ABB Robotics

Videos

Loading the player ...

- Offer Profile

- ABB is a global leader in power and automation technologies. Our solutions improve the efficiency, productivity and quality of our customers’ operations while minimizing environmental impact. Innovation is at the forefront of what we do and many of the technologies that drive modern society were pioneered by ABB.

Product Portfolio

Highlights

IRB 8700

The largest robot ABB has ever made.

In designing the IRB 8700 the focus was on delivering a very reliable robot with a low total cost of ownership. Through a combination of robust design elements, including simpler parts configurations where possible, ABB Robotics applied decades of engineering experience to combine the high performance customers require with low overall maintenance needs.

In addition, the IRB 8700 delivers 25% faster speeds than any other robot in this class size.

Features and benefits:- High payloads up to 1000 kg with the wrist down

- 25% faster speeds than other robots in this size class

- Highly reliable with simplified design and Foundry Plus 2 protection standard

- Built around LeanID for reduced wear on dress packs and ease of simulation

- Built using non-hazardous materials

IRB 910SC SCARA

The IRB 910SC (SCARA) is fast, cost-effective and, because it‘s from ABB, accurate.

In designing its Selective Compliance Articulated Robot Arm (SCARA), or IRB 910SC, ABB has delivered a single arm robot capable of operating in a confined footprint. ABB’s SCARA is ideal for the Small Parts Assembly, Material Handling and parts inspection.

Variants

With a maximum payload of 6 kg, the IRB 910SC is available in three configurations (IRB 910SC –3/0.45, IRB 910SC – 3/0.55m, and IRB 910SC – 3/0.65.) All are modular by design, with different linking arm lengths and have individual reaches of 450 mm, 550 mm and 650 mm, respectively.

Tabletop mountable, each member of our SCARA family is IP54-rated for optimum protection against dust and liquids. A Clean Room ISO-5 option is under development.

Applications

ABB’s SCARA family is designed for a variety of general-purpose applications such as tray kitting, component placement, machine loading/unloading and assembly. These applications require fast, repeatable and articulate point-to-point movements such as palletizing, depalletizing, machine loading/unloading and assembly.

ABB’s SCARA family is ideal for customers requiring rapid cycle times, high precision and high reliability for their Small Part Assembly applications and for laboratory automation and prescription drug dispensing.

YuMi®

YuMi® - Creating an automated future together.

You and me.

The new era of robotic co-workers is here. YuMi® is the result of years of research and development, making collaboration between humans and robots a reality, but it is also much more.

ABB has developed a collaborative, dual arm, small parts assembly robot solution that includes flexible hands, parts feeding systems, camera-based part location and state-of-the-art robot control. YuMi is a vision of the future. YuMi will change the way we think about assembly automation. YuMi is “you and me”, working together to create endless possibilities.

Human - robot collaboration

Innovative human - friendly dual arm robot with breakthrough functionality designed to unlock vast global additional automation potential in industry. YuMi® is designed for a new era of automation, for example in small parts assembly, where people and robots work side-by-side on the same tasks. Safety is built into the functionality of the robot itself. YuMi® removes the barriers to collaboration by making fencing and cages a thing of the past.

Dual arm robots

ABB dual arm robots have accurate vision, dexterous grippers, sensitive force control feedback, flexible software and built-in safety features that collectively allow for programming through teaching rather than coding.

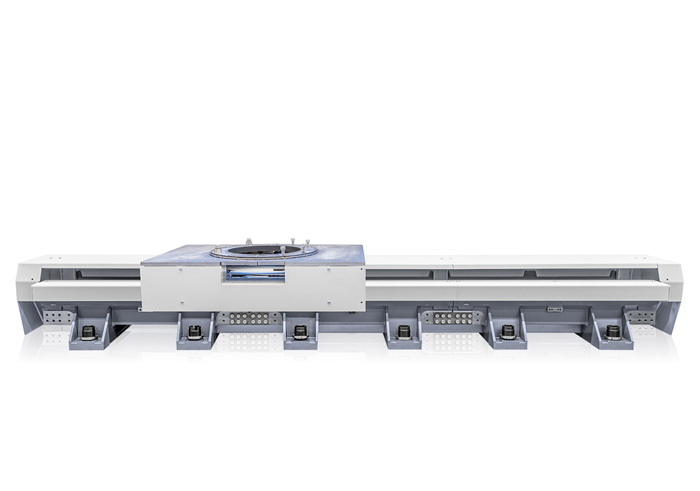

IRBT 2005 - Medium Track Motion Platform

The only track motion platform on the market to guarantee high speed and precision accuracy, the IRBT 2005 from ABB offers greater flexibility and up to 50% shorter cycle times.

