- Offer Profile

- For more than 50 years the employees of Bühler Technologies have been developing, manufacturing and distributing components and system solutions in the Gas Analysis and Fluidcontrol divisions. By specialising in the market niches Gas Analysis and Hydraulics and by offering a complete range of products for each, we have succeeded to become a worldwide leader in both disciplines.

Gas Analysis

- In the chemical industry, petrochemical, biochemical and other industrial fields, production and system safety is dependent upon determining reliable operation and process parameters. In a large number of these applications, gas analysis is the key to safe and efficient control of process flow, environmental protection and quality assurance in many industries, for example in power stations, air separation, sterile production and packaging in the food industry.

Sample Gas Probes

- Sample gas probes form a critical point between process and analysis system. They extract sample gas from the process stream and supply it to the analysis system. They should already remove undesirable particulates at the sampling point and avoid cold spots thus preventing false measurements. Our probes are easy to maintain without requiring a lot of tools. Their designs are suitable for critical ambient conditions such as explosive areas and provide weather protection.

Sample Gas Filters

- Even when the contaminants have been removed at the extraction point through effective particle filtration inside the sample gas probe, there is still a risk of finer dust entering the measuring system.

For this reason effective analysis filters are required, but also for use in stationary or portable sample gas conditioners. These can be in-line filters or panel filters with housings made from various material combinations. Equipped with easy to change filter elements with various retention rates and an adequate filter size they can be used for a wide range of applications.

Sample Gas Pumps

- Solid PTFE bellowpumps for transporting sample gas

Sample gas analysis systems require pumps when the process pressure is not sufficient to transport an adequate volume of sample gas to the analysers reliably. The frequent corrosive and aggressive nature of the sample gas demands special properties of the material in contact with the media. The pumps can also transport potential condensate.

Sample Gas Coolers - Electric Gas Coolers

- Removing any moisture from the gas is an important step in sample gas conditioning. To achieve this, suitable coolers are applied to reduce the gas temperature below the dew point in order to condense the moisture. To secure a reproducible analysis result the dew point must remain as stable as possible even when the ambient temperature fluctuates. The required cooling capacity depends on the temperature fluctuations at the sampling site (which may vary over the course of the year), the specific material combination for the heat exchanger to meet the sample gas composition and the energy-efficient operation of the cooler. Application specific different types of coolers and/or precoolers may be required. The coolers are primarily electric gas coolers, either semi-conductor or compressor coolers, the selection determined by the requirements or the operating conditions. Replaceable heat exchangers in a variety of material compositions and helpful accessories and monitors complete the product portfolio, including for EX zones.

Sample Gas Coolers - Condensate Removal

- The moisture separated in the sample gas cooler turns into condensate and must be removed from the system. Depending on the composition of the sample gas the condensate can be corrosive and/or toxic. External air should not enter the measuring system through the drain to prevent false measurements. Depending on the design of the analysis system the condensate can either be drained from the system automatically or using self-sealing pumps. We offer appropriately equipped vessels for proper condensate disposal.

Sample Gas Coolers - Moisture Detectors

- In extractive gas analysis the sample gas must be conditioned before it enters the measuring cell of the analyser. One of these conditioning stages is moisture condensing in the sample gas coolers. However, since the composition of the sample gas and the process parameters can fluctuate, condensate slip downstream from the cooler cannot be entirely ruled out. Moisture detectors installed at the cooler outlet indicate such slip. The detectors are extremely sensitive so fault conditions are detected early. Combined with suitable controllers this will generate the respective signals/alarms in the control system. In this function we offer various moisture detector models and a wide range of accessories.

Sample Gas Coolers - Dosing unit EMIDos

- One conditioning step in extractive analysis of process and emissions gases is reliable, constant reduction of humidity in the sample gas. The condensate this produces results in sometimes considerable washout effect. This can result in inaccurate measurements, particularly in acidic gas components (e.g. SO2). Adding acidic liquids at an appropriate point in the conditioning system reduces the acid solubility by manipulating the pH level in the condensate, ensuring reliable measurements. The EMIDos dosing unit was designed for this specific application.

