- Offer Profile

- Known worldwide for the quality of our design and innovation for more than a century, the Stäubli Group has brought its renowned engineering expertise and technological ingenuity to the forefront of robotics. Since 1982, we have built a highly regarded robotics business, and more significantly, transformed the way thousands of manufacturing operations perform. Today Stäubli Robotics is a leading player in robotics around the world, consistently delivering engineering as effective and reliable as our service and support.

Man and machine

-

Stäubli's last developments

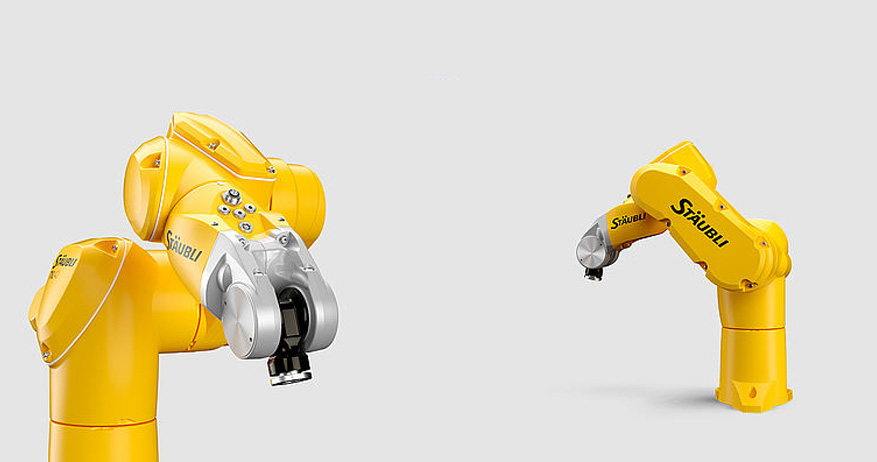

Robot Arms

-

Experts in Man and Machine

Stäubli Robotics is a leading international player in industrial automation, providing engineering and technical support recognized for their efficiency and reliability.

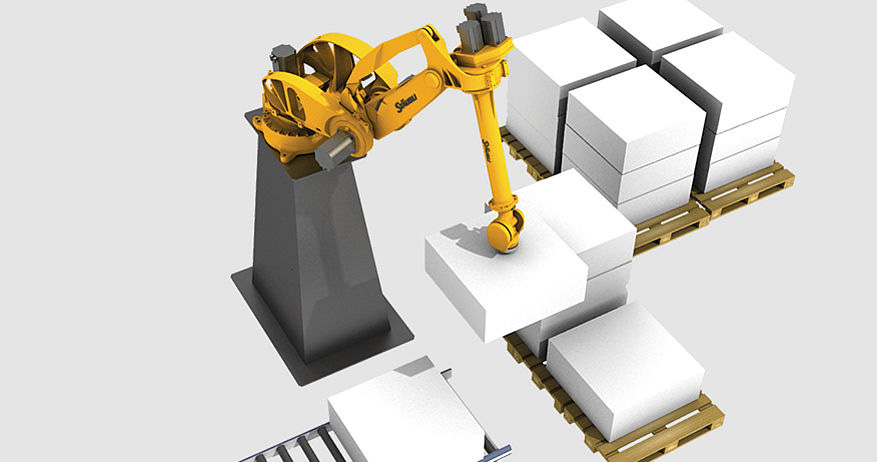

From SCARA, 6 axis robots and cobots to mobile robot systems, our powerful, high-precision solutions allow us to work with clients in many industries to help them tackle the challenges of Industry 4.0.Industrial robots, cobots and mobile robot systems

As a leading player in robotics, Stäubli provides efficient, reliable engineering solutions and related services to its clients around the world. The design quality of its line of industrial robots, POWER cobots, mobile robot systems and software, as well as its capacity for innovation, make it an unbeatable partner for joining the cutting edge of industrial robotics.

For over 40 years, Stäubli Robotics has helped thousands of companies transform and develop their industrial systems with its line of reliable, state-of-the-art products.

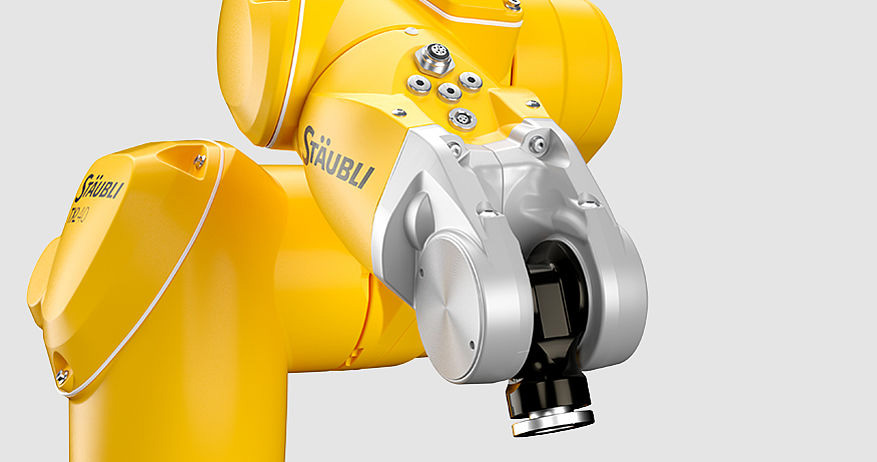

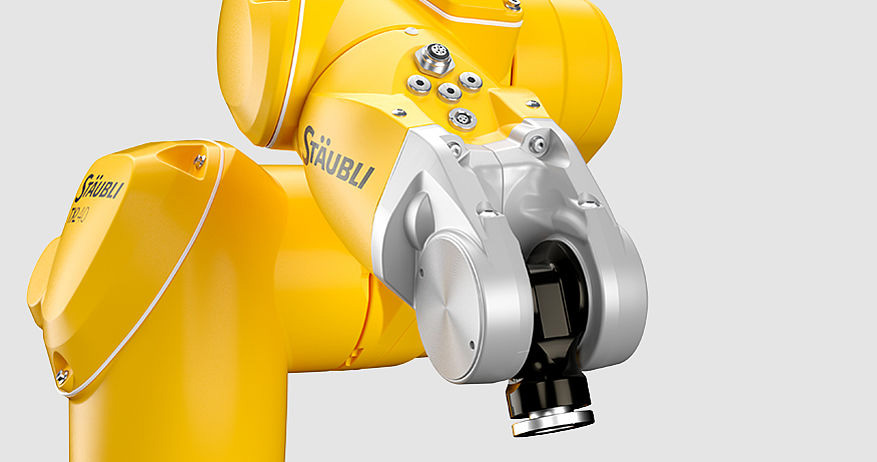

TX2touch POWER cobot range

-

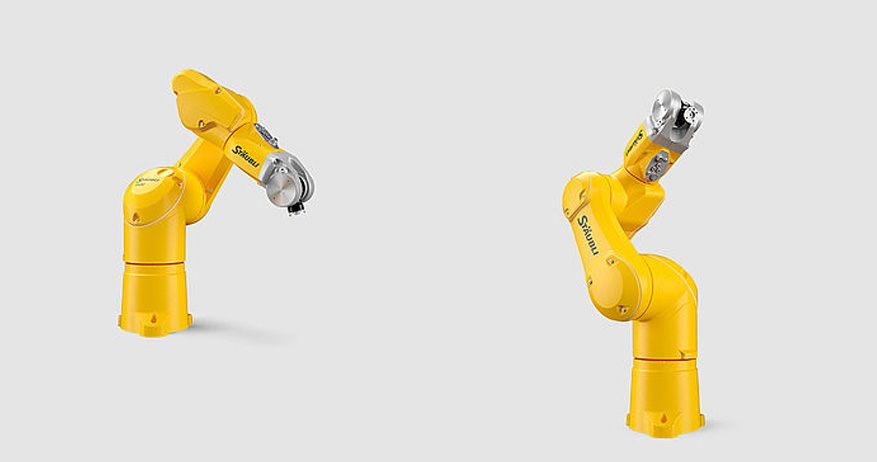

The TX2touch is a unique range of cobots designed for safe Man Robot Collaboration while maintaining high productivity. Based on the proven TX2 industrial robot, it offers safe operation thanks to its advanced skin technology, quick reaction time and embedded modular safety functions. TX2touch is the only cobot with the SIL3/PLe safety level. It is highly productive due to the performance, smart connectivity and reliability inherited from TX2 robots and its CS9 controller.

TX2touch-60 POWER cobot

-

- Reach: 670 mm to 920 mm

- Maximum payload: 5 kg to 9 kg

- Repeatability: ± 0.02 mm to ± 0.03 mm

TX2touch is the only cobot with the SIL3/PLe safety level. It is highly productive due to the performance, smart connectivity and reliability inherited from TX2 robots and its CS9 controller.

TX2touch-90 POWER cobot

-

- Reach: 1000 mm to 1450 mm

- Maximum payload: 9 kg to 20 kg

- Repeatability: ± 0.03 mm to ± 0.04 mm

TX2touch is the only cobot with the SIL3/PLe safety level. It is highly productive due to the performance, smart connectivity and reliability inherited from TX2 robots and its CS9 controller.

