- Offer Profile

- HAIMER is a family run,

medium size company located in Igenhausen, Bavaria near Augsburg, Germany.

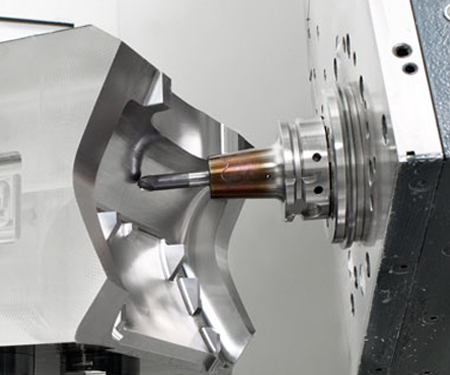

We design, produce and sell innovative, high precision products for metal

cutting as well as for other branches including automotive, aerospace,

energy, rail and general machining.

Next to our largest offering of tool holders in all popular interfaces and lengths, including our shrinking and balancing machines, as well as our 3-D Sensors, our product offering includes solid carbide tooling and grinding wheel adapters.

Tools and tool holding technology

Innovative solutions out of one hand.

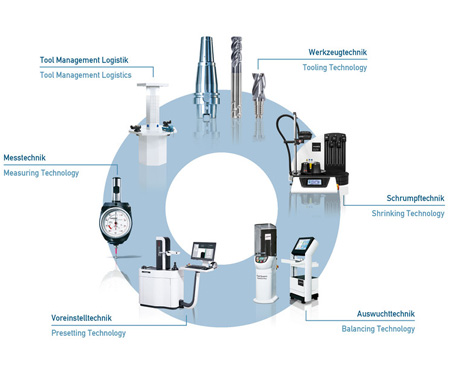

We at HAIMER see ourselves as a system provider along the complete value chain of tool holding.

With our extensive tool holder program, a associated balancing and shrinking technology, our tool management logistic systems, as well as the 3D measuring instruments and our new power mill tools, we are offering you a perfectly coordinated product portfolio.

Take advantage of our full technical know-how and many years of experience in tool holding technology. With our products we support you reducing your manufacturing costs sustainably and achieving a long term competitive advantage for your company.

Tool Holders

-

The right clamping technology for every kind of machining operation.

During machining, specific demands for tool holding are laid down by each industry and application. The range varies from high-speed cutting to heavy roughing.

HAIMER offers the right solution and clamping technology for all specific requirements. Therefore, each year we invest approximately 10 percent of our turnover in research and development.

Our primary interest is to offer our customers sustainable solutions which enable a competitive advantage. This way, you can always maintain your competitive advantage in machining.

Grinding wheel adapters

-

To achieve superior grinding results and to make your grinding process more

efficient, several factors play a decisive role: Besides a precise spindle interface and the use of fine-balanced grinding wheels, the right grinding wheel adapter is of great importance.

HAIMER grinding wheel adapters are manufactured just like all HAIMER tool holders - according to the highest quality standards and are characterized by the following features:

- Fine machined functional surfaces guarantee maximum precision at the spindle interface

- More accurate than DIN

- Body with balancing threads: Correction of the unbalance via balancing screws, even when using spacers without balancing threads

- Balanced

HAIMER offers grinding wheel adapters for the following tool grinding machines:- Deckel

- UWS (Reinecker)

- Rollomatic

- Walter

- Saacke

- Schütte

- Vollmer

Universal cutting tools

-

With the brand-new HAIMER Power Mill & Duo-Lock™ Series we provide you the right cutting tool for a broad range of applications in the machining process.

HAIMER Power Mill universal solid carbide endmills for machining steel, stainless steel and cast iron materials are available in a broad range of geometries and cutting edge designs. Latest PVD coating supply a maximum wear protection.

With Duo-Lock™, the modular interface of the latest generation for carbide tool heads, HAIMER offers a very flexible and universal tooling system. In combination with the Duo-Lock™ tool holders and shank extensions you always find the right solution for your application.

Modular Balancing technology

-

The spindle speed of modern machine tools have increased on a continuous basis in the last few years in order to achieve higher cutting volumes and machine in a profitable manner. The increases have also raised the demands for the tools and holders used, because the higher spindle speeds make the effects of imbalance increasingly more noticeable. The consequences are vibrations, bad surface finish and shorter tool life.

Only the high-precision balancing of tools and tool holders can make the complete capacity of the machines tool with regards to speed, cutting volume and produced surface finish accessible. Because balancing provides for fewer vibrations. It reduces wear of the spindle and tool, reduces the downtimes and increases process security.

Shrink Fit Technology - Power Clamp

-

For years, HAIMER has been leading in the development of inductive shrink technology for tool holders. Many patents, mainly in the area of inductive coils, are visible proof for innovation and progress.

The patented coil technology in conjunction with the intelligent power electronics form the core of HAIMER shrink fit technology.

Perfectly coordinated assembly groups and electronic components make sure that only the clamping area of the chuck is heated in the shrinking process.

This reduces the shrinking and cooling cycle to a minimum.

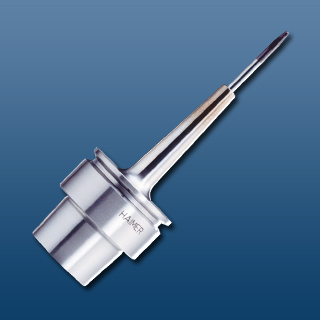

Measuring Instruments

-

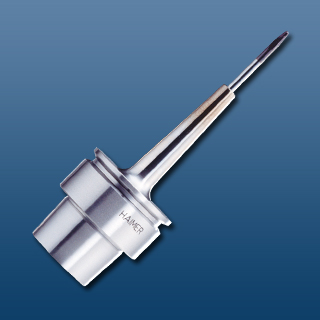

The HAIMER 3D-Sensors are very precise and wide-ranging measurement devices for milling and EDM machines (isolated probe tip). They are clamped into a tool holder and inserted into a milling spindle and make it possible to position the spindle axis exactly on the edges of the workpiece. This allows for zeros to be set and the length to be measured quickly and easily. You my approach in any direction (X-, Y-, Z-Axis). When the dial gage shows zero, the spindle axis is exactly on the workpiece edge.

Only the HAIMER 3D-Sensor allows for the edge to be found on the first attempt. No calculating of the probe’s ball diameter is necessary – just Zero it out! Problems with mathematics or calculations are eliminated, allowing for fewer operator errors.

By using the HAIMER Centro centering bores and arbors is quick and precise.

Presetting Technology

- HAIMER evolved to an entire system provider for tool management around the machine tool. HAIMER Microset tool presetting technology complements the existing HAIMER portfolio of an extensive tool holding program, shrinking and balancing technology, tool management logistics as well as 3D measuring devices and solid carbide cutting tools. As a result, we can offer you a perfectly matching product range from a single source.

Innovations – Ideas driven by passion

-

Research and development is the best investment in the future because innovative ideas and technical innovations can only arise in this way. HAIMER, technology leader for tool holders has therefore been investing approximately 10 percent of its annual turnover in research and development. Customer benefits is top priority when it comes to the new development of products. Our objective is to provide products which offer the maximum added value for both the user as well as the end customer.

HAIMER products represent quality and innovation in all sectors. Our innovative technical solutions represent the basis for the market success of our products.

Tool management

-

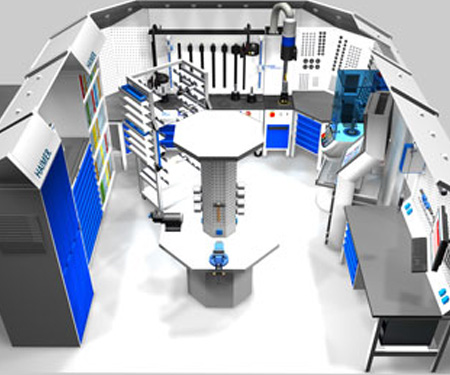

HAIMER tops off its portfolio as a system partner around tool clamping with

its Tool Management, the complete solution for tool presetting and

administration.

