- Offer Profile

- Renewable energy from

biogas plants

The number of our locations is growing continuously. The reason for this is that the advantages of biogas spread among governments, farmers and investors. But it is also because potential plant operators prefer searching for experienced partners.

EnviTec Biogas AG covers the entire value chain for the production of biogas - including the planning and turnkey construction of biogas plants as well as their commissioning.

The company provides the biological and technical service, and also offers full plant and operating management.

BIOGAS

-

BIOGAS - The allrounder among renewable energies

Whether as a source of electricity to generate heat locally, to supply heat by pipeline or to feed into the gas network after processing - Biogas is multi-talented and versatile. The weather-independent generation is a predictable source of revenue for the operator, since energy from biogas is not subject to any price fluctuations. At the same time, a biogas plant actively contributes to environmental protection and energy mix of the future.

THE ADVANTAGES OF BIOGAS AT A GLANCE:

- Multifunctional

- Generation of electricity

- Generation of heat and coldness

- Conversion to natural gas

- Highly efficient

- Highest energy recovery amongst all biomass project types

- Use of the whole crop in comparison to other bio fuels

- Variety of feed-stocks can be processed (e.g. organic waste)

- Storable and available

- Peak load capability

- Base load capability

- Power generation unrelated to weather conditions

- Output

- Clear net positive carbon footprint

- Suitable for the development of decentralised energy supply

- Fermentation residues suitable for premium fertilize

HOW DOES A BIOGAS PLANT WORK?

The basic principle of a biogas plant is relatively simple. Renewable raw materials from agriculture, animal droppings, residues from the food and agro-industry, can be used as input materials.

In airtight fermentation vessels - the so-called digesters - a fermentation process is stimulated and produces biogas using bacteria. The bacteria are similar to those which can also be found in the digestive tract of a cow. Main products of anaerobic degradation are energy-rich methane and carbon dioxide. Since both are gaseous, they separate from the fermentation substrate and form the main components of biogas. Carbon dioxide is not oxidized, but then can be supplied together with the energy-rich methane cogeneration power stations of combustion and fed into each locally existing heat network. - Multifunctional

BIOGAS: Agricultural biogas plants

-

BIOGAS IN AGRICULTURE: Energy, fertiliser and an additional source of revenue.

Agricultural companies have the opportunity of generating valuable, sustainable and renewable energy with by-products of their business such as liquid manure, biomass and organic agricultural waste. Generating biogas offers plant operators a source of revenue that can be accurately calculated for years – which is a factor that can be decisive for the long-term prospects of a farming business.

Long-term prospects for farms

Many farmers use biogas production to establish a second economic mainstay, thereby ensuring that their agricultural enterprises continue to flourish into the next generation.

No monocultures

All types of agricultural raw and residual materials can be used in our biogas plants. This assures farmers a healthy crop rotation and helps them prevent monocultures. Even catch crops, whole-plant silage and energy beets deliver top yields.

Added value for the region

Decentralised biogas production using independent resources strengthens the added value in rural areas. Using renewable resources effectively reduces the dependence on foreign energy imports, so that revenues remain in the region. More and more bioenergy villages are showing us how biogas can be used to get the most out of local synergies.

Valuable fermentation residues without smells

If a biogas plant is operated properly, there are no odour nuisances, since the produced gas cannot escape from the closed cycle. The fully fermented end product has a noticeably reduced odour after the fermentation process. As a fertiliser with a high nutrient content, these fermentation residues relieve farmers from purchasing expensive mineral fertiliser.

