- Offer Profile

- We stand for much more than

'just' good machines.

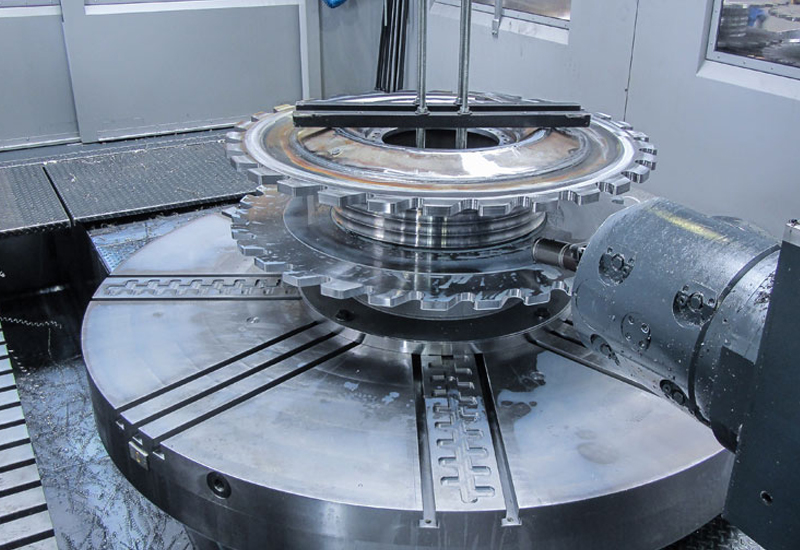

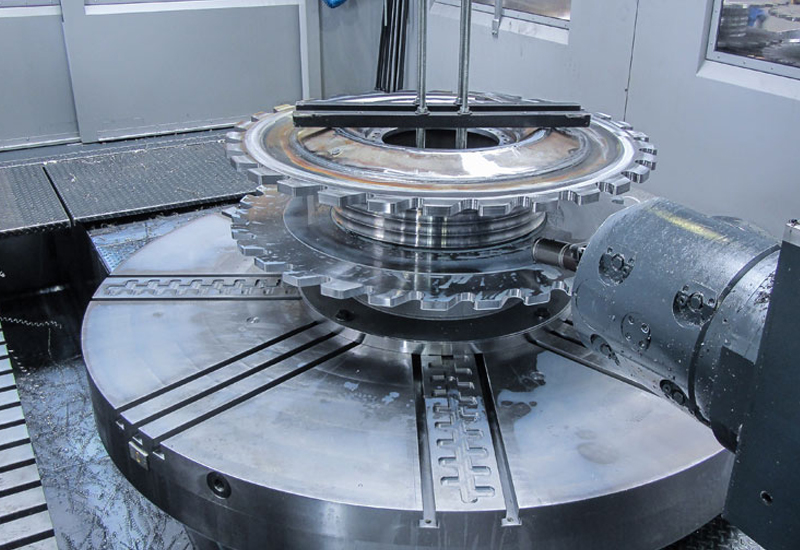

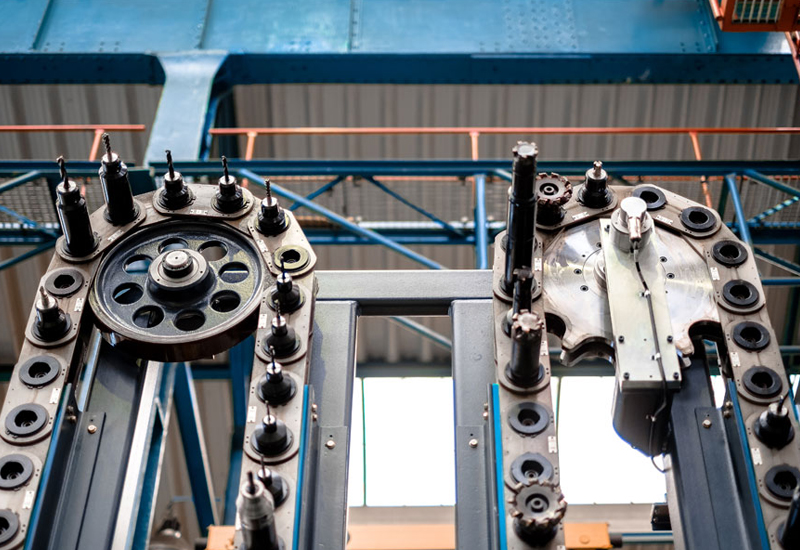

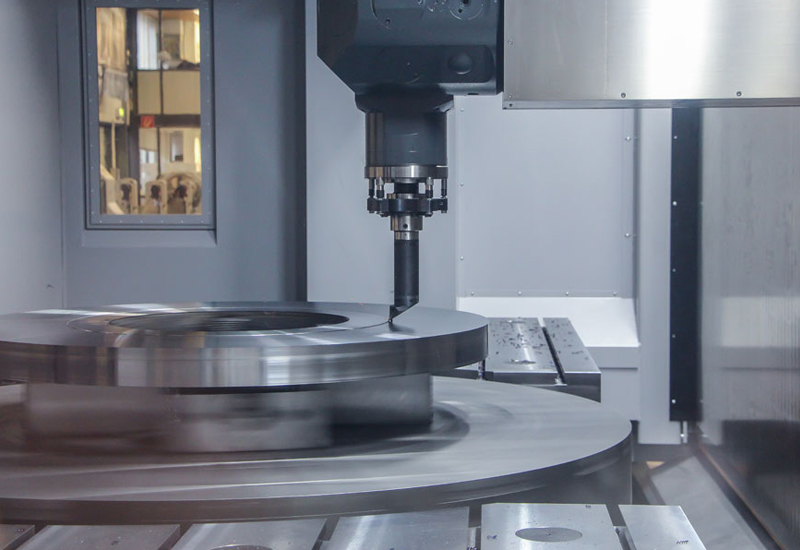

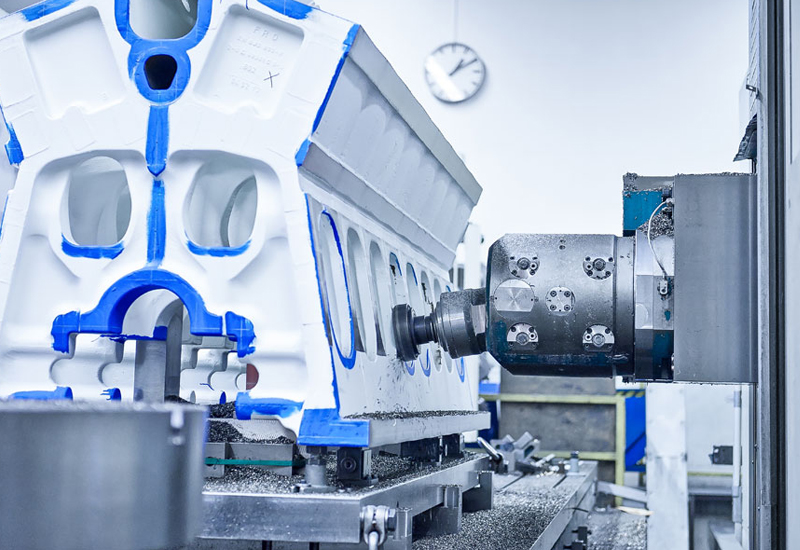

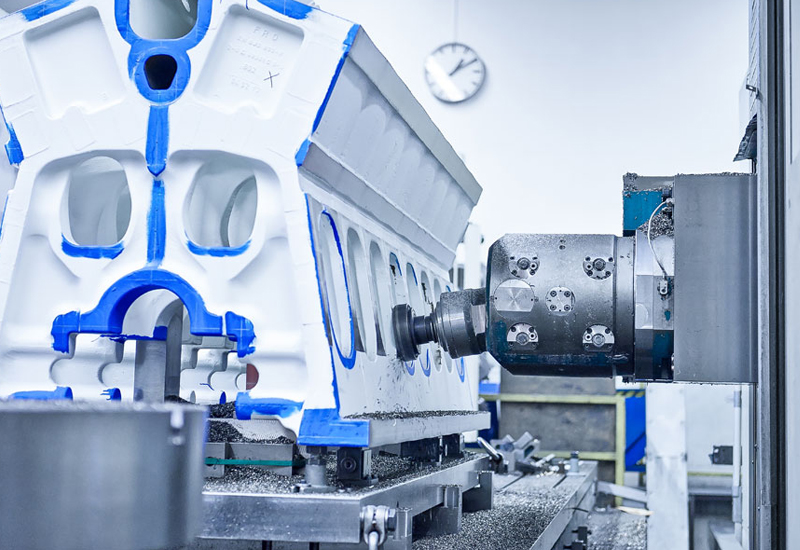

SHW Werkzeugmaschinen GmbH is one of the world’s leading manufacturers of travelling column machines and an internationally renowned specialist for machine processing. Among the items our machines produce are large parts for machine and plant construction, for large diesel engines, for turbines and for environmental technology. The head of every machine and the heart of every plant is the SHW milling head. All our expertise can be found here – guaranteeing the uncompromising precision that our customers demand.

Machining centers

-

We stand for much more than 'just' good machines.

SHW Werkzeugmaschinen GmbH is one of the world’s leading manufacturers of travelling column machines and an internationally renowned specialist for machine processing. Among the items our machines produce are large parts for machine and plant construction, for large diesel engines, for