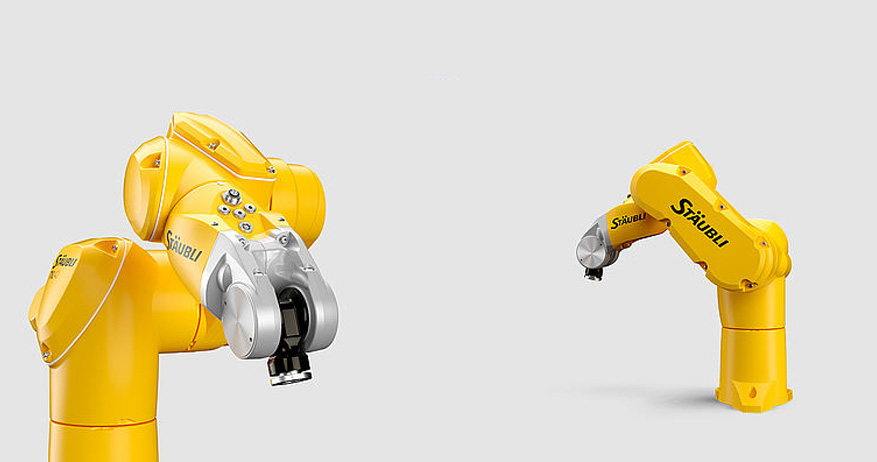

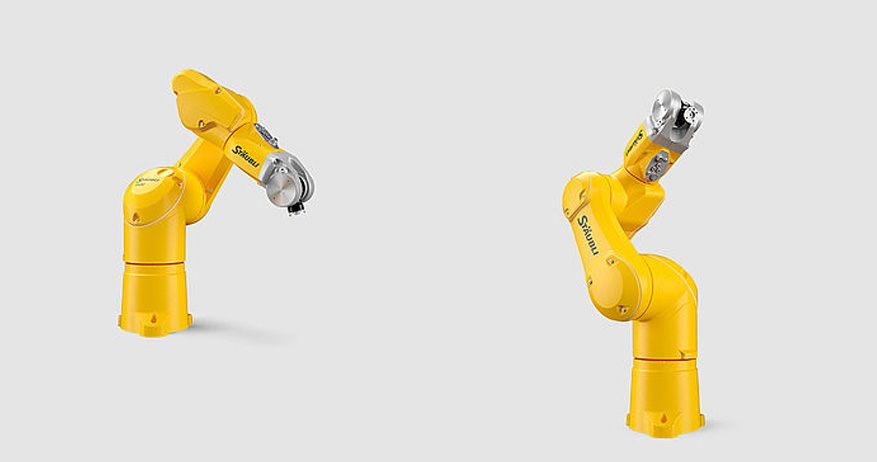

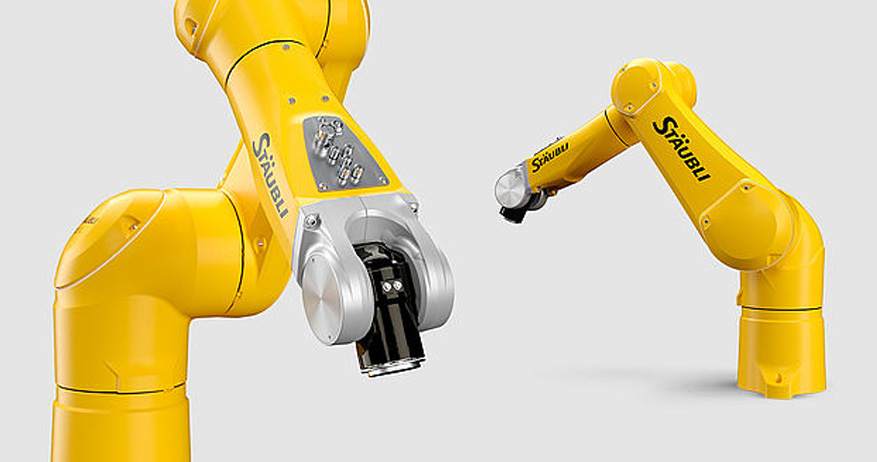

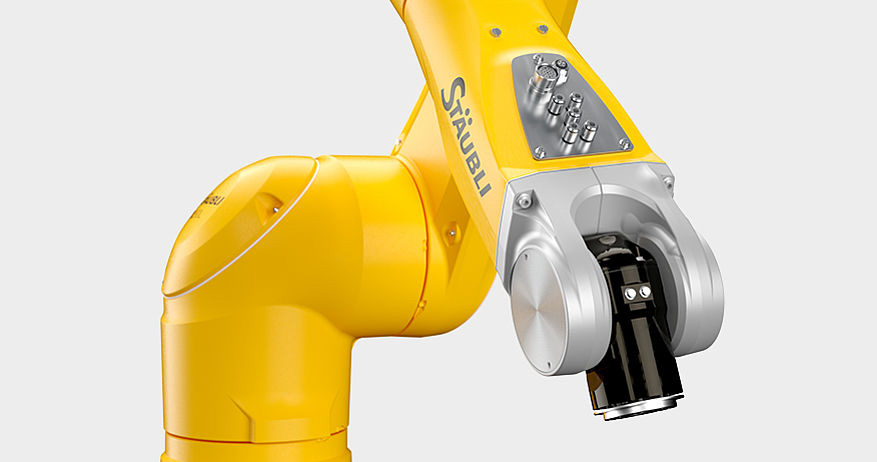

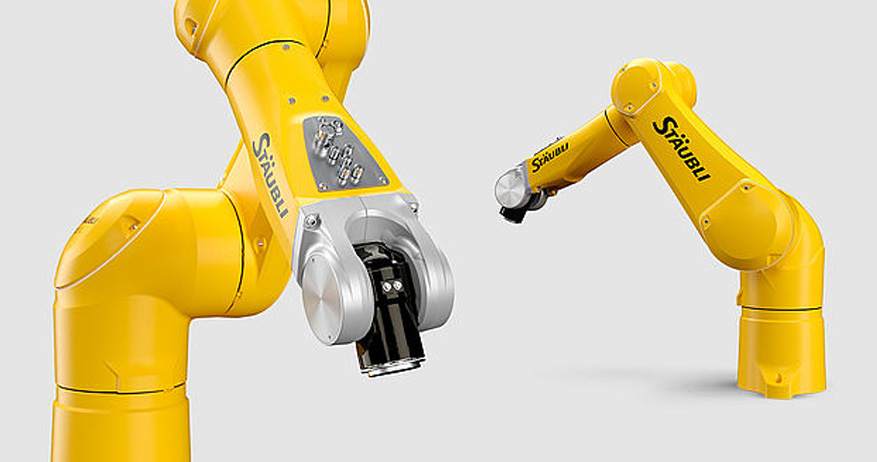

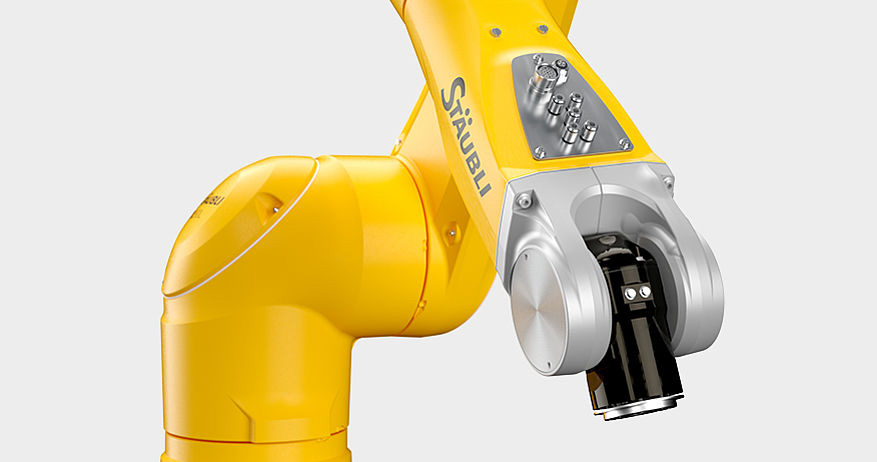

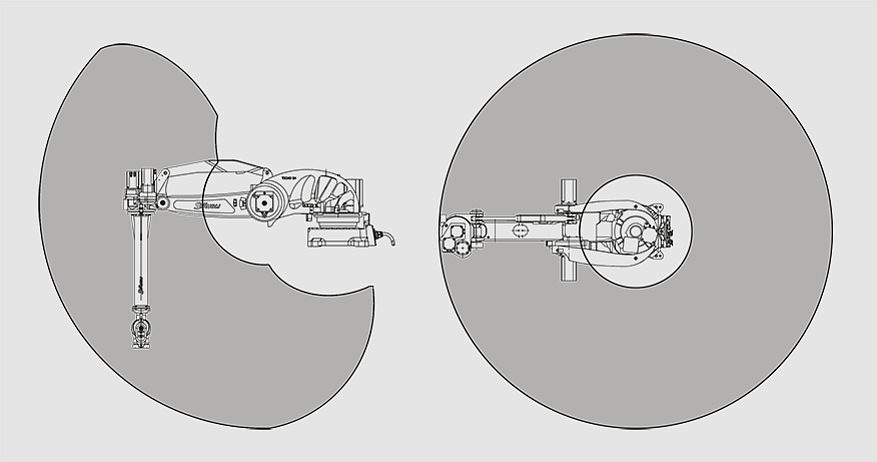

Our 6-axis industrial robots

-

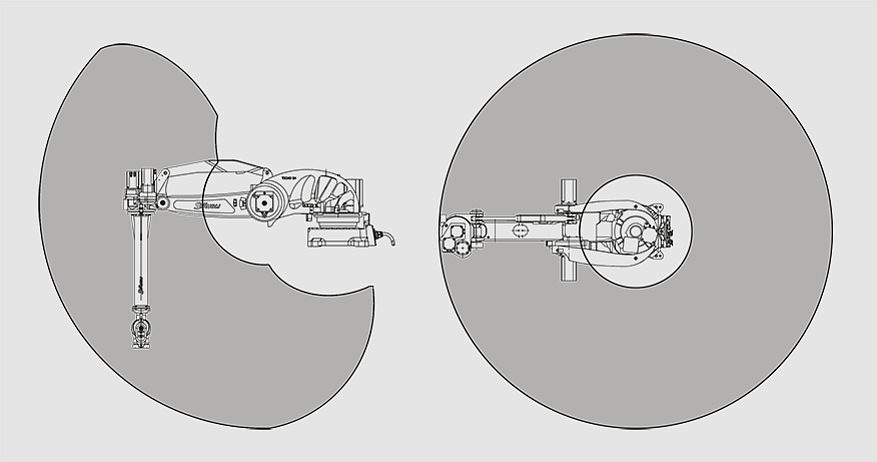

Stäubli’s 6 axis robots deliver increased dexterity and flexibility. The compact arm and large work envelope allow maximum utilization of cell workspace. The variety of mounting configurations (floor, wall, ceiling) makes it easier to integrate the robot into the production line.

This range of robots is perfectly suited to numerous applications in many industries.

The TX2 series and its generic CS9 controller feature optional SIL3-PLe safety functionalities enabling high productivity AND Man-Machine collaboration.

TX2-40 6-axis industrial robot

-

- Reach: 515 mm

- Maximum payload: 2.3 kg

- Repeatability: ± 0.02 mm

- Sensitive environment versions: Stericlean - ESD

Our fast and precise TX2 industrial robots are the next generation of 6-axis robotic arms. This line of robots provides the ideal combination of speed, rigidity, size and precision. These robots have unique features that make them adaptable to all industries, including sensitive environments.

Optional SIL3-PLe safety functionalities allow high productivity while ensuring Man-Machine collaboration.

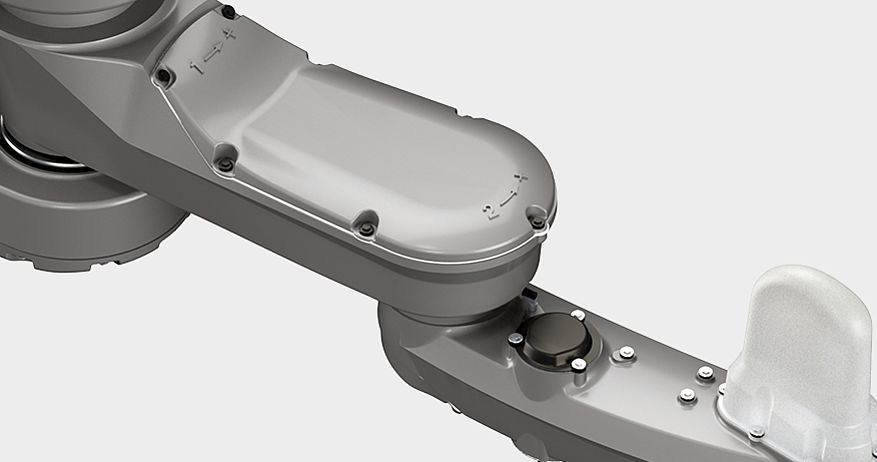

TX2-60 6-axis industrial robots

-

- Reach: 670 mm to 920 mm

- Maximum payload: 5 kg to 9 kg

- Repeatability: ± 0.02 mm to ± 0.03 mm

- Sensitive environment versions: HE - Stericlean - Cleanroom - ESD

Our fast and precise TX2 industrial robots are the next generation of 6-axis robotic arms. This line of robots provides the ideal combination of speed, rigidity, size and precision. These robots have unique features that make them adaptable to all industries, including sensitive environments.

Optional SIL3-PLe safety functionalities allow high productivity while ensuring Man-Machine collaboration.

TX2-90 6-axis industrial robot

-

- Reach: 1000 mm to 1450 mm

- Maximum payload: 9 kg to 20 kg

- Repeatability: ± 0.03 mm to ± 0.04 mm

- Sensitive environment versions: HE - Stericlean - Cleanroom - ESD

Our fast and precise TX2 industrial robots are the next generation of 6-axis robotic arms. This line of robots provides the ideal combination of speed, rigidity, size and precision. These robots have unique features that make them adaptable to all industries, including sensitive environments.

Optional SIL3-PLe safety functionalities allow high productivity while ensuring Man-Machine collaboration.

RX160 6-axis industrial robot

-

- Reach: 1710 mm to 2010 mm

- Maximum payload: 28 kg to 34 kg

- Repeatability: ± 0.05 mm

- Sensitive environment versions: HE - Stericlean - Cleanroom - ESD

The RX160 6-axis robot is an articulated arm with 6 axes for increased flexibility. The spherical work envelope allows maximum utilization of cell workspace. It can also be mounted on the floor or ceiling. The fully enclosed structure (IP65) makes the robotic arm ideal for applications in harsh environments.

TX200 6-axis industrial robot

-

- Reach: 2194 mm to 2594 mm

- Maximum payload: 100 kg to 150 kg

- Repeatability: ± 0.06 mm to ± 0.1 mm

- Sensitive environment versions: HE - Stericlean - Cleanroom - ESD

The TX200 6-axis robot is an articulated arm with 6- axis for increased flexibility. The spherical work envelope allows maximum utilization of cell workspace. It can also be mounted on the floor or ceiling. The fully enclosed structure (IP65) makes the robotic arm ideal for applications in harsh environments.

TX340 SH (shelf) 6-axis robot

-

- Reach: 3680 mm

- Maximum payload: 190 kg

- Repeatability: ± 0.1 mm

The TX340 SH (shelf) 6-axis robot is an articulated arm with 6 axes for increased flexibility. The work envelope allows the robot to work under its base to be positioned on top of a machine. Its IP65 rating makes the robotic arm suited for applications in harsh environments. The TX340 SH 6-axis robot has a maximum payload of 190 kg and a 3680 mm reach.

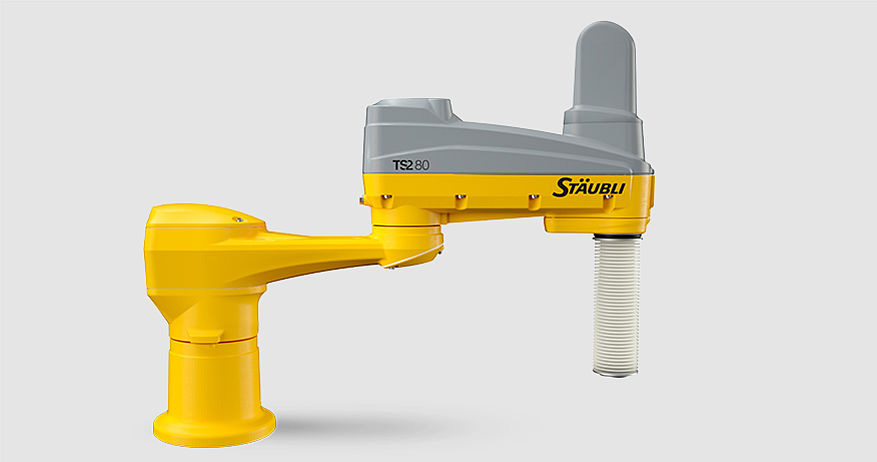

Our 4-axis SCARA robots

-

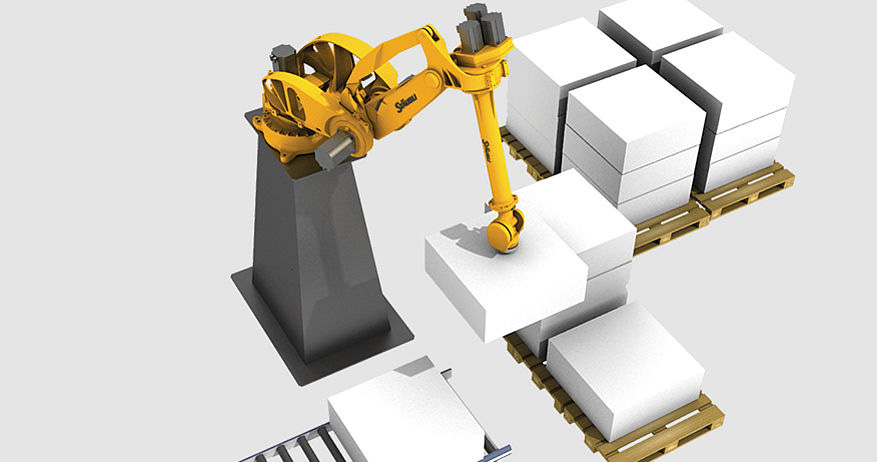

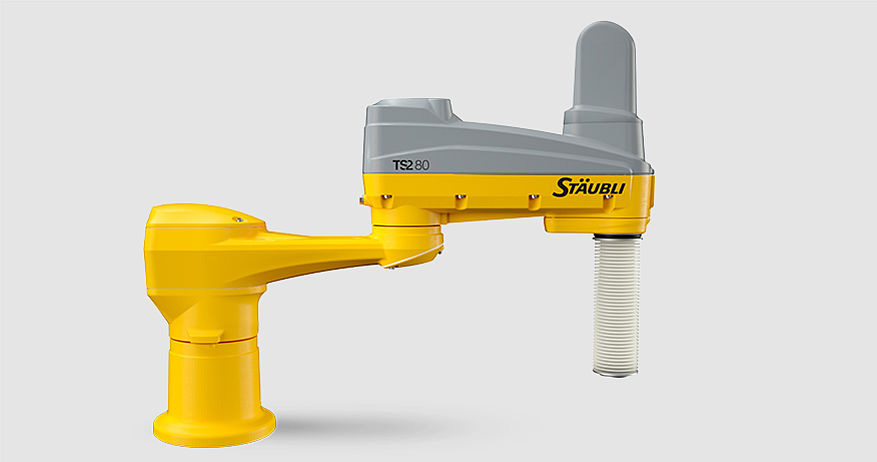

Stäubli has developed a line of extremely powerful 4-axis robots designed to meet the most stringent requirements in fields such as the automotive, food, pharmaceuticals, plastics and electrical or electronics sectors. Selective Compliance Assembly Robot Arms (SCARA) are useful in a variety of applications. They can carry out precise and repetitive tasks, such as loading/unloading, assembly, packaging/palletization, pick and place/handling, sorting, piling and spacing, at very high speeds.