Sample Gas Coolers - Precoolers

- Very humid processes may require the use of a precooler prior to the main cooler. This reduces the load on the actual sample gas cooler lowering energy consumption.

Sample Gas Coolers - Water Coolers/Gas Scrubbers

- Instead of electric sample gas coolers, scrubbers and water coolers may be used for specific applications. The following models describe the basic versions.

Flow Meters

- Reliable analysis results require consistent operating conditions. This also includes setting the flow rate and monitoring it accurately. As with all other assemblies in contact with the media the focus on suitable flow meters is selecting highly durable materials and easy maintenance. Inductive limit switches and suitable controllers allow the flow meter meters to be integrated into the system controls.

Accessories

- A range of helpful accessories makes it easier for the system integrator to plan and build systems for gas analysis. An important component used between the sampling point and the analysis system are heated lines to prevent cold spots. These are available for both safe and explosive areas with a wide range of options making them suitable for virtually any application. The back pressure regulators are used in analysis systems downstream of the oxygen analyser in order to eliminate the impact of the air pressure variation on the outlet, thus preventing deviations in the measurements. For adjusting the flow rate, needle valves of the NVT-3 series are particularly suitable for corrosive gases. The valve body and the needle itself are made from solid PTFE for maximum durability. Adding test gas or similar functions can easily be integrated in analysis systems with multi-path ball valves from the GKH series. We offer various styles and materials. Plastic or stainless steel fittings and connectors for hose and glass junctions are the ideal addition to these products. Plastic fittings are available in a variety of materials such as PVDF, PFA, ensuring they are suitable for special corrosion resistance. We offer a wide range of thread sizes and shapes to suit any application. To manage various pressure ranges, flow rates, and material resistance requirements, pressure regulators by GO offer a variety of solutions.

NOx Converter

- In order to protect life and the environment, the emission of nitric oxides must be reduced and monitored. To allow the use of cost-effective analysis methods, e.g. infrared technology for monitoring the NO2 content in the emitted gas, the sample is catalytically converted to NO. This is achieved by using electrically heated small reactors filled with various catalyst materials for different applications. Energy-efficient operation of these NOx converters requires the operating temperature to be as low as possible. This also will prevent CO production. Long life reactor cartridges are available to ensure extended operation. The converter series BÜNOx 2+ offers high energy efficiency, converter materials with a high conversion rate, and an optionally integrated bypass valve. The on-board NOxCal service controller provides data for predictive maintenance.

Gas Analysers

- Our over 50 years of experience in gas analysis was used as a basis for a select line of gas analysers. The product line includes easy to maintain in-situ / Closed-coupled extractive analysers with ZrO2 cells and units for extractive analysis systems. Portable analysers are for example used in the food industry, completing our product range. Our single and multi-channel analysers designed for extractive applications in process and emissions measurement can be equipped with various measuring cells. Depending on the application, paramagnetic cells, ZrO2 modules, IR banks, or electrochemical cells are integrated into our units.

Portable Probes & Gas Conditioning Systems

- In addition to stationary analysers, gas analysis for monitoring emissions also uses portable methods. The actual measuring task determines the complexity of the sampling and gas conditioning units and analysers. Since not all control points are easy to access, operators are interested in suitable and light equipment with a small packing size. Even under these premises, extracting the sample gas must meet high standards to ensure the measurements are reliable.

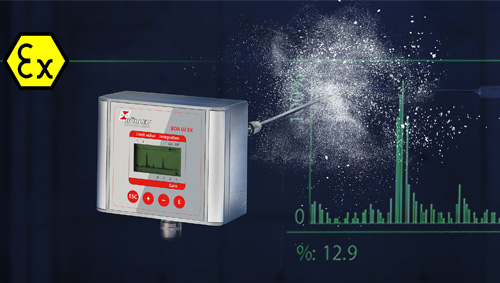

Particle Monitoring

- The user-friendly BDA series particle monitors are high quality systems for monitoring dust filters and separators. Monitoring and diagnosing dust leaks makes filtration system service predictable for active filter management. Depending on the version the units can be calibrated, and the measurement can be displayed in mg/m3. Approved technology according to TA Luft.