Modular platform design

ABB’s Medium Track Motion (MTM)’s design is smart and compact with a symmetrical profile. Maximum integration ensures the protection of components in a small footprint.

The IRBT 2005 consists of a standard 1 meter long module that allows for the addition of numerous track and travel lengths for robots and transfer applications. The track’s modularity allows for product evolution during its entire life span. Adaptable to various environments, the IRBT 2005 is available in two variants, standard uncovered and fully covered.

Prepared for different process applications

The IRBT 2005 is available with multiple carriages - two for the robot and up to three for transfer applications. The robot track is available with additional carriage plates that allow them to carry the required equipment for specific applications such as Arc Welding and Sealing.

The internal cable chain of IRBT 2005 can be delivered pre-equipped with the suitable cables for different arc welding sources, or different customer power and signal cables. Each robot carriage has the option of being equipped with an empty external cable chain for additional application cables. Robot pedestals range from 250mm to 1000mm and can be selected as can robot orientations.

Outstanding speed and accuracy

ABB’s unique QuickMove™ and TrueMove are also critical to the MTM’s functionality. Together they guarantee optimal movement for the robot and the track with actual load. Path accuracy and speed are also optimized.

Industrial Robots

- ABB provides a comprehensive range of robots to help manufacturers improve productivity, product quality and worker safety. Regardless of application we have a robot to meet your needs. ABB has installed more than 250,000 robots worldwide.

Articulated Robots

IRB 120

-

For flexible and compact production

ABB's smallest ever multipurpose industrial robot weighs just 25kg and can handle a payload of 3kg (4kg for vertical wrist) with a reach of 580mm. It is a cost-effective and reliable choice for generating high production outputs in return for low investment. A white finish Clean Room ISO 5 (Class 100) version, certified by IPA, is also available.

ABB's faster IRB 120

The IRB 120T is the benchmark for rapid pick and place applications requiring extreme flexibility combined with industry leading 10 micron repeatability. While keeping its trademark compact, agile and lightweight features, the six-axis IRB 120T variant delivers a substantial increase in the maximum speeds of axis 4,5 and 6, resulting in cycle time improvements of up to 25%.

IRB 1200

-

A compact, flexible, fast and functional small industrial robot

Have you ever wanted to make your machines 15% smaller and 10% faster? ABB’s IRB 1200 allows you to do exactly that. Specifically, it addresses the needs of the material handling and machine tending industries for flexibility, ease of use, compactness and short cycle times while still maintaining large working envelopes.

IRB 140

-

Small, powerful and fast 6-axes robot

Compact and very powerful. The IRB 140 six axes multipurpose industrial robot handles a payload of 6kg with a reach of 810mm (to axis 5) It can be floor mounted, inverted or wall mounted at any angle.

Available in standard, FoundryPlus, Clean Room & washdown versions, the robot is IP67 protected in its entirety, making it suitable for a wide range of applications.

The robust design with fully integrated cables adds to the overall flexibility and the Collision Detection function, with full path retraction, ensures the robot is reliable and safe.

IRB 1410

-

Superior levels of control and path-following accuracy

IRB 1410 is a well-proven and cost-efficient robot with a stroke and reach sufficient for most arc welding applications. It is based on IRB 1400, delivered in over 14,000 units world-wide. IRB 1410 is only delivered in the function package IRB 1410 ArcPack.- Reliable - Stiff and robust design

The IRB 1410 design translates into low noise levels, long service intervals and long economic life.

- Accurate - Consistent parts quality

Superior levels of control and path-following accuracy (+ 0.05 mm) provide excellent work quality.

- Strong - Maximized utilization

The robot has a large working area and long reach (max 1.44 m). The handling capacity is 5kg plus an unique 18kg supplementary load on the upper arm for process equipment.