HAIMER backs its workbenches and modules with specific solutions which have grown and matured over the years in their own production. The whole working area is specifically designed for tool storage, assembly and administration. All auxiliary materials are firmly established. All requirements have been thought of for an efficient and ergonomic working for tool management ranging from lighting to the dust bin.

If desired, HAIMER will take over the complete functional design of working areas which focuses on storage, assembly, presetting and administration of tools

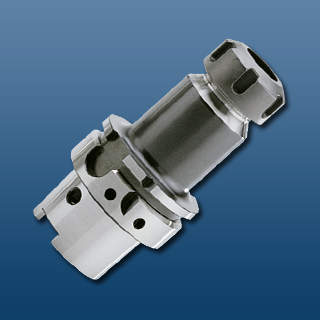

Tool Holders

Steep taper DIN 69871 SK30/SK40/SK50

- The traditional interface for milling spindles DIN 69871 distinguishes itself through its extremely robust design. Its field of application ranges from fine machining to heavy duty roughing. The tool holder is pulled in the milling spindle with the help of an additional pull stud. The centering takes place via the taper contact. Therefore, the DIN 69871 interface is primarily suitable for applications with a spindle speed of up to 12,000 rpm.

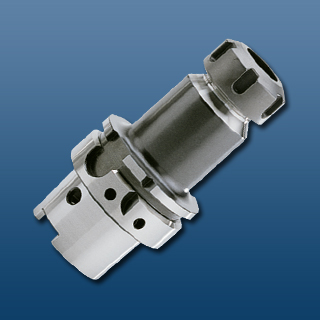

Shrink Fit Chuck Standard Version, DIN 69871 · SK30

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

Shrink fit chuck suitable to all kind of shrink fit units.

With steep taper SK30 DIN 69871.

- Heat resistant hot-working steel

- Hardened 54 – 2 HRC

- For HSS and solid carbide tools

- Shank tolerance h6

- With threaded holes in order to balance with balancing screws

- Cooling with Cool Jet for an extra charge

- Cooling with Cool Flash for an extra charge

- Included in delivery: Backup screw

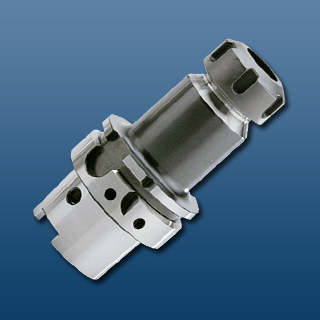

Shrink Fit Chuck Standard Version, DIN 69871 · SK40

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

Shrink fit chuck suitable to all kind of shrink fit units.

With steep taper SK40 form ADB DIN 69871.

Form ADB means: Central coolant supply and coolant channels through the flange which can be sealed again.- Heat resistant hot-working steel

- Hardened 54 – 2 HRC

- For HSS and solid carbide tools

- Shank tolerance h6

- With threaded holes in order to balance with balancing screws

- Cooling with Cool Jet for an extra charge

- Cooling with Cool Flash for an extra charge

- Included in delivery: Backup screw

Shrink Fit Chuck Standard Version with Cool Jet DIN 69871 · SK40

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

Shrink fit chuck suitable to all kind of shrink fit units.

With steep taper SK40 form ADB DIN 69871.

Form ADB means: Central coolant supply and coolant channels through the flange which can be sealed again.- Heat resistant hot-working steel

- Hardened 54 – 2 HRC

- For HSS and solid carbide tools

- Shank tolerance h6

- With threaded holes in order to balance with balancing screws

- Cool Jet coolant bores included

- Cooling with Cool Flash for an extra charge

- Included in delivery: Backup screw

Shrink Fit Chuck Standard Version with Safe-Lock™ DIN 69871 · SK40

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

Shrink fit chuck suitable to all kind of shrink fit units.

With steep taper SK40 form ADB DIN 69871.

Form ADB means: Central coolant supply and coolant channels through the flange which can be sealed again.- Heat resistant hot-working steel

- Hardened 54 – 2 HRC

- For HSS and solid carbide tools

- Shank tolerance h6

- With threaded holes in order to balance with balancing screws

- Cooling with Cool Jet for an extra charge

- Cooling with Cool Flash for an extra charge

- Safe-Lock™ pull out protection included

- Included in delivery: Backup screw, tension spring

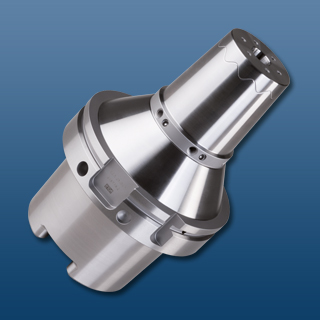

Power Shrink Chuck DIN 69871 · SK40

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

- Cool Jet, can be sealed

Shrink fit chuck suitable to all inductive shrink fit units.

The Power Shrink Chuck is the shrink fit chuck for highest machining capacity in high-speed manufacturing. The optimized design combines high rigidity with dampening vibrations, therefore giving more protection to machines, spindles and tools.

- Increased machining capacity due to higher spindle speed, higher feed and larger cutting depth

- Shorter processing times

- Quieter running, therefore better surface quality and protection of tools, spindles and machines

- Higher machining accuracy

- With threaded holes in order to balance with balancing screws

- Cool Jet bores that can be sealed included

- Cooling with Cool Flash for an extra charge

Power Shrink Chuck with Safe-Lock™ DIN 69871 · SK40

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

- Cool Jet, can be sealed

The Power Shrink Chuck is the shrink fit chuck for highest machining capacity in high-speed manufacturing. The optimized design combines high rigidity with dampening vibrations, therefore giving more protection to machines, spindles and tools.

- Increased machining capacity due to higher spindle speed, higher feed and larger cutting depth

- Shorter processing times

- Quieter running, therefore better surface quality and protection of tools, spindles and machines

- Higher machining accuracy

- With threaded holes in order to balance with balancing screws

- Cool Jet bores that can be sealed included

- Cooling with Cool Flash for an extra charge

- Safe-Lock™ pull out protection included

Power Mini Shrink Chuck DIN 69871 · SK40

-

- Chuck fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

Shrink fit chuck suitable to all inductive shrink fit units.

Power Mini Shrink Chuck is perfect for 5-axis-machining in the die & mould and in the medical industry. Very slim at the top like the HAIMER Mini Shrink Chucks, the Power Mini Shrink is reinforced at the base. Thereby efficient milling is possible with an angled tool even at long protruding lengths.

- 3 mm wall thickness

- 3° slope at the top

- For solid carbide tools with shank tolerance h6

- With threaded holes in order to balance with balancing screws

Power Mini Shrink Chuck extra slim DIN 69871 · SK40

-

- Chuck fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

Shrink fit chuck suitable to all inductive shrink fit units.

Power Mini Shrink Chuck is perfect for 5-axis-machining in the die & mould and in the medical industry. Very slim at the top like the HAIMER Mini Shrink Chucks, the Power Mini Shrink is reinforced at the base. Thereby efficient milling is possible with an angled tool even at long protruding lengths.

- Extra slim (1.5 mm wall thickness)

- 3° slope at the top

- For solid carbide tools with shank tolerance h6

- With threaded holes in order to balance with balancing screws

Collet Chuck Type ER DIN 69871 · SK40

-

- Chuck body fine balanced G2.5 at 22.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For clamping tools with cylindrical shank in ER collets according to ISO 15488.

With steep taper SK40 form ADB DIN 69871.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.- Included in delivery: Locknut (balanced, with slide coating for higher clamping forces)

- Locknut type HS (High-Speed, fine balanced, with slide coating for higher clamping forces) for an extra charge

- Enlarging of size L upon request

Power Collet Chuck DIN 69871 · SK40

-

- Chuck body fine balanced G2.5 at 25.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For clamping tools with cylindrical shank in HAIMER Power Collets and ER collets according to ISO 15488.

