- Offer Profile

-

Qimarox is a leading manufacturer of components for material handling systems. As a manufacturer of, among other things, palletisers, product lifts, pallet lifts, packaging machines and shielding systems, Qimarox distinguishes itself by its contemporary vision and approach, in which innovation, quality and added value are of paramount importance.

PALLETIZATION SOLUTIONS

Palletization Solutions – Palletizers

A palletizer or palletiser is a machine which provides automatic means for stacking cases of goods or products onto a pallet. In the past this was done manually, this was time consuming, expensive and hard labor for the workers. The first mechanized Palletizer was designed, built, and installed in 1948 by a company formerly known as Lamson Corp. Since then the original concept has been improved many times and nowadays you have a variety of different palletizing solutions. A few different palletizing solutions are:

conventional layer palletizers: high-level (high input) and low-level (low input) * High-level layer palletizers are constructed in such a way that the wooden pallet receives the layers of parcels on the floor, then goes down as the layers are added. * Low-level layer palletizers are built so that the wooden pallet remains on the lower floor, and the layers of packages are mounted higher and higher.

The other option is are the Palletizing robots. Palletizing robots are enclosed in a security zone to protect operators. A palletizing robot is equipped with one or more gripping heads to perform different tasks at a time.

The reason for these development is there is a variety of different materials to palletize. You can think of things like:

Bags, boxes, crates, tray’s and more. Each of these items have their own ways of handling. The one is more delicate then the other. Also the products inside of the items may vary a lot which also means they could need different handling. For example glass can break easily, while clothes cannot.The benefits of palletization

There are a lot of reasons why manufacturers choose to palletize their products. The main reason why palletization in logistics is so popular is because of the many advantages that it brings. That is also the reason why the pallet is now the standard unit load for warehousing and material handling. Benefits of palletization are:- Palletized products can be moved more quickly.

- Reduce the risk of product damage

- Faster turnaround of delivery vehicles.

- Less labor required.

- Perishable products are moved faster, reducing the risk of perishing.