turbines and for environmental technology. The head of every machine and the heart of every plant is the SHW milling head. All our expertise can be found here – guaranteeing the uncompromising precision that our customers demand.

Machining centers

-

Characteristics:

- full enclosured

- foundationless

- configurable

- powerful

Editions:- Milling machine

- Turning and milling machine

- Head change machine

- Pallet changing machine

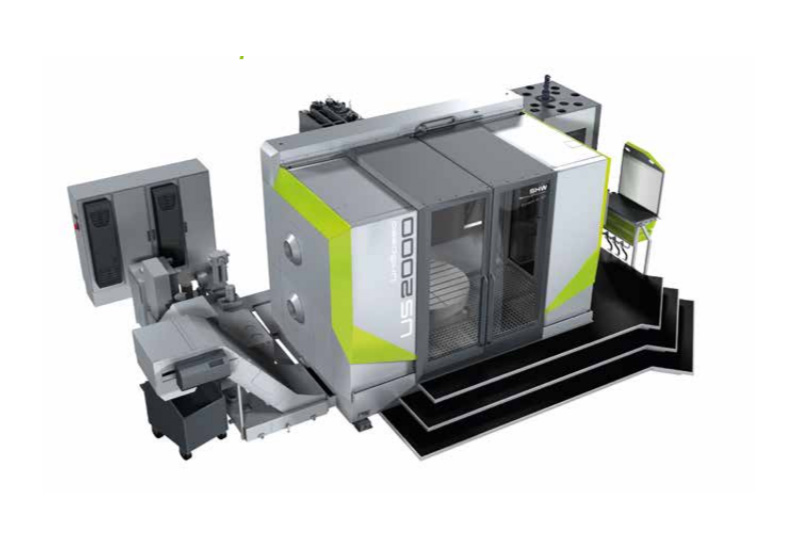

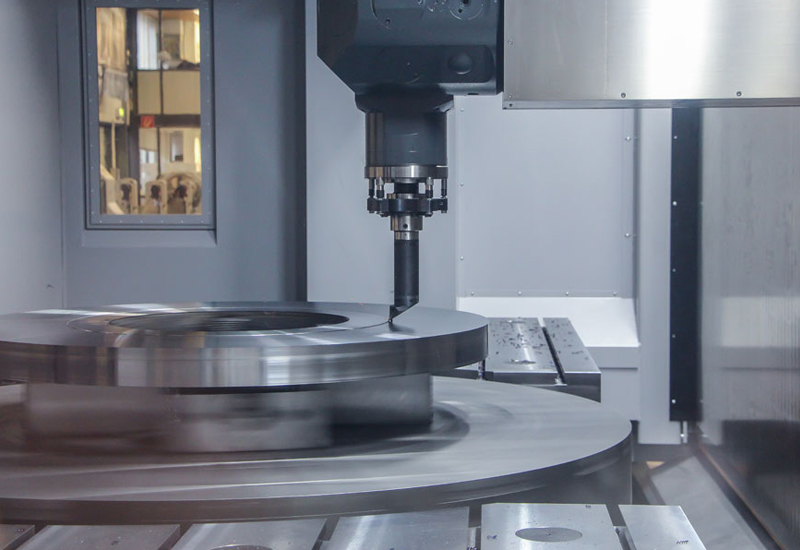

The universal, compact machining centers of the UniSpeed and the TightBlock series implement dynamics with highest efficiency for milling and mill-turning. They are especially well suited for model and die production, for subcontracting and for the tool and aviation industry.

The machines in the UniSpeed and TightBlock series are equipped with our automatic universal milling head in orthogonal design. This head offers, in its standard execution, up to 64 800 programmable head positions. As an option we offer this head with continuous axes. Further milling head executions on demand.

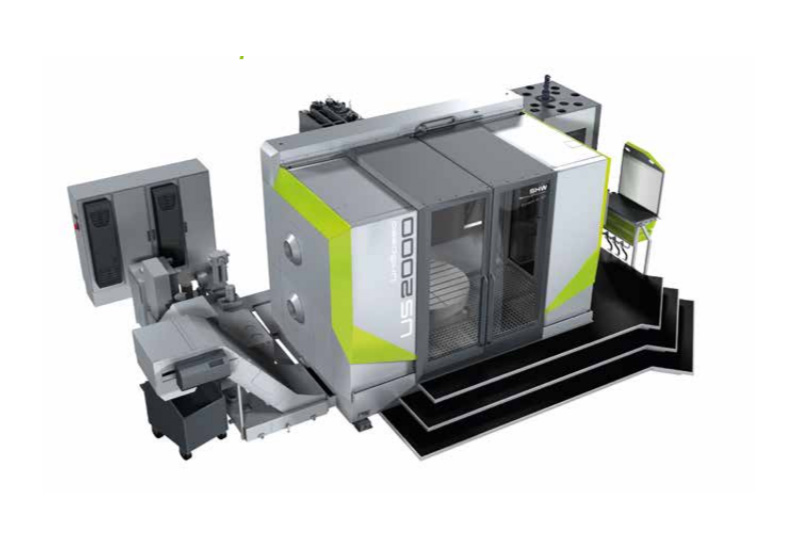

UniSpeed 2000

- Machining travels (maximum)