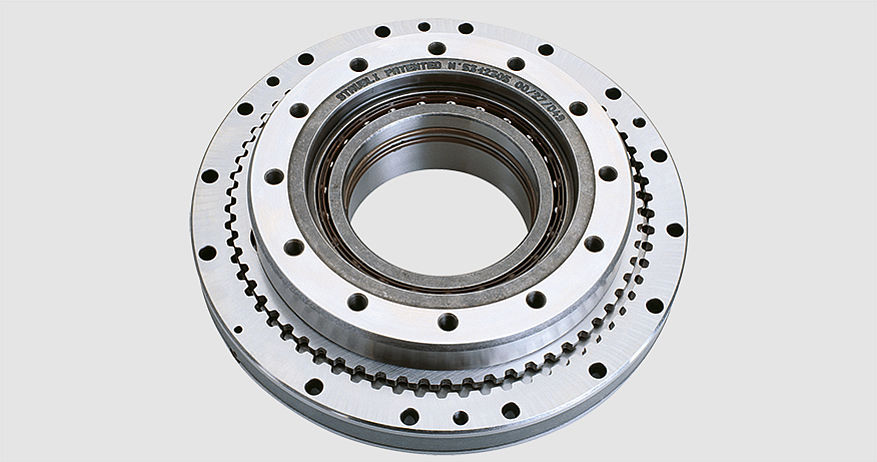

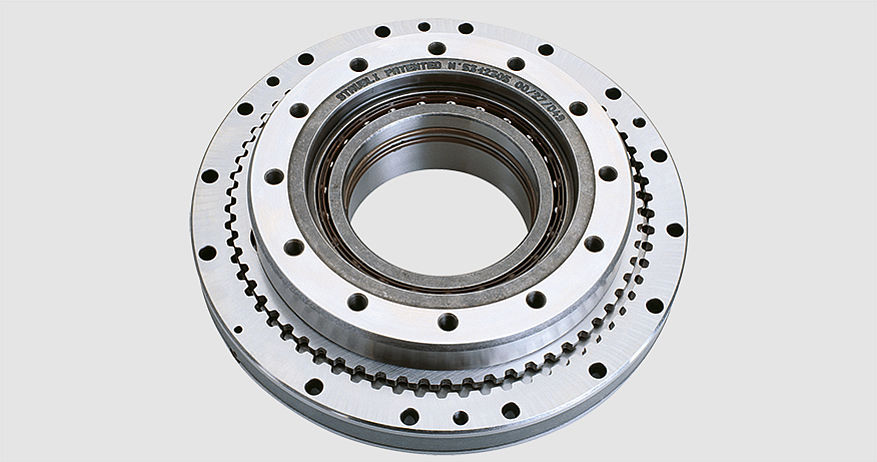

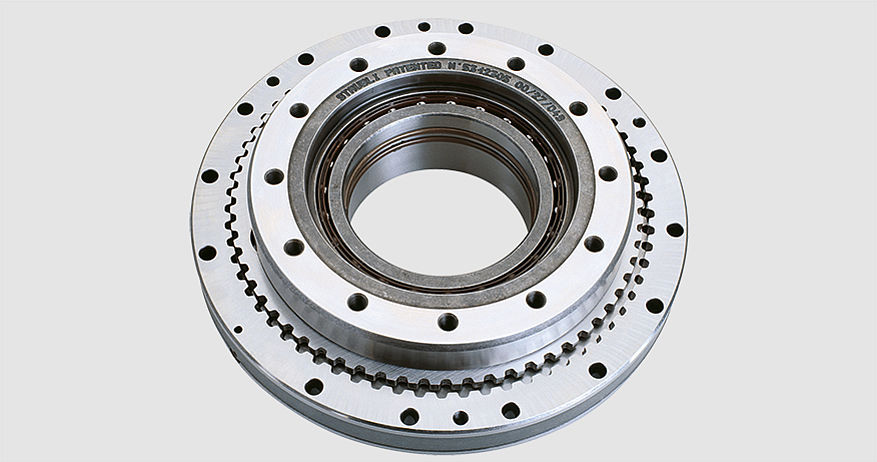

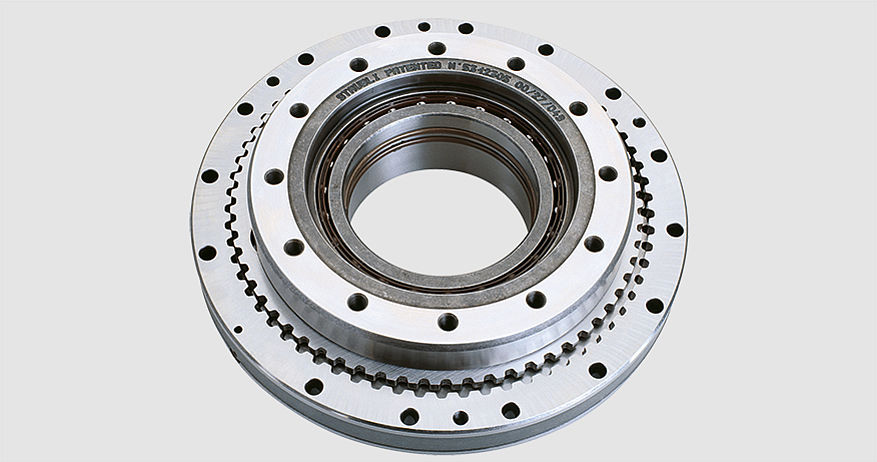

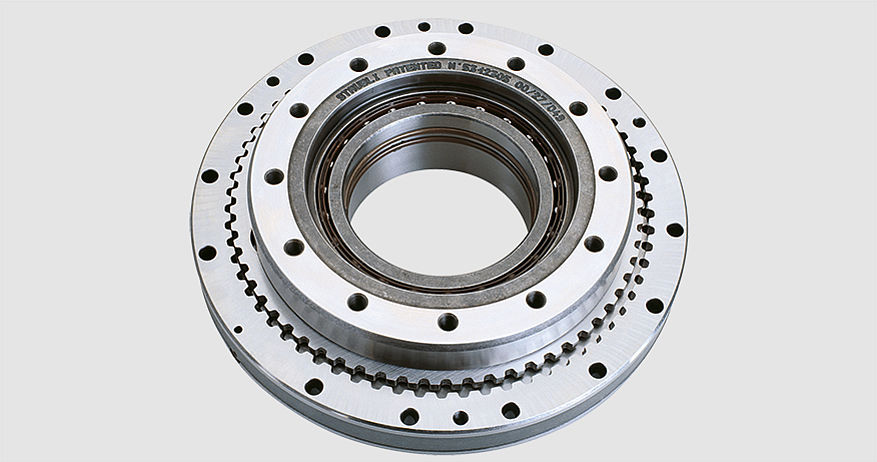

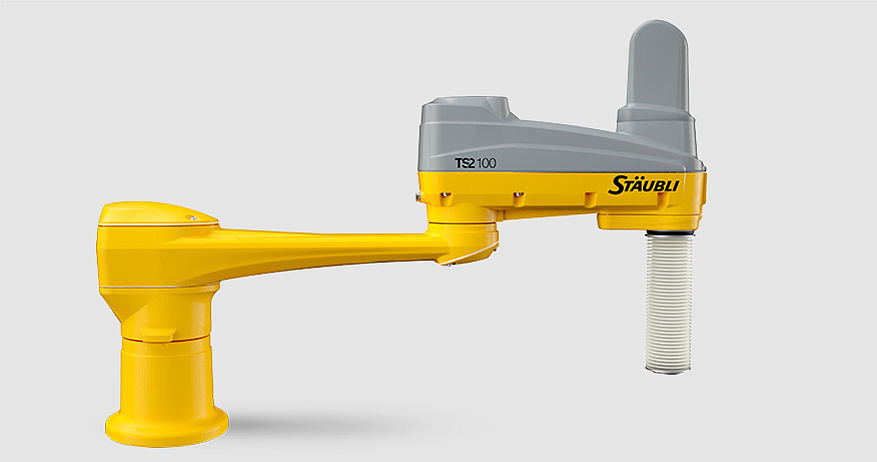

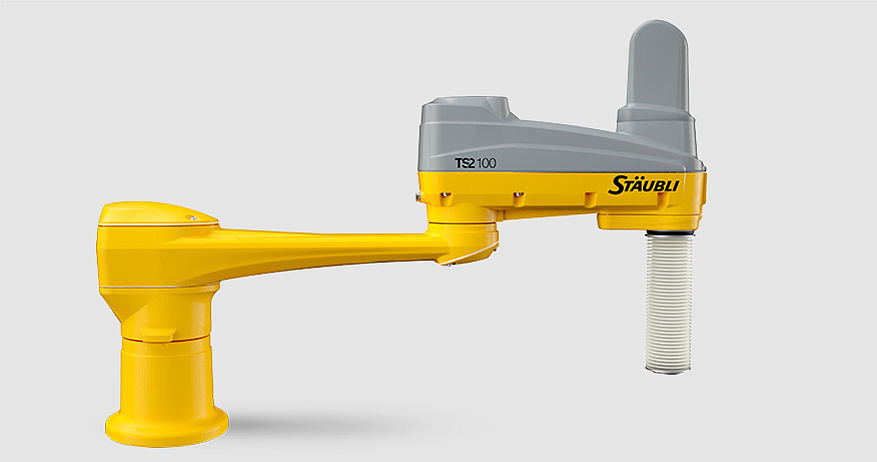

The TS2 SCARA series share the same structural segments as the 6-axis TX2 robots, offering an identical footprint for high modularity and optimized development times, as well as the same CS9 controller.

TS20 SCARA robot

-

- Reach: 220 mm

- Maximum payload: 1 kg

- Repeatability: ± 0.01 mm

The fast and compact TS20 SCARA 4-axis robot has special features, such as a maximum payload of 1 kg with a 220 mm reach and repeatability of ±0.01 mm. It is perfect for even the most sensitive applications, such as those in electronics or food environments.

TS2-40 SCARA robot

-

- Reach: 460 mm

- Maximum payload: 8,4 kg

- Repeatability: ± 0.01 mm

- Stroke: 200 mm (400 mm optional)

