increased sawing depths (S) achievable with reductions in speed/feed

- Re-sharpen-Service 2x

- Minimum distance for operations to shoulders: 0.001 mm

CT Tools

-

Counterbores and Countersinks

- Fixed dimension countersinks are suitable for counterboring of pre-drilled or casted holes

- Counterbores are suitable for producing cuts for cylinder head bolts, ejector pins, on cuts, sealing surfaces

- Internal coolant

- Narrow tolerances ± 0,05 mm

- Long lifetimes

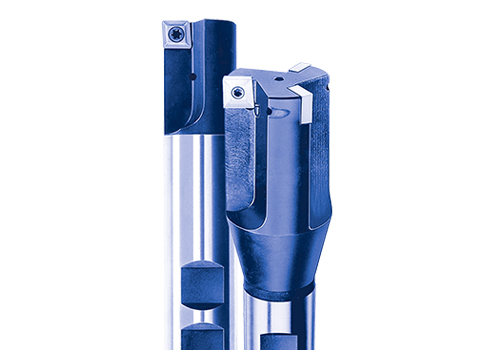

PolyREAM

-

RPK-Reamers with Polygonal Insert Seat for High Chip Removal

A new generation of Reamers to machine blind and through holes in components with greater accuracy. The polygonal connection between the insert and the shank provides improved strength allowing greater cutting forces which in turn makes for economical machining.

Two basic types RPK 40 and RPK 42 are available, which cover a wide range of applications by their different shanks and cutting insert designs. Changing the insert is quick and easy. The front clamping screw absorbs none of the cutting forces and is merely there to hold the insert in place. Different overall lengths are available.- High-tensile connection by polygonal insert seat

- Easy insert change

- Internal coolant supply directly to the cutting edge

- High concentricity

- Longer durabilities

- High precision

- Higher volume of metal removed by reaming

- Higher feeds

- Shorter processing times

- Special dimensions available

Axial Cutting Tool

-

with scalable cutting diameter and fine-adjustment

This tool makes operations possible in workpieces, which cannot be clamped on turning machines.

Making grooves (DIN- or special grooves) up to a- Cutting depth of max. 4 mm

- Cutting width of max. 6 mm

Axial Cutting Tool (Fixed dimension)

-

for PolyMILL-System

This tool makes operations possible in workpieces, which cannot be clamped on turning machines.

Making grooves (DIN- or special grooves) up to a

- Outer diameter of max. 28 mm

- Inner diameter of min. 5 mm

Driven Toolholders

Mazak

EMAG

BMT

DMG MORI

Pti

Capto

Okuma

Sauter

Haas

Angle Heads Monoblock

Angle Head BT30 with eltimon – Industry 4.0 (IIoT) Ready!

- Angle Head 90° BT30 Ultra Light – eltimon® integrated for FANUC machining centers

Monoblock Angle Heads

- Our program of monblock angle head tools provides our customers with the means for complete, integrated machining. It is now no longer necessary to repeatedly relocate tools, which means a considerable reduction in production costs, rationalization and the increase in flexibility over the entire production process.

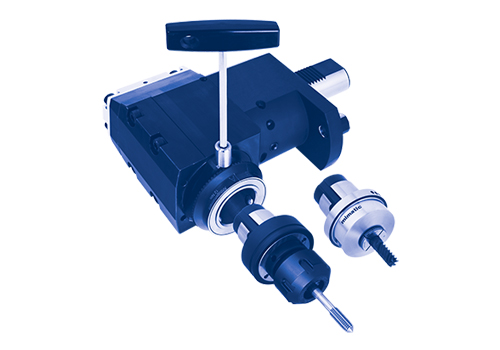

Modular Tool Systems

mimaticMi

-

Modular Quick Change System

- Universal tool clamping system for all production areas

- Presetting of the tools off-line by length adjustment screw

- Tool change within seconds

- Concentricity of the interface < 0.002 mm

- Secure holding force by form-locking

- Very short design

- Toolholders in different sizes

- All toolholders with internal coolant

HydroFLEX

-

Vibration reduced tool clamping system

for all applications (reaming, drilling, milling)- For use in our mimatic® driven tool units