ENVIFARM BIOGAS PLANTS

-

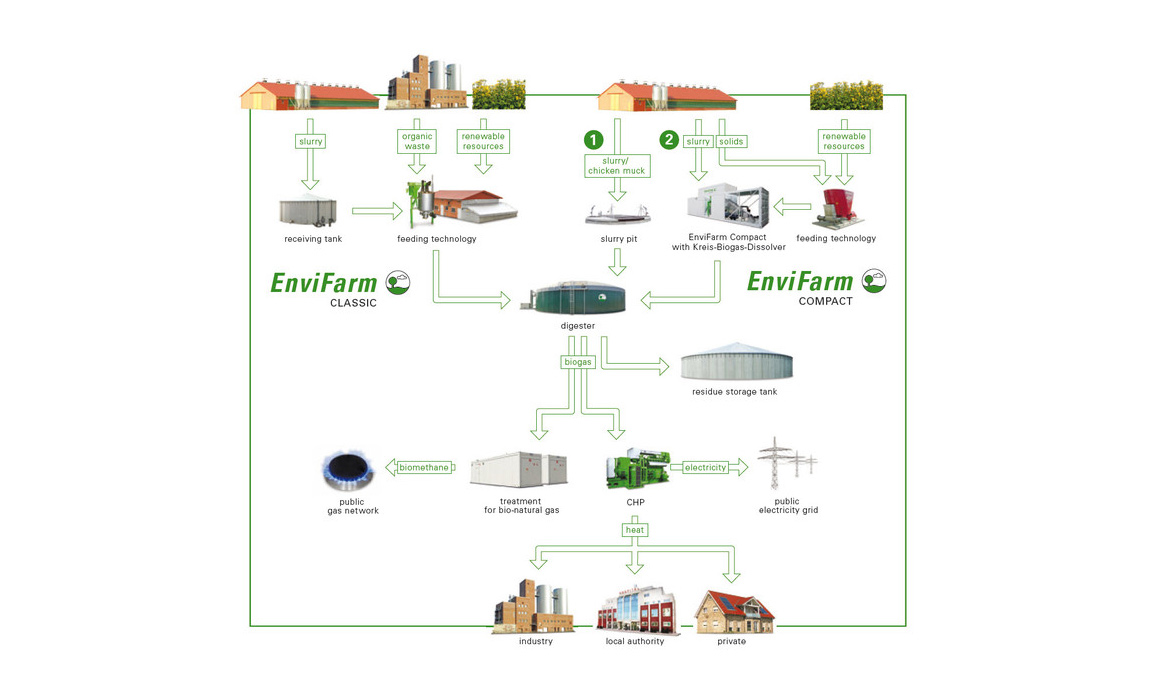

ENVIFARM BIOGAS PLANTS: Our solution for the agricultural sector

Our field-tested EnviFarm biogas plants offer you a flexible choice of input materials, and are tailored individually to your business and your specific requirements. As an alternative to being run as slurry-only plants, you can also operate them with biomass or with any type of organic waste. The stable and spacious technical building offered by an EnviFarm plant allows optimum temperature control with innovative ventilation technology, plus weather-independent operation and storage.

EnviFarm is equally impressive in its compact version (plant output from 75 kWel). The modular, container-based format means EnviFarm can be installed as a compact plant that makes the most of available space. Whatever the model, all our biogas plants have one thing in common: impressively high efficiency and maximum profitability.

YOUR ADVANTAGES AT A GLANCE

- Optimum safety and dependable EnviTec quality

- A made-to-measure match for your business

- High plant efficiency (gas yield up to 9% higher thanks to patented Kreis Biogas Dissolver)

- CE marking for EnviTec’s scope of delivery

- Technical customer service and biological service from a single source

Driven by our technological farsightedness and the very highest quality standards, we’ve been researching additional technologies capable of optimising biogas plant usage from the very start. And this hard work has paid off: our ‘Kreis Dissolver’ mixing system offers impressively high substrate savings and higher gas yields, for example. Our EnviTec Feedcontrol feeding system maximises the capacity utilisation of your biogas plant, saving you valuable input materials.

AGRICULTURE 2.0

-

Smart investments and innovative models for successful producers in the biogas market

Those who opt for a biogas plant have learnt early on that it is not only the scope of such a project that presents a challenge. Even an intelligent energy concept and cooperative integration of the vicinity and environment require an intensive discussion.

The following projects show how we have used completely different starting scenarios to build a single, successful model.

High efficiency and competitive edge thanks to free-of-charge waste heat

-

- Location: Wöbbelin (Germany)

- Capacity: 2 x 526 kWel

- Input materials: Manure, renewable resources

- Features: All the waste heat of the biogas plants is used for heating the farm’s greenhouses and buildings.

Integration of the environment – flagship project for entire region

-

- Location: Stowell Farms, Wiltshire (England)

- Capacity: 499 kWel

- Input materials: Manure, grass and maize silage, feed remains

- Features: Processes the slurry of 500 herds of cattle into high-quality fertilisers.