- Palletizing is cost effective compared to traditional material handling

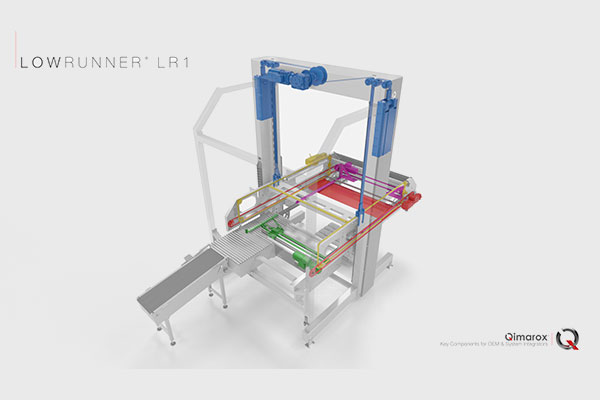

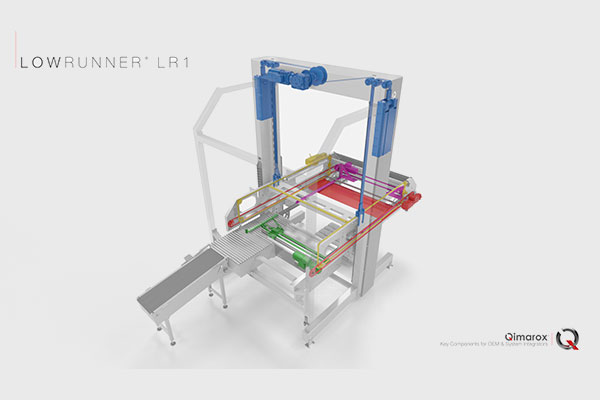

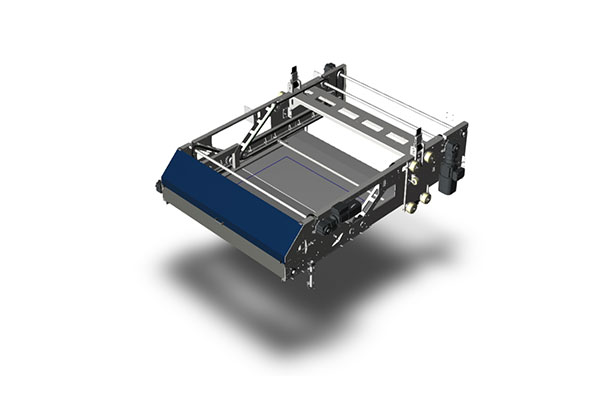

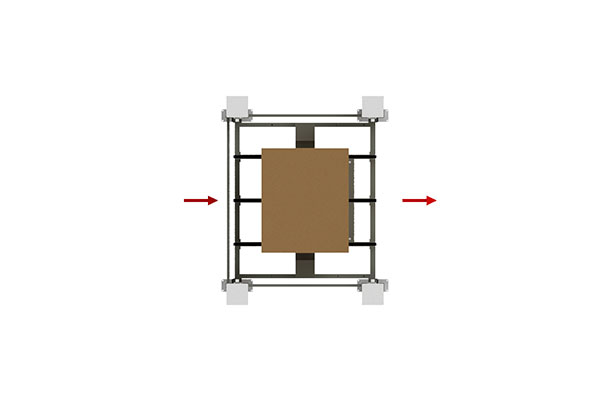

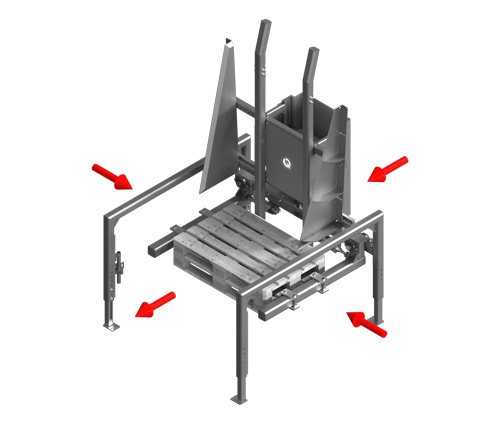

Palletizer Lowrunner LR1

-

The modular LOWRUNNER LR1 palletizer from Qimarox is a 5-axis palletizer with a capacity of up to 800 packages per hour. It is an entry-level model, suitable for an environment where rapid return on investment is desired or necessary. Optionally, the LOWRUNNER mk1 can also places the pallets and intermediate sheets by itself.

The modular LOWRUNNER LR1 palletizer from Qimarox is a 5-axis palletizer with a capacity of up to 800 packages per hour. It is an entry-level model, suitable for an environment where rapid return on investment is desired or necessary. Optionally, the LOWRUNNER LR1 can also places the pallets and intermediate sheets by itself. *NOTE: Delivery time to be discussed*

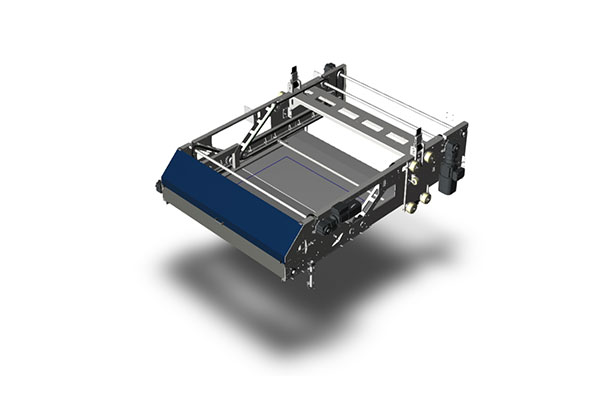

Low level infeed

With the Lowrunner LR1 there is no need for an operator platform as the complete layer formation station is placed at floor level. The unique Qimarox layer formation station can place every product on an exact location. This is done with a product pusher that places every product into a row of product. If a row is completed this row is placed onto the stacking plate. This is an unique feature as most low level palletizers handle products layer-by-layer. By putting the products row-by-row onto the pallet the floor space of the machine can be minimized.

By pulling out the stacking plate in two directions, to the front and back side of the pallet, a solid pallet load is guaranteed. Due to this solution the Lowrunner LR1 palletizer is very suitable for a large variety of products.

Pallet handling

As an add-on it's possible to handle empty pallets without adding additional system components or need for more floor space. A stack of empty pallets is placed underneath the layer formation station and can be picked up by the stacking plate. This functionality normally is only known in robotic palletizing solutions.

Intermediate sheets handling

The same system used to pick-and-place empty pallets can also be used for putting intermediate sheets between layers. Intermediate sheets can be used to increase load stability to a pallet. By using the Lowrunner LR1 modular palletizer from Qimarox with the ability to put down rows there is less need for intermediate sheets. This because the outside of the cartons are always perfectly outlined on top each other so the maximum strength of the carton is used.

The Lowrunner LR1 can handle a wide range of products:

- boxes

- boxes with lids

- trays

- trays with foil

- buckets

- crates

- jerrycans

- etc.

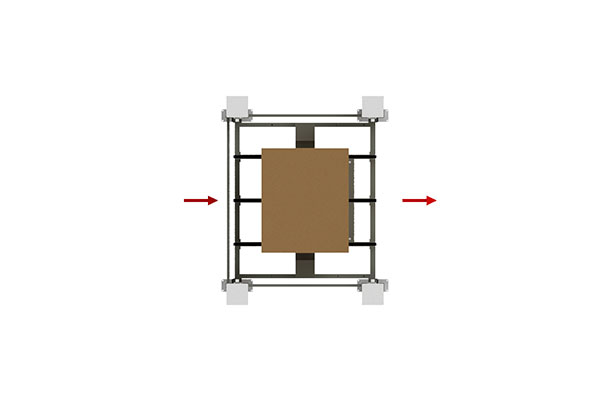

Palletizer Lowrunner LR3

-

Flexible palletizing

The modular LOWRUNNER LR3 palletizer from Qimarox is a palletizer with a capacity of up to 1,500 packages per hour. It is suitable for an environment where rapid return on investment is desired or necessary. Optionally, the LOWRUNNER LR3 can also be equipped with the Qimarox Sheetrunner to put intermediate sheets between layers.