- Dedicated version: ESD

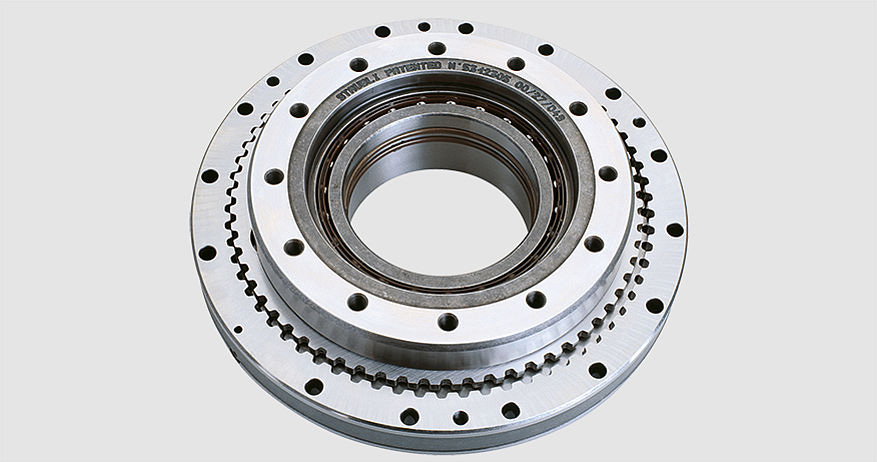

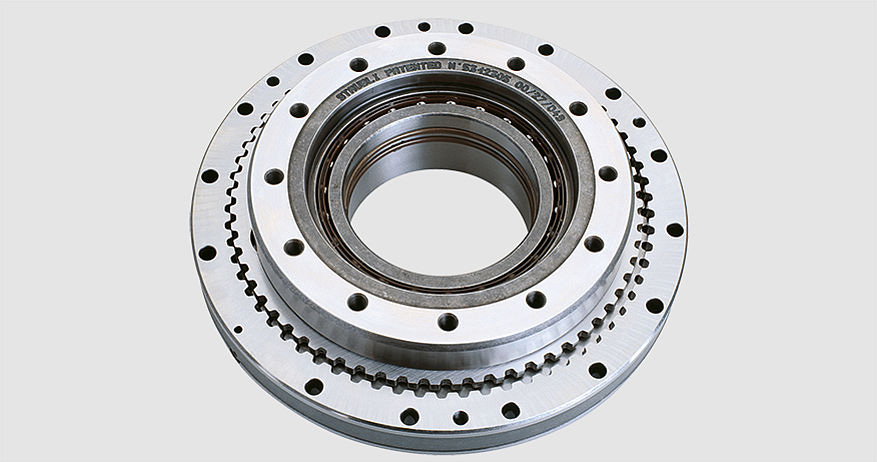

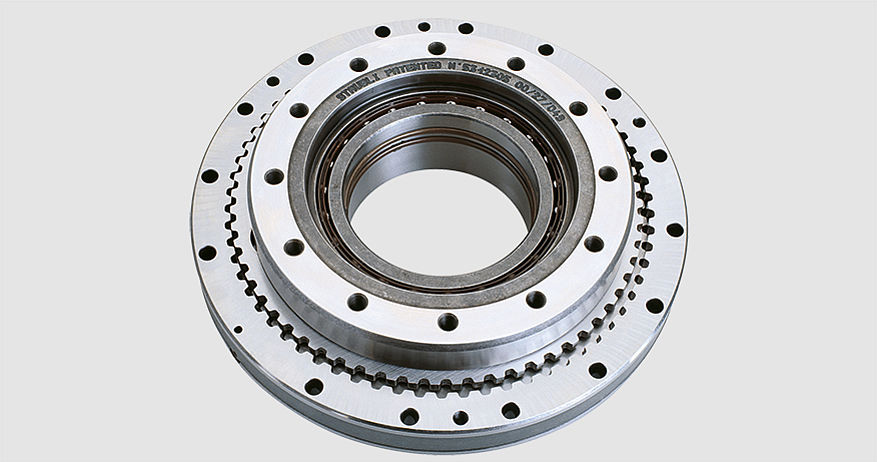

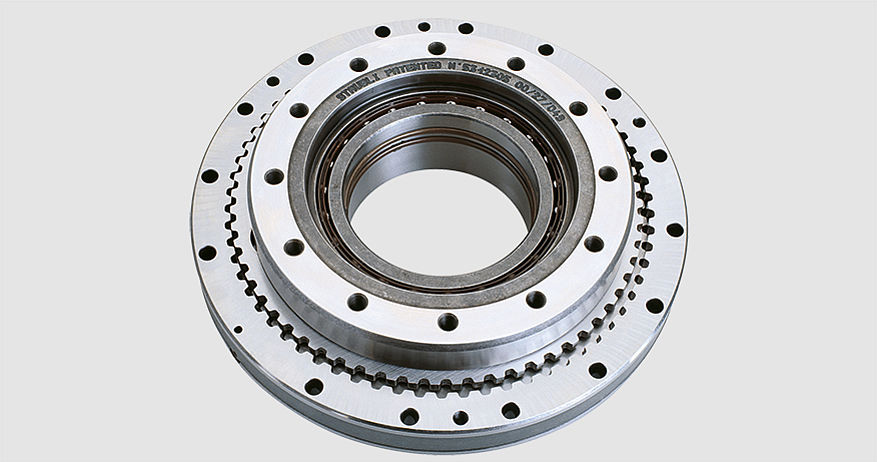

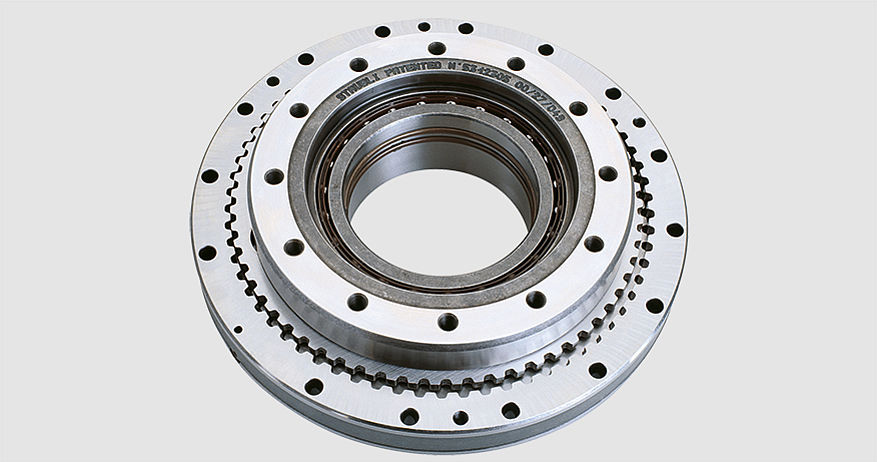

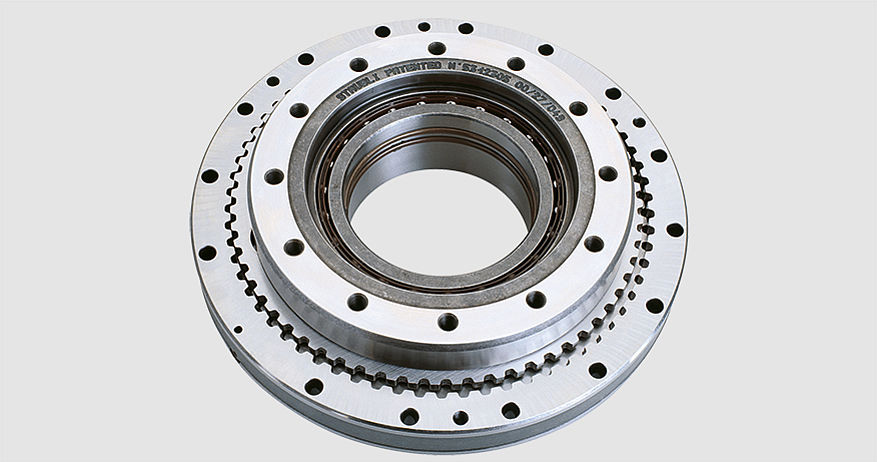

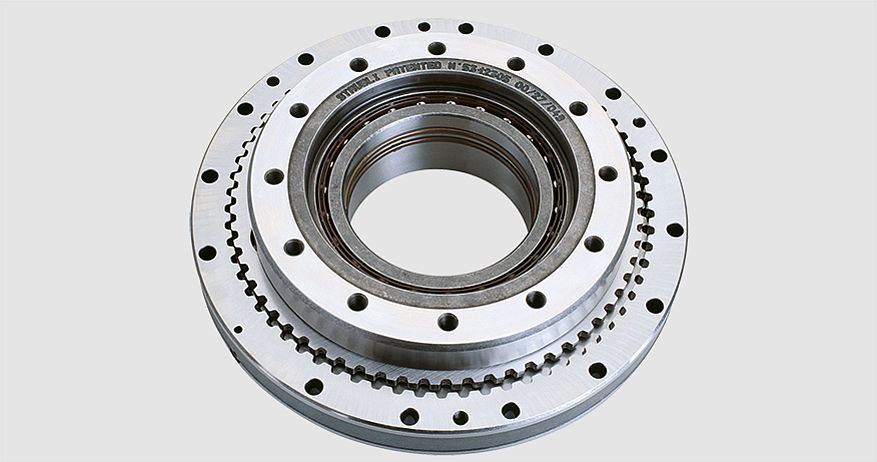

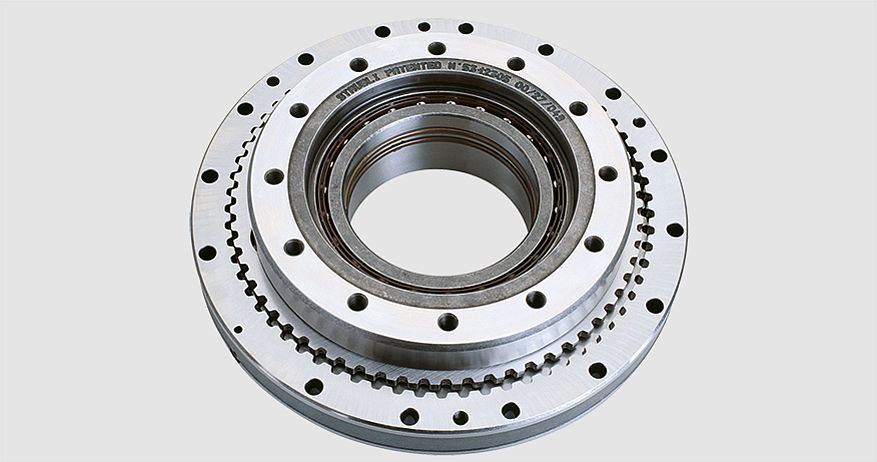

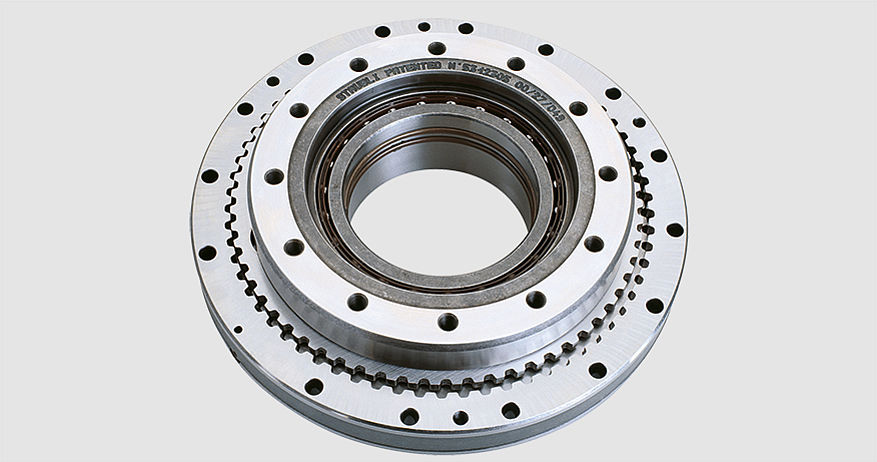

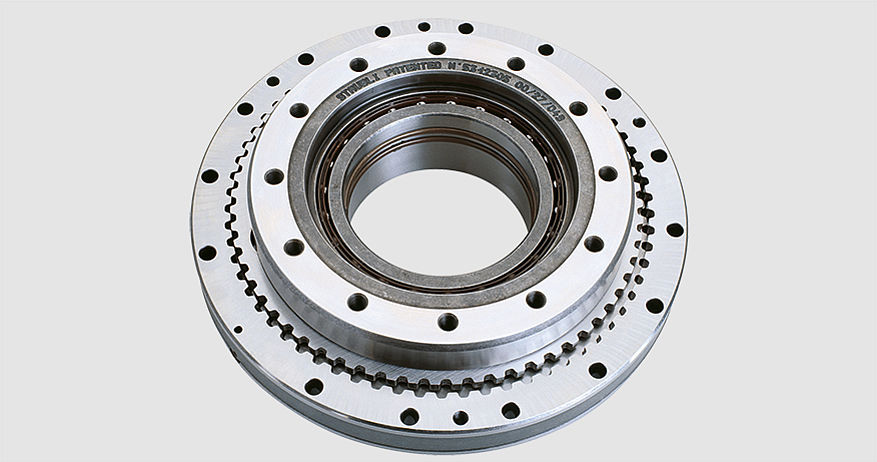

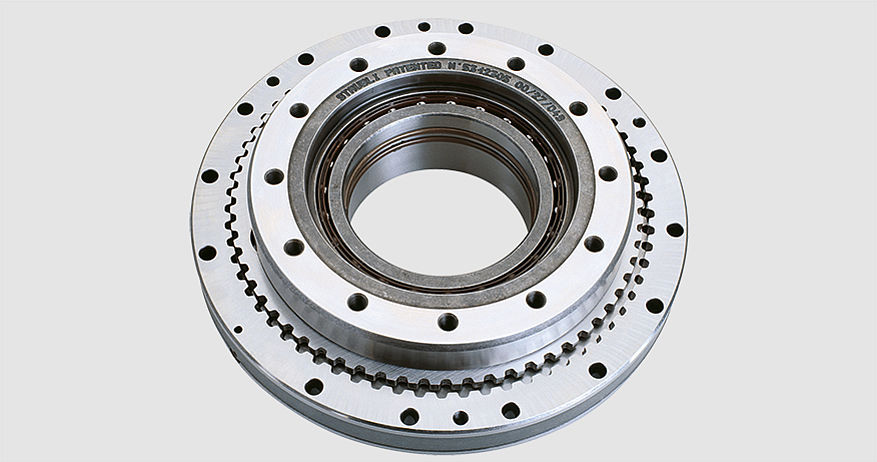

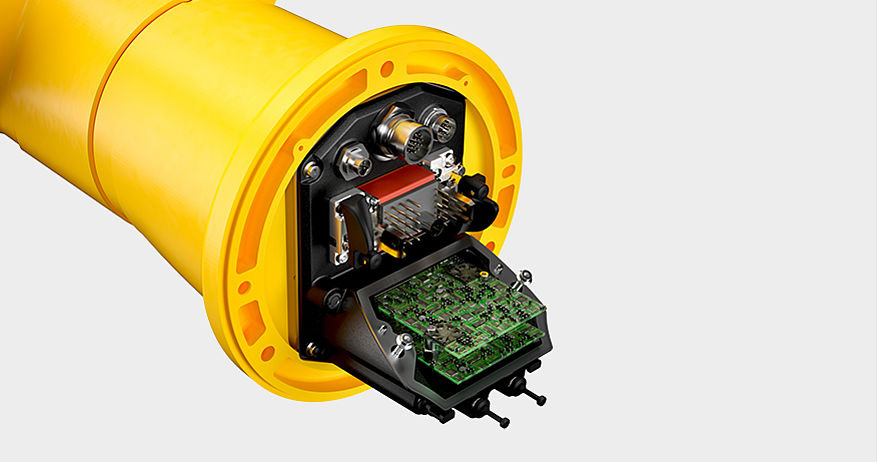

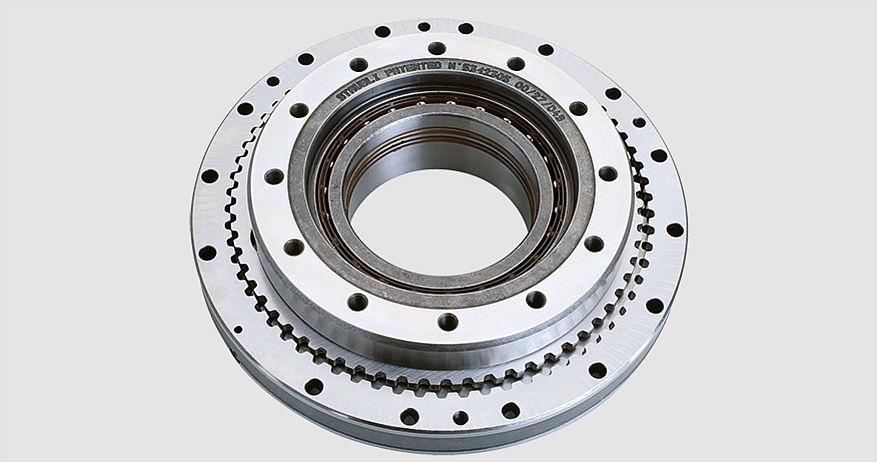

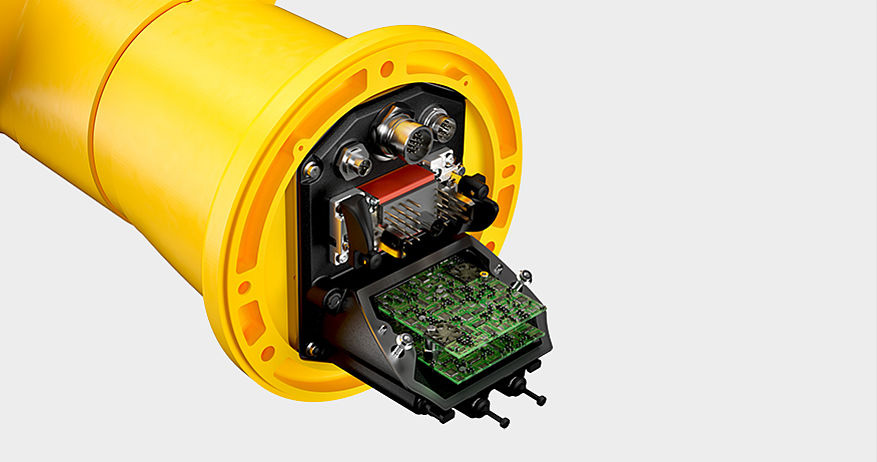

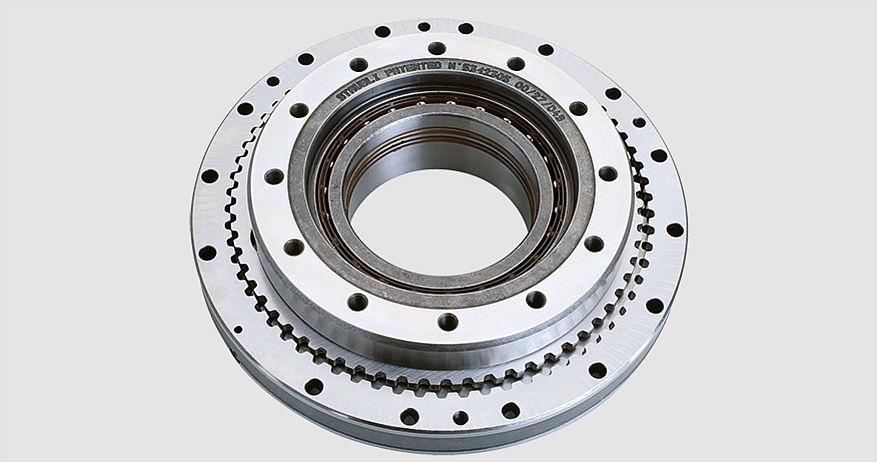

Stäubli is entering a new performance class with its TS2 SCARA series. The completely redesigned 4-axis machine with proprietary JCS drive technology facilitates ultra-short cycle times and high repeatability. It also has a revolutionary encapsulated design which opens up new possibilities for use in sensitive environments. It is piloted by the generic CS9 controller that also controls TX2 6-axis robots.