The Power Collet Chuck is the collet chuck for the highest machining capacity in high-speed manufacturing. The optimized design with better construction combines high rigidity with vibration dampening features, giving more protection to machines, spindles and tools. The universal Power Collet Chuck is a unique high performance chuck that can also be used with standard collets.

- High runout accuracy: 0.003 mm at 3 × D with HAIMER Power Collets

- Also for standard collets ER according to ISO 15488 (Please note when use with standard ER collets the gage length A will vary compared to A dimension given below!)

- High rigidity

- Smoother running thanks to vibration absorbing geometry, therefore better surface quality and protection of tools, spindles and machines

- Increased machining capacity due to higher spindle speeds, higher feed rates and larger cutting depths

- Shorter processing times, higher machining accuracy, high clamping force

- Equally suited to high-speed manufacturing and heavy milling

- With threaded holes in order to balance with balancing screws

- Optional: With Safe-Lock™ Power Collets from ER 25

- Optional: Cool Jet bores on Power Collets from ER 25 Ø 6 mm

High Precision Collet Chuck

DIN 69871 · SK40-

- Chuck body fine balanced G2.5 bei 30.000 1/min

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For clamping tools with cylindrical shank in HAIMER Power Collets and ER collets according to ISO 15488.

The High Precision Collet Chuck is the collet chuck for the highest machining capacity in high-speed manufacturing. The optimized design with better construction combines high rigidity with vibration dampening and noise-reducing features, giving more protection to machines, spindles and tools. The universal High Precision Collet Chuck is a unique high performance chuck that can also be used with standard collets.

High-Precision Chuck DIN 69871 · SK40

-

- Chuck fine balanced G2.5 at 25.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For high-precise clamping of tools with cylindrical shank with special collets. Also for shanks with clamping flats. Very useful for high-speed machining.

With steep taper SK40 form ADB DIN 69871.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.- Delivery comprises: High-precision chuck with clamping screw and pull-out hook without collet

- Shank tolerance h6

- Optional: Cool Jet bores on HG Collets from Ø 6 mm

- Extensions available for High-Precision Chucks

Weldon Tool Holder DIN 69871 · SK40

-

- Chuck fine balanced G2.5 at 22.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For clamping cutters with cylindrical shank and Weldon flat similar to DIN 1835-B and DIN 6535-HB.

Similar to DIN 6359-2 with taper SK40 form ADB DIN 69871.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.- Included in delivery: Clamping screw

- Extra short design only available in form AD

- Cooling with Cool Jet for an extra charge

Weldon Tool Holder with Cool Jet DIN 69871 · SK40

-

- Chuck fine balanced G2.5 at 22.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For clamping cutters with cylindrical shank and Weldon flat similar to DIN 1835-B and DIN 6535-HB.

Similar to DIN 6359-2 with taper SK40 form ADB DIN 69871.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.- Included in delivery: Clamping screw

- Coolant supply only available in form AD

- Cool Jet coolant bores included

Face Mill Arbor DIN 69871 · SK40

-

- Chuck body fine balanced G2.5 at 22.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For holding face mill cutters and cutters with radial driving slot DIN 1880 and exceeding clamping diameter 40 clamping according to DIN 2079 is possible, too (4 additional tapping holes).

According to DIN 6357 with taper SK40 form ADB DIN 69871.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.- With coolant exit bores on the end face for milling cutters with central cooling

- Included in delivery: Tightening bolt

Combination Shell End Mill Arbor DIN 69871 · SK40

-

- Chuck body fine balanced G2.5 at 22.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For clamping shell end mills DIN 841 and DIN 1880 as well as angular milling cutters DIN 842 and cutters DIN 1830.

According to DIN 6358 with taper SK40 form ADB DIN 69871.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.- Included in delivery: Tightening bolt, driving ring and feather key

- Coolant bores on front side for an extra charge

Whistle Notch Tool Holder DIN 69871 · SK40

-

- Chuck body fine balanced G6.3 at 8.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For clamping cutters with cylindrical shank and inclined flat similar to DIN 1835-E and DIN 6535-HE.

DIN 6359-2 with taper SK40 form ADB DIN 69871.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.- Included in delivery: Camping screw and adjusting screw

- Fine-balancing for an extra charge

- Cooling with Cool Jet for an extra charge

Adapter for Morse Taper with Thread DIN 69871 · SK40

-

- Chuck body fine balanced G6.3 at 8.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

For clamping tools with Morse Taper with drawbar thread according to DIN 228-1 form A.

Similar to DIN 6383 with taper SK40 form A DIN 69871.

- Included in delivery: Tightening bolt

- Fine-balancing for an extra charge

Adapter for Morse Taper with Tang DIN 69871 · SK40

-

- Chuck body fine balanced G6.3 at 8.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

For holding tools with Morse Tapers with tang according to DIN 228-11 form B.

Similar to DIN 6383 with taper SK40 form AD DIN 69871.

- Fine-balancing for an extra charge

Blank Adapter DIN 69871 · SK40

-

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For manufacturing special tools in your factory.

With taper SK40 form ADB DIN 69871.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.

Design:

Taper and groove are hardened and ground, the cylindrical part is soft.

Quick Change Tapping Chuck DIN 69871 · SK40

-

- All functional surfaces fine machined

- Taper tolerance AT3

- Internal highpressure cooling up to 50 bar

For tapping preferably on NC milling machines. Axial length compensation on tension and pressure.

With steep taper SK40 form ADB DIN 69871.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.

Advantages:- Specially developed system

- Interior coolant supply up to 50 bar

- High centering precision

- High-pressure clamping system (safe clamping for high-pressure cooling)

- Advantageous quick change inserts for all available taps (Not compatible for system BILZ!)

Short Drill Chuck DIN 69871 · SK40

-

- Chuck fine balanced G2.5 at 22.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For clamping tools with cylindrical shank, for left and right hand turn, clamping and loosening with a hexagon socket wrench.

With taper SK40 form ADB DIN 69871 ADB.

Drill Chuck Adapter DIN 69871 · SK40

-

- Chuck body fine balanced G6.3 at 8.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

For holding chucks with three jaws e.g. according to DIN 6349.

According to DIN 238 with steep taper SK40 form A DIN 69871.

- Fine-balancing for an extra charge

Shrink Fit Chuck Standard Version DIN 69871 · SK50

-

- Chuck body fine balanced G2.5 at 25.000 rpm

- Taper tolerance AT3

- Coolant supply form ADB

Shrink fit chuck suitable to all kind of shrink fit units.

With steep taper SK50 form ADB DIN 69871.

Form ADB means: Central coolant supply and coolant channels through the flange which can be sealed again.- Heat resistant hot-working steel

- Hardened 54 – 2 HRC

- For HSS and solid carbide tools

- Shank tolerance h6

- With threaded holes in order to balance with balancing screws

- Cooling with Cool Jet for an extra charge

- Cooling with Cool Flash for an extra charge

- Included in delivery: Clamping screw

Shrink Fit Chuck Standard Version with Cool Jet DIN 69871 · SK50

-

- Chuck body fine balanced G2.5 at 25.000 rpm

- Taper tolerance AT3

- Coolant supply form ADB

Shrink fit chuck suitable to all kind of shrink fit units.

With steep taper SK50 form ADB DIN 69871.

Form ADB means: Central coolant supply and coolant channels through the flange which can be sealed again.- Heat resistant hot-working steel

- Hardened 54 – 2 HRC

- For HSS and solid carbide tools

- Shank tolerance h6

- With threaded holes in order to balance with balancing screws

- Cool Jet coolant bores included

- Cooling with Cool Flash for an extra charge

- Included in delivery: Clamping screw

Power Shrink Chuck DIN 69871 · SK50

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

- Cool Jet, can be sealed

Shrink fit chuck suitable to all inductive shrink fit units.

The Power Shrink Chuck is the shrink fit chuck for highest machining capacity in high-speed manufacturing. The optimized design combines high rigidity with dampening vibrations, therefore giving more protection to machines, spindles and tools.