The modular palletizer Lowrunner LR3 from Qimarox is a palletizer with a capacity of up to 1,500 packages per hour. It is suitable for an environment where rapid return on investment is desired or necessary. Optionally, the Lowrunner LR3 can also be equipped with the Qimarox Sheetrunner to put intermediate sheets between layers. *NOTE: Delivery time to be discussed*

Low level infeed

With the Lowrunner LR3 there is no need for an operator platform as the complete layer formation station is placed at floor level. The unique Qimarox layer formation station can place every product on an exact location. This is done with a product pusher that places every product into a row of product. If a layer is completed this layer is placed onto the bi-directional stacking plate. This is an unique feature as most low level palletizers handle layers with a single direction stacking plate. By using a bi-directional stacking plate to put layers onto the pallet the outline of the pallet will be very consistent to get the maximum strength out of a carton box and a solid pallet load is guaranteed. Due to this solution the Lowrunner LR3 palletizer is very suitable for a large variety of products.

The Lowrunner LR3 can handle a wide range of products:

- boxes

- boxes with lids

- trays

- trays with foil

- crates

- etc.

The Lowrunner is modular constructed. This means that several options are available for each module depending on the customer requirements and the products requiring palletization.

In short, you will end up with the system that best suits your needs. However, this system can be completely adapted to changing circumstances in the future thanks to the interchangeability of its modules.

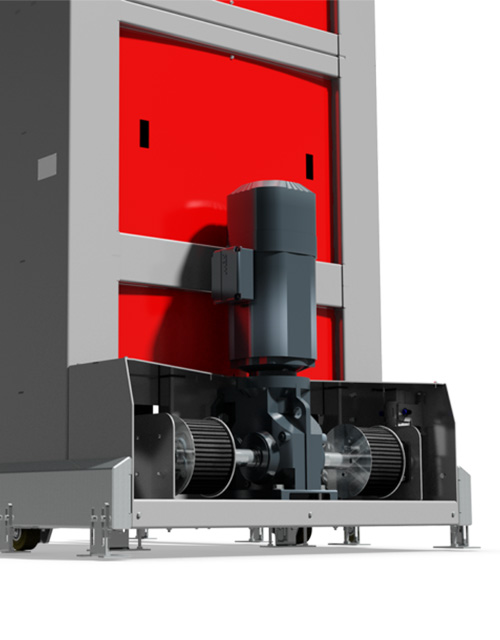

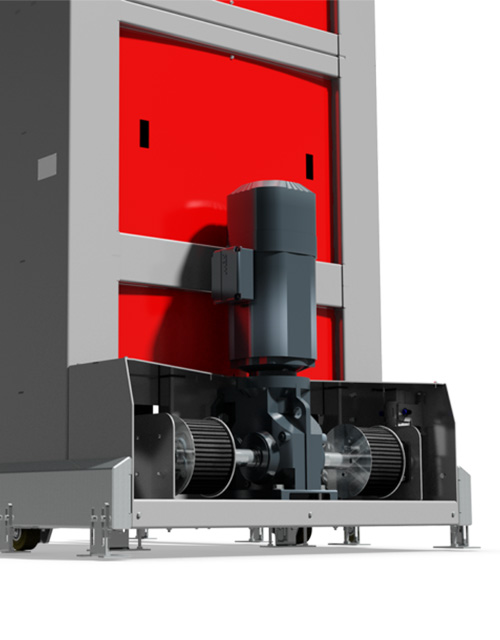

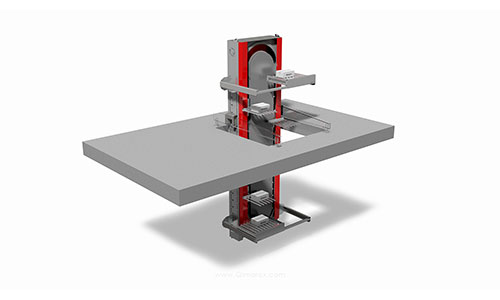

Palletizer Highrunner HR7

-

Flexible palletizer

The Highrunner HR7 series is used for handling capacities of 500 – 4.500 products per hour.

Palletizer Highrunner HR7: rapidly putting down layers

Palletizing Layer by layer

The Highrunner HR7 is the fastest, most flexible palletizer from the Qimarox range. What is interesting is that the products are deposited on the pallet layer by layer with the Highrunner HR7. To do so the machine has a built-in buffer, where each formed row remains until a layer is complete. By depositing an entire layer at a time, the Highrunner HR7 needs to make fewer movements. This saves time, which increases the capacity.

Because it's the pallet that moves up and down with the Highrunner HR7 flexible palletizer, the rows no longer need to be moved up and down while being deposited. That saves even more time, especially with pallets that need to be stacked 1.80 metres or higher. This makes the Highrunner HR7 one of the fastest palletizers on the market.

Infeed and outfeed of pallets

As soon as a pallet is full, the pallet lift moves all the way down so that it can be carried away via a pallet transport system. An empty pallet can be supplied from the opposite direction at the same time.

The Highrunner HR7 can handle a wide range of products:

- boxes

- boxes with lids

- trays

- trays with foil

- buckets

- crates

- jerrycans

- etc.