- Fast - Short cycle times

The robust design together with the fast and accurate IRC5 controller enables short cycle times.

- Arc welder - Adapted for arc welding

Integrated wire feed cabling and mounting holes for fast and optimized assembly of process equipment on the arm. Easy-to-use arc welding functions with IRC5 and unique patented single point of programming/operation with the FlexPendant.

- Reliable - Stiff and robust design

IRB 1520ID

-

The Lean Arc Welder

ABB's IRB 1520ID is a high precision arc welder, with integrated process dressing that combines 24/7 production output with 50% lower cost of maintenance to deliver the lowest cost per weld in its class.

The IRB 1520ID can be up and running in hours and will boost your productivity with cost-efficient and highly reliable production. Thanks to the integrated dressing, the hose package on the upper arm and the welding cablings at the base are totally integrated into the robot. This means that all the media necessary for arc welding, including power, welding wire, shielding gas and pressurized air, is routed for maximized performance and energy efficiency.

With the IRB 1520ID you get stable welding, high path accuracy, short cycle times and long lifetime of the hose package and cablings. Thanks to the integrated dressing, welding around cylindrical objects can be carried out without any stops and hard to reach weld seams are more easily accessed.

IRB 1600

-

The highest performance 10 kg robot

Performance is often a trade off, optimizing for speed or accuracy. With ABB’s IRB 1600, you don’t have to choose. The robot’s cycle times are shorter, sometimes half that of other robots’, allowing you to increase throughput. Meanwhile, you will enjoy the work piece quality that only an ABB robot can offer. Extra everything.

Key Features and benefits:- Double your throughput

The IRB 1600 has up to 50% shorter cycle times than competing robots in Material Handling, Machine Tending and process applications.

- No more cutting corners

At high speed, most robots will cut corners. With the IRB 1600, the path will be the same regardless of speed, thanks to the robot’s unique combination of brains and muscles.

- Outstanding reliability

The IRB 1600 offers outstanding reliability, even in the toughest environments and the most demanding 24/7 duty cycles.

- Easy to integrate

Mounting is fully flexible: on a shelf, on the wall, tilted or inverted. You can even fit the IRB 1600 inside a machine.

- Sustainable and healthy

Low friction spur gears, and no unnecessary moves due to QuickMove and TrueMove, bring power consumption down to 0.58 kW at max speed, and even lower at low speeds.

- Double your throughput

IRB 1600ID

-

Dedicated arc welding robot

In IRB 1600ID (Integrated Dressing), all cables and hoses are routed inside the upper arm, making the robot perfectly suitable for arc welding. The dress pack carries all the media necessary for arc welding, including power, welding wire, shielding gas and pressurized air.- Reliable – High production up time

Faulty process cabling is a common cause of unpredicted line stops. With the IRB1600ID, stops can be reduced to a minimum. Because the cables are routed inside the upper arm, their motion is predicted given a certain cycle. When the motion is predicted, so is the lifetime.

- Accurate – Consistent part quality

There is always a blind spot when programming a conventional robot. Because of the external routing of the dress pack and its unpredictable motion, programmers have to use their imagination to ensure the dress pack won’t hit anything during operation.

- Strong – Maximized utilization

Payload is 4 kg and maximum reach 1.5 m.

- Reliable – High production up time

IRB 2400

-

The most popular industrial robot

The IRB 2400 in its different versions and best accuracy, gives excellent performance in material handling, machine tending and process applications. IRB 2400 offers you increased production rates, reduced lead times and faster delivery for your manufactured product.- Reliable – High production up time

IRB 2400 is the world’s most popular industrial robot The robust construction and use of minimum parts contribute to high reliability and long intervals between maintenance.

- Fast – Short cycle times

Thanks to the ABB´s unique motion control of the robot optimizes the acceleration and retardation, which results in shortest cycle time possible.

- Accurate – Consistent parts quality

Best in class regarding path accuracy and position repeatability (RP = 0.06 mm)

- Strong – Maximized utilization

Payload options are between 12-20 kg. Max reach 1.55 m.

- Robust – Harsh production environment

IP 67 classified, steam washable, clean room (class 100) and “Foundry Plus” optional.