A small slurry plant in Italy – ecologically useful and profitable

-

- Location: Casaletto Ceredano, Lombardei/Italy

- Capacity: 249 kWel

- Input Materials: Pig slurry, maize meal

- Features: The power is fed into the public grid. The heat generated is used for heating the digester.

Biogas: Waste to energy plants

-

ENVIWASTE - Turning waste into biogas

Waste materials and by-products are accrued in conjunction with every single manufacturing operation, such as enterprises associated with the food and restaurant sector, the fuel industry, the cosmetics sector and the animal husbandry sector. However, the quantity of organic waste produced by the citizenry is also significant for communes – about half a tonne per year per person. In addition to saving you the trouble of disposing of your residual products, our biogas technology also makes it possible for you to convert the waste into useful energy.

ADVANTAGES FOR PRODUCERS

- Own energy from cogeneration : electricity, steam and heat

Biogas can be used as a source of electricity or to generate heat. After it has been processed into biomethane, it may also be fed into the gas grid. In case of industrial utilisation, the heat that accrues in conjunction with the combustion process taking place in the CHP can be returned to the company in the form of process heat. This is particularly worthwhile for energy-intensive companies with high heat requirements. It makes it possible for such companies to save on heating expenses. - Odor-free, natural fermentation residues for agriculture

If a biogas plant is operated properly, there are no odour nuisances since the produced gas cannot escape from the closed cycle. The fully fermented end product has a noticeably reduced odour after the fermentation process. As high-nutrient fertilisers, these fermentation residues make it unnecessary for farmers to purchase expensive and pollutant mineral fertilisers. - Filtering and cleaning the digestate residues to process water

Ultra-modern filtration technology makes it possible to further process the digestate. This procedure yields processed service water that can be used for the subsequent industrial process. - Improved CO2 balance

Thanks to the high energy yield in the EnviWaste plants, the required amount of fossil fuels undergoes a reduction, resulting in a considerable improvement in the CO2 figures of production plants. This gives you an important competitive edge, as more and more consumers and companies are emphasising sustainable production when purchasing products.

- Own energy from cogeneration : electricity, steam and heat

Waste materials from the industrial, business and

agricultural sectors- Many different organic waste materials are well-suited for being used as raw materials for the production of biogas. When used in conjunction with the right technology as high-value substrates, food and restaurant waste, green waste, glycerine, slaughterhouse waste and botanical and animal fat can lead to an impressive income. In this regard, the advantage that residual materials have over other input materials which appear to be equally attractive from an energy-related point of view is the fact that these residues do not require any cultivation areas.

Unpacking and cleaning the waste materials

- Even packaged waste can be used for biogas production following an automatic separation from its casing. It must also be cleaned, in order to ensure that it is harmless (from the point of view of hygiene) and is free of pathogens. Waste fermentation plants are subject to stringent technical requirements, since plastic packages and the like are non-recyclable and must be removed before the fermentation process is carried out.

Pre-processing and disintegration

- In order to ensure that the raw materials are fermented in the best possible manner, they must be broken down to the highest possible degree. Our patented Kreis-Biogas-Dissolver optimally mixes and shreds the input materials to a fine dimension, thereby increasing the biogas output. Various other mixing devices ensure that substrates of varying consistencies can be fed in.

Production of biogas in the digester

- In the heated and air-tight digester, the biomass ferments in conjunction with the production of methane, the so-called biogas. The resultant residual product, i.e. the fermented biomass, can be used instead of expensive mineral fertilisers as a low-odour, natural fertiliser in the agricultural or horticultural sector. The filtration of the fermentation residues can also yield process water.

Combustion of the biogas in the CHP

- The biogas is incinerated in the combined heat and power plant (CHP), and electricity for which compensation can be obtained is generated. The accruing heat can either be returned to the respective company or fed into the district heating grid. The CHP can be regulated in terms of its utilisation. Consequently, it can correspond to various remuneration regulations and be complemented through other heating concepts.