Complete Systems

- We supply modular 19 systems for one or multiple gas paths, as well as custom analysis systems. Additionally we supply mobile or stationary conditioning systems with integrated analysers as an option. For emissions testing Bühler offers a DIN EN15267-3 approved modular system which is suitable for different measuring tasks in various applications.

Maritime application

- With components from Bühler Technologies free ride for shipping, chargeless for environmental protection ...

- Exhaust gas cleaning on seagoing ships with heavy oil drives has been mandatory since January 1st, 2020

- Monitoring emissions from these facilities is mandatory

- Bühler Technologies has components certified by classification societies for these monitoring systems

Service

- Customisation and flexibility are also the focus of our service. Our service team is not only a reliable resource for Bühler products but also for products from other manufacturers. We work together with our customers to design custom maintenance plans and commissioning which guarantee 100% service quality. This includes a 24 h hotline, reliable appointments, quick parts despatch, quick response times for on-site customer service as well as service personnel training including certification.

Fluidcontrol

- We offer flexible, system-compatible sensors and devices with state-of-the-art output signals for liquid level, temperature and pressure monitoring as well as for filter and moisture monitoring in hydraulic-systems. With the oil-water and oil-air coolers, filtering units and customer-specific subsystems, we meet todays requirements in terms of a cost-effective and reliable operation of oil installations, even in hazardous areas. The Bühler Fluidcontrol product line extends the service life of oil and components, provides connectivity for automated operation, facilitates condition monitoring and helps reduce operating and maintenance costs.