- Versatile – Flexible integration and production

All models offered with inverted mounting capability

- Reliable – High production up time

IRB 260

-

The packing robot

The IRB 260 is designed and optimized primarily for packing applications. It is built to meet your reach and payload requirements whilst being small enough to fit into compact packing machines. Combined with ABB motion control and tracking performance, the robot is ideal in flexible packing systems.- Reliable – High production up time

The IRB 260 is based upon the world’s most popular industrial robot, IRB 2400, with an installed base >14.000 units.

- Fast – Short cycle times

Design optimized for packing in combination with ABB unique motion control ensures short packing cycle times.

- Accurate – Consistent parts quality

The robot has best in class accuracy and superior ABB conveyor tracking performance resulting in excellent pick and place accuracy, both when working with fixed positions as well as on the fly.

- Strong – Maximized utilization

The robot is optimized for packing application and combines compactness and high speed with a 30 kg payload capacity.

- Robust – Harsh production environment

Durable in tough environments - IP67.

- Reliable – High production up time

IRB 2600

-

ABB further extends its mid range robot family with the new IRB 2600.

The IRB 2600 family contains 3 robot models, with a 12 to 20 kg handling capacity, all of which are designed to increase productivity in machine tending, material handling, arc welding and other process applications.

A new compact design that offers a high payload capacity of up to 20kg and a working range optimized for material handling, machine tending and arc welding. It also offers the best accuracy and acceleration in its class, securing high output and low scrap rates for improved productivity.

Flexible mounting possibilities including floor, tilted, wall, inverted or shelf mounted, which help to reduce floor space and increase access to the equipment being served. The wall mounted version has outstanding performance. These features enable more creative cell designs and enables floor space to be optimized in a wide variety of industrial segments and applications.

Three versions: two short arm variants (1.65m) for 12 or 20 kg payloads and a long arm variant (1.85m) with a 12 kg payload. Up to 27 kg payload is achievable for pick & place, and packaging applications, with the wrist held vertical.

IRB 2600ID

-

The IRB 2600ID industrial robot delivers higher output from a smaller

footprint in Arc Welding, Materials Handling & Machine Tending applications.

Thanks to the Integrated Dressing (ID) technology and the larger working envelope, cycle times can be reduce by up to 15% and cost of ownership reduced by 75%. There are two versions available: 15kg with 1.85m reach and 8kg with 2.0m reach.

With the IRB 2600ID cycle times are significantly reduced and reliability increased. With all cables and hoses firmly secured, movements are easily predicted making off-line programming and simulations perfect representations of the actual robot system. Programming is faster and more reliable. And with less swing of cables, the robot can run at maximum achievable acceleration at all times.

With its compact design and without loose hoses and cables, the IRB 2600ID has a very small footprint allowing for productive, high-density installations with 50% more robots, and up to 50% higher output from a production cell.

IRB 4400

-

Fast, compact and versatile industrial robot

The IRB 4400 is a compact robot that can handle loads up to 60 kg. Exceptional all-round capabilities and stiffness make IRB 4400 perfectly matched for variety of applications where accuracy, speed rigidity and flexibility are important.

Features and benefits:- Fast acceleration and top speed – short cycle times

- Accurate – consistent parts quality

- Versatile – flexible integration and production

- Protected for harsh environments to IP 67 for the entire robot

- Optional FoundryPlus version - can be washed down with high pressure steam.

- Optional FoundryPrime version - for waterjet cleaning of castings and machined parts.

IRB 460

-

High speed robotic palletizer

Leading ABB’s new palletizing offering is the compact, 110 kg capacity, IRB 460 - the fastest palletizing robot in the world.

Capable of up to 2,190 cycles per hour, this 4-axis robot is perfect for high-speed end-of-line palletizing and bag palletizing. The IRB 460 has a reach of 2.4 meters, occupies 20 percent less floor space and runs 15% faster than its nearest rivals.

NEW: Also available is the PalletPack 460 Function Package. This is a set of pre-engineered products configured for end-of-line palletizing that greatly improves ease of use for integrators. It is available for either high-speed bag palletizing or compact end-of-line case palletizing and consists of IRB 460 palletizing robot, IRC5 controller, Flex-Gripper (either the Claw or one-zone Clamp gripper), dressing kit, ABB PLC, Jokab Safety PLC, software, user documentation and FlexPendant with tailored graphical HMI.