- Increased machining capacity due to higher spindle speed, higher feed and

larger cutting depth

- Shorter processing times

- Quieter running, therefore better surface quality and protection of tools, spindles and machines

- Higher machining accuracy

- With threaded holes in order to balance with balancing screws

- Cool Jet bores that can be sealed included

- Cooling with Cool Flash for an extra charge

The long versions (A = 160 and 200 mm) with slim tips are especially versatile to use.

- High rigidity

- Slim at the tip

- Dampen vibrations

- High clamping force

- Equally suited to high-speed manufacturing and heavy milling

- Universal usage, saves space in tool magazine

Power Shrink Chuck with Safe-Lock™ DIN 69871 · SK50

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

- Cool Jet, can be sealed

Shrink fit chuck suitable to all inductive shrink fit units.

The Power Shrink Chuck is the shrink fit chuck for highest machining capacity in high-speed manufacturing. The optimized design combines high rigidity with dampening vibrations, therefore giving more protection to machines, spindles and tools.

- Increased machining capacity due to higher spindle speed, higher feed and

larger cutting depth

- Shorter processing times

- Quieter running, therefore better surface quality and protection of tools, spindles and machines

- Higher machining accuracy

- With threaded holes in order to balance with balancing screws

- Cool Jet bores that can be sealed included

- Cooling with Cool Flash for an extra charge

Heavy Duty Shrink Chuck DIN 69871 · SK50

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

- Cool Jet, can be sealed

Shrink fit chuck suitable to all high performance inductive shrink fit units.

For heavy machining applications it is now possible to replace the Weldon tool holders finally. Heavy Duty Chuck is the shrink fit chuck for extreme cases. The contour is optimized for highest rigidity and clamping force.

- Smooth clamping of the tool shank

- No deformation at the tool shank after shrink process

- High runout accuracy: 3 μm

- Reinforced outer contour

- With dirt groove in the clamping bore

- With threaded holes in order to balance with balancing screws

- Cool Jet bores that can be sealed included

- Cooling with Cool Flash for an extra charge

To shrink with all HAIMER Power Clamp 20 kW shrink fit units and shrink fit machines with 13 kW HD-Coil.

Heavy Duty Shrink Chuck with Safe-Lock™ DIN 69871 · SK50

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

- Cool Jet, can be sealed

Shrink fit chuck suitable to all high performance inductive shrink fit units.

For heavy machining applications it is now possible to replace the Weldon tool holders finally. Heavy Duty Chuck is the shrink fit chuck for extreme cases. The contour is optimized for highest rigidity and clamping force.

- Smooth clamping of the tool shank

- No deformation at the tool shank after shrink process

- High runout accuracy: 3 μm

- Reinforced outer contour

- With dirt groove in the clamping bore

- With threaded holes in order to balance with balancing screws

- Cool Jet bores that can be sealed included

- Cooling with Cool Flash for an extra charge

- Safe-Lock™ pull out protection included

To shrink with all HAIMER Power Clamp 20 kW shrink fit units and shrink fit machines

Heavy Duty Shrink Chuck for 13 kW shrink fit machine DIN 69871 · SK50

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

- Cool Jet, can be sealed

Shrink fit chuck suitable to all inductive shrink fit units.

For heavy machining applications it is now possible to replace the Weldon tool holders finally. Heavy Duty Chuck is the shrink fit chuck for extreme cases. The contour is optimized for highest rigidity and clamping force.

- Smooth clamping of the tool shank

- No deformation at the tool shank after shrink process

- High runout accuracy: 3 μm

- Reinforced outer contour

- With dirt groove in the clamping bore

- With threaded holes in order to balance with balancing screws

- Cool Jet bores that can be sealed included

- Cooling with Cool Flash for an extra charge

To shrink with all HAIMER Power Clamp 13 kW shrink fit units.

Power Mini Shrink Chuck DIN 69871 · SK50

-

- Chuck fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

Shrink fit chuck suitable to all inductive shrink fit units.

Power Mini Shrink Chuck is perfect for 5-axis-machining in the die & mould and in the medical industry. Very slim at the top like the HAIMER Mini Shrink Chucks, the Power Mini Shrink is reinforced at the base. Thereby efficient milling is possible with an angled tool even at long protruding lengths.

- 3 mm wall thickness

- 3° slope at the top

- For solid carbide tools with shank tolerance h6

- With threaded holes in order to balance with balancing screws

Power Mini Shrink Chuck extra slim DIN 69871 · SK50

-

- Chuck fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

Shrink fit chuck suitable to all inductive shrink fit units.

Power Mini Shrink Chuck is perfect for 5-axis-machining in the die & mould and in the medical industry. Very slim at the top like the HAIMER Mini Shrink Chucks, the Power Mini Shrink is reinforced at the base. Thereby efficient milling is possible with an angled tool even at long protruding lengths.

- Extra slim (1.5 mm wall thickness)

- 3° slope at the top

- For solid carbide tools with shank tolerance h6

- With threaded holes in order to balance with balancing screws

Collet Chuck Type ER DIN 69871 · SK50

-

- Chuck body fine balanced G2.5 at 22.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For clamping tools with cylindrical shank in ER collets according to ISO 15488.

With steep taper SK50 form ADB DIN 69871.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.- Included in delivery: Locknut (balanced, with slide coating for higher clamping forces)

- Locknut type HS (High-Speed, fine balanced, with slide coating for higher clamping forces) for an extra charge

- Enlarging of size L upon request

Power Collet Chuck DIN 69871 · SK50

-

- Chuck body fine balanced G2.5 at 25.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For clamping tools with cylindrical shank in HAIMER Power Collets and ER collets according to ISO 15488.

The Power Collet Chuck is the collet chuck for the highest machining capacity in high-speed manufacturing. The optimized design with better construction combines high rigidity with vibration dampening features, giving more protection to machines, spindles and tools. The universal Power Collet Chuck is a unique high performance chuck that can also be used with standard collets.

- High runout accuracy: 0.003 mm at 3 × D with HAIMER Power Collets

- Also for standard collets ER according to ISO 15488 (Please note when use with standard ER collets the gage length A will vary compared to A dimension given below!)

- High rigidity

- Smoother running thanks to vibration absorbing geometry, therefore better surface quality and protection of tools, spindles and machines

- Increased machining capacity due to higher spindle speeds, higher feed rates and larger cutting depths

- Shorter processing times, higher machining accuracy, high clamping force

- Equally suited to high-speed manufacturing and heavy milling

- With threaded holes in order to balance with balancing screws

- Optional: With Safe-Lock™ Power Collets from ER 25

- Optional: Cool Jet bores on Power Collets from ER 25 Ø 6 mm

High Precision Collet Chuck DIN 69871 · SK50

-

- Chuck body fine balanced G2.5 at 25.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For clamping tools with cylindrical shank in HAIMER Power Collets and ER collets according to ISO 15488.

The High Precision Collet Chuck is the collet chuck for the highest machining capacity in high-speed manufacturing. The optimized design with better construction combines high rigidity with vibration dampening and noise-reducing features, giving more protection to machines, spindles and tools. The universal High Precision Collet Chuck is a unique high performance chuck that can also be used with standard collets.

High-Precision Chuck DIN 69871 · SK50

-

- Chuck fine balanced G2.5 at 25.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For high-precise clamping of tools with cylindrical shank with special collets. Also for shanks with clamping flats. Very useful for high-speed machining.

With steep taper SK50 form ADB DIN 69871.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.- Delivery comprises: High-precision chuck with clamping screw and pull-out hook without collet

- Shank tolerance h6

- Optional: Cool Jet bores on HG Collets from Ø 6 mm

- Extensions for High-Precision Chuck available

Weldon Tool Holder DIN 69871 · SK50

-

- Chuck fine balanced G2.5 at 22.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For clamping cutters with cylindrical shank and Weldon flat similar to DIN 1835-B and DIN 6535-HB.