Logistics Palletizer Highrunner HR9

-

Highrunner HR9: automatically layer pattern selection

The Qimarox Highrunner HR9 Logistics palletizer is specially designed for logistic operations. Therefore, this machine is very effective where many different products are handled in short batches. Our unique and patented layer-formation system can generate a large variety of layer patterns. These patterns can be selected automatically or generated by the state-of-the-art pattern generator. A specially designed pattern generator will present to you the most optimal layer pattern according to box size and pallet size. As example, if the installation is equipped with a full 3D product scanner it is even possible to have the system working fully autonomously.

Because the pattern formation system is at high level and the pallet is moving up and down with the pallet lift, (Qimarox Prorunner mk10) higher throughputs can be achieved. The top of the pallet is consequently always located at the same level as the pattern-formation conveyor. As a result higher layer capacity is possible as stacking plates can receive a new layer quickly after a layer is placed onto a pallet.

Layer by layer

The Highrunner HR9 Logistics palletizer is based on the Highrunner HR7. This machine is the fastest, most flexible palletizer from the Qimarox range. What is interesting is that the products are deposited on the pallet layer by layer with this machine. To do so the machine has a built-in buffer, where each formed row remains until a layer is complete. By depositing an entire layer at a time, the Highrunner HR9 needs to make fewer movements. This saves time, which increases the capacity.

Because it is the pallet that is moving up and down with the Highrunner HR9 palletizer, the layers no longer need to be moved up and down while being deposited. As a result time is saved, especially with pallets that need to be stacked 1.80 meters or higher. This makes the Highrunner HR9 one of the fastest palletizers on the market.

Infeed and outfeed of pallets

As soon as a pallet is full, the pallet lift moves all the way down so that it can be carried away via a pallet transport system. An empty pallet can be supplied from the opposite direction at the same time.

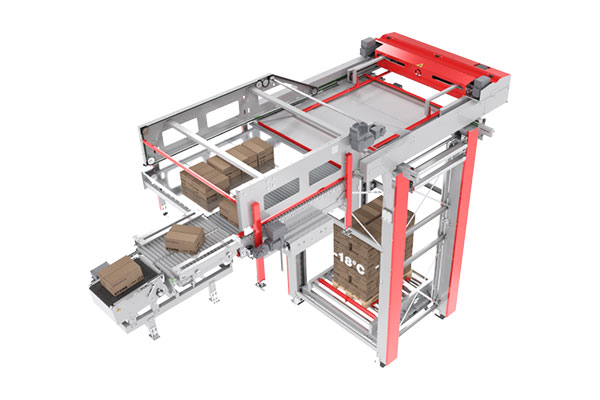

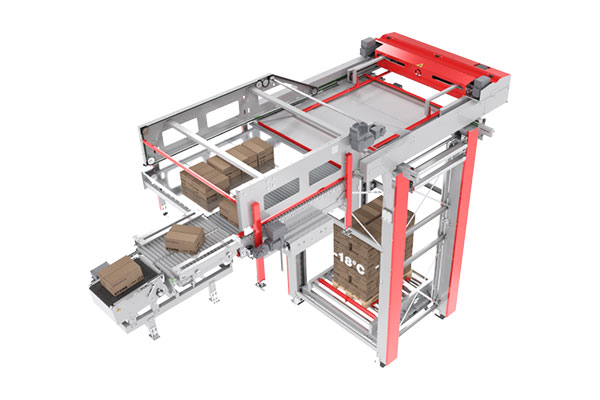

Frozen Food Palletizer Highrunner HR8

-

The Highrunner HR8 Frozen Food Palletizer is configured to deal with all challenges within the frozen food sector when it comes to palletizing. Several options are available for each module depending on the customer requirements and the products requiring palletization.

Benefits:

- Unique method of pattern formation, where products are positioned on exact coordinates (patented)

- Vertical pallet conveyor included, with automated drop-down safety

- Built-in buffer for depositing products in layers

- User-friendly touchscreen operation

- Pattern generator included

- Freely programmable stacking patterns

- Solid construction with perfect finishing for tough jobs

- Easy access for service and maintenance

- No more than 2.4 x 3.4 metres of space is required

- Standard machine with commercially available components

Unique layer formation system

What sets every Qimarox layer palletizer apart from any other solution on the market is the unique way a layer is build. With the patented design every layer pattern used within the frozen food industry can be created without any manual adjustment.

As floorspace is very expensive, the line infeed of the flexible palletizer also ensures the possibility to place machines close next to each other so the machine can be placed in line with the casepacker.

Palletizing cartons with frozen vegetables needs a layer formation system that can handle both normal cartons but also cartons that are bulged due to the - often - lower carton quality and the properties of the natural product that is being packed. By moving and positioning each row of cartons individually it is possible to create exact gaps between the individual row. These gaps are used to absorb the tolerances on the cartons when the layer is placed onto the pallet.

This way of layer handling had proven over-and-over again that it offers the best solution to create solid and stable pallet loads, even with bulged cartons.