IRB 4600

-

New Design. New Features. New Technologies.

- Sharpest path accuracy and motion control on the market

Acquire high and consistent quality in your production.

- Ultra wide working range

Semi-shelf capability. Up to 1.73 cm vertical reach down.

- Short cycle times

Up to 20-25 % shorter cycle time than its precursors.

- Flexible mounting possibilities

Can be mounted in various ways, on the floor, semi-shelf, tilted or even hanging.

- Great protection

All versions of the IRB 4600 fully support the IP 67 standard and can stand harsh environments, such as in foundry and cleaning.

- Sharpest path accuracy and motion control on the market

IRB 660

-

Taking palletizing to new heights

Thanks to its state-of-the-art 4-axes design, customers can look forward to a speedy machine that combines a 3.15 meter reach with a 250 kg payload, making it ideal for palletizing bags, boxes, crates, bottles and more. In fact, ABB is set to reinforce its position as the sole global supplier of complete robot-based packaging line automation.- Reliable - High production up time

The IRB 660 is considerably faster than its predecessor. Its optimized motor power and motion performance ensure significantly shorter cycle times than competing products.

- Fast - Short cycle times

Standard packaging software

- Accurate - Consistent parts quality

Outstanding position repeatability (± 0.2mm) and very good path accuracy.

- Strong - Maximized utilization

High speed version capable of handling 180 kg at full speed, and at a 250 kg version for high through-put with 3.15 m reach

- Robust - Harsh production environment

The robot’s rugged design and IP 67 tightness make for steady performance in even the toughest environments.

- Reliable - High production up time

IRB 6620

-

The agile spot welder

IRB 6620 was developed with our major automotive customers to be compact and agile. Its unique design makes it possible to mount the robot floor standing, shelf, inverted or in tilted positions.

Features and benefits:- Agile - Large vertical stroke

- Compact - Increased robot density

- Reliable - High production up time

- Fast – Short cycle times

- Strong – Maximized utilization

- Robust – Collision resistant design

- Versatile – Four robots in one

IRB 6620LX

-

An industrial robot on a linear gantry.

ABB's IRB 6620LX combines the advantages of both a linear axis and a 5 axis robot, resulting in a 6-axis robot with a 150 kg payload capacity, large scalable work envelope and the inherent flexibility of ABB's proven articulated arm robots.

It is designed with high performance and reliability in mind resulting in increased productivity and high utilization.

IRB 6640

-

A strong robot in the Power Robot family

IRB 6640 remains the perfect robot for various applications focusing on high production capacity. Still available is our two Foundry Prime variants with a payload of up to 235 kg, the IRB 6640 is especially suited for harsh washing and cleaning applications.

IRB 6650S

-

Offers a unique working envelope

The IRB 6650S is the shelf robot form of the Power Robot family which offers a unique working envelope. The IRB 6650S is capable of a full vertical and horizontal stroke motion, as well as an increased forward and downward reach. This combination offers new possibilities to robot functions in numerous application areas.- Reliable – High production up time

- Security - A safe investment

- Fast – Short cycle times

- Accurate – Consistent parts quality

- Strong – Maximized utilization

- Robust – Harsh production environment

- Versatile – Flexible integration and production

IRB 6660 for press tending

-

The optimised press tending robot

The main goal of IRB 6660 is to provide a faster robotics solution within the press tending application. Concerning part transferring operations, it’s very important to reduce press occupation time. By improving the robot speed performance, the output of the press line is greatly increased.- Optimised for press tending

- The new striff design together wiht the long reach is perfect for high-performance press tending applications.

- This results in high accuracy and uptime.

- A fast robot

This robot is fast, and 15% shorter cycle times are normally achieved inside the presses. - High productivity

The overall cycle time is directly affected by using this faster robot, and so the line output. - Longer lifetime

- The most gears have been reinforced, gear life time is also improved when running fast in press tending.

- Using proven components from the IRB 6600 family creates an extremely reliable robot.