Similar to DIN 6359-2 with steep taper SK50 form ADB DIN 69871.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.- Included in delivery: Clamping screw

- Cooling with Cool Jet for an extra charge

Weldon Tool Holder with Cool Jet DIN 69871 · SK50

-

- Chuck fine balanced G2.5 at 22.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For clamping cutters with cylindrical shank and Weldon flat similar to DIN 1835-B and DIN 6535-HB.

Similar to DIN 6359-2 with steep taper SK50 form ADB DIN 69871.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.- Cool Jet coolant bores included

- Included in delivery: Clamping screw

Face Mill Arbor DIN 69871 · SK50

-

- Chuck body fine balanced G2.5 at 22.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For holding face mill cutters and cutters with radial driving slot DIN 1880 and exceeding clamping diameter 40 clamping according to DIN 2079 is possible, too (4 additional tapping holes).

According to DIN 6357 with steep taper SK50 form ADB DIN 69871.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.- With coolant exit bores on the end face for milling cutters with central cooling

- Included in delivery: Tightening bolt

Combination Shell End Mill Arbor DIN 69871 · SK50

-

- Chuck body fine balanced G2.5 at 22.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For clamping shell end mills DIN 841 and DIN 1880 as well as angular milling cutters DIN 842 and cutters DIN 1830.

According to DIN 6358 with steep taper SK50 form ADB DIN 69871.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.- Included in delivery: Tightening bolt, driving ring and feather key

- Coolant bores on front side for an extra charge

Whistle Notch Tool Holder DIN 69871 · SK50

-

- Chuck body fine balanced G6.3 at 8.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For clamping cutters with cylindrical shank and inclined flat similar to DIN 1835-E and DIN 6535-HE.

DIN 6359-2 with steep taper SK50 form ADB DIN 69871.

Form ADB means: central coolant supply and coolant channels on the collar which can be sealed again.- Delivery: with clamping screw and adjusting screw

- Fine-balancing for an extra charge

- Cooling with Cool Jet for an extra charge

Adapter for Morse Taper with Thread DIN 69871 · SK50

-

- Chuck body fine balanced G6.3 at 8.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

For clamping tools with Morse taper with drawbar thread according to DIN 228-1 form A.

Similar to DIN 6383 with steep taper SK50 form A DIN 69871.

- Included in delivery: Tightening bolt

- Fine-balancing for an extra charge

Adapter for Morse Taper with Tang DIN 69871 · SK50

-

- Chuck body fine balanced G6.3 at 8.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

For holding tools with Morse Tapers with tang according to DIN 228-11 form B.

Similar to DIN 6383 with steep taper SK50 form AD DIN 69871.

- Fine-balancing for an extra charge

Blank Adapter DIN 69871 · SK50

-

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For manufacturing special tools in your factory.

Withsteep taper SK50 form ADB DIN 69871.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.

Design:

Taper and groove are hardened and ground, the cylindrical part is soft.

Quick Change Tapping Chuck DIN 69871 · SK50

-

- All functional surfaces fine machined

- Taper tolerance AT3

- Internal highpressure cooling up to 50 bar

For tapping preferably on NC milling machines. Axial length compensation on tension and pressure.

With steep taper SK50 form ADB DIN 69871.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.

Advantages:- Specially developed system

- Interior coolant supply up to 50 bar

- High centering precision

- High-pressure clamping system (safe clamping for high-pressure cooling)

- Advantageous quick change inserts for all available taps (not compatible for system BILZ!)

Fine-balancing for an extra charge.

Short Drill Chuck DIN 69871 · SK50

-

- Chuck fine balanced G2.5 at 22.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For clamping tools with cylindrical shank, for left and right hand turn, clamping and loosening with a hexagon socket wrench.

With steep taper SK50 form ADB DIN 69871 ADB.

Drill Chuck Adapter DIN 69871 · SK50

-

- Chuck body fine balanced G6.3 at 8.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

For holding chucks with three jaws e.g. according to DIN 6349.

According to DIN 238 with steep taper SK50 form A DIN 69871.

- Fine-balancing for an extra charge

Adapter DIN 69871 · SK50

-

- Chuck body fine balanced G6.3 at 8.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

For holding tapers according to DIN 69871 AD SK 40

and JIS B 6339 BT 40.With steep taper SK50 form AD DIN 69871.

- Included in delivery: Adapter mounted tightening bolt

- Fine-balancing for an extra charge

JIS (MAS 403) BT30/BT40/BT50

- The spindle interface JIS B 6339 as the traditional interface for milling spindles distinguishes itself through it robust design. Its field of application ranges from fine machining to heavy duty roughing. The tool holder is pulled in the milling spindle with the help of an additional pull stud. The centering takes place via the taper contact. Therefore, the JIS B 6339 interface is primarily suitable for applications with a spindle speed of up to 12,000 rpm.

Shrink Fit Chuck Standard Version JIS B 6339 · BT30

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

Shrink fit chuck suitable to all kind of shrink fit units.

JIS B 6339 BT30.

- Heat resistant hot-working steel

- Hardened 54 – 2 HRC

- For HSS and solid carbide tools

- Shank tolerance h6

- Cooling with Cool Jet for an extra charge

- Cooling with Cool Flash for an extra charge

- Included in delivery: Backup screw

Power Mini Shrink Chuck JIS B 6339 · BT30

-

- Chuck fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form AD

Shrink fit chuck suitable to all kind of shrink fit units.

Power Mini Shrink Chuck is perfect for 5-axis-machining in the die & mould and in the medical industry. Very slim at the top like the HAIMER Mini Shrink Chucks, the Power Mini Shrink is reinforced at the base. Thereby efficient milling is possible with an angled tool even at long protruding lengths.

- 3° slope at the top

- For solid carbide tools with shank tolerance h6

- With threaded holes in order to balance with balancing screws

Collet Chuck Type ER JIS B 6339 · BT30

-

- Chuck body fine balanced U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

For clamping tools with cylindrical shank in ER collets according to ISO 15488.

JIS B 6339 BT30.

- Included in delivery: Locknut type HS (fine balanced, with slide coating for higher clamping forces)

- Enlarging of size L upon request

Power Collet Chuck JIS B 6339 · BT30

-

- Chuck body fine balanced U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form AD

For clamping tools with cylindrical shank in HAIMER Power Collets and ER collets according to ISO 15488.

The Power Collet Chuck is the collet chuck for the highest machining capacity in high-speed manufacturing. The optimized design with better construction combines high rigidity with vibration dampening features, giving more protection to machines, spindles and tools. The universal Power Collet Chuck is a unique high performance chuck that can also be used with standard collets.

- High runout accuracy: 0.003 mm at 3 × D with HAIMER Power Collets

- Also for standard collets ER according to ISO 15488 (Please note when use with standard ER collets the gage length A will vary compared to A dimension given below!)

- High rigidity

- Smoother running thanks to vibration absorbing geometry, therefore better surface quality and protection of tools, spindles and machines

- Increased machining capacity due to higher spindle speeds, higher feed rates and larger cutting depths

- Shorter processing times, higher machining accuracy, high clamping force

- Equally suited to high-speed manufacturing and heavy milling

- With threaded holes in order to balance with balancing screws

- Optional: With Safe-LockTM Power Collets from ER 25

- Optional: Cool Jet bores on Power Collets from ER 25 Ø 6 mm

Face Mill Arbor JIS B 6339 · BT30

-

- Chuck body fine balanced G2.5 at 22.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

For holding face mill cutters and milling cutters with radial driving slot DIN 1880.

Similar to DIN 6357 with steep taper JIS B 6339 BT30 form AD.

- With coolant exit bores on the end face for milling cutters with central cooling

- Included in delivery: Complete with tightening bolt

Shrink Fit Chuck Standard Version JIS B 6339 · BT40

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

Shrink fit chuck suitable to all kind of shrink fit units.

JIS B 6339 BT40 form ADB.