Pattern Generator

Every HR8 comes with the commonly used layer-patterns within the industry pre-programmed. Every layer pattern is freely adjustable with the HMI and also complete new layer patterns can be created very easily. This can be done with the Qimarox Pattern Generator and can be used without detailed knowledge on the palletizer. You can simply enter the product and pallet dimensions and the system will show you the most optimal layer patterns to choose from.

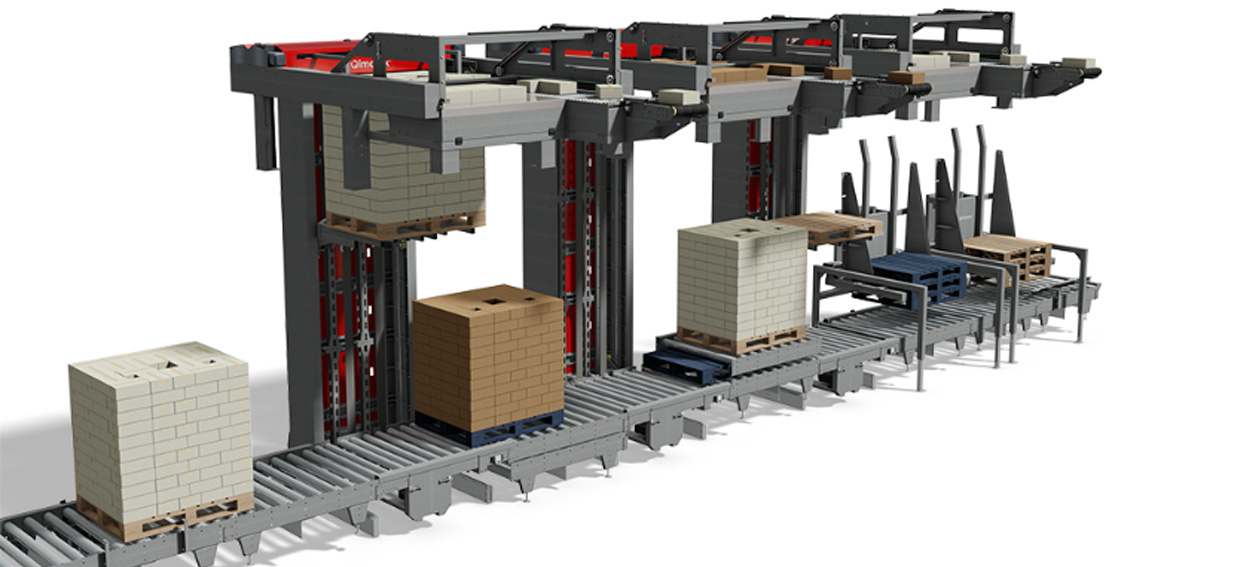

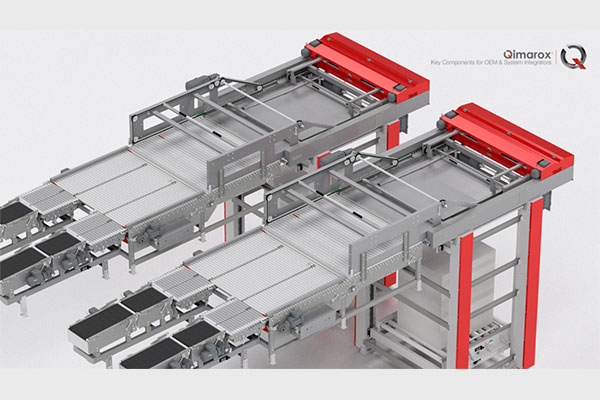

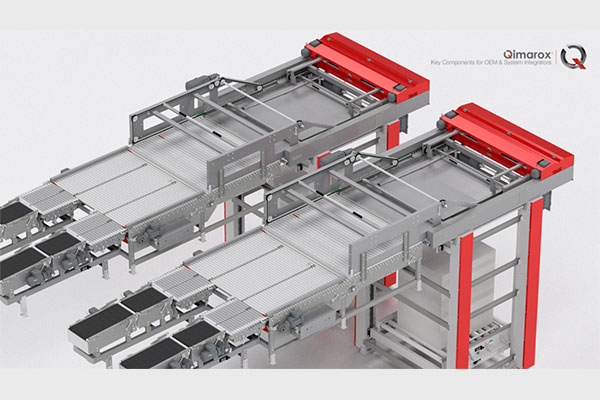

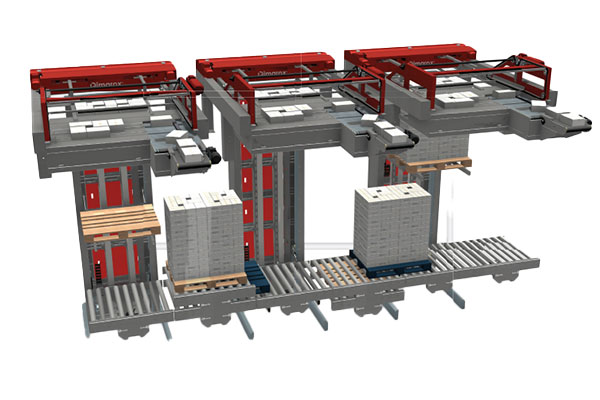

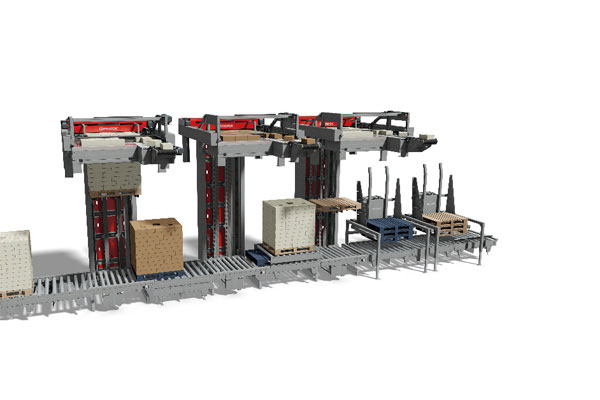

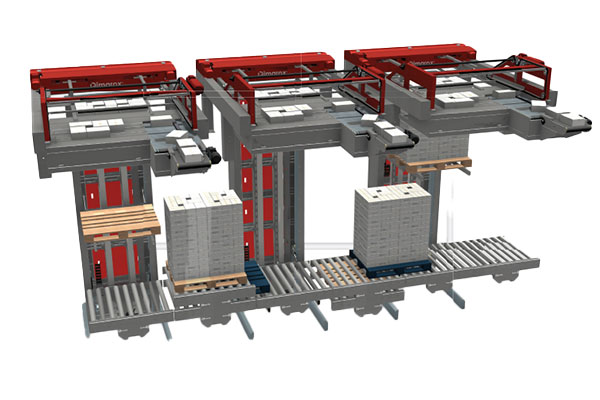

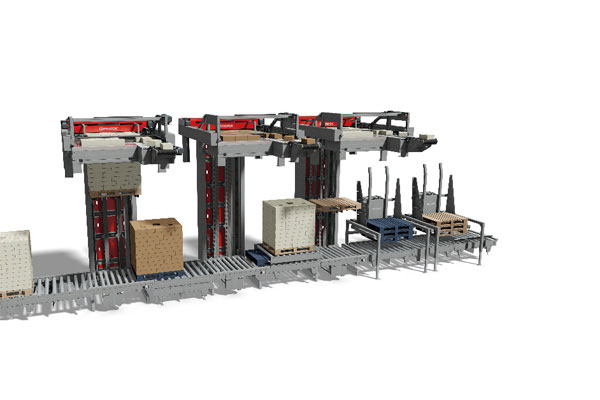

Crossrunner®

-

Crossrunner: in-line palletizing

Qimarox Crossrunner is a space saving solution for in-line placing of multiple palletizers. Thanks to the unique design, a single roller conveyor is sufficient to feed pallets in and out for multiple palletizers operating in line.The products are supplied by means of a feed belt that is placed on left or right side of the formation system. Each individual product is placed on an exact location until a full row of product is formed. Each formed row is placed onto an buffer where it remains until a layer is complete. By depositing an entire layer at a time, the Highrunner HR7 needs to make fewer movements. This saves time, increasing the capacity when compared to other palletizing systems.