Production of electricity, heat, bio-natural gas and fuel

- Biogas can be used in a variety of ways: It can be used to produce electricity and heat for private residences, and it can also be used to supply public buildings or the selfsame manufacturing company. Apart from that, biogas can be channelled into the gas grid after it has been processed into biomethane. It can also be utilized as a fuel that may, for example, be used to facilitate motor vehicle transportation or the actuation of in-house motors.

SUSTAINABLE REUSE OF WASTE MATERIALS?

-

Benefits for manufacturing and municipalities!

Several companies and communes make use of the financial assistance that the political system provides for the realisation of the energy-related potential of waste management or just benefit from producing their own energy. Since the year 2002, we have developed technologies for biogas plants that produce impressive income from food waste, glycerine, slaughterhouse waste and fats.

Prize-winning biogas plant in the USA

-

- Location: Stanley, New York

- Capacity: 541 kWel

- Input materials: Manure from 1,500 Holstein dairy cows, feed refusal, yogurt processing wastes, food waste

- Features: Since 2014, the average degree of capacity utilization exceeds 91%.

Waste material recycling with a small footprint

-

- Location: Kishiwada, Osaka (Japan)

- Capacity: 249 kWel

- Input materials: Food Waste

- Features: Complete container solution, Power to the public grid, Heat utilization by the adjacent factory

Unpacking and cleaning of waste materials in Ribeauvillé (France)

-

- Location: Ribeauvillé (France)

- Capacity: 1,4 MWel

- Input materials: Cattle slurry, renewable resources, waste materials from the food industry

- Features: Separate hygienisation plant with a capacity of 25,000 t/a.

Heat and electricity for L’Oreal

-

- Location: Libramont (Belgium)

- Capacity: 3,2 MWel

- Input materials: Maize, food waste, fats

- Features: The plant in Libramont is unique in that it completely utilises the generated electricity

- and the heat that has been transformed into vapour within the factory itself.

BIOGAS: Repowering

-

EFFICIENCY FOR YOUR BIOGAS PLANT

You want to get the highest return of your investment? So do we!

Research and innovation is a constant process at EnviTec Biogas and, thanks to our engineers, the customer is always kept up to date of the latest technological progress to improve plant efficiency – whether that be decreases in feed input with the same gas yield or expansion of the site’s energy output and upgraded gas production.

Your system can be most easily adapted to the latest technological developments. An investment in the "health" of your biogas plant is worthwhile, because it usually pays for itself in a short time.