Form ADB means: Central coolant supply and coolant channels through the flange which can be sealed again.- Heat resistant hot-working steel

- Hardened 54 – 2 HRC

- For HSS and solid carbide tools

- Shank tolerance h6

- With threaded holes in order to balance with balancing screws

- Cooling with Cool Jet for an extra charge

- Cooling with Cool Flash for an extra charge

- Included in delivery: Back-up screw

Shrink Fit Chuck Standard Version with Cool Jet JIS B 6339 · BT40

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

Shrink fit chuck suitable to all kind of shrink fit units.

JIS B 6339 BT40 form ADB.

Form ADB means: central coolant supply and coolant channels through the flange which can be sealed again.- Heat resistant hot-working steel

- Hardened 54 – 2 HRC

- For HSS and solid carbide tools

- Shank tolerance h6

- With threaded holes in order to balance with balancing screws

- Cool Jet coolant bores included

- Cooling with Cool Flash for an extra charge

- Included in delivery: Back-up screw

Shrink Fit Chuck Standard Version with Safe-Lock™ JIS B 6339 · BT40

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

Shrink fit chuck suitable to all kind of shrink fit units.

JIS B 6339 BT40 form ADB.

Form ADB means: Central coolant supply and coolant channels through the flange which can be sealed again.- Heat resistant hot-working steel

- Hardened 54 – 2 HRC

- For HSS and solid carbide tools

- Shank tolerance h6

- With threaded holes in order to balance with balancing screws

- Cooling with Cool Jet for an extra charge

- Cooling with Cool Flash for an extra charge

- Safe-Lock™ pull out protection included

- Included in delivery: Back-up screw, tension spring

Power Shrink Chuck JIS B 6339 · BT40

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

- Cool Jet, can be sealed

Shrink fit chuck suitable to all inductive shrink fit units.

The Power Shrink Chuck is the shrink fit chuck for highest machining capacity in high-speed manufacturing. The optimized design combines high rigidity with dampening vibrations, therefore giving more protection to machines, spindles and tools.

- Increased machining capacity due to higher spindle speed, higher feed and larger cutting depth

- Shorter processing times

- Higher machining accuracy

- With threaded holes in order to balance with balancing screws

- Cool Jet bores that can be sealed included

- Optional: Cooling with Cool Flash for an extra charge

Power Shrink Chuck with Safe-Lock™ JIS B 6339 · BT40

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

- Cool Jet, can be sealed

Shrink fit chuck suitable to all inductive shrink fit units.

The Power Shrink Chuck is the shrink fit chuck for highest machining capacity in high-speed manufacturing. The optimized design combines high rigidity with dampening vibrations, therefore giving more protection to machines, spindles and tools.

- Increased machining capacity due to higher spindle speed, higher feed and larger cutting depth

- Shorter processing times

- Higher machining accuracy

- With threaded holes in order to balance with balancing screws

- Cool Jet bores that can be sealed included

- Optional: Cooling with Cool Flash for an extra charge

- Safe-Lock™ pull out protection included

Power Mini Shrink Chuck JIS B 6339 · BT40

-

- Chuck fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

Shrink fit chuck suitable to all inductive shrink fit units.

Power Mini Shrink Chuck is perfect for 5-axis-machining in the die & mould and in the medical industry. Very slim at the top like the HAIMER Mini Shrink Chucks, the Power Mini Shrink is reinforced at the base. Thereby efficient milling is possible with an angled tool even at long protruding lengths.

- 3 mm wall thickness

- 3° slope at the top

- For solid carbide tools with shank tolerance h6

- With threaded holes in order to balance with balancing screws

Power Mini Shrink Chuck extra slim JIS B 6339 · BT40

-

- Chuck fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

Shrink fit chuck suitable to all inductive shrink fit units.

Power Mini Shrink Chuck is perfect for 5-axis-machining in the die & mould and in the medical industry. Very slim at the top like the HAIMER Mini Shrink Chucks, the Power Mini Shrink is reinforced at the base. Thereby efficient milling is possible with an angled tool even at long protruding lengths.

- Extra slim (1,5 mm wall thickness)

- 3° slope at the top

- For solid carbide tools with shank tolerance h6

- With threaded holes in order to balance with balancing screws

Collet Chuck Type ER JIS B 6339 · BT40

-

- Chuck body fine balanced G2.5 at 22.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For clamping tools with cylindrical shank in ER collets according to ISO 15488.

With taper JIS B 6339 BT40 form ADB.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.- Included in delivery: Locknut (balanced, with slide coating for higher clamping forces)

- Locknut type HS (High-Speed, fine balanced, with slide coating for higher clamping forces) for an extra charge

- Enlarging of size L for an upon request

Power Collet Chuck JIS B 6339 · BT40

-

- Chuck body fine balanced G2.5 at 25.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For clamping tools with cylindrical shank in HAIMER Power Collets and ER collets according to ISO 15488.

The Power Collet Chuck is the collet chuck for the highest machining capacity in high-speed manufacturing. The optimized design with better construction combines high rigidity with vibration dampening features, giving more protection to machines, spindles and tools. The universal Power Collet Chuck is a unique high performance chuck that can also be used with standard collets.

- High runout accuracy: 0.003 mm at 3 × D with HAIMER Power Collets

- Also for standard collets ER according to ISO 15488 (Please note when use with standard ER collets the gage length A will vary compared to A dimension given below!)

- High rigidity

- Smoother running thanks to vibration absorbing geometry, therefore better surface quality and protection of tools, spindles and machines

- Increased machining capacity due to higher spindle speeds, higher feed rates and larger cutting depths

- Shorter processing times, higher machining accuracy, high clamping force

- Equally suited to high-speed manufacturing and heavy milling

- With threaded holes in order to balance with balancing screws

- Optional: With Safe-Lock™ Power Collets from ER 25

- Optional: Cool Jet bores on Power Collets from ER 25 Ø 6 mm

High-Precision Chuck JIS B 6339 · BT40

-

- Chuck fine balanced G2.5 at 25.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For high-precise clamping of tools with cylindrical shank with special collets. Also for shanks with clamping flats. Very useful for high-speed machining.

With taper JIS B 6339 BT 40 form ADB.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.- Delivery comprises: High-precision chuck with clamping screw and pull-out hook without collet

- Shank tolerance h6

- Optional: Cool Jet bores on HG Collets from Ø 6 mm

- Extensions available for High-Precision Chuck

Face Mill Arbor JIS B 6339 · BT40

-

- Chuck body fine balanced G2.5 at 22.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For holding face mill cutters and milling cutters with radial driving slot DIN 1880.

Similar to DIN 6357 with taper JIS B 6339 BT40 form ADB.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.- With coolant exit bores on the end face for milling cutters with central cooling

- Included in delivery: Complete with tightening bolt

Combination Shell End Mill Arbor JIS B 6339 · BT40

-

- Chuck body fine balanced G2.5 at 22.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For clamping shell end mills DIN 841 and DIN 1880 as well as angular milling cutters DIN 842 and cutters DIN 1830.

According to DIN 6358 with taper JIS B 6339 BT40 form ADB.

Form ADB means: central coolant supply and coolant channels on the collar which can be sealed again.- Included in delivery: Tightening bolt, driving ring and feather key

- Coolant bores on front side for an extra charge

Adapter for Morse Taper with Thread JIS B 6339 · BT40

-

- Chuck body fine balanced G6.3 at 8.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

For clamping tools with Morse taper with drawbar thread according to DIN 228-1 form A.

Similar to DIN 6383 with taper JIS B 6339 BT40 form AD.

- Included in delivery: Tightening bolt

- Fine-balancing for an extra charge

Without bore for tang Form AD

Adapter for Morse Taper with Tang JIS B 6339 · BT40

-

- Chuck body fine balanced G6.3 at 8.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

For holding tools with Morse Tapers with tang according to DIN 228-11 form B.

Similar to DIN 6383 with taper JIS B 6339 BT40 form AD.

- Fine-balancing for an extra charge

Shrink Fit Chuck Standard Version JIS B 6339 · BT50

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- Taper tolerance AT3

- Coolant supply form ADB

Shrink fit chuck suitable to all kind of shrink fit units.