With the Crossrunner space saving palletizing, products are deposited on the pallet layer by layer. Because, just like with the Highrunners, it's the pallet that moves up and down, the rows no longer need to be moved up and down while being deposited. That saves, especially with pallets that need to be stacked 1.8 metres or higher. That makes the Crossrunner a palletizer that can operate at very high speeds.

To allow full pallets to be able to pass underneath, the Crossrunner is a lot higher. While a Highrunner reaches to a height of 3 metres, a structure with Crossrunners can easily require a height of 6 metres.

The Crossrunner is modular constructed. This means that several options are available for each module depending on the customer requirements and the products requiring palletization.

In short, you will end up with the system that best suits your needs. However, this system can be completely adapted to changing circumstances in the future thanks to the interchangeability of its modules.

Advantages of the Crossrunner:- Unique method of pattern formation, where products are positioned on exact coordinates (patented)

- Set up multiple machines in areas with limited space through patented system design.

- Required floor area only 2.5 x 2.5 metres

- Pallet lifter for moving pallets up and down

- Built-in buffer for depositing products in layers

- User-friendly touchscreen operation

- Freely programmable stacking patterns

- Solid construction with perfect finishing for tough jobs

- Easy access for service and maintenance

- Not more than 2.4 x 3.4 metres of space needed on the platform

- Standard machine with commercially available components

VERTICAL CONVEYORS FOR PALLETS

- Qimarox offers various types of vertical conveyors for empty or loaded pallets which can be used in combination with our palletising modules or as stand-alone units in pallet conveyor systems.