Depending on the plant quality we offer

- Technology for better utilization of different input materials

- Technology for the reduction of operation costs

- Technology for a higher energy output

- Technology to maximize storage capacity

- Technology for biogas upgrading by EnviThan

BIOMETHANE - The renewables all-rounder

-

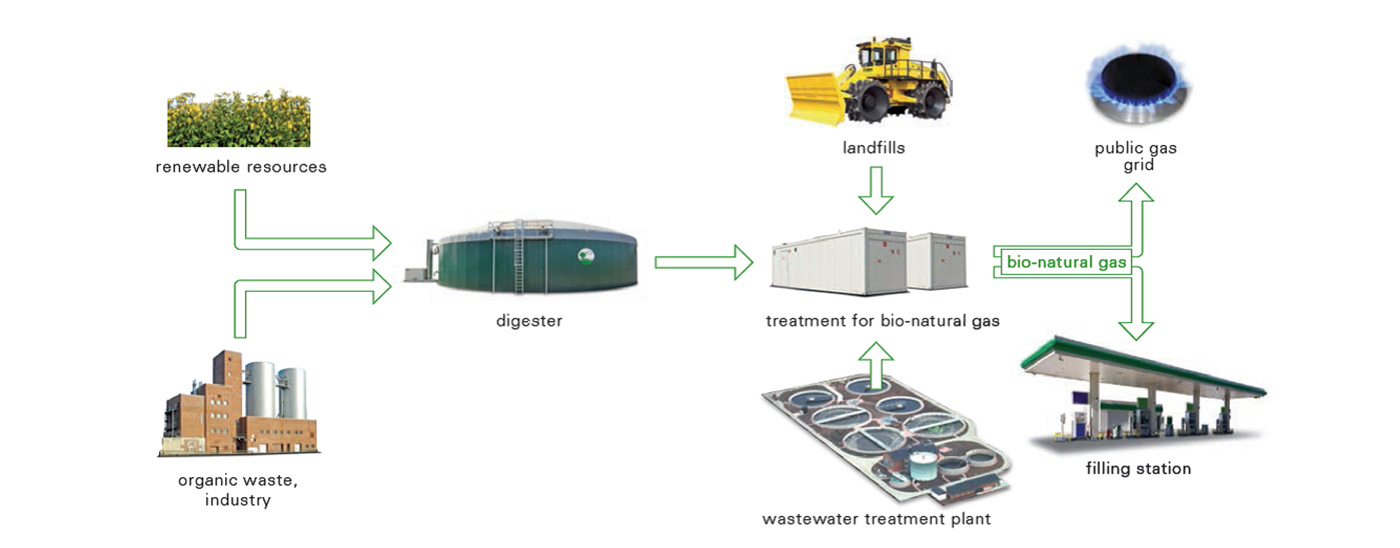

Biomethane upgrading opens up a promising future market for the biogas industry. With feed-in into the public natural gas grid, the green all-rounder is perfect for the decentralised supply of energy, offering a long-term replacement for fossil natural gas and driving the energy transition forward. What’s more, the biomethane manufactured in the gas upgrading plant has the exact same properties as natural gas, being just as flexible in its usage and easier to store than other energy sources. Plus, it’s renewable.

How is this valuable bio natural gas produced?

Anaerobic digestion of organic materials creates a gas composed of methane and carbon dioxide. To upgrade the biogas to natural gas-quality biomethane, the crude gas is first purified and compressed. The membrane technology we use then exploits the different sizes and permeation speeds of the two kinds of gas molecules involved: since carbon dioxide molecules are smaller than methane molecules, they can migrate through the membrane much more quickly. As a result, the methane remains on the high-pressure side, while the CO2 molecules in the biogas pass through. As a result, the gas upgrading needs neither chemicals nor water nor any other resources.

The starting point for producing biomethane doesn’t have to be biogas, however. After a preliminary purification stage, gas from landfill and wastewater treatment plants can also be used to produce biomethane.

The biomethane so produced is the all-rounder among renewable energy sources, and can replace fossil fuel-based natural gas anywhere it is used. On the following pages, you can find out about the many uses for this valuable and renewable natural gas, and how it can play a part in an environmentally-friendly energy supply system.

THE ADVANTAGES OF BIOMETHANE AT A GLANCE:

- FLEXIBILITY OF USE

Whether in the home, as a carbon-neutral fuel (CNG) for the transport sector or converted on-demand into electricity and heat, biomethane is a true all-rounder that can also be used in a decentralised system - INDEPENDENT

Biomethane frees us from our dependence both on fossil natural gas and natural gas importers, thereby helping to support predictable long-term pricing trends in domestic energy market. - EXCELLENT PUBLIC ACCEPTANCE

Biomethane is renewable. This means heating consumers benefit from an improved CO2 footprint and potential savings resulting from the more efficient use of energy. As a highly efficient fuel, biomethane is also a star performer in the fuel market and can help to reduce emissions many times over. - STRONG MARKET POTENTIAL

Since crude gas sources and gas grid infrastructure are both available, neither time nor capital investment is necessary to establish them. On the contrary: the use of biomethane can unburden the electricity network and contribute to a temporary easing of cost-intensive upgrading work. - REGIONAL VALUE CHAINS

Biomethane promotes economic growth both in the feed-in region – which is in the immediate vicinity of the gas generating plant – and in the consuming region, which is independent of the feed-in location. - AN ADDITIONAL PILLAR FOR YOUR BUSINESS

Since our gas upgrading systems are exceptionally efficient and cost-effective, they can offer biogas plant operators another attractive source of revenue from biomethane production.