- Optimised for press tending

IRB 6660 for pre machining

-

The optimised pre-machining robot

The IRB 6660 for pre machining is the first robot on the market that is dedicated to pre-machining applications in the Foundry industry.

This new robot is designed for high-performance applications where robot stability is a key factor for success.- Optimised for finishing and pre-machining applications

- Based on reqiurements from machining operations.

- For applications such as finishing, milling, grinding, cutting & sawing.

- High productivity

- Improve material removal rate.

- Shorter cycle time.

- High accuracy

- Stiff, compact & robust design to withstand high process forces.

- Parallel arm structure gives stiffness

- Optimised for finishing and pre-machining applications

IRB 6660FX

-

ABB has been developing robot-based press automation solutions for nearly two

decades.

Its latest solution, the IRB 6660FX, is a rapid and flexible transfer system for medium size parts. Identical in design to ABB’s large part transfer system, the IRB 7600FX, the IRB 6660FX is a perfect complement to ABB’s parts transfer offering.

Suitable for both new and existing press lines, a dual action unit has been integrated into the IRB 6660 to create a 7-axis robot, which allows medium size parts to be transferred rapidly along a linear path. As a result, vibrations created when parts are rotated 180° by a conventional 6-axis robot are eliminated. The system is also equipped with integrated dynamic model control to coordinate all seven axes to ensure optimum speed, accuracy and lifetime.

IRB 6700

-

The IRB 6700 family of robots is a natural evolution following 40 years of large robot heritage at ABB.

This 7th generation of large ABB robots features a multitude of next generation improvements derived from intimate customer relationships and exhaustive engineering studies. The IRB 6700 is more robust than its predecessor and maintenance has been simplified, making it the highest performing robot for the lowest total cost of ownership in the 150-300 kg class.

Features and benefits:- Increased service intervals and decreased service times

- Longer uptime—mean time between failures 400,000 hours

- Available with Lean ID for cost effectively increasing dress pack lifetimes

- More robust with a rigid structure and a new generation of motors and compact gearboxes

- Increased speed and shorter cycle times—on average 5 percent faster

- Improved accuracy and higher payloads

- Built to operate in the harshest environments—available with Foundry Plus 2 package

- 15 percent lower power consumption

IRB 760

-

High speed, full-layer, palletizing robot

Boasting an impressive payload capacity of 450 kilograms and a reach of 3.2 meters, this robot features high wrist inertia – double that of competitors – that enables it to rotate heavier and larger products faster than any other robot. This superior speed makes the IRB 760 especially suited for palletizing beverages, building materials and chemicals

IRB 7600

-

The Power Robot

A new world of possibilities opens up with ABB’s power robot family. It comes in several variants, up to 630 kg handling capacities. The IRB 7600 is ideal for weighty applications, regardless of industry. Characteristics such as high available torque and inertia capability, rigid design and powerful acceleration have earned this market leader its “Power Robot” title.- Reliable – High production up time

- Security - A safe investment

- Fast – Short cycle times

- Accurate – Consistent parts quality

- Strong – Maximized utilization

- Robust – Harsh production environment

- Versatile – Flexible integration and production

IRB 8700

-

The largest robot ABB has ever

made.

In designing the IRB 8700 the focus was on delivering a very reliable robot with a low total cost of ownership. Through a combination of robust design elements, including simpler parts configurations where possible, ABB Robotics applied decades of engineering experience to combine the high performance customers require with low overall maintenance needs.

In addition, the IRB 8700 delivers 25% faster speeds than any other robot in this class size.

Features and benefits:- High payloads up to 1000 kg with the wrist down

- 25% faster speeds than other robots in this size class

- Highly reliable with simplified design and Foundry Plus 2 protection standard

- Built around LeanID for reduced wear on dress packs and ease of simulation

- Built using non-hazardous materials

IRB 910SC SCARA

-

The IRB 910SC (SCARA) is fast, cost-effective and, because it‘s from ABB,

accurate.

In designing its Selective Compliance Articulated Robot Arm (SCARA), or IRB 910SC, ABB has delivered a single arm robot capable of operating in a confined footprint. ABB’s SCARA is ideal for the Small Parts Assembly, Material Handling and parts inspection.