TS2-60 SCARA robot

-

- Reach: 620 mm

- Maximum payload: 8,4 kg

- Repeatability: ± 0.01 mm

- Stroke: 200 mm (400 mm optional)

- Dedicated version: ESD

Stäubli is entering a new performance class with its TS2 SCARA series. The completely redesigned 4-axis machine with proprietary JCS drive technology facilitates ultra-short cycle times and high repeatability. It also has a revolutionary encapsulated design which opens up new possibilities for use in sensitive environments. It is piloted by the generic CS9 controller that also controls TX2 6-axis robots.

TS2-80 SCARA robot

-

- Reach: 800 mm

- Maximum payload: 8,4 kg

- Repeatability: ± 0.015 mm

- Stroke: 200 mm (400 mm optional)

- Dedicated version: ESD

Stäubli is entering a new performance class with its TS2 SCARA series. The completely redesigned 4-axis machine with proprietary JCS drive technology facilitates ultra-short cycle times and high repeatability. It also has a revolutionary encapsulated design which opens up new possibilities for use in sensitive environments. It is piloted by the generic CS9 controller that also controls TX2 6-axis robots.

TS2-100 SCARA robot

-

- Reach: 1000 mm

- Maximum payload: 8,4 kg

- Repeatability: ± 0.02 mm

- Stroke: 200 mm (400 mm optional)

- Dedicated version: ESD

Stäubli is entering a new performance class with its TS2 SCARA series. The completely redesigned 4-axis machine with proprietary JCS drive technology facilitates ultra-short cycle times and high repeatability. It also has a revolutionary encapsulated design which opens up new possibilities for use in sensitive environments. It is piloted by the generic CS9 controller that also controls TX2 6-axis robots.