- FLEXIBILITY OF USE

Technology

-

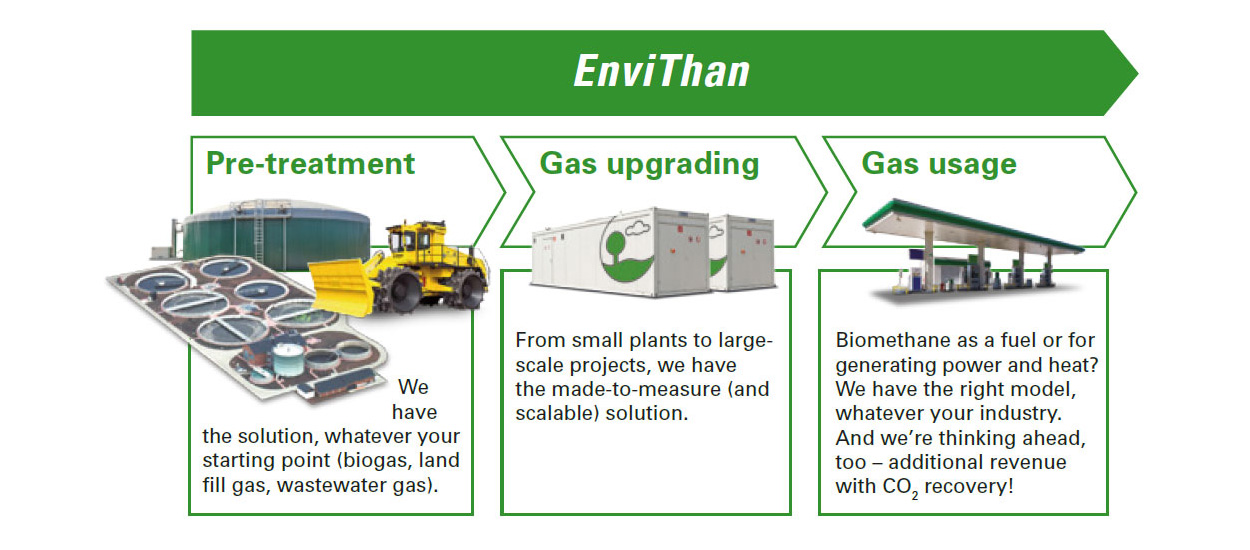

ENVITHAN GAS UPGRADING - Refreshingly simple and flexible

Our EnviThan concept offers an all-round carefree package. We provide you with an integrated solution from pre-treatment and raw gas purification, the treatment of biogas in biomethane quality to the final utilisation of the gas.

EnviTec Biogas - a strong partner from start to finish.

OUR SOLUTION AND YOUR ADVANTAGES AT A GLANCE:

- INTEGRATED MODEL

Our EnviThan model offers you a tailor-made solution along the entire value chain, from the initial pre-treatment of your raw gas, gas upgrading into biomethane, various options for gas marketing (CNG, electricity, heat), and all rounded off by our comprehensive after sales service.

- STRAIGHTFORWARD, COMPACT AND MODULAR DESIGN

EnviThan gas upgrading is simple and robust while also being compact and space-saving. The components for desulphurisation, compression, condensation, filtration and gas purification are installed in self-contained modules. Thanks to its modular design, the technology can be installed quickly and easily, and flexibly adapted to the specific quality standards and performance capacities of each operator. The system is also designed to ensure impressively low maintenance costs. The modular construction of an EnviThan plant also offers plenty of reserve capacity, making subsequent expansion of the plant easily possible.

- STRONG PARTNER

We use SEPURAN® Green modules from Evonik Industries for the membrane separation process in our gas upgrading plants. These hollow-fibre membranes purify the raw biogas generated in the biogas plants from 50 to over 97 percent by volume – a very high figure compared with other technologies. The successful partnership between EnviTec and Evonik is not only reflected in the fact that we are the world’s largest buyer of these leading Evonik modules, but also in the fact that EnviTec is the only company worldwide that operates an internal gas upgrading plant for the purpose of carrying out R&D into these innovative membrane systems. - RAPID CONTROLLABILITY FOR SHORT START-UP TIMES

EnviThan gas upgrading plants are equipped with a high number of sensors to guarantee optimal analysis and evaluation of the process. Quality fluctuations, e.g. in the raw gas quality or due to external influences, are immediately detected and can be precisely regulated. This ensures a constant feed-in quality. Our gas upgrading plants have short start-up times and can be quickly adjusted to changes in volume flow rates thanks to good controllability. This guarantees the simple and flexible operational management of EnviThan plants. - EXTREMELY EFFICIENT