- X-axis (horizontal lengthwise) in mm 2.000

- Y-axis (vertical) in mm 1.300

- Z-axis (horizontal crosswise) in mm 1.300

Milling head- Universal milling head of orthogonal design

- swivel range standard A-axis 180°

- C-axis 360°

Motion speeds- Feed rates and rapid traverses (X, Y, Z) in mm/min up to 30.000

- Acceleration of linear axis in m/s2 2

Tool holder- SK 50 BIG-PLUS

- HSK 100 A DIN 69893

Versions

- Milling machine

- Mill-Turn-machine

- Machine with pallet changer

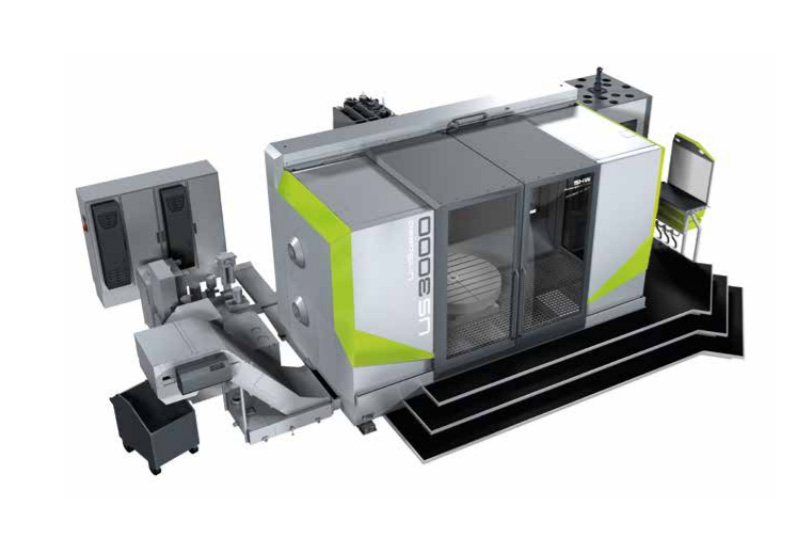

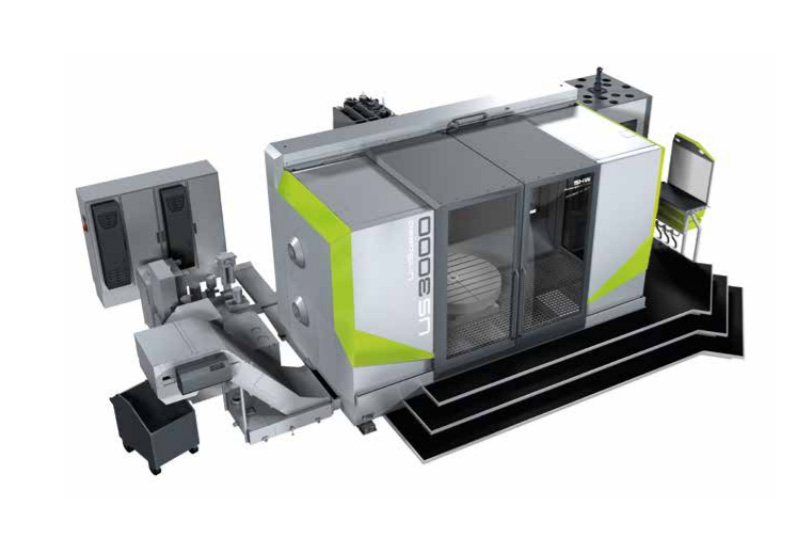

UniSpeed 3000

- Machining travels (maximum)

