Danfoss A/S

- Offer Profile

- Your one-stop partner for industrial control components and systems. Through Danfoss Industrial Automation, you gain access to the entire Danfoss pool of technology, with a special focus on monitoring or control of pressure and temperature, and fluid control. We take pride in the diversity of our markets, and we have a long tradition of serving some of the world's most demanding industries. Reliability, durability and innovation are therefore key ingredients in every product offering.

Product Portfolio

Valves

BM shut-off diaphragm valve

- BML is a manual shut-off valve designed for installation in the liquid, suction and hot gas lines of refrigeration plants. The valve can be delivered with flare, ODF solder or ODF solder with extended ends. In the same product category, BMT 6 is a three-way manual shut-off valve with similar characteristics.

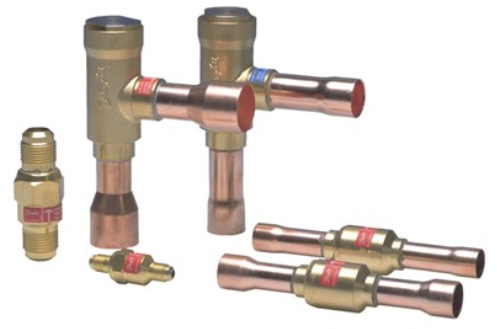

Check valves

- Danfoss offers NRV check valves for a wide range of refrigeration applications. You will also find a range of VCH check valves for high pressure pump applications.

Control and regulating valves

- Find a wide range of valves for control and regulation within industrial refrigeration applications. The Danfoss ICV Flexline™ platform for industrial refrigeration.

Electric expansion valves

- The Danfoss portfolio of electric expansion valves consists of solenoid expansion valves and stepper motor expansion valves, including versions for CO₂ systems.

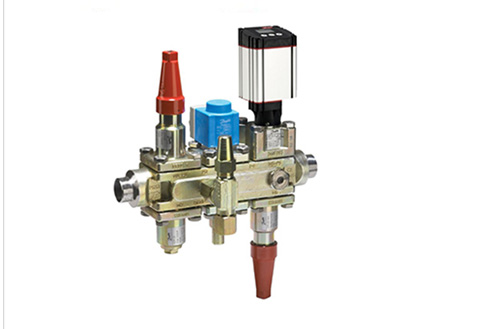

ICF Flexline™ valve station

- Unmatched freedom is the keyword of ICF Flexline™ valve stations. As part of the Flexline™ platform, these valve stations are based on a unique modular concept.

Externally operated valves

- Externally operated valves are designed for more specialized applications, such as: media with high dirt content, media with high viscosity, high ambient temperatures, large flow quantities, damp environments and where there is a risk of explosion.

Pressure relief valves VPH/VRH

- Reliable pressure relief valves for high-pressure applications. The relief valve is used for protecting the components of a system against overload as a result of a pressure peak.

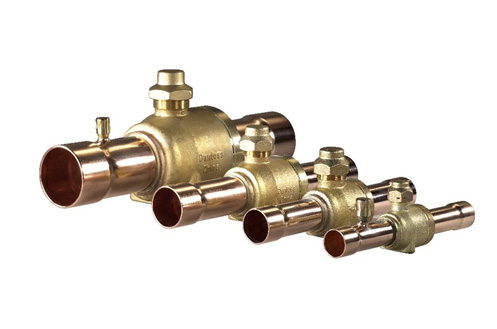

Shut-off ball valves for refrigeration, GBC

- GBC ball valves are manually operated shut-off valves suitable for applications where bi-directional flow is a requirement. GBC valves are approved for applications in liquid, suction, and hot gas lines in refrigeration and air conditioning systems.

Solenoid valves

- Find solenoid valves for refrigeration applications - EVR and EVUL. Also the industrial solenoid valves from Danfoss covering a wide range of valves for industrial applications.

SVL Flexline™

- SVL Flexline™ product platform targeted to meet industrial refrigeration requirements. The range cover five different functions with just two valve models.

Thermostatic expansion valves

- Thermostatic expansion valves (TXV) are available as parts programs, i.e. with separate valve body and orifice assemblies, or as complete valves (fixed orifice). The category also contains thermostatic injection valves.

Thermostatic valves

- Thermostatic valves are a simple and reliable control solution requiring neither electricity nor control air. An example of application is automatic control of water temperature in cooling systems.The valves are available with remote or built-in sensor.

Hydronic balancing and control

- The most efficient cooling or heating installation can only be realized by ensuring optimal hydronic balance and perfect temperature control. We have years of experience in this area and we can supply high quality solutions that are innovative and easy to use.

Motorized control valves and actuators

- Motorized control valves ensure perfect control and efficiency for every building and application. Danfoss Motorized Control Valves (MCV) for district heating and cooling, HVAC and central heating systems ensure stable and accurate control of water, glycol mixtures and steam.