Compared with other approaches to biogas upgrading, EnviThan technology requires less energy, which ensures its running costs stay as low as possible. Nor does this gas upgrading method require any chemicals, water or other resources. Much of the heat generated during the upgrading process can also be recovered and utilised. Compared with other methods – such as amine scrubbing, pressure swing adsorption or high-pressure water scrubbing – it is also inexpensive and environmentally friendly since it produces no wastewater or emissions. - DIVERSE REVENUE OPPORTUNITIES

The demand for sustainably produced LNG is increasing. If biomethane, which is produced and liquefied from waste materials in accordance with the REDII directive, is used as bio-LNG in heavy-duty transport, additional revenue opportunities will arise through certificate trading. Due to the process, membrane technology already delivers high-purity CO2, which can thus be marketed as a second product gas. - TOP QUALITY AND MAXIMUM SAFETY – MADE IN GERMANY!

Quality is our top priority at EnviTec Biogas. To ensure we can meet our high standards at all times, all EnviThan plants are designed and built at our facility in Saerbeck (Germany). In addition, we also work only with hand-picked suppliers that share our commitment to quality – and our business relationships with these suppliers now go back many years. - SEASONED EXPERTISE

Apart from the efficiency and technical quality of our gas upgrading systems, our long-standing international expertise in biogas plant construction is another reason why customers worldwide entrust their projects to EnviTec. Germany, UK, France, China, Estonia and Denmark – EnviThan is conquering the gas upgrading market on a global scale. - SOLID FINANCIAL BASIS

EnviTec Biogas has been listed on the Frankfurt Stock Exchange since July 2007. The EnviTec Group’s strong financial background offers financial peace of mind to investors, customers and partners. The high standards of reliability we set ourselves is also reflected by our business model: investment in our own, internally operated plants enables us to pursue the continued improvement and optimisation of our technologies, and to offer our customers high levels of reliability and efficiency for their own plant operations.

- INTEGRATED MODEL

Possibilities of utilizing biomethane

-

BIOMETHANE - The all-round talent

From a macroeconomic and climate perspective, biomethane is now the most cost-effective, climate-friendly fuel for achieving progress towards climate targets and sustainable transport in Germany and the EU. The all-round talent is virtually carbon-neutral and can be stored, which means it is continuously available, making it attractive not only for the transport sector!

In addition, the all-rounder can be used wherever fossil natural gas had been used: this includes CHP applications, demand-based power and heat generation and use as a material in the chemical industry. Biomethane is therefore an important building block of the energy transition.

Progressive fuel

-

The advantages of bio-LNG (liquefied natural gas) as a carbon-neutral fuel are obvious: in the transport sector alone, the use of biomethane allows a CO2 reduction of up to 97 percent compared to fossil fuels.

For this reason, we are tapping into a new field of the future as a plant manufacturer by constructing Germany's first integrated bio-LNG plant, which will both make heavy goods transport greener and also allow biogas plant operators to profit. This is because the reduction in greenhouse gas emissions required of the German fuel mix by the Renewable Energy Directive RED II means that green fuel production is being implemented ambitiously for the first time. As a result, those placing fuels on the market must now cut their GHG emissions by 25 percent by 2030 compared with 1990 levels.

Following the expiry of state subsidies for biogas plants, our all-round concept for gas treatment offers a sustainable solution for the profitable continued operation of existing plants through the sale of your biomethane or potentially its contract liquefaction into bio-LNG.

Heat

- To boost the share of heat from renewable sources to 14 percent by 2020, using biomethane in combined heat and power (cogeneration) plant is one of the most sustainable technologies currently available. Especially in cases where other kinds of renewable energy technologies or measures to reduce energy requirements are not deployable to the extent needed for structural reasons, the use of biomethane in heating-only applications is a useful alternative.

There are several usage models for biomethane-based heating. Typical consumers are the plant operator’s own property or business premises, housing complexes or public facilities fed via heating grids, as well as horticultural, commercial and manufacturing companies. All of this makes biomethane an inexpensive and efficient renewable energy option on the heating market.