- X-axis (horizontal lengthwise) in mm 3.000

- Y-axis (vertical) in mm 1.300

- Z-axis (horizontal crosswise) in mm 1.300

Milling head- Universal milling head of orthogonal design

- swivel range standard A-axis 180°

- C-axis 360°

Main drive- Drive power in kW up to 36

- Speed range in min-1 up to 8.000

Motion speeds- Feed rates and rapid traverses (X, Y, Z) in mm/min up to 30.000

- Acceleration of linear axis in m/s2 2

Tool holder- SK 50 BIG-PLUS

- HSK 100 A DIN 69893

Versions

- Milling machine

- Mill-Turn-machine

- Machine with pallet changer

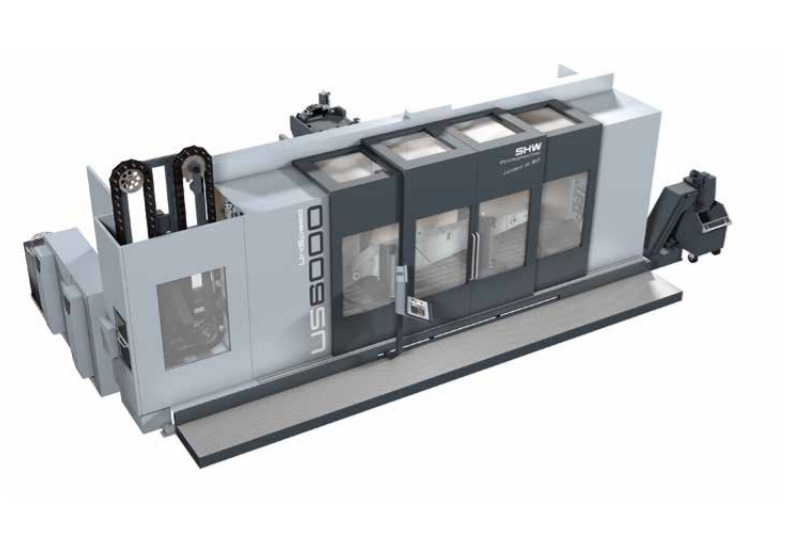

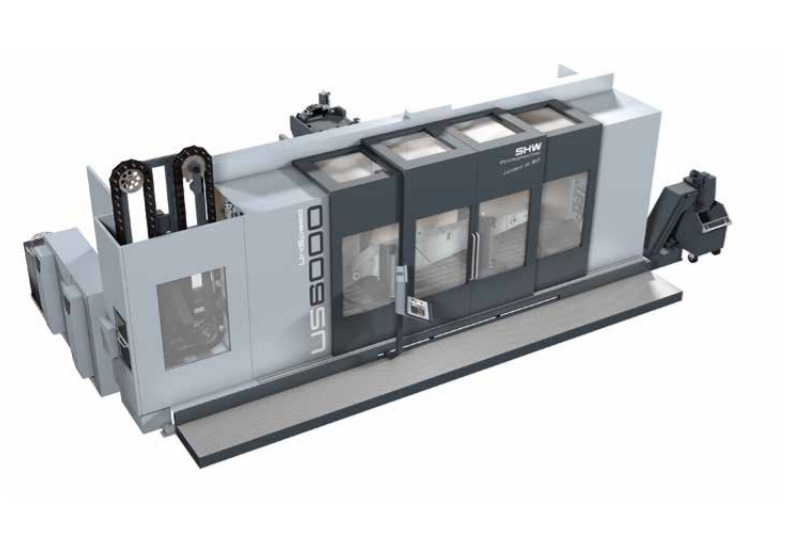

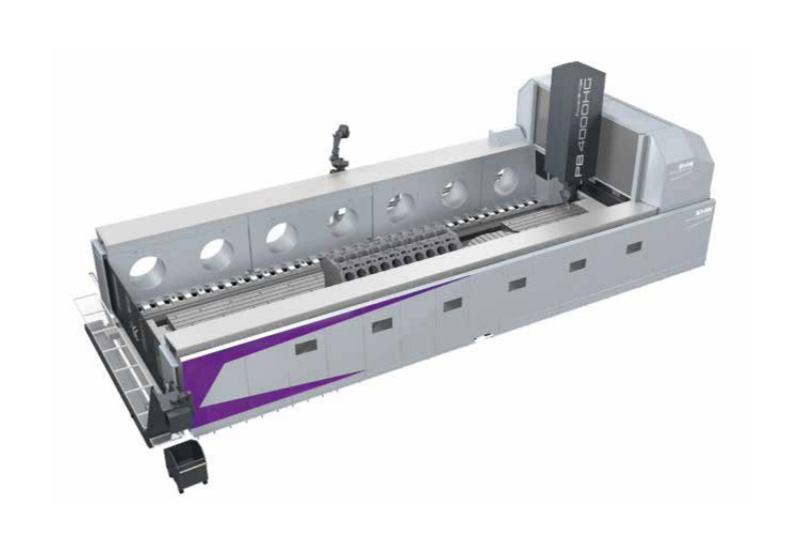

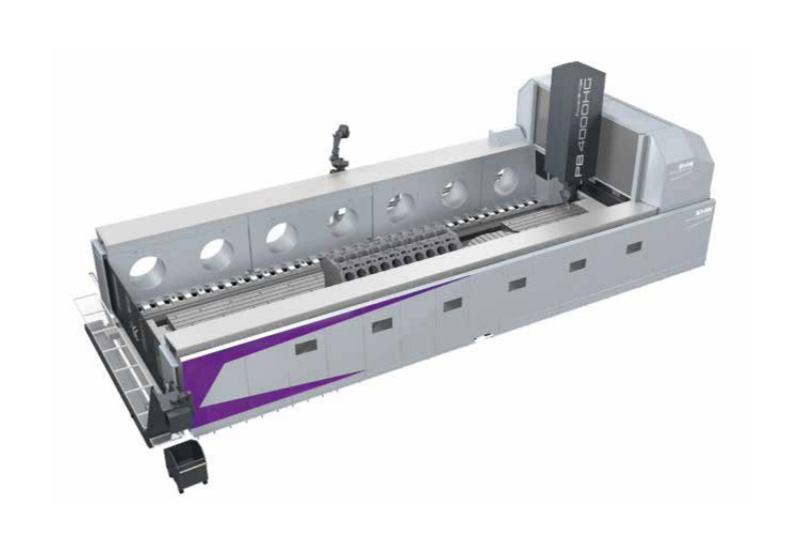

UniSpeed 6000

-

Characteristics:

- full enclosured

- foundationless

- configurable

- powerful

Editions:- Milling machine

- Turning and milling machine

- Pallet changing machine

Machining travels (maximum)- X-axis (horizontal lengthwise) in mm 6.000

- Y-axis (vertical) in mm 1.600

- Z-axis (horizontal crosswise) in mm 1.300

Milling head- Universal milling head of orthogonal design

- swivel range standard A-axis 180°

- C-axis 360°

Main drive- Drive power in kW up to 44

- Speed range in min-1 up to 8.000

Motion speeds- Feed rates and rapid traverses (X, Y, Z) in mm/min up to 30.000

- Acceleration of linear axis in m/s2 3,5

Tool holder- SK 50 BIG-PLUS

- HSK 100 A DIN 69893

Versions

- Milling machine

- Mill-Turn-machine

- Machine with pallet changer

TightBlock 6000

- Machining travels (maximum)

- X-axis (horizontal lengthwise) in mm 6.000

- Y-axis (vertical) in mm 2.600

- Z-axis (horizontal crosswise) in mm 1.300

Fräskopf- Universal milling head of orthogonal design

- swivel range standard A-axis 180°

- C-axis 360°

Main drive- Drive power in kW up to 44

- Speed range in min-1 up to 8.000

Motion speeds- Feed rates and rapid traverses (X, Y, Z) in mm/min up to 30.000

- Acceleration of linear axis in m/s2 5

Tool holder- SK 50 BIG-PLUS

- HSK 100 A DIN 69893

Versions

- Milling machine

- Mill-Turn-machine

- Machine with pallet changer

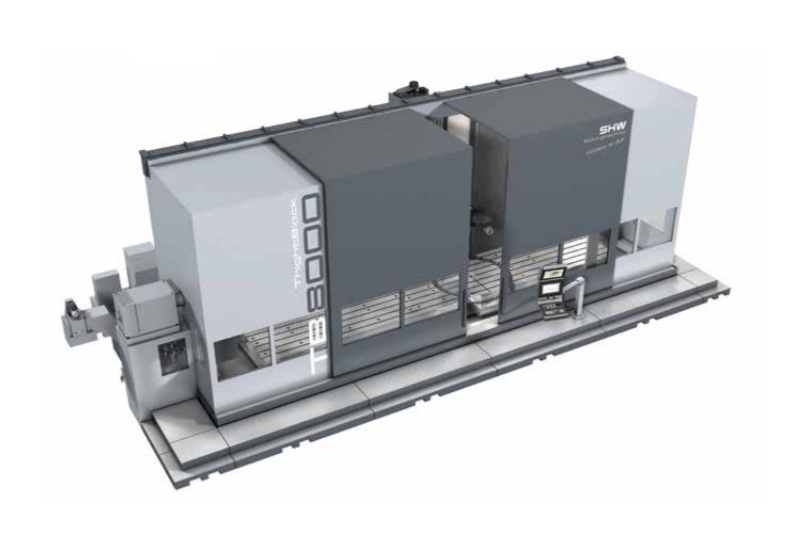

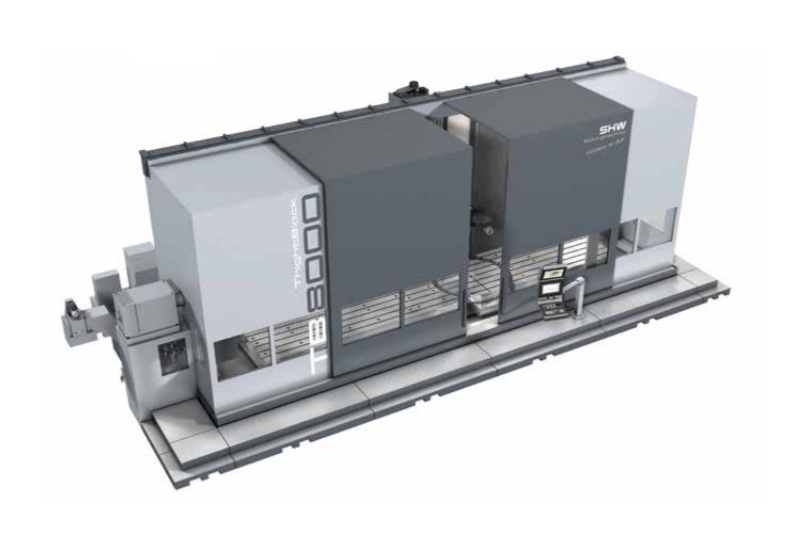

TightBlock 8000

- Machining travels (maximum)