Features:- A Clean Room ISO-5 option is under development

- IP54 protection

- Table top mountable

- Ease of integration

- Custom interfaces

- Modular design

Customer benefits:- Short cycle times which achieved by high speed

- High precision which is achieved by superior motion control

- Superb reliability due to reuse and standard proven components

Collaborative Robots

IRB 14000 YuMi

- The new era of robotic co-workers is here. YuMi® is

the result of years of research and development, making collaboration

between humans and robots a reality, but it is also much more.

ABB has developed a collaborative, dual arm, small parts assembly robot solution that includes flexible hands, parts feeding systems, camera-based part location and state-of-the-art robot control. YuMi is a vision of the future. YuMi will change the way we think about assembly automation. YuMi is “you and me”, working together to create endless possibilities.

YuMi was officially introduced to the market at the Hannover Messe on Monday, April 13, 2015. For further information, and to register your interest in YuMi, please contact your local ABB Robotics office using the Contact Information section below.

Paint Robots

IRB 52

-

A compact painting specialist.

The IRB 52 is a compact painting robot designed specifically for consumable parts painting in general industry. With its small size and large working envelope, it is flexible and versatile, while its high speed and accuracy offers short cycle times.

It includes ABB’s unique integrated paint system, IPS.- Reliable – A combination of proven technology and well tested innovations

- Fast – High speed in all axes delivering improved cycle times

- Accurate – Outstanding position repeat-ability resulting in high process and product quality

- Flexible – versatile mounting options enabling space saving layouts

- Versatile – wide reach, long stroke and ability to handle large payloads

- Compact – smaller spray booth size and reduced ventilation needs resulting in increased energy efficiency

IRB 580

-

A highly flexible, cost-effective and accurate paint robot system.

The IRB 580 complements our 540 and 5400 series with the same relentless commitment to quality that our customers have been relying on since 1969.

Precision has always been our primary goal and the common denominator of our globally renowned paint robots. IRB 580 takes precision a step further by combining the advanced functions of the IRB 5400 series with a compact design.

The hollow-wrist IRB 580 is a compact, fast and accurate paint robot, which offers increased productivity, high precision and efficiency. It is available in two versions:- short (1220 mm)

- long (1620 mm) horizontal arm

IRB 5400

-

Built to fit your needs

The FlexLine system provides paint solutions which maximize your performance and minimize your costs.

The IRB 5400 is a family of paint robots offering accurate painting, high uptime, low paint consumption, short cycle times and effective integration of paint application equipment. Additional benefits include an expansive working envelope, high load capacity and reliable operation. ABB's unique Integrated Process System (IPS) features closed loop regulation and high-speed control for paint and airflow adjustment which minimizes overspray and secures a uniform film build.

The time and paint savings of the IRB 5400-series will impress you. By integrating colour change valves, pumps, flow sensors and air- and paint regulators into the arm of the IRB 5400, we have made the IRB 5400 one of the most reliable, cost-effective paint process robots in its class.

IRB 5500-22

-

FlexPainter -

A new way of exterior painting

The unique design and configuration of the wall mounted FlexPainter IRB 5500 has created the largest and most flexible robot working envelope of any exterior car body paint robot.

It takes two FlexPainter IRB 5500s to handle jobs that up until now have required four paint robots. The results are lower cost, both initially and in the long run, faster installation, high uptime and reliability.

The FlexPainter IRB 5500-22 is specifically designed for ABB’s efficient FlexBell Cartridge System (CBS). The loss during color change is close to zero. It is the best solution for non-batch painting and multiple colors.

Benefits:- Faster return on investment

- Improved reliability of a complete automation system

- Increased flexibility for new processes and new vehicle models

- Reduced size and environmetal impact of robotic paint booths

- Reduced required booth length and width for a robotic paint system

- Reduced air handling volumes for ventilation

- Reduced emissions from booth exhausts

- Reduced machine programming efforts, in time and personnel requirements

IRB 5500-25

-

The Elevated Rail for the IRB 5500-25 reduces

cycle times by as much as 10% on Stop & Go automotive paint lines.

The Elevated Rail for the IRB 5500-25 system is one of the most advanced paint solutions available on the market. Ideally suited for both interior and exterior automotive painting as well as other paint applications, the system expands the fl exibility of the IRB 5500-25 FlexPainter, which is the most versatile working envelope of any paint robot.