JIS B 6339 BT50 form ADB.

Form ADB means: Central coolant supply and coolant channels through the flange which can be sealed again.- Heat resistant hot-working steel

- Hardened 54 – 2 HRC

- For HSS and solid carbide tools

- Shank tolerance h6

- With threaded holes in order to balance with balancing screws

- Cooling with Cool Jet for an extra charge

- Cooling with Cool Flash for an extra charge

- Included in delivery: Back-up screw

Power Shrink Chuck JIS B 6339 · BT50

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

- Cool Jet, can be sealed

Shrink fit chuck suitable to all inductive shrink fit units.

The Power Shrink Chuck is the shrink fit chuck for highest machining capacity in high-speed manufacturing. The optimized design combines high rigidity with dampening vibrations, therefore giving more protection to machines, spindles and tools.

- Increased machining capacity due to higher spindle speed, higher feed and larger cutting depth

- Shorter processing times

- Quieter running, therefore better surface quality and protection of tools, spindles and machines

- Higher machining accuracy

- With threaded holes in order to balance with balancing screws

- Cool Jet bores that can be sealed included

- Cooling with Cool Flash for an extra charge

The long versions (A = 160 and 200 mm) with slim tips are especially versatile to use.

Power Shrink Chuck with Safe-Lock™ JIS B 6339 · BT50

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

- Cool Jet, can be sealed

Shrink fit chuck suitable to all inductive shrink fit units.

The Power Shrink Chuck is the shrink fit chuck for highest machining capacity in high-speed manufacturing. The optimized design combines high rigidity with dampening vibrations, therefore giving more protection to machines, spindles and tools.

- Increased machining capacity due to higher spindle speed, higher feed and larger cutting depth

- Shorter processing times

- Quieter running, therefore better surface quality and protection of tools, spindles and machines

- Higher machining accuracy

- With threaded holes in order to balance with balancing screws

- Cool Jet bores that can be sealed included

- Cooling with Cool Flash for an extra charge

- Safe-Lock™ pull out protection included

Heavy Duty Shrink Chuck JIS B 6339 · BT50

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

- Cool Jet, can be sealed

Shrink fit chuck suitable to all high performance inductive shrink fit units.

For heavy machining applications it is now possible to replace the Weldon tool holders finally. Heavy Duty Chuck is the shrink fit chuck for extreme cases. The contour is optimized for highest rigidity and clamping force.

- Smooth clamping of the tool shank

- No deformation at the tool shank after shrink process

- High runout accuracy: 3 μm

- Reinforced outer contour

- With dirt groove in the clamping bore

- With threaded holes in order to balance with balancing screws

- Cool Jet bores that can be sealed included

- Cooling with Cool Flash for an extra charge

To shrink with all HAIMER Power Clamp 20 kW shrink fit units and shrink fit machines with 13 kW HD-Coil.

Heavy Duty Shrink Chuck with Safe-Lock™ JIS B 6339 · BT50

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

- Cool Jet, can be sealed

Shrink fit chuck suitable to all high performance inductive shrink fit units.

For heavy machining applications it is now possible to replace the Weldon tool holders finally. Heavy Duty Chuck is the shrink fit chuck for extreme cases. The contour is optimized for highest rigidity and clamping force.

- Smooth clamping of the tool shank

- No deformation at the tool shank after shrink process

- High runout accuracy: 3 μm

- Reinforced outer contour

- With dirt groove in the clamping bore

- With threaded holes in order to balance with balancing screws

- Cool Jet bores that can be sealed included

- Cooling with Cool Flash for an extra charge

- Safe-Lock™ pull out protection included

To shrink with all HAIMER Power Clamp 20 kW shrink fit units and shrink fit machines

Heavy Duty Shrink Chuck for 13 kW shrink fit machine JIS B 6339 · BT50

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

- Cool Jet, can be sealed

Shrink fit chuck suitable to all inductive shrink fit units.

For heavy machining applications it is now possible to replace the Weldon tool holders finally. Heavy Duty Chuck is the shrink fit chuck for extreme cases. The contour is optimized for highest rigidity and clamping force.

- Smooth clamping of the tool shank

- No deformation at the tool shank after shrink process

- High runout accuracy: 3 μm

- Reinforced outer contour

- With dirt groove in the clamping bore

- With threaded holes in order to balance with balancing screws

- Cool Jet bores that can be sealed included

- Cooling with Cool Flash for an extra charge

To shrink with all HAIMER Power Clamp 13 kw shrink fit units.

Collet Chuck Type ER JIS B 6339 · BT50

-

- Chuck body fine balanced G2.5 at 22.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For clamping tools with cylindrical shank in ER collets according to ISO 15488.

With taper JIS B 6339 BT50 form ADB.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.- Included in delivery: Locknut (balanced, with slide coating for higher clamping forces)

- Locknut type HS (High-Speed, fine balanced, with slide coating for higher clamping forces) for an extra charge

- Enlarging of size L upon request

Power Collet Chuck JIS B 6339 · BT50

-

- Chuck body fine balanced G2.5 at 25.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For clamping tools with cylindrical shank in HAIMER Power Collets and ER collets according to ISO 15488.

The Power Collet Chuck is the collet chuck for the highest machining capacity in high-speed manufacturing. The optimized design with better construction combines high rigidity with vibration dampening features, giving more protection to machines, spindles and tools. The universal Power Collet Chuck is a unique high performance chuck that can also be used with standard collets.

- High runout accuracy: 0.003 mm at 3 × D with HAIMER Power Collets

- Also for standard collets ER according to ISO 15488 (Please note when use with standard ER collets the gage length A will vary compared to A dimension given below!)

- High rigidity

- Smoother running thanks to vibration absorbing geometry, therefore better surface quality and protection of tools, spindles and machines

- Increased machining capacity due to higher spindle speeds, higher feed rates and larger cutting depths

- Shorter processing times, higher machining accuracy, high clamping force

- Equally suited to high-speed manufacturing and heavy milling

- With threaded holes in order to balance with balancing screws

- Optional: With Safe-LockTM Power Collets from ER 25

- Optional: Cool Jet bores on Power Collets from ER 25 Ø 6 mm

High-Precision Chuck JIS B 6339 · BT50

-

- Chuck fine balanced G2.5 at 25.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For high-precise clamping of tools with cylindrical shank with special collets. Also for shanks with clamping flats. Very useful for high-speed machining.

With taper JIS B 6339 BT50 Form ADB.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.- Delivery comprises: High-precision chuck with clamping screw and pull-out hook without collet

- Shank tolerance h6

- Optional: Cool Jet bores on HG Collets from Ø 6 mm

- Extensions for High-Precision Chuck available

Weldon Tool Holder JIS B 6339 · BT50

-

- Chuck fine balanced G2.5 at 22.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For clamping cutters with cylindrical shank and Weldon flat similar to DIN 1835-B and DIN 6535-HB.

According to DIN 6359 with taper JIS B 6339 BT50 Form ADB.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.- Included in delivery: Clamping screw

- Cooling with Cool Jet for an extra charge

Face Mill Arbor JIS B 6339 · BT50

-

- Chuck body fine balanced G2.5 at 22.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For holding face mill cutters and cutters with radial driving slot DIN 1880 and exceeding clamping diameter 40 clamping according to DIN 2079 is possible, too (4 additional tapping holes).

Similar to DIN 6357 with taper JIS B 6339 BT50 form ADB.

Form ADB means: central coolant supply and coolant channels on the collar which can be sealed again.- With coolant exit bores on the end face for milling cutters with central cooling

- Included in delivery: Complete with tightening bolt

Combination Shell End Mill Arbor JIS B 6339 · BT50

-

- Chuck body fine balanced G2.5 at 22.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For clamping shell end mills DIN 841 and DIN 1880 as well as angular milling cutters DIN 842 and cutters DIN 1830.