- X-axis (horizontal lengthwise) in mm 8.000

- Y-axis (vertical) in mm 3.100

- Z-axis (horizontal crosswise) in mm 1.500

Milling head- Universal milling head of orthogonal design

- swivel range standard A-axis 180°

- C-axis 360°

Main drive- Drive power in kW up to 55

- Speed range in min-1 up to 8.000

Motion speeds- Feed rates and rapid traverses (X, Y, Z) in mm/min up to 30.000

- Acceleration of linear axis in m/s2 5

Tool holder- SK 50 BIG-PLUS

- HSK 100 A DIN 69893

Versions

- Milling machine

- Mill-Turn-machine

- Machine with pallet changer

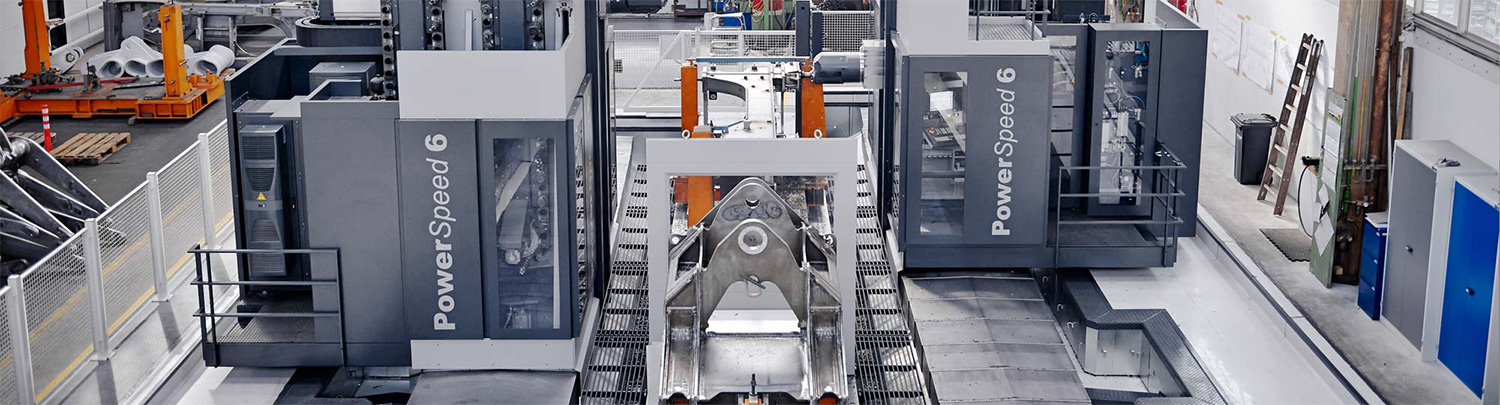

Travelling column machines

-

Characteristics:

- flexible

- uncompromising

- configurable

- powerful

Editions:- Milling machine

- Turning and milling machine

- Head change machine

- Pallet changing machine

- Double column machine

Our travelling column machines are designed for heavy-duty machining of large components. Their numerous variants, in connection with a wide range of options, allow tailor-made solutions for any machining task. Despite their sturdy and robust design, our travelling column machines grant top-class values as to precision and productivity.

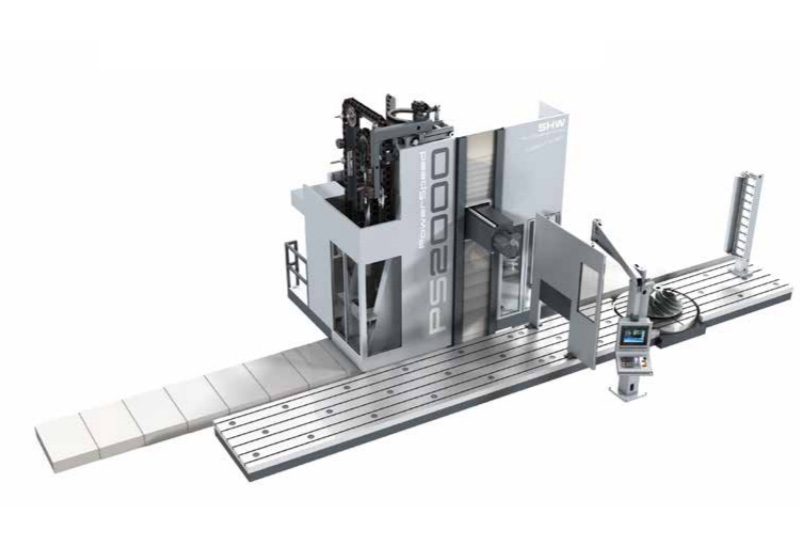

PowerSpeed 2000

-

Characteristics:

- flexible

- uncompromising

- configurable

- powerful

Editions:- Milling machine

- Turning and milling machine

- Head change machine

- Double column machine

Machining travels (maximum)- X-axis (horizontal lengthwise) in mm 30.000

- Y-axis (vertical) in mm 2.600

- Z-axis (horizontal crosswise) in mm 1.300

Milling head- Universal milling head of orthogonal design

- swivel range standard A-axis 180°

- C-axis 360°

Main drive- Drive power in kW up to 44

- Speed range in min-1 up to 8.000

Motion speeds- Feed rates and rapid traverses (X, Y, Z) in mm/min up to 30.000

- Acceleration of linear axis in m/s2 5

Tool holder- SK 50 BIG-PLUS

- HSK 100 A DIN 69893

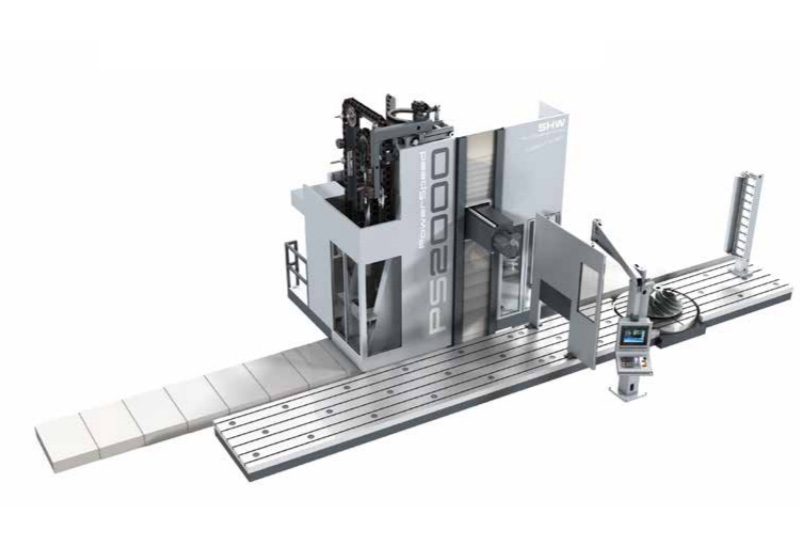

PowerSpeed 4000

-

Characteristics:

- flexible

- uncompromising

- configurable

- powerful

Editions:- Milling machine

- Turning and milling machine

- Head change machine

- Double column machine

Machining travels (maximum)- X-axis (horizontal lengthwise) in mm 40.000

- Y-axis (vertical) in mm 4.100

- Z-axis (horizontal crosswise) in mm 1.600

Milling head- Universal milling head of orthogonal design

- swivel range standard A-axis 180°

- C-axis 360°

Main drive- Drive power in kW up to 75

- Speed range in min-1 up to 8.000

Motion speeds- Feed rates and rapid traverses (X, Y, Z) in mm/min up to 40.000

- Acceleration of linear axis in m/s2 5

Tool holder- SK 50 BIG-PLUS

- HSK 100 A DIN 69893

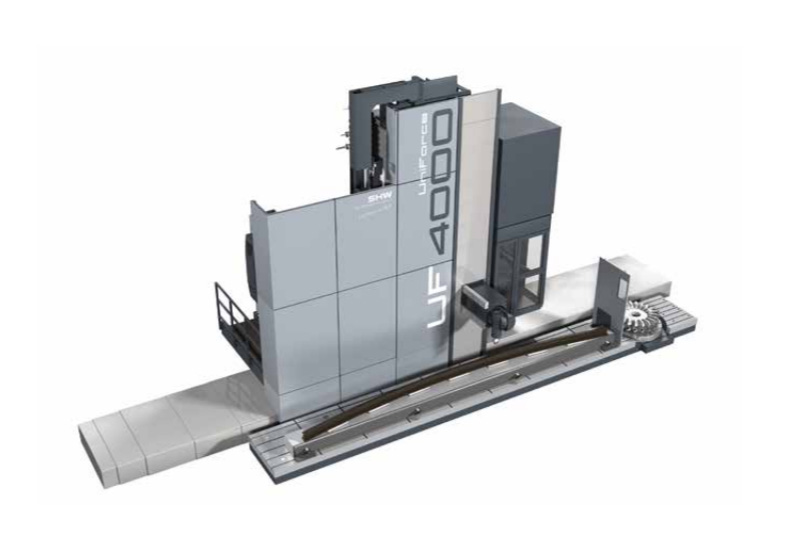

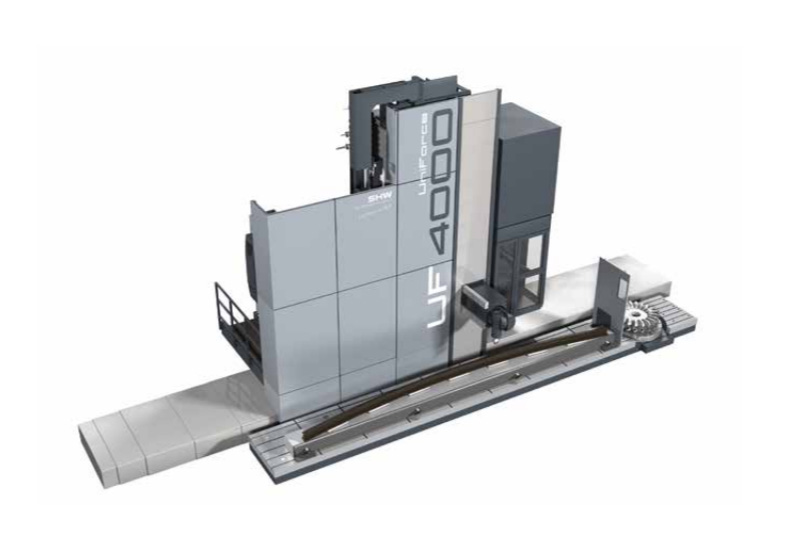

UniForce 4000

-

Characteristics:

- flexible

- uncompromising

- configurable

- powerful

Editions:- Milling machine

- Turning and milling machine

- Head change machine

- Double column machine

Machining travels (maximum)- X-axis (horizontal lengthwise) in mm 40.000

- Y-axis (vertical) in mm 4.100

- Z-axis (horizontal crosswise) in mm 1.600

Milling head- Universal milling head of orthogonal design

- swivel range standard A-axis 180°

- C-axis 360°

Main drive- Drive power in kW up to 53

- Speed range in min-1 up to 4.000

Motion speeds- Feed rates and rapid traverses (X, Y, Z) in mm/min up to 36.000

- Acceleration of linear axis in m/s2 2

Tool holder- SK 50 BIG-PLUS

- HSK 100 A DIN 69893

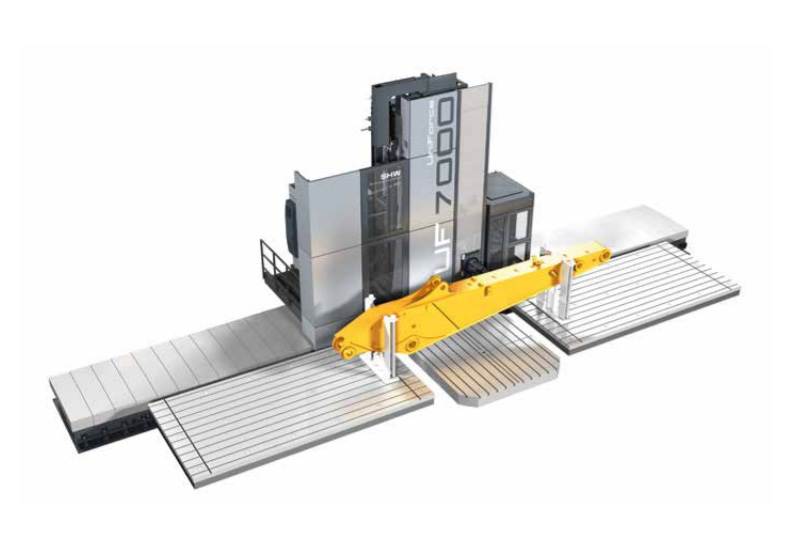

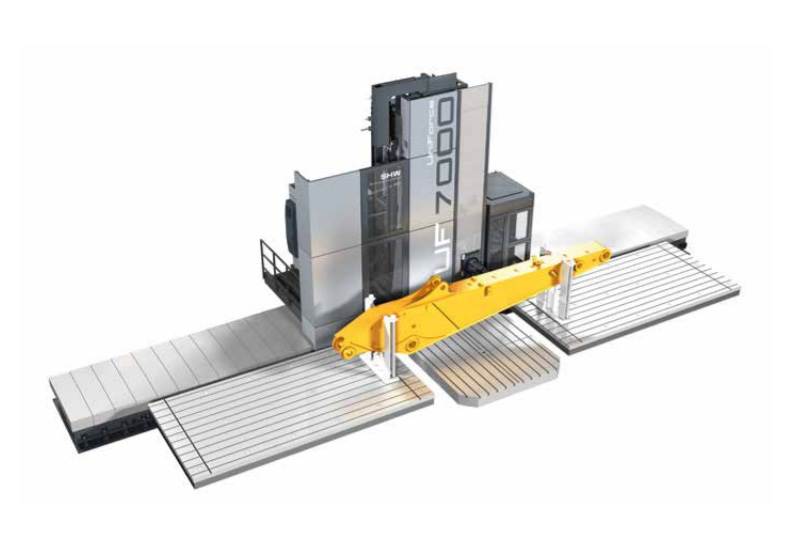

UniForce 7000

-

Characteristics:

- flexible

- uncompromising

- configurable

- powerful

Editions:- Milling machine

- Turning and milling machine

- Head change machine

- Double column machine

Machining travels (maximum)- X-axis (horizontal lengthwise) in mm 40.000

- Y-axis (vertical) in mm 7.100

- Z-axis (horizontal crosswise) in mm 1.800

Milling head- Universal milling head of orthogonal design

- swivel range standard A-axis 180°

- C-axis 360°

Main drive- Drive power in kW up to 63

- Speed range in min-1 up to 5.000

Motion speeds- Feed rates and rapid traverses (X, Y, Z) in mm/min up to 36.000

- Acceleration of linear axis in m/s2 2

Tool holder- SK 50 BIG-PLUS

- HSK 100 A DIN 69893

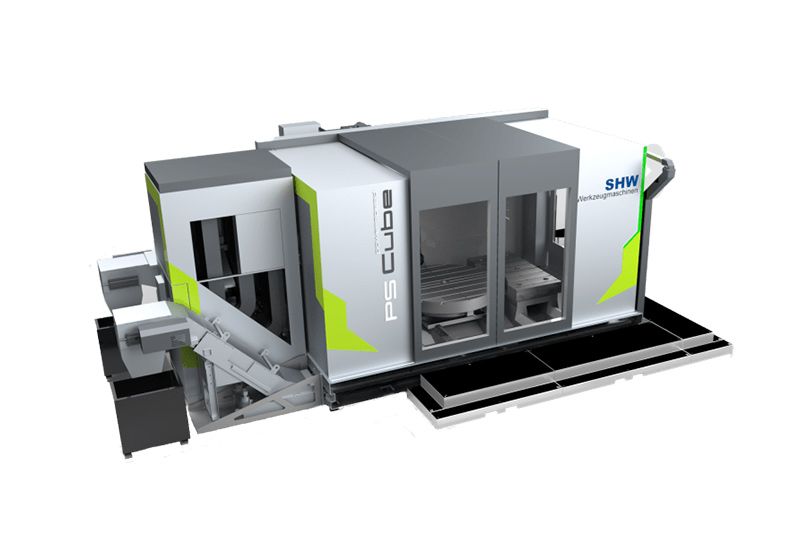

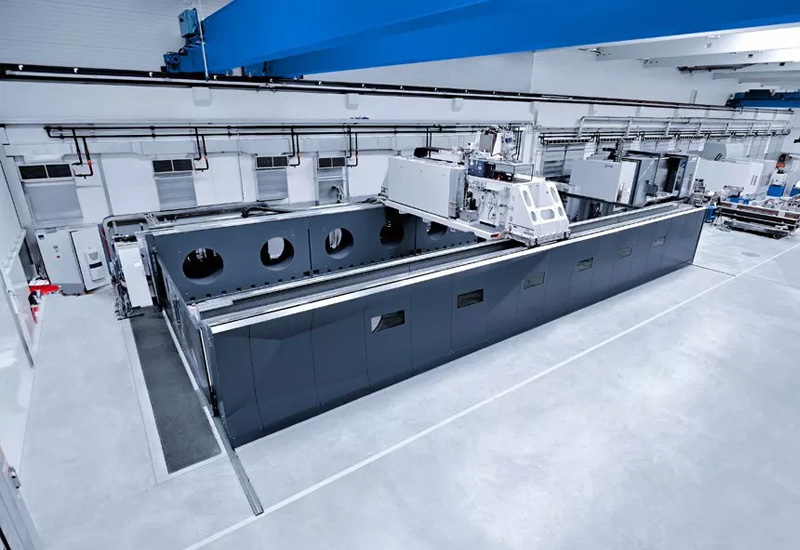

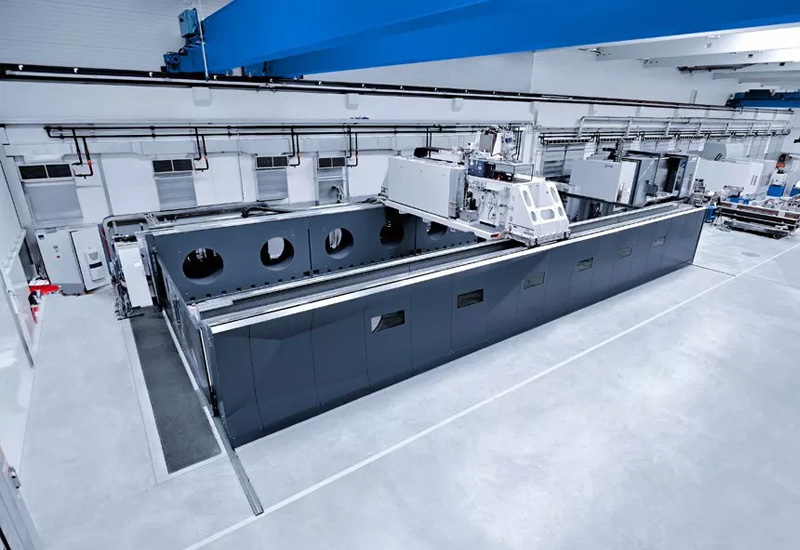

PowerSpeed cube

-

The possibility to combine your individual requirements of a machine with a large number of quality elements have prompted us to consider a new machine concept.

Variant diversity, based on configurable travels and clamping situations, makes your PowerSpeed Cube to a tailor-made solution for your machining tasks. The main axes symbolically represent the corner of a cube, which becomes a scalable cube by the 3x3x3 combination possibilities. The Tightblock, which allows a floor level installation without a complicated step foundation, the opti-mized chip management, the complete housing of the machine and numerous integrated opti-ons complete the classic travelling column machine and take machining to a new level.

Gantry machines

-

Characteristics:

- flexible

- uncompromising

- configurable

- powerful

Editions:- Milling machine

- Turning and milling machine

- Head change machine

- Pallet changing machine

Our PowerBridge series is the answer to portal-type machines in the upper capacity range. The portal design grants, by its very construction, a high rigidity, allowing for example 5-sides machining of motor blocks in their installation position. The central components of our portal-type machines - bridge, headstock, milling head, rack and pinion drive - were taken from our travelling column machines and adapted to suit the PowerBridge. Simply put - for this purpose we have tilted the travelling column into the horizontal position. Excellent cutting performance, precision, productivity, reliability and flexibility of the SHW travelling column machines have been transferred to the portal concept.

We offer for each and any manufacturing concept the suitable solution - high or low - the guiding of the bridge in longitudinal direction will be executed as per your requirements.

PowerBridge 5000 LG

-

Characteristics:

- flexible

- uncompromising

- configurable

- powerful

Editions:- Milling machine

- Turning and milling machine

- Head change machine

Machining travels (maximum)- X-axis (horizontal lengthwise) in mm 50.000

- Y-axis (horizontal crosswise) in mm 4.100

- Z-axis (vertical) in mm 1.800

Milling head- Universal milling head of orthogonal design

- swivel range standard A-axis 180°

- C-axis 360°

Main drive- Drive power in kW up to 63

- Speed range in min-1 up to 5.000

Motion speeds- Feed rates and rapid traverses (X, Y, Z) in mm/min up to 36.000

- Acceleration of linear axis in m/s2 2

Tool holder- SK 50 BIG-PLUS

- HSK 100 A DIN 69893

PowerBridge 5000 HG

- Milling heads

- Universal heads

- Fork milling heads

- Horizontal milling heads

- Angular milling heads

- Special head executions

- Clamping plate

- Rotary table(s)

- Turning table(s)

- Reversible clamping device(s)