Designed for Stop & Go automotive paint lines, the Elevated Rail for the IRB 5500-25 increases the flexibility on these types of lines and allows for easy repositioning of the robot, guaranteeing an effective backup solution. It is able to accommodate most car body sizes which has the added advantage of potentially reducing the number of robots on a paint line. This added flexibility and the ability to place the robot in an optimal position directly contributes to reducing cycle times by up to 10%.

IRB 5350

-

The IRB 5350 door opener robot is a compact and precise robot assistant for

automotive interior painting, both for stop-and-go and moving-line solutions.

- Optimized design for various applications

- Compact design and flexible installation

- High performance and reliability

- Easy control and programming

- Global service and support

The IRB 5350 comes in two versions:- 3 axes stop-and-go version

- 4 axes moving-line version

Parallel Robots

IRB 360 FlexPicker™

-

The second generation FlexPicker robot is even more productive

For nearly 15 years, ABB’s IRB 360 FlexPicker has been the leader in state-of-the-art high speed robotic picking and packing technology. Compared to conventional hard automation, the IRB 360 offers much greater flexibility in a compact footprint while maintaining accuracy and high payloads.

With the introduction of the IRB 360-6, the latest robot to be added to the IRB 360 family, ABB has delivered a FlexPicker with a reach of 1600 mm and a mid-range payload of 6 kg. The sacrifice of a small amount of payload versus the 8 kg FlexPicker has resulted in a long reach for applications in which conveyors must be far apart or other environmental factors require long distances between pick and place movements.

Controllers

-

ABB’s industrial robot controllers offer superior motion control and enable quick integration of additional hardware. IRC5 is ABB’s fifth generation robot controller. Its motion control technology, featuring TrueMove & QuickMove, is key to the robot’s performance in terms of accuracy, speed, cycle-time, programmability and synchronization with external devices. Other features include FlexPendant with touch screen and joystick programming, flexible RAPID language, and powerful communication capabilities.

RobotWare is at the heart of the system and features a number of optional plug-ins designed to increase functionality for robot users. For example multitasking, transfer of information from file to robot, communications with external systems or advanced motion tasks..

SafeMove marks a major step in removing the bonds placed on industrial robots and makes possible human - robot collaboration. Developed and tested to comply with international safety standards, SafeMove is an electronics and software based solution that ensures safe and predictable robot motion.

IRC5

-

ABB's fifth generation robot controller.

Its motion control technology, TrueMove and QuickMove, is key to the robot’s performance in terms of accuracy, speed, cycle-time, programmability and synchronization with external devices. Watch the FANTA Can Challenge movie below to see this superior motion control in action.

IRC5C Compact Industrial Robot Controller

-

The IRC5C offers the capabilities of the powerful IRC5 controller in a compact format. It delivers space saving benefits and easy commissioning through one phase power input.

It comes equipped with external connectors for all signals and a built in expandable 16 in, 16 out I/O system.

IRC5P Paint Industrial Robot Controller

-

Quality painting made easy IRC5P is the newest generation paint robot control system from ABB. With its own FlexPaint Pendant it is specifically designed for the paintshop.

Faster installation and commissioning

The new paint robot control system significantly reduces the time for installation and commissioning. IRC5P provides faster set up and configuration of IPS, RobotWare Paint, RobView and PLC mapping. The system automatically adapts to the process configuration in the installation.

IRC5 PMC Panel Mounted Controller

- Available without a cabinet, the Panel Mounted Controller, or PMC, can be integrated into any enclosure for customization or for special environmental requirements. It is comprised of two modules, one for the drive modules and one for the computer.

Software Downloads

-

Download RobotStudio with RobotWare, and PowerPacs

You can download and use RobotStudio in Basic Functionality mode for free. To enable Premium Functionality mode, please contact an ABB sales representative to purchase a RobotStudio subscription. Each PowerPac requires a separate subscription.

RobotStudio includes a matching version of RobotWare. Previous versions can be downloaded from within RobotStudio.

For evaluation purposes, you can try Premium Functionality and PowerPacs for 30 days free of charge.