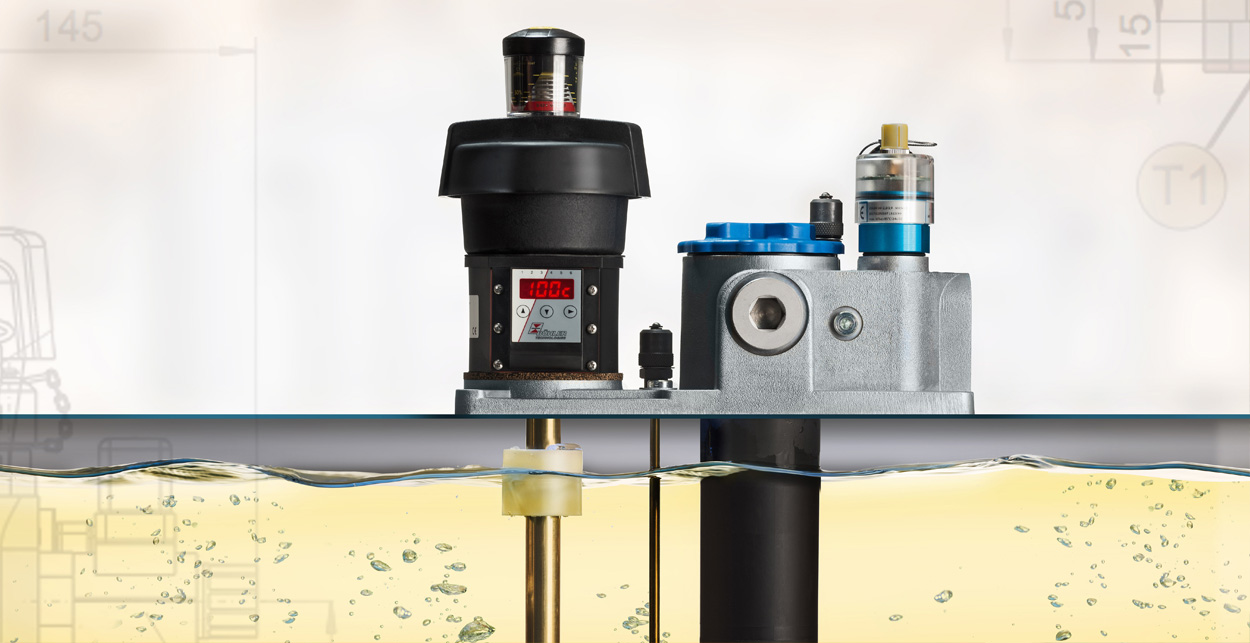

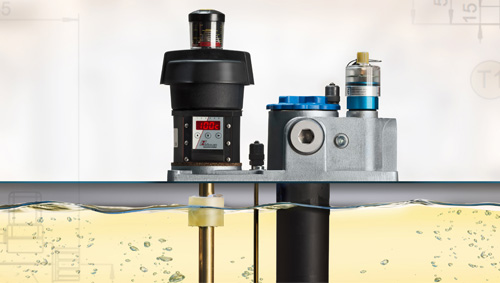

Liquid Level Monitoring

- Tank Top Installation Multifunctional Liquid Level / Temperature / Ventilation / Return Line Filtration

Our multifunctional devices reduce space requirements and facilitate routine maintenance. - Tank Top Installation Liquid Level / Temperature / Ventilation

Devices designed as float switches for liquid level monitoring (as multifunctional devices for the simultaneous monitoring of liquid level and temperature) in oil tanks for hydraulic and lubrication systems. - Tank Top Installation Liquid Level

Particularly oil tanks installed below ground or in cavities level require monitoring devices, which can be installed on the top of the tank, to visually monitor the liquid level. - External Installation Liquid Level

Liquid level monitoring, particularly in tall oil tanks, pressure tanks or large oil-filled housings requires liquid level monitors to be installed externally.

- Tank Top Installation Multifunctional Liquid Level / Temperature / Ventilation / Return Line Filtration

Temperature Monitoring

- Temperature switches and sensors for the measurement and monitoring of the operating temperature. Local or remote display with programmable outputs.

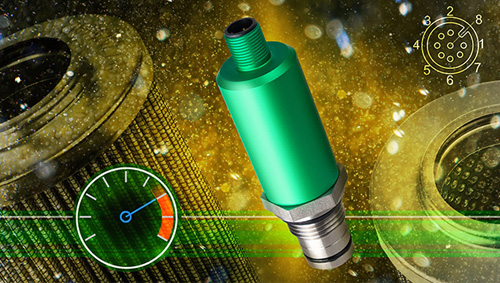

Pressure Monitoring

- Pressure monitoring in hydraulic systems is a parameter for the transmitted power. In lubrication systems, the monitoring of the system pressure indicates whether all lubrication points of the system are being sufficiently provided with lubricant.

Traditionally, conventional pressure switches, where metering points and displays are separated, transmitters and displays are connected by pipes or hoses.

Bühlers pressure measurement technology eliminates these connections and replaces them using flexible cables. This reduces the risk of leakage and the installation costs decrease significantly.

Display and Control Units

- The Multitronik product line provides a standardised menu and operating concept, to display and control the most frequently required measurement parameters in fluid technology such as temperature and pressure as well as if required, even liquid level. It was developed following the VDMA (German Mechanical Engineering Industry Association) standard specification 245741 and offers the users a number of advantages. Compared with traditional displays (which mainly use brackets or separate installation aids) the Multitronik controllers benefit significantly from the rail mount technology.

Water alarms

- Physical or electronic devices for reporting or measuring free water or relative moisture in oil. Moisture sensors with local or remote display.

Oil condition sensors

- A hydraulic system or lubricating system working properly among other things essentially depends on the fluid choice and quality. Both subtle processes such as the ingress of moisture through air or even sudden errors in the system along with contamination with foreign substances can cause the fluid quality to deteriorate, resulting in costly damage to the unit or tool.

Continuous oil condition monitoring is therefore of utmost importance to extend the system life and optimise oil change intervals. Bühler Technologies offers a wide range of stationary measuring instruments which remain in the system for a variety of oil and lubricant quality parameters.

Filter Monitoring

-

The off-line filtration is often the only effective option for keeping hydraulic fluids at a certain purity level. In the off-line circuit, a circulation pump is combined with a correspondingly sized filter and the oil is circulated under constant conditions irrespective of the flow rate in the overall system. These off-line filters also work if there is absolutely no oil being pumped in the main system.