According to DIN 6358 with taper JIS B 6339 BT50 form ADB.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.- Included in delivery: Tightening bolt, driving ring and feather key

- Coolant bores on front side for an extra charge

Adapter for Morse Taper with Thread JIS B 6339 · BT50

-

- Chuck body fine balanced G6.3 at 8.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

For clamping tools with Morse taper with drawbar thread according to DIN 228-1 form A.

Similar to DIN 6383 with taper JIS B 6339 BT50 form A.

- Included in delivery: Tightening bolt

- Fine-balancing for an extra charge

Adapter for Morse Taper with Tang JIS B 6339 · BT50

-

- Chuck body fine balanced G6.3 at 8.000 rpm

- All functional surfaces fine machined

- Taper tolerance AT3

For holding tools with Morse Tapers with tang according to DIN 228-11 form B.

Similar to DIN 6383 with taper JIS B 6339 BT50 Form AD.

- Fine-balancing for an extra charge

Blank Adapter JIS B 6339 · BT50

-

- All functional surfaces fine machined

- Taper tolerance AT3

- Coolant supply form ADB

For manufacturing special tools in your factory.

With taper JIS B 6339 BT50 Form ADB.

Form ADB means: Central coolant supply and coolant channels on the collar which can be sealed again.

Design:

Taper and groove are hardened and ground, the cylindrical part is soft.

DIN 69893 HSK-A, HSK-E, HSK-F

- The interface DIN 69893 has become the new standard for machining centres. The holder is clamped via its taper with flange contact surface. By doing so, a highly accurate centring and fixed axial position of the holder in the spindle is granted with a high repetitive accuracy when exchanging the tools. In the DIN 69893-1 HSK-A interface design an additional torque transmission takes place at the taper shank with drive keys. DIN 69893 HSK-A/HSK-E/HSK-F is mainly used in high-speed machining.

Shrink Fit Chuck Standard Version DIN 69893-1 · HSK-A32

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- More accurate than DIN

Shrink fit chuck suitable to all kind of shrink fit units.

DIN 69893-1

- Heat resistant hot-working steel

- Hardened 54 – 2 HRC

- For HSS and solid carbide tools

- Shank tolerance h6

- With threaded holes in order to balance with balancing screws

- Cooling with Cool Jet for an extra charge

- Cooling with Cool Flash for an extra charge

- Delivery comprises: Shrink fit chuck with backup screw, without coolant tube

Collet Chuck Type ER DIN 69893-1 · HSK-A32

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- More accurate than DIN

For clamping tools with cylindrical shank in ER collets according to ISO 15488.

DIN 69882-6

- Included in delivery: Locknut type HS (High-Speed, fine balanced, with slide coating for higher clamping forces); without coolant tube

- Enlarging of size L upon request

Power Collet Chuck DIN 69893-1 · HSK-A32

-

- Chuck body fine balanced G2.5 at 25.000 rpm

- All functional surfaces fine machined

- More accurate than DIN

- Coolant supply form ADB

For clamping tools with cylindrical shank in HAIMER Power Collets and ER collets according to ISO 15488.

The Power Collet Chuck is the collet chuck for the highest machining capacity in high-speed manufacturing. The optimized design with better construction combines high rigidity with vibration dampening features, giving more protection to machines, spindles and tools. The universal Power Collet Chuck is a unique high performance chuck that can also be used with standard collets.

- High runout accuracy: 0.003 mm at 3 × D with HAIMER Power Collets

- Also for standard collets ER according to ISO 15488 (Please note when use with standard ER collets the gage length A will vary compared to A dimension given below!)

- High rigidity

- Smoother running thanks to vibration absorbing geometry, therefore better surface quality and protection of tools, spindles and machines

- Increased machining capacity due to higher spindle speeds, higher feed rates and larger cutting depths

- Shorter processing times, higher machining accuracy, high clamping force

- Equally suited to high-speed manufacturing and heavy milling

- Optional: With Safe-Lock™ Power Collets from ER 25

- Optional: Cool Jet bores on Power Collets from ER 25 Ø 6 mm

Weldon Tool Holder DIN 69893-1 · HSK-A32

-

- Chuck fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- More accurate than DIN

For clamping cutters with cylindrical shank and Weldon flat similar to DIN 1835-B and DIN 6535-HB.

DIN 69882-4

- Included in delivery: Backup screw, without coolant tube

- Cooling with Cool Jet for an extra charge

Shrink Fit Chuck Standard Version DIN 69893-1 · HSK-A40

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- More accurate than DIN

Shrink fit chuck suitable to all kind of shrink fit units.

DIN 69893-1

- Heat resistant hot-working steel

- Hardened 54 – 2 HRC

- For HSS and solid carbide tools

- Shank tolerance h6

- With threaded holes in order to balance with balancing screws

- Cooling with Cool Jet for an extra charge

- Cooling with Cool Flash for an extra charge

- Included in delivery: Shrink fit chuck with backup screw, without coolant tube

Collet Chuck Type ER DIN 69893-1 · HSK-A40

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- More accurate than DIN

For clamping tools with cylindrical shank in ER collets according to ISO 15488.

DIN 69882-6

- Included in delivery: Locknut type HS (High-Speed, fine balanced, with slide coating for higher clamping forces); without coolant tube

- Enlarging of size L upon request

Power Collet Chuck DIN 69893-1 · HSK-A40

-

- Chuck body fine balanced G2.5 at 25.000 rpm

- All functional surfaces fine machined

- More accurate than DIN

- Coolant supply form ADB

For clamping tools with cylindrical shank in HAIMER Power Collets and ER collets according to ISO 15488.

The Power Collet Chuck is the collet chuck for the highest machining capacity in high-speed manufacturing. The optimized design with better construction combines high rigidity with vibration dampening features, giving more protection to machines, spindles and tools. The universal Power Collet Chuck is a unique high performance chuck that can also be used with standard collets.

- High runout accuracy: 0.003 mm at 3 × D with HAIMER Power Collets

- Also for standard collets ER according to ISO 15488 (Please note when use with standard ER collets the gage length A will vary compared to A dimension given below!)

- High rigidity

- Smoother running thanks to vibration absorbing geometry, therefore better surface quality and protection of tools, spindles and machines

- Increased machining capacity due to higher spindle speeds, higher feed rates and larger cutting depths

- Shorter processing times, higher machining accuracy, high clamping force

- Equally suited to high-speed manufacturing and heavy milling

- Optional: With Safe-Lock™ Power Collets from ER 25

- Optional: Cool Jet bores on Power Collets from ER 25 Ø 6 mm

Weldon Tool Holder DIN 69893-1 · HSK-A40

-

- Chuck fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- More accurate than DIN

For clamping cutters with cylindrical shank and Weldon flat similar to DIN 1835-B and DIN 6535-HB.

DIN 69882-4

- Included in delivery: Clamping screw, without coolant tube

- Cooling with Cool Jet for an extra charge

Face Mill Arbor DIN 69893-1 · HSK-A40

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- More accurate than DIN

For holding face mill cutters and cutters with radial driving slot DIN 1880 and exceeding clamping diameter 40 clamping according to DIN 2079 is possible, too (4 additional tapping holes).

DIN 69882-3

- With coolant exit bores on the end face for milling cutters with central cooling

- Included in delivery: Tightening bolt, without coolant tube

Combination Shell End Mill Arbor DIN 69893-1 · HSK-A40

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- More accurate than DIN

For clamping shell end mills DIN 841 and DIN 1880 as well as angular milling cutters DIN 842 and cutters DIN 1830.

DIN 69882-2

- Included in delivery: Tightening bolt, driving ring and feather key, without coolant tube

- Coolant bores on front side for an extra charge

Shrink Fit Chuck Standard Version DIN 69893-1 · HSK-A50

-

- Chuck body fine balanced G2.5 at 25.000 rpm or U < 1 gmm

- All functional surfaces fine machined

- More accurate than DIN

Shrink fit chuck suitable to all kind of shrink fit units.

DIN 69893-1

- Heat resistant hot-working steel

- Hardened 54 – 2 HRC

- For HSS and solid carbide tools

- Shank tolerance h6