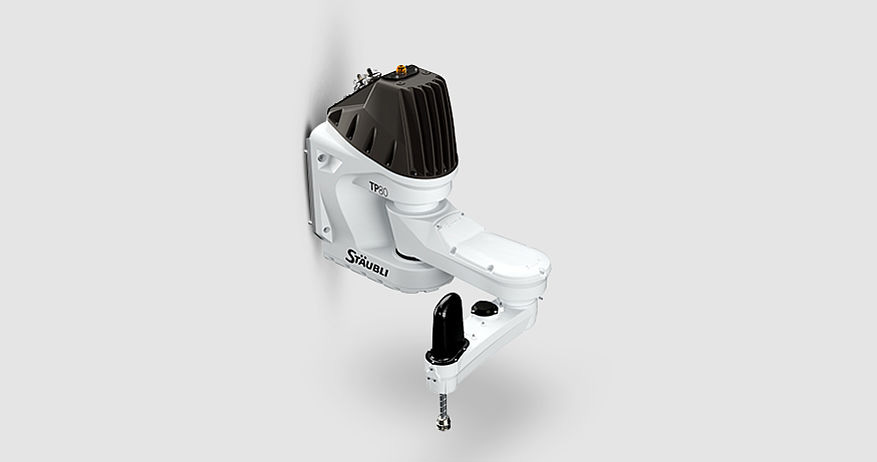

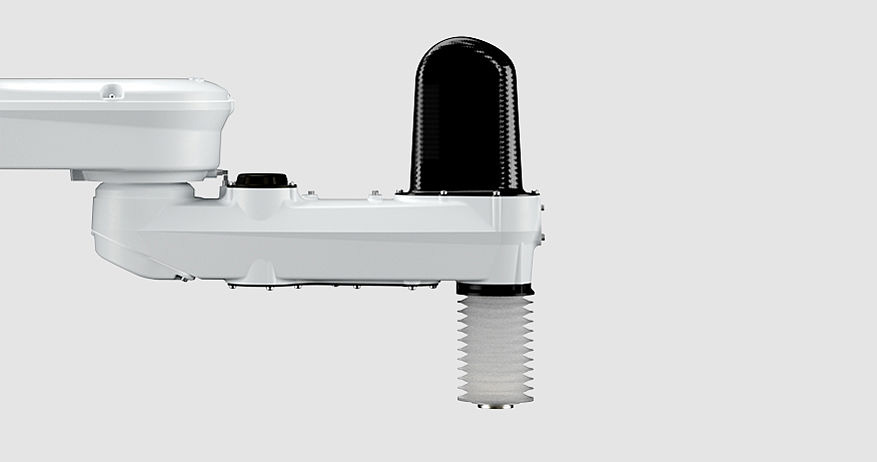

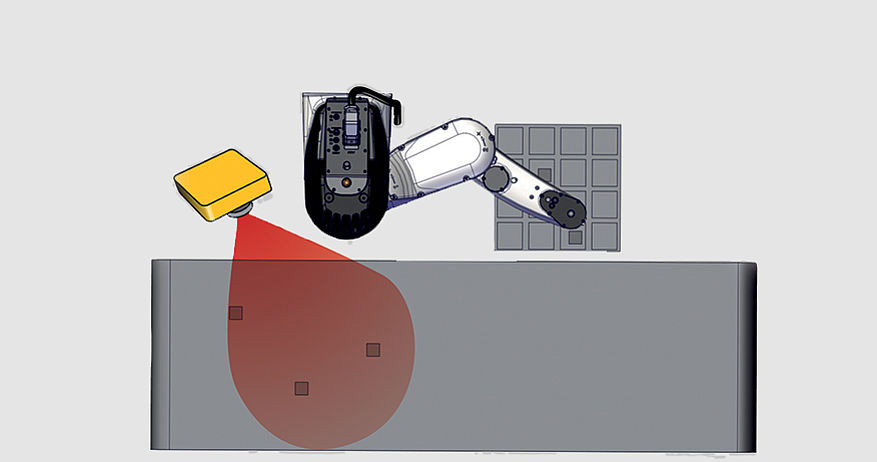

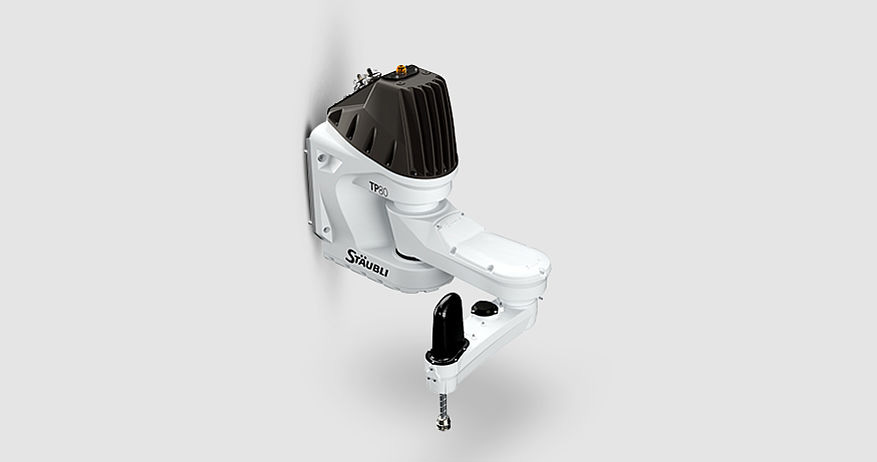

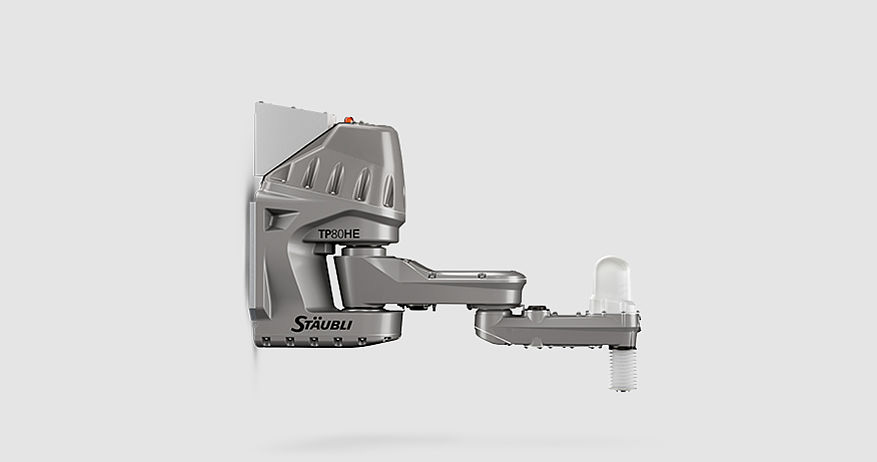

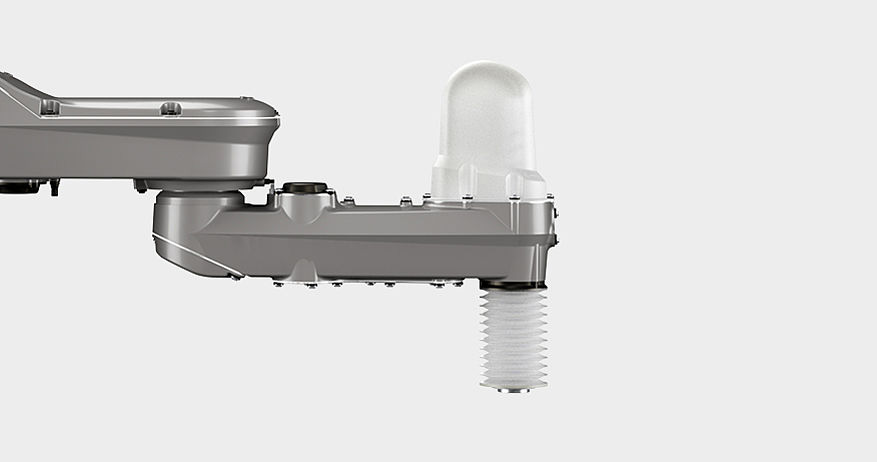

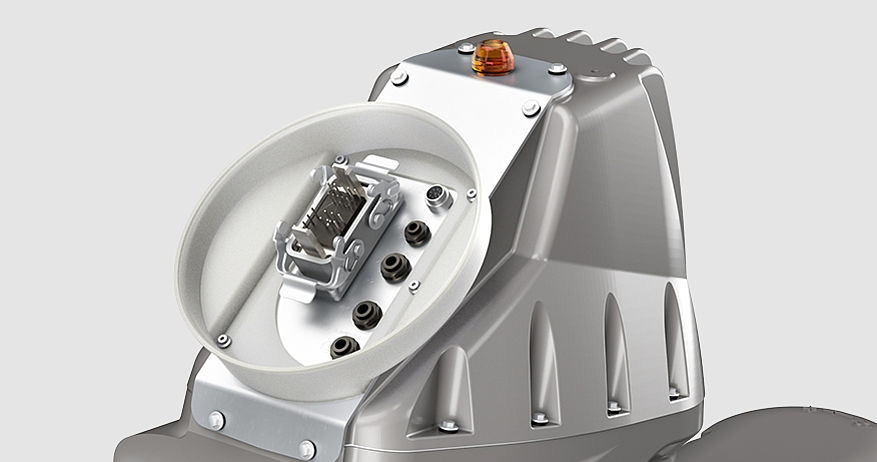

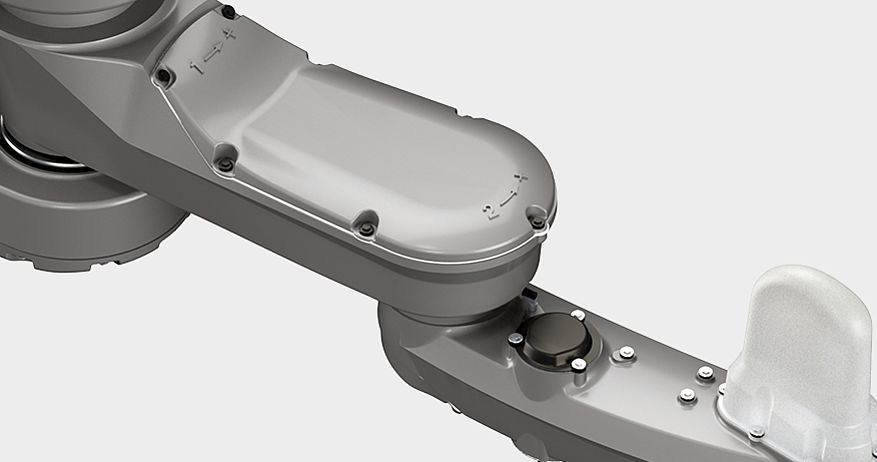

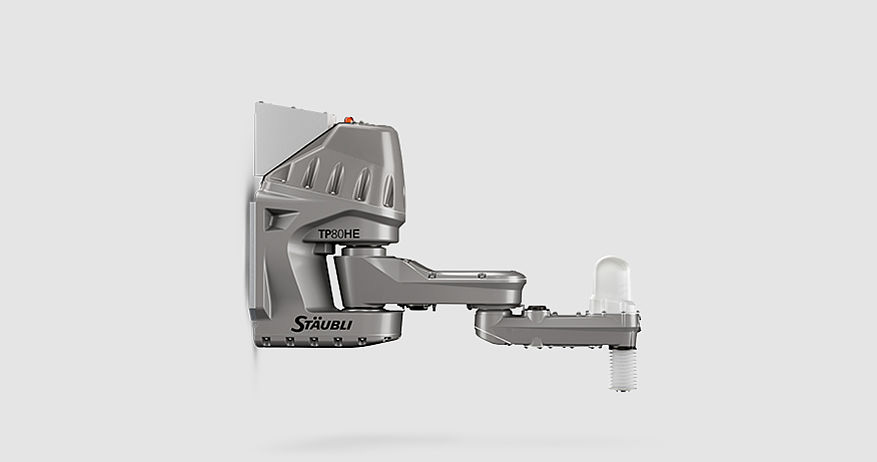

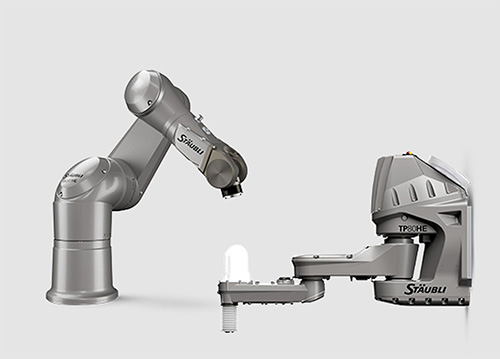

Our FAST picker TP80 4-axis robots

-

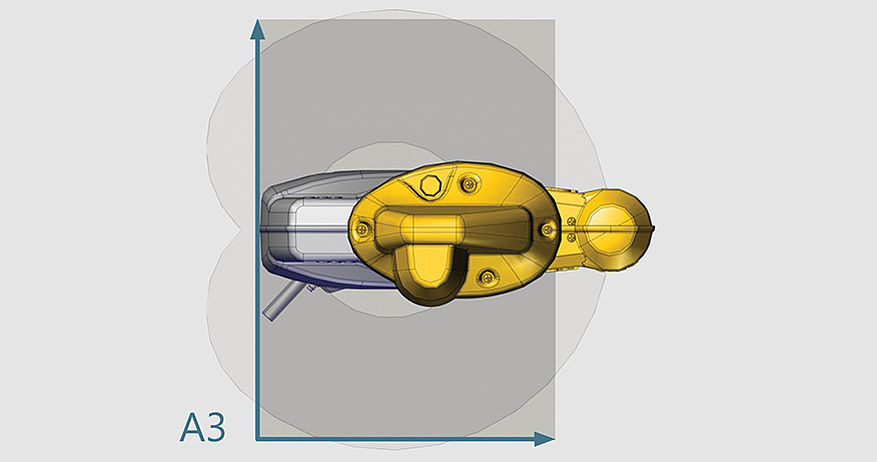

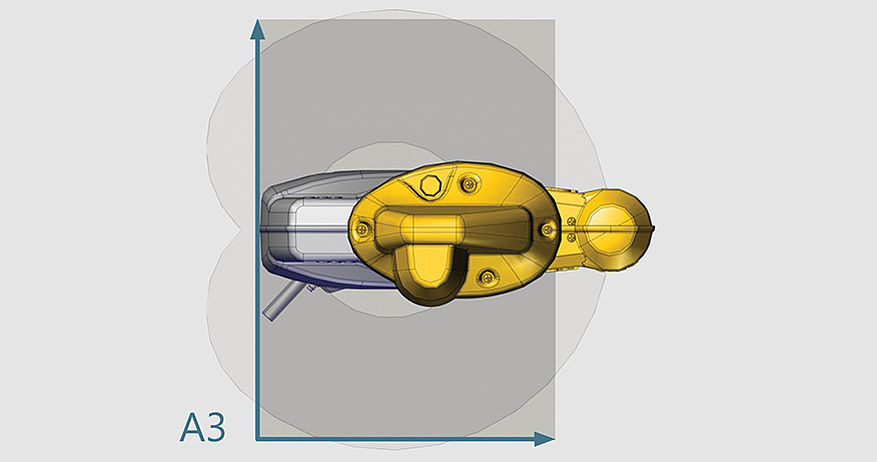

The FAST picker TP80 robots are particularly well-suited for packaging applications in various fields such as food, pharmaceuticals, photovoltaics and cosmetics. These extremely fast robotic arms are designed for small parts handling operations. They deliver repeatability of ± 0.05 mm, a work envelope of up to 800 mm reach and speeds of up to 200 picks per minute. In addition, thanks to the design of the TP80, there are no support structure or retention areas above the products.

FAST picker TP80 robot

-

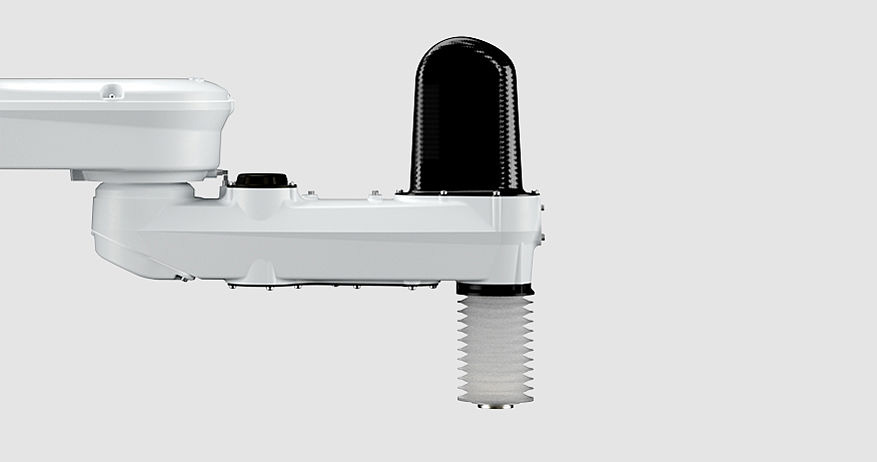

Designed by Stäubli, the FAST picker TP80 is the only truly clean picker robot around. It’s an extremely fast robotdesigned for small and light parts (<1 kg) handling operations. The FAST picker TP80 robot is particularly well-suited for packaging applications in various fields such as food, pharmaceuticals, photovoltaics and cosmetics. It also comes in an HE version that can stand up to humid environments.

Advantages

- High speed

The FAST picker TP80 is an extremely fast robot with sustained 200 picks per minute capability under continuous operation. - No interference with camera line of vision

The FAST picker TP80 is specially designed not to interfere with a camera’s line of vision. - Able to operate in confined areas

The FAST picker TP80’s slim forearm allows it to access confined spaces, for example loading and unloading through slotted machine openings. - Large work envelope

With its 800 mm reach and 100 mm (or optional 200 mm) stroke, the FAST picker TP80 robot can cover a large work envelope at very high speeds. - Sensitive environments

Thanks to its protective housing and bellows, the FAST picker TP80 can work in sensitive environments. Its fully enclosed structure and smooth surfaces make the robot easy to clean.

Specifications

- Degrees of freedom: 4

- Nominal load capacity: 0.5 kg

- Maximum load capacity*: 1 kg

- Reach at wrist: 800 mm

- Repeatability: ±0.05 mm

- Stroke: 100 or 200 mm

- Protection class: IP54 (IP65*)

- Attachment methods: Wall

- Stäubli CS8 series controller: CS8C

* With specific configuration. Contact us for details.

- High speed

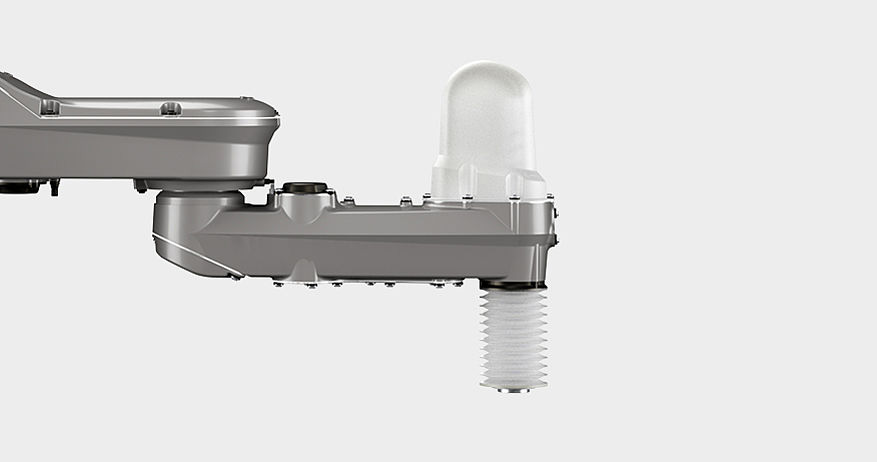

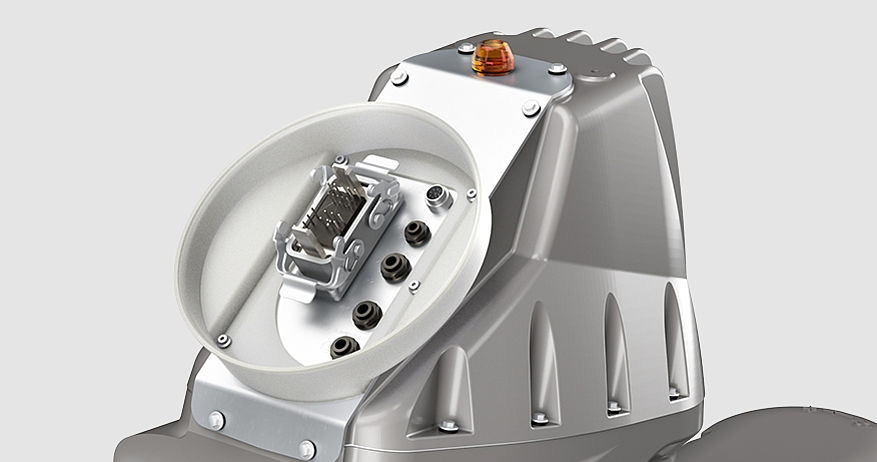

FAST picker TP80 HE robot

-

The FAST picker TP80 HE is the world's fastest picker, fully designed for hygienic processing and packaging, entirely based on EHEDG recommendations. Its unique design makes this robot completely airtight to work in humid environment.

High Performance

Up to 200 picks per minute with a consistent repeatability of ± 0.05 mm across the entire work envelope of 1 600 mm diameter.Hygienic and washable design

Compatible with lots of cleaning and decontamination solutions. Fully enclosed and pressurized structure designed for highest hygienic requirements.Advantages

- No micro organism penetration

Fully enclosed and pressurized structure. - High connectivity for sensitive environment

Designed to protect all connections.

Fully integrated internal cabling and tubing. - Optimal work area

Most efficient work envelope in fast pickers category.

Up to 200 mm vertical stroke. - Attachment for smart integration

Rear attachment without visible threads on the product side.

No supporting gantry-framework above the products.

Saves a lot of space on multi-robot lines compared to delta robots.

Reduction of retention zones above products. - Hygienic design

Smooth rounded and tilted surfaces.

Optimized liquid run-off.

Food compliant full head stainless screws.

Coating with surface roughness < 0.8 μm.

Specifications

- Degrees of freedom: 4

- Nominal load capacity: 0.5 kg

- Maximum load capacity*: 1 kg

- Reach at wrist: 800 mm

- Repeatability: ±0.05 mm

- Stroke: 100 or 200 mm

- Protection class: IP65

- Attachment methods: Wall

- Stäubli CS8 series controller: CS8C

* With specific configuration. Contact us for details.

- No micro organism penetration

Our robots for sensitive environments

- Stäubli robots are designed to function reliably under the most extreme conditions, whether in sensitive environments or for specific applications. Our robotic arms are effective for a wide range of situations, from cleanrooms to harsh environmentsto machining operations. As a result, our robots are particularly adapted to the most stringent sectors such as food pharmaceuticals and electronics industries.

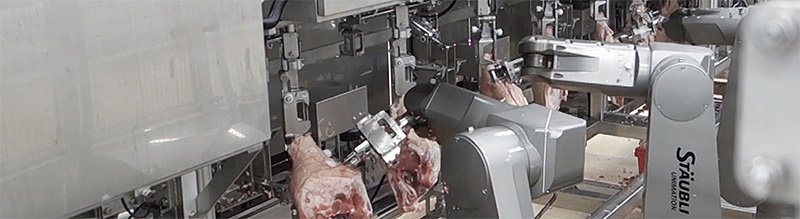

HE robotic arms (Humid Environment)

- All around the world, the food and beverage industry makes extensive use of industrial robots, particularly HE robots for humid environments. Stäubli’s HE robotic arms have become the market leader thanks to their fully hygienic design, unmatched technical performance and ability to completely eliminate bacterial contamination risks. This major innovation has revolutionized the food industry.

HE robots are also suitable for applications such as waterjet cutting and washing.

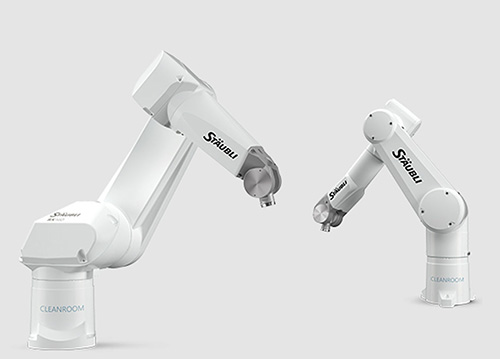

Our Cleanroom robotic arms

- Our Cleanroom robots have been developed specifically to meet the requirements of clean environments. All robots are ISO class 2/3 (SCR) or class 4 (CR) certified for use in semiconductor, biotechnology, pharmaceutical, medical and other industries.

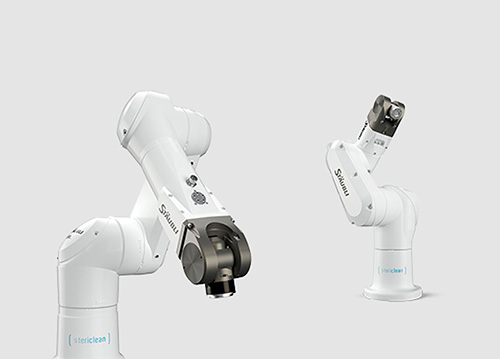

Stericlean robotic arms

- Stäubli has many customers in the life sciences industry and works closely with leading pharmaceutical companies. This gave our engineers a leg up when adapting our well-known range of industrial Cleanroom robots to new hydrogen peroxide decontamination standards. Our line of Stericlean robots meets the most stringent requirements for pharmaceutical and cleanroom applications.

ESD robotic arms (ElectroStatic Discharge)

- The ESD line of robots is designed to prevent electrostatic discharges and comes in 4- and 6-axis versions in various sizes with reaches ranging from 400 to 2,600 mm. These high performance robots deliver the perfect level of speed, precision and reliability for handling electronic components.