The product line includes small compact standard units as well as subsystems arranged according to customer specifications.

Approvals/Customised Solutions

- IO-Link

IO-Link - a globally standardized IO technology (IEC 61131-9) for the integration of sensors in digital communication systems with reduced engineering effort and minimal hardware requirements. Find out more about our IO-Link products. - Approvals

The machine tool industry, the marine and offshore industries, or hazardous areas require specifically designed and approved equipment. We offer for such areas a broad range of equipment approved by different classification bodies. - Customised solutions

Professional operating production Companies very often reduce the number of suppliers by setting up internal standards for various equipment. OEMs also standardise on a very narrow range of equipment to increase the purchase volume and impact of service. This chapter carries a number of customer released products. Since this is an ongoing process, please contact our factory for the actual status.

- IO-Link

Oil/water coolers

-

The most effective coolant to stabilise the operating temperature in oil operated systems is water. Internal cooling cicuits as typically found in large production facilities and other cooling water sources supply water at temperatures that provide sufficiant delta T compared to the oil input temperature.

The BWT plate heat exchangers provide a very effective heat transfer. Thanks to the compact plate assembly and the sophisticated profiled plates, we achieve specific outputs which lead to significantly smaller dimensions compared to traditional shell and tube heat exchangers.

Oil/air coolers

- A complete product line for efficient temperature stabilisation using ambient air in oil systems. Robust cooling matrixes and energy-efficient low noise fans are the key components of these low-maintenance designs. Combined with compact gerotor pumps, they are the basis for efficient cooling circuits, cooling filter circuits or subsystems.

Off-line filters/coolers

- The auxiliary circuits described in the chapter Off-line filtration frequently are combined with the required oil cooler. The advantage of this arrangement is that as a result of the constant flow rates in such off-line units, the required cooler size can be determined more precisely and can often be designed smaller.

Off-line filtration

- The off-line filtration is often the only effective option for keeping hydraulic fluids at a certain purity level. In the off-line circuit, a circulation pump is combined with a correspondingly sized filter and the oil is circulated under constant conditions irrespective of the flow rate in the overall system. These off-line filters also work if there is absolutely no oil being pumped in the main system. The product line includes small compact standard units as well as subsystems arranged according to customer specifications.

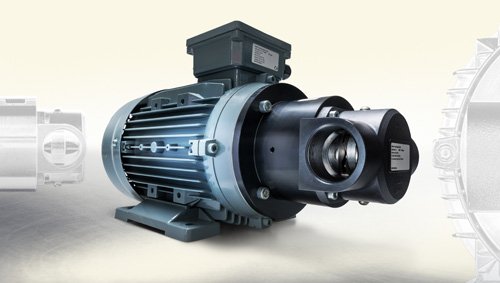

Circulation Pumps

- External filter and/or cooling circuits require circulation pumps with low noise emissions and limited pressure ripples. Gerotor pumps are a perfect solution for such applications. This design principle combines low noise emissions with limited susceptibility to solid contaminiation.

Industrial Filtration

- The Filtration Group (formerly MAHLE Industriefiltration) offers a wide, comprehensive range of filters for custom solutions. Products range from components such as filter elements, bag and cartridge filters to filter housings and modules all the way to complete filtration systems. As long standing premium partner of Filtration Group, the company supports Bühler Technologies in always defining the optimal filtration product for your application. During this process we rely on the complete range of fluid products of the Filtration Group, which includes suction filters, pressure filters, duplex filters, bypass filters, return filters, vent filters and air filters as well as standard and DIN versions of filter elements. Other products offered are contamination indicators, oil separators and many quality products.

Subsystems

- We design and manufacture subsystems, to complete your systems. We concentrate on applications focused on temperature stabilisation (heating/cooling), filtration and sensors/controllers. The extent of such systems can, if necessary, be limited to mechanical assembly but can also include complete electrical control and/or wiring. The supply of complete installation units is also possible.