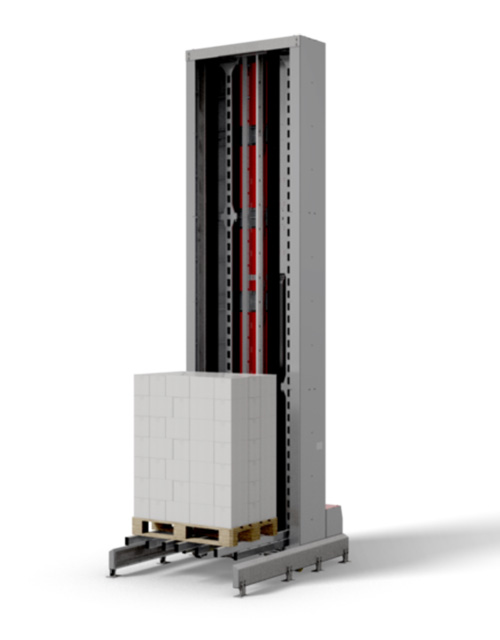

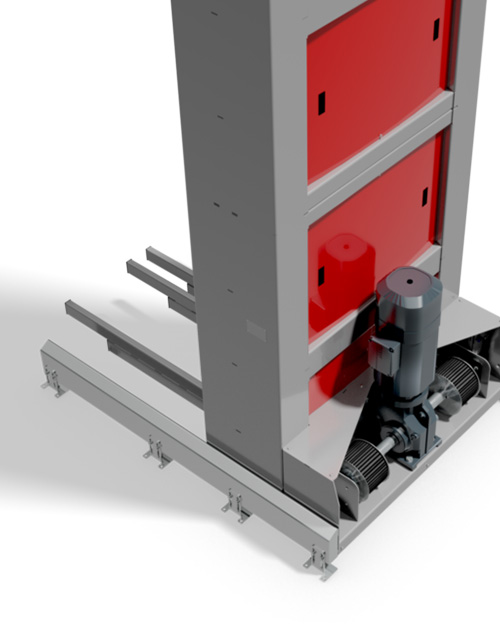

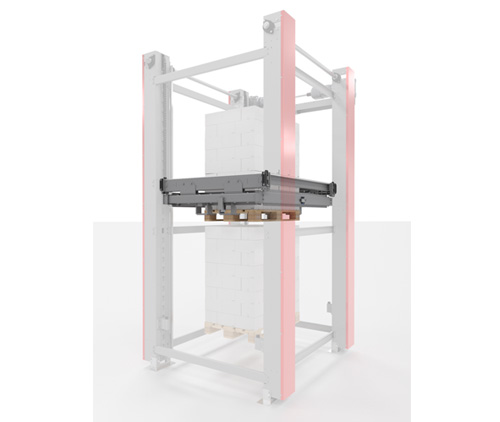

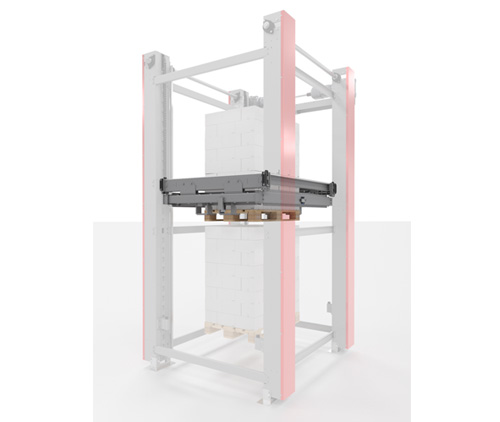

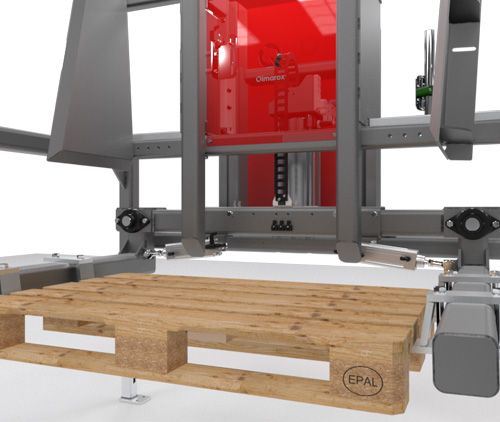

Pallet lift Prorunner mk9

-

The Prorunner mk9 is a rugged pallet lift that will lift and lower your pallets, until the end of time.

The Prorunner mk9 is a rugged pallet lift that will lift and lower your pallets, until the end of time. That is, it does what it is supposed to do and looks after itself. The Prorunner mk9 is the perfect solution for capacities of up to 60 pallets per hour. Because of its extremely small footprint, this lift fits into virtually any layout. This compact unit is very easy to integrate into your transport system and can be equipped with roller conveyor or chain conveyor. Thanks to its design and highly reliable components, the machine hardly requires any maintenance. In short: an easy-to-integrate pallet lift that remains affordable.