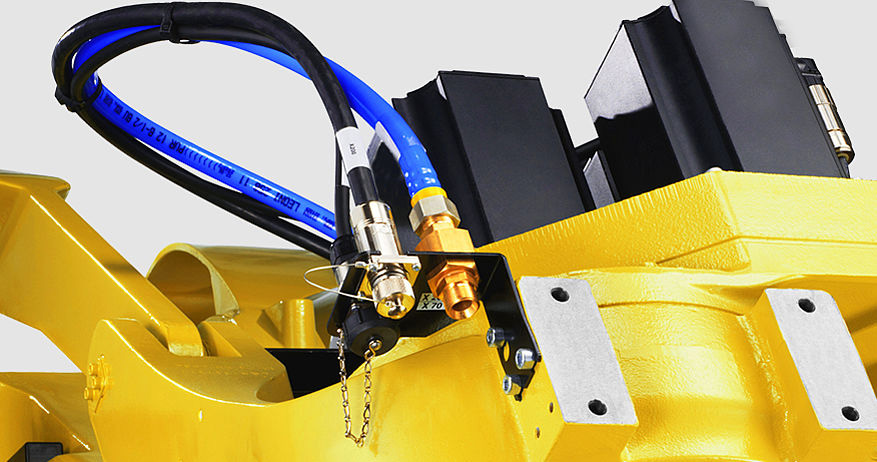

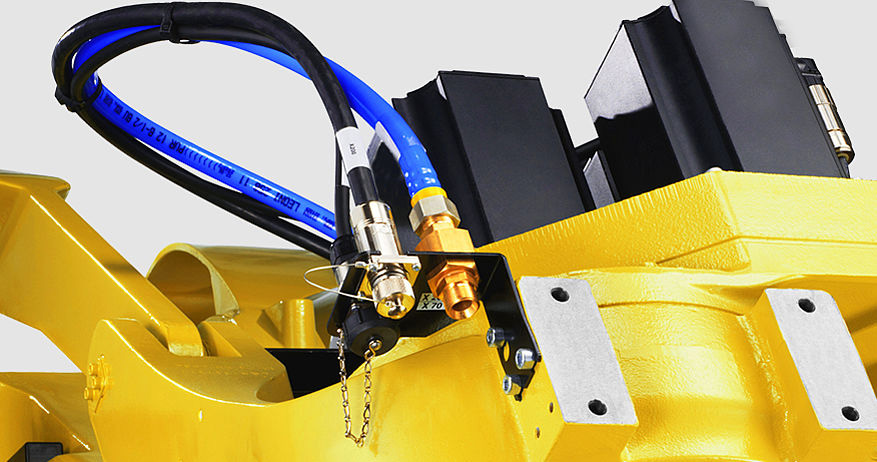

Painting robots

- The Paint system is designed to provide an automation package ready to be integrated into your cell. It includes an electrical cabinet and purge system, with the analog I/O module ready to connect for paint parameters such as fan width, material flow, atomizing pressure or voltage and bell speed for electrostatic applications.

Robot Controllers

-

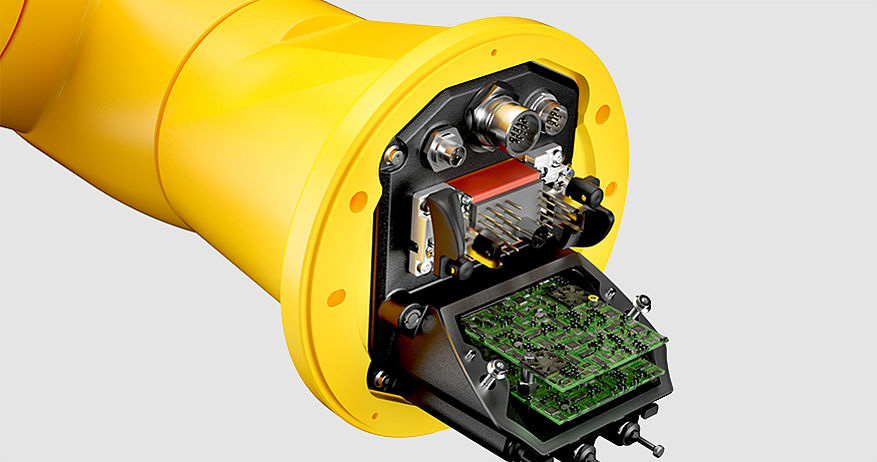

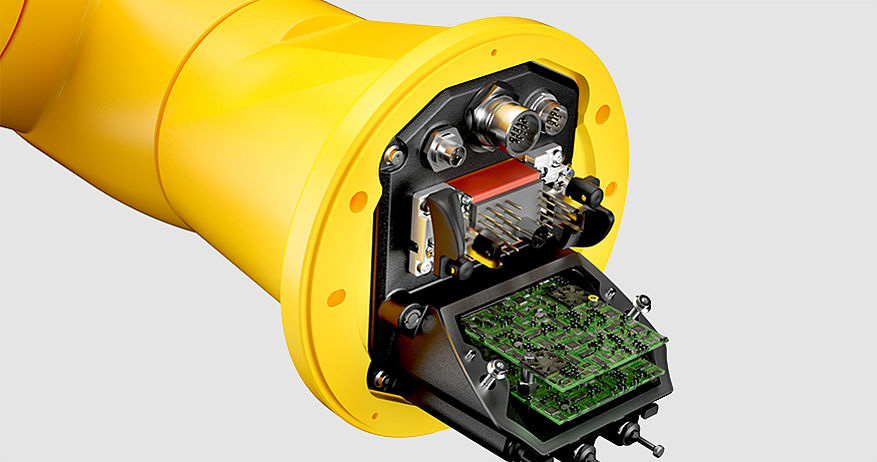

Robot controllers for all applications

Sophisticated technology has never been simpler. The CS8 and CS9 robot controller series in the VAL3 environment control all Stäubli robots without exception, providing a single platform, both powerful and easily upgradeable, for running all of your applications.