Electricity

- A reliable electricity supply requires a balance between electricity production and demand at all times. Accordingly, the load at any point in time must be met by a guaranteed level of (power generation) performance. As power generation from fossil fuels and nuclear power plants starts to be wound down, alternative solutions to provide this level of performance are required. Flexible power generation plants are a viable option here: these can respond quickly to changes in electricity generation from the fluctuating feed-in of renewable energy sources and handle the tasks required to secure the energy supply. The use of biomethane enables the provisioning of the relevant system services on the basis of renewable energy sources and so reduces the need for fossil-based power plants.

CO2 recovery

- The CO2 generated during biomethane production can be reused and liquefied. Ultrapure carbon dioxide offers an interesting additional source of revenue for plant operators, and can be utilised in a wide variety of industries (such as the food industry, in horticulture, for firefighting or in refrigeration plants).

GAS TO GRID - Our biomethane projects!

-

Cost-effective, efficient and reliable technology, plus smart business models that cover the entire value chain for the biomethane market. Our expertise is in demand worldwide.

Plant profile: Glamsbjerg, Flemløse

-

- Location: 5620 Glamsbjerg, Flemløse , Denmark

- In-service date: 2020

- Input materials: Maize and grass silage, solid manure, wet manure, straw, organic residues

Special features

- 850 Nm3/h adjoining biogas upgrading plant

- Biomethane is fed directly into the local grid

From the source to the steering wheel: EnviThan makes inroads into fuel market in China

-

- Location: Penglai City (Shangdong province, China)

- Capacity: 2 x 1000 Nm³/h biomethane

- Input materials: Poultry litter from the owner’s approx. 1 million head of poultry

- Features: This plant is the first biogas upgrading plant from EnviTec Biogas in China. Both of the structurally identical EnviThan upgrading systems, each with a capacity of 1.000 Nm³/h biomethane, deliver bio-CNG (compressed natural gas from biogas) as the end product of biomethane treatment. The bio-CNG is used as a green fuel in the company’s own filling station and in the nearby city of Yantai.

We make efficient technology even better - with our own R&D plant to ensure optimal results

-

- Location: Sachsendorf (Germany)

- Capacity: 350 Nm³/h biomethane

- Special features: Whatever our many successes, we don’t rest on our laurels. We work continuously on the further improvement and optimisation of our technologies. In the EnviThan demonstration plant that we run in Sachsendorf, Germany, the components and materials are operated to the limits of their capacity, and the results analysed in order to ensure an optimal plant design and control response while extracting the maximum possible added value and efficiency. Forward-thinking, reliable and efficient – EnviThan.

Energy for 2,150 households: our flagship project in Icknield (UK)

-

- Location: Ipsden, Oxfordshire (UK)

- Capacity: 700 Nm³/h biomethane + 360 kWel CHP

- Input materials: Pig slurry, farm by-products, energy crops

- Special Features: The plant is capable of supplying enough gas to meet the annual needs of around 2,150 households. The subsequent reuse of the digestate as fertiliser also helps to reduce the use of chemical fertilisers by local agricultural businesses.

Compact, modular design offers customers maximum flexibility: EnviThan gas feed-in France

-

- Location: Senlis (France)

- Capacity: 250 Nm³/h biomethane

- Input materials: Silage, sugar beet pulp, agricultural waste

- Special features: This is EnviTec’s first gas upgrading plant in France. Our Senlis-based customer enjoys multiple benefits from the compact, modular design used by EnviThan plant. Thanks to the quick and easy installation of the technical systems, the operator started feeding biomethane into the local gas grid after a construction period of just ten months. The modular design of EnviThan plants and the built-in performance reserves also offer a straightforward approach to expanding gas upgrading capacity.

Proven technology + reliable after sales service = satisfied customer!

-

- Location: Hammel (Denmark)

- Capacity: 1335 Nm³/h biomethane

- Input materials: Grass silage, sugar beet, straw, turkey litter and glycerine

- Special features:Our customer is Denmark’s largest land-owner, with over 10,000 hectares to its name. Apart from our efficient EnviThan technology, we also impressed the client as a solid partner with a portfolio of successful international references. EnviTec’s flexibility and the reliability of our gas upgrading plants, plus our comprehensive – and local – after sales service were decisive factors for winning this contract. And we continue to impress: the customer has already made multiple expansions to the plant.