Shut-off ball and butterfly valves for district energy

- Shut-off ball valves are the components that provide on/off regulation of the district heating application. In every district heating utility, combined heat and power plant, distribution network and substation, there is a need for on/off control of the building system connection.The on/off regulation enables the carrying out of service, maintenance and repairs to the system by allowing it to be shut down for a period of time.

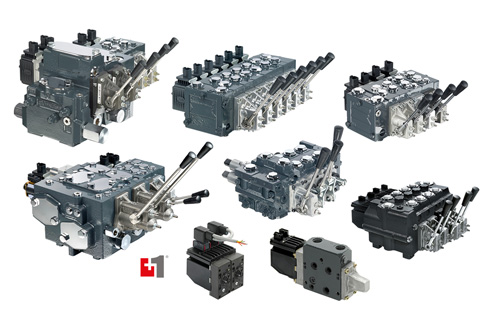

PVG proportional valves

- PVG electrohydraulic valves provide an almost infinite number of configurations – from simple load-sensing solutions to CAN bus communication – ensuring smooth machine control.

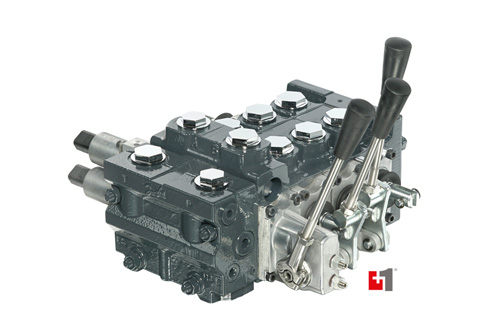

DCV directional control valves

- Reliability, robustness and efficiency are a must when choosing the right valve solution for your machine.

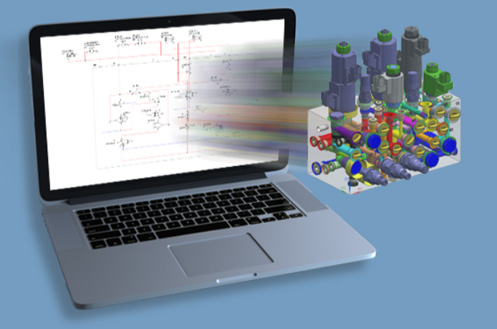

ICS cartridge valves and HICs

- Integrated Circuit Solutions (ICS) cartridges and manifolds offer an unlimited number of high-quality solutions that can be customized to meet your specific machine’s requirements.

Pumps

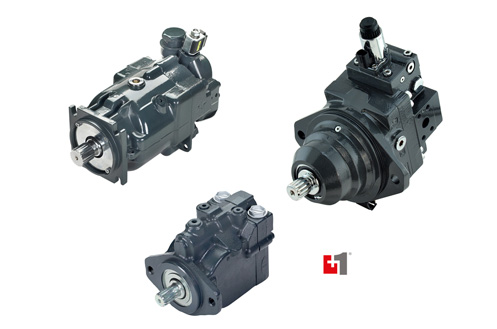

Hydrostatic Pumps

- Trust our compact piston pumps to give your transmission the power it needs with the low emissions that satisfy todays global regulations. Performance, power density and functionality are standard features of our axial piston pumps for the diverse off-highway mobile market. We have the displacement, configuration and control option to suit your specific open or closed circuit system.

High-pressure pumps for reverse osmosis applications

- High-pressure pumps for land based, off-shore and marine reverse osmosis applications

High-pressure pumps for tap water applications

- High-pressure pumps for tap water applications: PAH high-pressure pumps for water hydraulics, dust suppression and firefighting applications. PAH-F high-pressure pumps for only firefighting applications.

High-pressure pumps for chemical solvent applications

- The Danfoss PAHT C pumps are engineered to handle chemical solvents at high-pressure. The pumps can meet the needs for various applications demanding low or high chemical concentration.

High-pressure pumps for ultra pure water applications

- High-pressure pumps for ultra-pure water applications i.e. with de-ionized, de-mineralized or distilled water. Appropriate for critical applications such as high-pressure cleaning and humidification.

High-pressure pumps for ZLD and MLD reverse osmosis applications

- The APP W HC pump is suitable for ZLD and MLD reverse osmosis applications used in industrial wastewater treatment.

High-pressure pumps for gas turbine applications

- The PAHT G pumps have been designed to meet the high demands within the gas turbine market. The pumps operate on ultra-pure water.

Motors

Hydrostatic motors

- Our motor family allows top design flexibility whether you are looking for high sophistication or simplicity itself. Designed for intelligent vehicle management systems, our range brings you closer to your goals for reduced fuel consumption and high operator comfort. Our motors fit low, medium and high-power applications, including single and dual path propulsion drives and closed loop auxiliary transmissions.

Orbital motors

- The Danfoss orbital motor range is the broadest on the market. It's your safest bet for quality, durability, efficiency and reliability.

Electric motors

- Electric motors for vehicles, machines and marine applications.