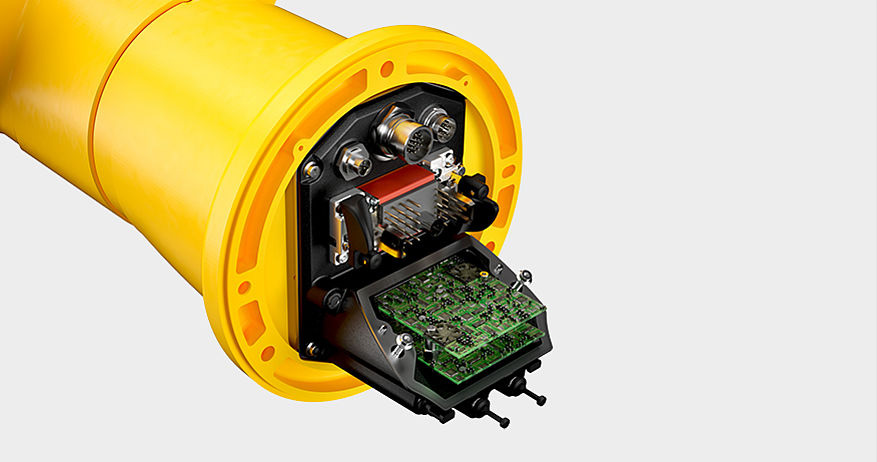

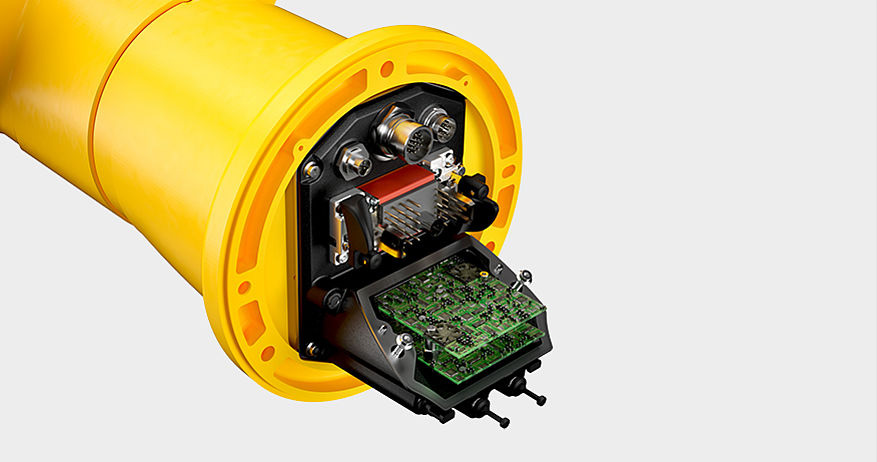

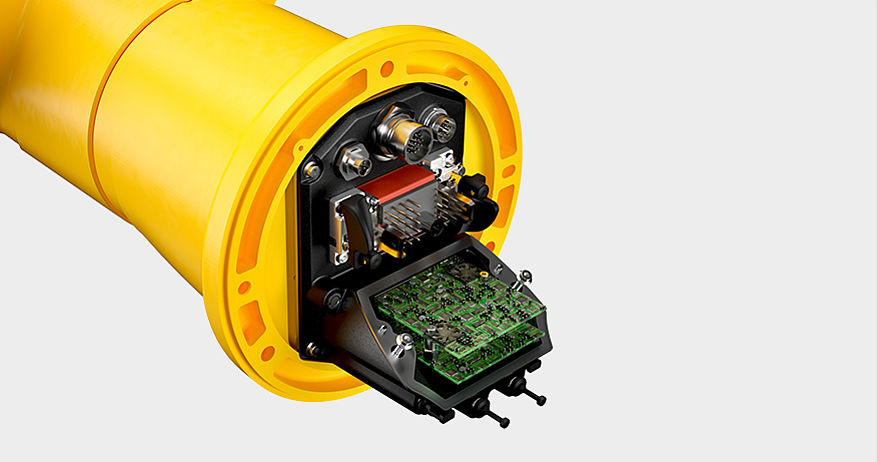

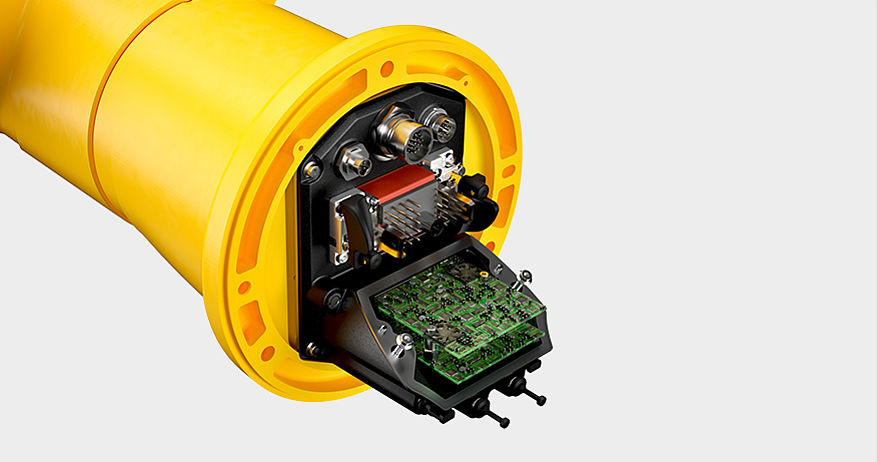

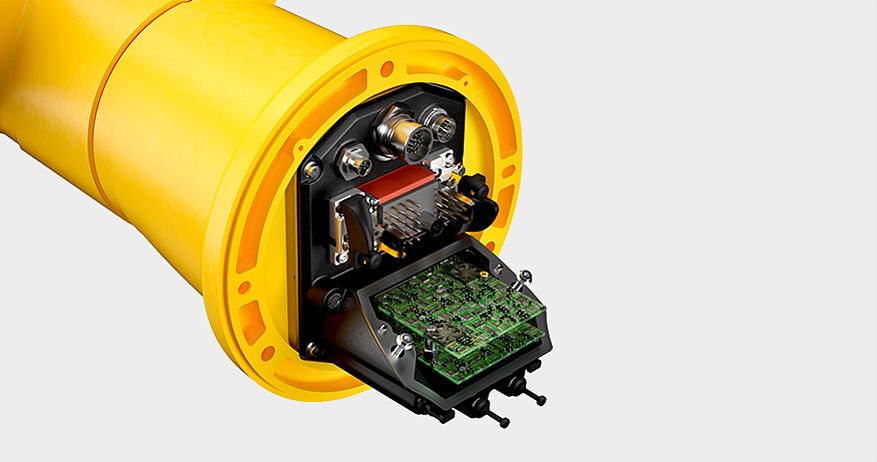

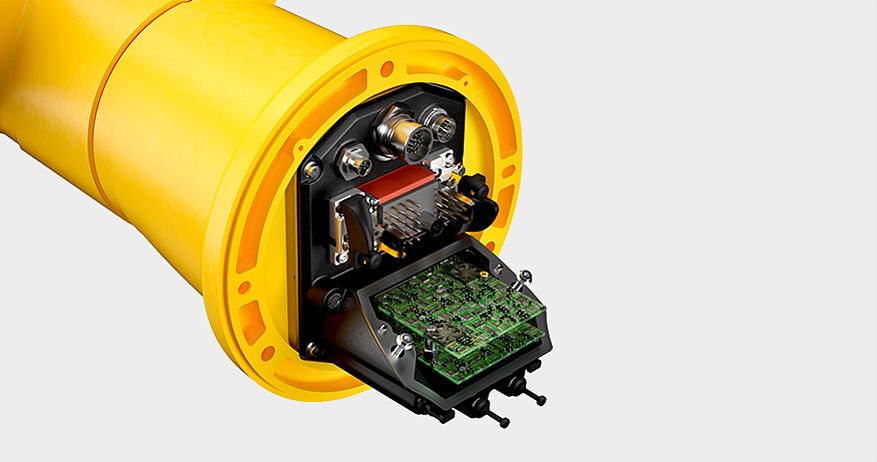

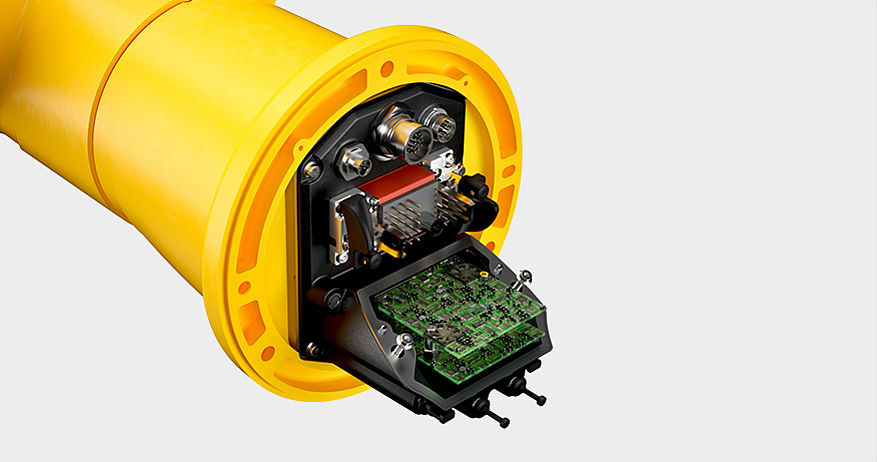

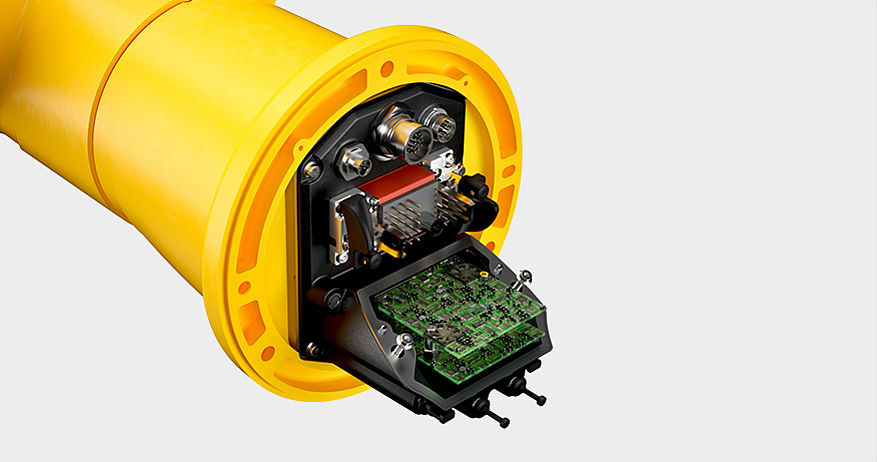

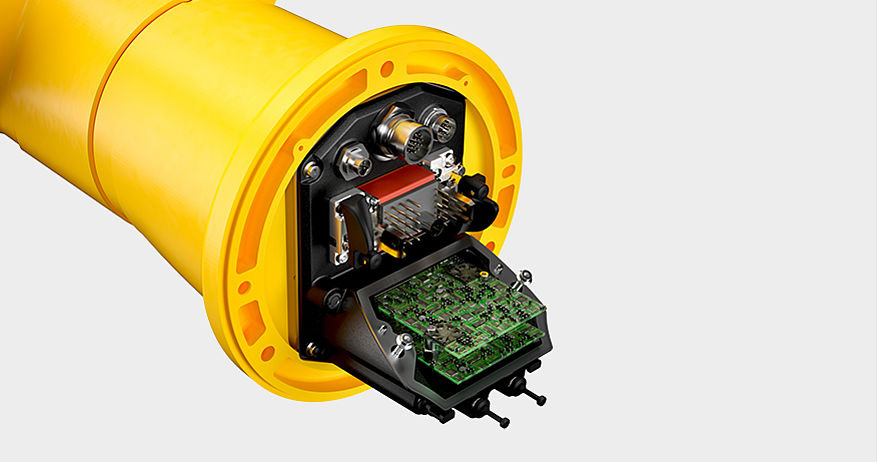

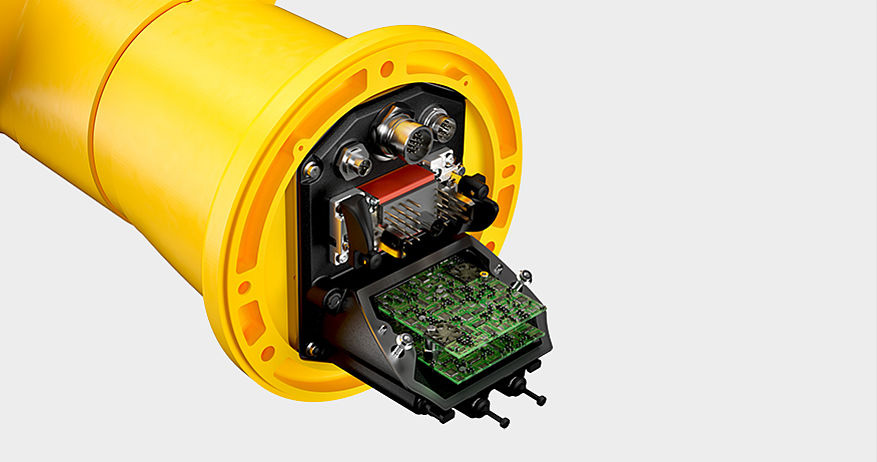

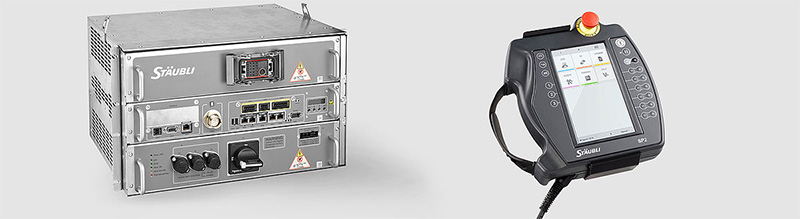

CS9 robot controller: the next generation of controllers

- This new lightweight and compact controller offers a variety of integrated functions providing faster integration and consistent availability with minimal maintenance. This innovative CS9 sets new standards in safety which protects production, equipment and people.

Features- Easy to remove drawers from the front

- Status display on front panel

- All filters can be removed from front

- All user connection on the front with easy to wire connectors

- Light and compact size

- 19 inch rack mount

- Standard TCP/IP

- Multiple fieldbus including realtime Ethernet

- Safety over hardware IOs or realtime Ethernet

- Multiple languages available

- Energy Saving Eco Mode

CS8 robot controllers: a single family for all applications

- Our CS8 series robot controllers provide a single, user-friendly platform for controlling Stäubli robots, offering shared advantages across a broad spectrum of robotic solutions.

Robot Software

-

Stäubli robot software: an outstanding value for every need

Stäubli offers a comprehensive suite of powerful yet user-friendly software solutions perfectly adapted for all: end users, integrators, OEMs and machine builders. Stäubli Robotics Controls

- A range of powerful yet user-friendly software solutions hosted on the central CS8 controller for programming all robotic functions with ease.

VALproducts solutions

-

A suite of plug-and-play market solutions, perfectly adapted for all end users.

Primary benefits

Because VALproducts software is so user-friendly, there is a very short learning curve, and no programming knowledge is required. The modular suite is highly intuitive, featuring familiar interactive menus and a standardized interface for all VALproducts solutions.

VAL 3 language

-

An advanced robotics environment for building high-end and tailored applications, perfectly adapted for integrators and OEMs.

A dedicated robotics language, VAL 3 language commands powerful robotics function sets. A highly flexible, modular approach makes it possible to reuse and capitalize on accumulated knowledge. Even greater flexibility is afforded by a wide range of connection possibilities, including DIO, AIO and field bus. Full robot and controller access from a single teach pendant interface makes sophisticated programming simple.

uniVAL drive

- uniVAL is a “ready to plug” solution to drive Stäubli’s entire range of picker, 4 and 6 axis robots with generic industrial multi-axis controllers or PLCs.

Stäubli Robotics Suite

Stäubli Robotics Suite

- PC Software Suite for robotics application development and maintenance.

Solutions / Applications

-

Stäubli Robotics: Meeting the requirements of every industry

Provide high performance in all areas of industry. This singular principle governs the development of all Stäubli solutions. Designed to work in the most hostile environments as well as cleanrooms, Stäubli robots demonstrate their efficacy under all conditions. Wherever speed, compactness, precision and reliability are demanded, Stäubli has the right technology - regardless of industry sector or type of application.

Industrial robots for the food industry

- In the food and beverage industry, when equipment operates at high throughput, frequent manual manipulation can compromise performance and hygiene. Automated solutions maximize efficiency by minimizing interruptions, increasing flexibility and eliminating the risks of contamination. That is why food industry customers need the highest performing robotic solutions. Our robotic arms are designed to handle all applications, from upstream processing through to sorting, packing and end-of-line palletizing.

Robotic laser cutting

- Stäubli's range of 6-axis laser-cutting robots offer the perfect combination of precise trajectory control, extensive reach, high speed and compact size. These robots have an enclosed structure and can be top mounted to facilitate cutting and parts handling. This increased flexibility improves productivity at an extremely competitive price.

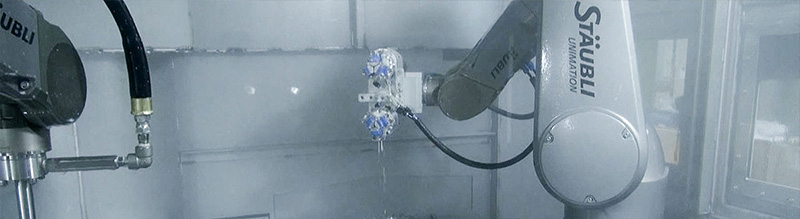

Stäubli washing robots: the cleaner solution

- Automated washing solutions have increased production and improved product quality while reducing operating costs. Stäubli HE industrial washing robots are specially sealed, meaning they can handle the water jet and the workpiece. They are also waterproof and can withstand a range of chemical solutions, in both acidic and alkaline environments. They are perfect for low- and high-pressure cleaning, very high-pressure deburring, degreasing, rinsing, and drying applications.

Life sciences, pharmaceutical robots

-

Stäubli robots are up to any productivity challenge

In drug production, maximum output is essential. Whether handling and packaging of IV bags, syringes and vials, aseptic dispensing or loading and unloading of insulators, Stäubli robots score particularly well in terms of ultra-short cycle times.

Loading and unloading of machine tools

- Our experience in machine tool loading/unloading lets us work with manufacturers and system integrators to design industrial robots for applications on all machine types: single, twin and multi-spindle lathes, rotary/linear transfer machines, machining/tapping centers, and grinding, honing, boring, cutting as well as superfinishing machines.

HSM (High Speed Machining) robots for machining

- Stäubli Robotics offers a complete range of High-Speed Machining (HSM) robots for machining operations that require high flexibility. Stäubli's TX90, RX160 and TX200 HSM robots are particularly well-suited for high-speed machining operations such as finishing, die trimming, modeling, drilling, tapping, deburring, contouring and weld bead machining on various materials.

Stäubli Paint robots meet all finishing needs

-

From traditional applications to electrostatic processes, Stäubli Paint robots cover all finishing needs in a wide range of industries: automotive components, household appliances, consumer electronics, etc.

- Better process control

Stäubli’s PaintiXen advanced control software allows the user to control all paint parameters, including electrostatic charge, atomization area, fan width and product pressure. - Increased paint and solvent savings

Automation reduces paint and solvent waste, extends filter lifetime and minimizes mud and dust in the paint booth (+30% transfer rate). - High quality

Paint robots execute trajectories precisely, with no part deviation and perfectly controlled paint gun starts. Specified thicknesses are guaranteed, with minimum variations. - High flexibility

Our paint robots allow the management of complex/multiple-sized parts as well as switching to different products (sizes or colors) according to the line PLC. Plus, user-friendly programming enables the automation of many small parts. - Increased throughput

Faulty part rates and the need for manual touch-ups decrease, while overspray reduction allows the removal of finishing and polishing workstations. Paint parameters can be modified by painters without stopping the production line. Further, Stäubli paint robots are designed to operate several shifts daily with very high availability rates and MTBF.

- Better process control

Solutions and applications for the plastics industry

-

Stäubli’s range of plastics robots is the first line of 6-axis robots designed specifically for use in the plastics industry. They were developed following detailed consultation and evaluation by both injection molding companies and system integrators, ensuring highly specialized automation solutions.

FEATURES AND BENEFITS

- Flexibility

Simply re-program the robot when the mold changes, and fully utilize the machine’s capacity by grouping various molds together. Our plastics robots can easily be integrated and moved to other injection molding machines (IMMs). New molds or processes are easily accommodated by our extensive plastics range.

- Speed

Stäubli plastics robots are the fastest 6-axis robots on the market in terms of speed and acceleration (for example, 0.8 second demold time inside a 4-second cycle).

- Cleanliness

Class 100 comes standard.

- Fulfill plastics industry requirements

The robots are available ready to use with pre-wired Euromap (Europe) or SPI (USA) hardware and safety interlock, along with dedicated industry interface.

- Flexibility

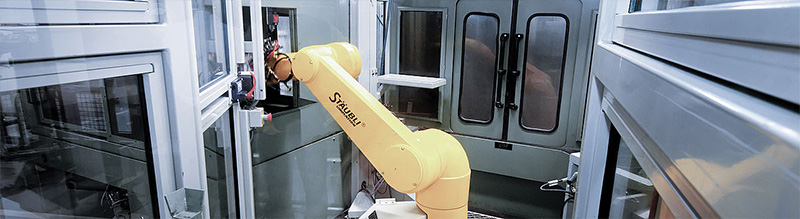

Our Cleanroom robots blend precision, speed and cleanliness

-

The electronics and semiconductor industries are particularly demanding when it comes to precision, speed and reduced particle emissions. To meet their robotics needs, Stäubli offers an ultra-high performance line of Cleanroom robotic arms for highly sensitive applications. Our robots can manipulate the silicon wafers used to make semiconductors with exceptional accuracy, high speed and smooth trajectories.

Features and benefits

The robots meet ISO 14644-1 class 2/3 or FED209E subclass 1 standards and feature a totally enclosed arm with a glossy polyurethane surface, capable of high dexterity. A compact arm footprint helps to save precious cleanroom volume.

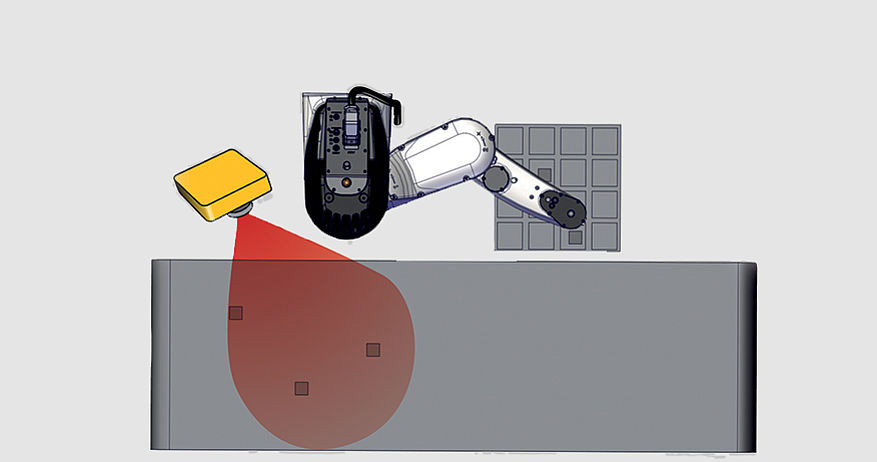

Solar and photovoltaics robots

-

Robots for crystalline production

Stäubli has designed a full range of specialized robotics solutions for solar and photovoltaic production. Our 4 and 6-axis robotic arms combine reliability, precision and dexterity to reduce manufacturing costs while boosting productivity and quality.

From the ultra-precise 4-axis FAST picker TP80, SCARA TS to the 6-axis TX, our specialized robots can handle all crystalline (c-Si) production processes. They can handle a range of solar applications, including theTechnical characteristics:- Closed robot arm with rigid structure

- Clean robot for all applications

- High speed

- High accuracy

- Smooth robot motion: best in its class

Advantages:

- 30+ years experience in the cleanroom and semiconductor industries

- Partnerships with system integrators and OEMs worldwide

- Synergy between Electrical Connectors and Robotics division activities provides a global solution to PV module manufacturers

- Dedicated line of robots for PV markets