- Concentricity < 0,002 mm

- Holding forces up to 290 Nm

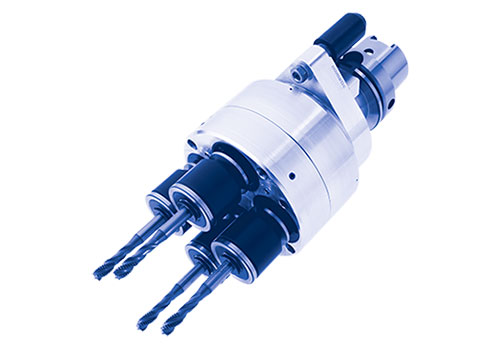

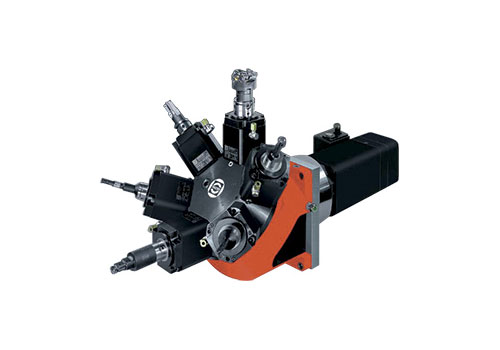

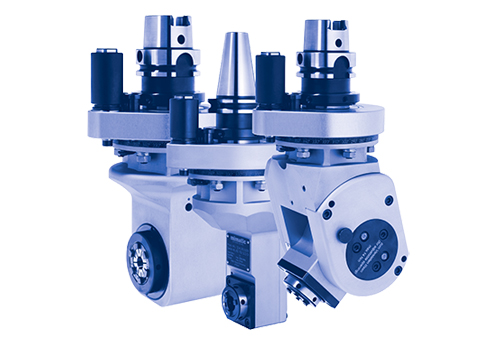

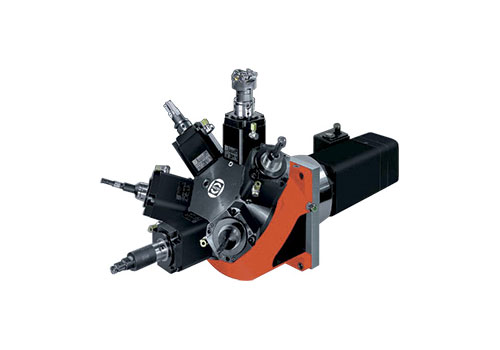

MULTI-SPINDLE TECHNOLOGY

Multi Spindle Technology

-

mimatic® Multi Spindle Technology Increases Your Productivity

The multi spindle technology is characterized by the rule that almost no working issue resembles the other one. Our strength lies in our ability to prepare individual solutions for each of these cases.

The fixed multi spindle units are usable for drilling, thread cutting, countersinking, reaming and for multi spindle milling. Many tool interfaces such as mimatic® mi, HSK, collets, etc. are possible.

Our customers are mainly the automotive industry and machine tool manufacturers (HSC milling machines-, CNC machining centers-, special- and transfer machine manufacturer).

MIMATIC ID-TAG = DIGITAL TYPE PLATE NFC

mimatic ID-tag = digital type plate

-

- For unique and automatic identification

- Automated stock keeping

- Digital data for the robot

- Digital data for the machine tool

- Digital measurement data of the cutting edge

- Linking with relevant documents

ELTIMON TOOL MONITORING

ELTIMON TOOL MONITORING

-

eltimon (electronic live tool integrated monitoring)

for digitization of live tools, angle heads in machining centers and driven tools in CNC lathes- Visualization using eltimon-app on your mobile phone

- Data storage in the eltimon-core in the live tool

- Synchronization through eltimon-cloud

- Real time analyses, trends and status

- Augmented operator, decision-support, reminders

- Maximum lifetime for your live tools

Clamping Technology

Mazak

Sauter

VDI Toolholders DIN 69880