- Tool changer

- Tool magazine

- Tool loading station

- Pick-Up-Station

- Siemens

- Heidenhain

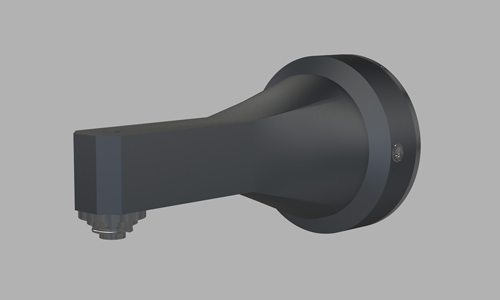

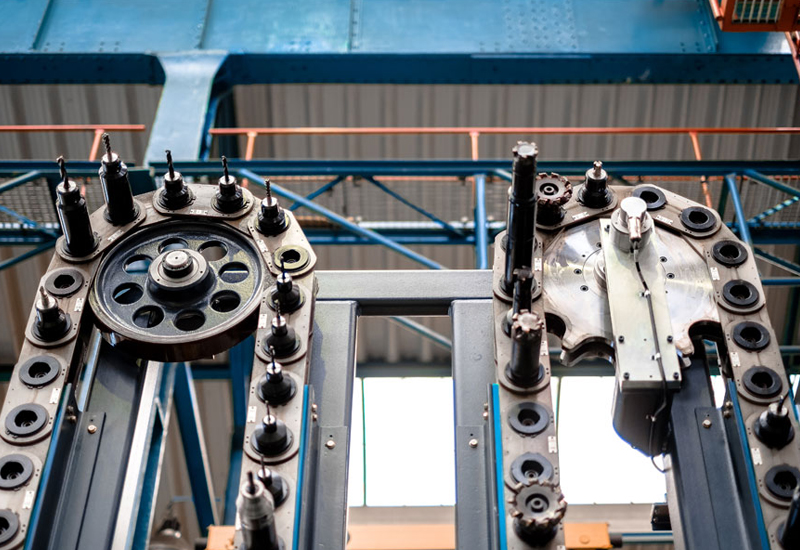

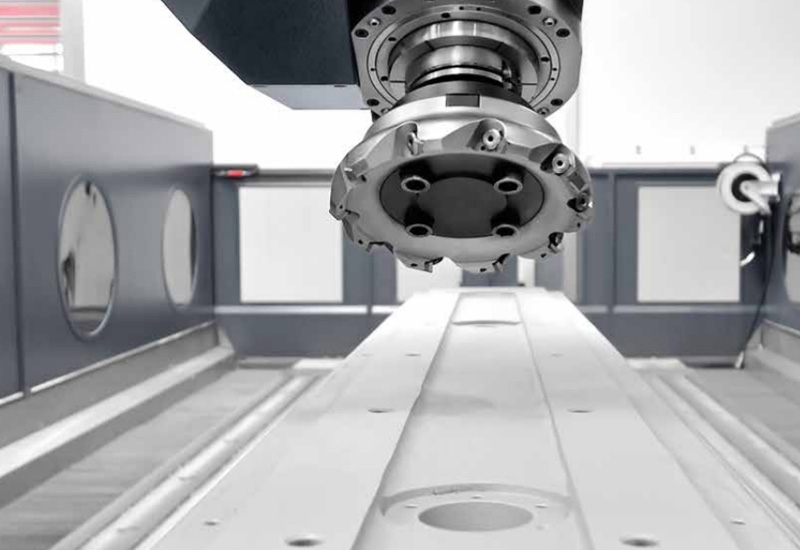

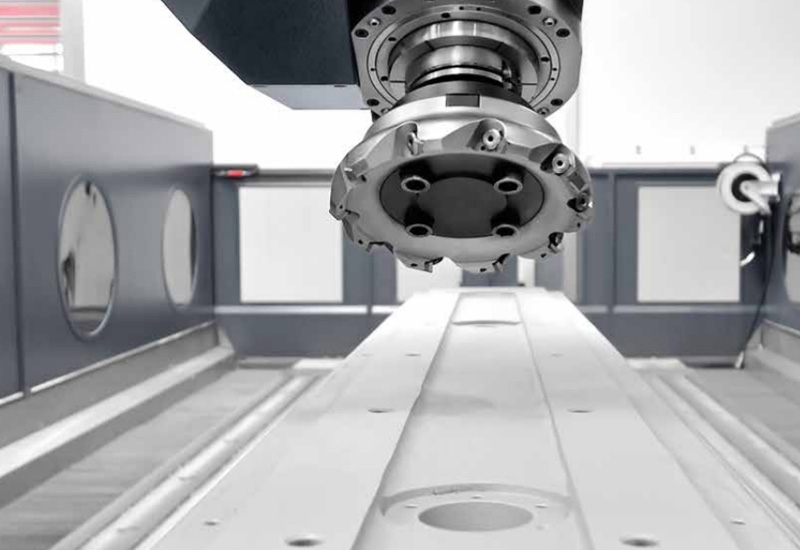

Milling heads

-

Characteristics:

- versatile

- fast

- exact

- powerful

Editions:- Single head

- Change head

Our milling head competence centre is unique in the industry. Over an area of more than 900 m² we pooled all our know-how about milling heads at our headquarters in Aalen. Not only are the development, testing and manufacture of new milling heads under one roof, but also overhauling and repair of used heads are carried out in the competence centre. Angular milling heads

-

Key data:

- Drive power up to 90 kW

- Spindle speed up to 2.500 min-1

- Torque up to 350 Nm

Swivelling range:- C-axis (Milling head holder) 360°

- Division: continuous

Tool holders:- SK 50

- HSK 63/100

- BigPlus

- CAPTO C6/8

Universal milling heads

-

Types:

- Milling head in orthogonal design

- Milling head in diagonal design

Variants:- Single head

- Change head

Milling head in orthogonal design

-

Key data:

- Drive power up to 90 kW

- Spindle speed up to 8.000 min-1

- Torque up to 2.300 Nm

Swivelling range:- A-axis (Milling head axis) up to 240°

- C-axis (Milling head holder) up to 360°

- Division: 1°/continuous

Tool holders:- SK 50

- HSK 63/100

- CAT V50

- BigPlus

- CAPTO C6/8

Milling head in diagonal design

-

Key data:

- Drive power up to 90 kW

- Spindle speed up to 8.000 min-1

- Torque up to 2.300 Nm

Swivelling range:- A-axis (Milling head axis) 360° endless

- Division: 1°

- C-axis (Milling head holder) 180°

- Division: 1°/continuous

Tool holders:- SK 50

- BigPlus

Fork milling heads

-

Types:

- Eccentric fork milling head

- Centric fork milling head

Variants:- Single head

- Change head

Eccentric fork millinghead

-

Key data:

- Drive power up to 28 kW

- Spindle speed up to 20.000 min-1

- Torque up to 145 Nm

Swivelling range:- A-axis (Milling head axis) up to 120°

- C-axis (Milling head holder) up to 360°

- Division: continuous

Tool holders:- HSK 63

Centric fork milling head

-

Key data:

- Drive power up to 56 kW

- Spindle speed up to 18.000 min-1

- Torque up to 145 Nm

Swivelling range:- A-axis (Milling head axis) 105°

- C-axis (Milling head holder) 200°

- Division: continuous

Tool holders:- HSK 63

- HSK 100

Horizontal milling heads

-

Types:

- Eccentric horizontal milling head

- Centric horizontal milling head

Variants:- Single head

- Change head

Eccentric horizontal milling head

-

Key data:

- Drive power up to 90 kW

- Spindle speed up to 8.000 min-1

- Torque up to 2.300 Nm

- Swivelling range:

- C-axis (Milling head holder) 360°

- Division: continuous

Tool holders:- SK 50

- HSK 63/100

- CAT V50

- BigPlus

- CAPTO C6/8

Centric horizontal milling head

-

Key data:

- Drive power up to 90 kW

- Spindle speed up to 6.000 min-1

- Torque up to 1.725 Nm

Tool holders:- SK 50

- HSK 63/100

- CAT V50

- BigPlus

- CAPTO C6/8

Special milling heads

-

Types:

- Plano milling head

- Multi-spindle drilling head

- Turning heads horizontal/vertical

Variants:- Single head

- Change head

Plano milling head

-

Key data:

- Drive power up to 90 kW

- Spindle speed up to 500 min-1

- Torque up to 1.725 Nm

Tool equipment:- U-Tronic D'Andrea

Multi-spindle drilling head

-

Key data:

- Drive power up to 90 kW

- Spindle speed up to 2.500 min-1

- Torque up to 60 Nm

Tool holders:- HSK 50

Turning heads horizontal/vertical

-

Key data:

- C-axis clamping torque up to 20.000 Nm

Swivelling range:- C-axis (Milling head holder) 360°

- Division: continuous

Tool holders:- CAPTO C6/10