The specifications of the vertical pallet conveyor Prorunner mk9 are:• Lowest infeed/outfeed position of the mk9: 500 mm / 16 inch

• Highest infeed/outfeed position of the mk9: 10,900 mm / 420 inch

• Max. column height: 14,300 mm / 47 feet

• Max. pallet weight: 1250 kg / 2,800 lbs

• Max. pallet size: 1,300 x 1,250 mm / 51 x 49 inch

• Max. throughput: 100 pallets p/hourAdvantages:

- Minimal footprint

- Right-angled setup also possible

- Suitable for vertical sorting (multiple floors)

- Pallets, racks, etc. up to 1,250 kg

- Sturdy, low maintenance machine

- No chains need lubricating or tightening

- It makes minimal operating sound

- Solid steel construction

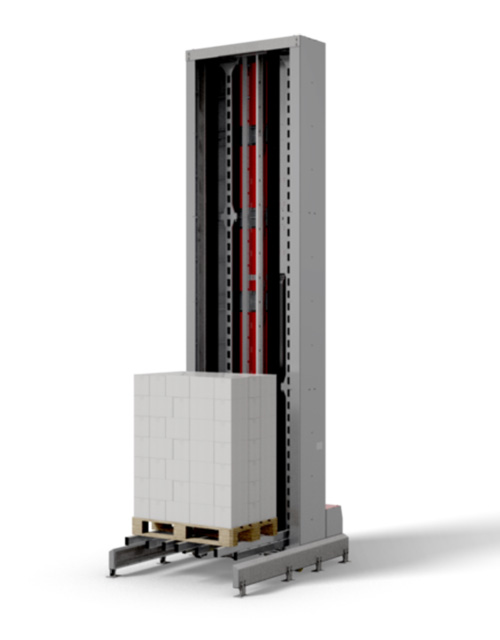

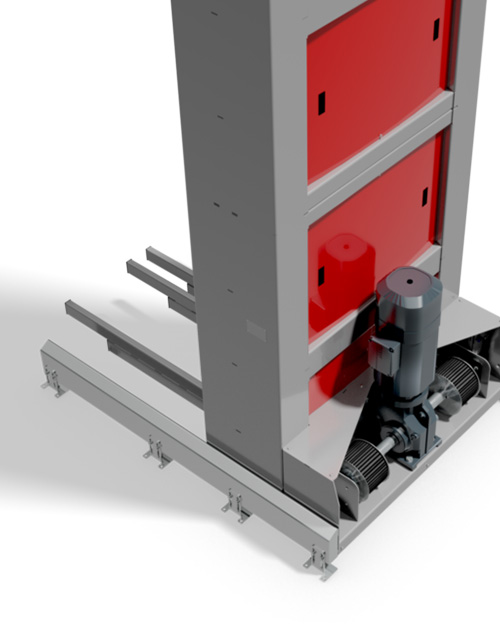

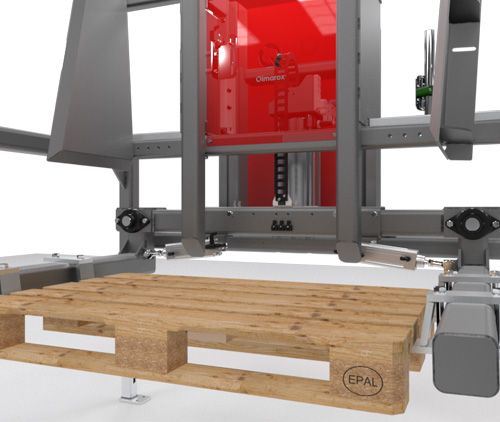

Pallet lift Prorunner mk10

-

A rugged pallet lift that will lift and lower heavy pallets

The Prorunner mk10 is a sturdy pallet lift that can automate the pallet transport in your facility. It is capable of transporting pallets up and down to the desired level of your facility. The Prorunner mk10 consists of four columns, allowing it to easily transport pallets up to 2,000 kg. The Prorunner mk10 is the perfect pallet lift to handle heavy pallets. Capacities of up to 100 pallets per hour can easily be achieved with the Pallet lift.

Compact unit

Because of its extremely small footprint, this lift fits into virtually any layout. It can easily bridge any difference in height between 0.40 and 10 ft, even at the maximum height difference of 10 ft. The Prorunner mk10 is equipped with a lifting platform of 1200 x 1100 mm as standard that can be fitted with a pallet track, so that it can handle not only euro pallets, but also product carriers of different sizes such as block pallets.This compact unit is very easy to integrate into your transport system and can be equipped with roller conveyor or chain conveyor. Thanks to its design and highly reliable components, the PRmk10 pallet lift for heavy pallets hardly requires any maintenance. In short: an easy-to-integrate vertical conveyor for pallets that remains affordable.

The specifications of the vertical pallet conveyor Prorunner mk10 are:• Lowest infeed/outfeed position of the mk10: 400 mm / 16 inch

• Highest infeed/outfeed position of the mk10: 24,900 mm / 981 inch

• Max. column height: 25,000 mm / 82 feet

• Max. pallet weight: 2000 kg / 4410 lbs

• Max. pallet size: 1,650 x 1,400 mm / 65 x 55 inch

• Max. throughput: 100 pallets p/hourAdvantages:

- Minimal footprint

- Infeed / discharge to all sides

- Suitable for vertical sorting (multiple floors)

- Pallets, racks, etc. up to 2000 kg

- Sturdy, low maintenance machine

- Quiet

- Solid steel construction

- Standard equiped with drop-down safety

VERTICAL CONVEYORS FOR SMALL GOODS

- Qimarox is very well known from its Prorunner mk5 vertical conveyor, but we have more solutions to offer for you to get your product to any level. You can choose the best solution for you needs.

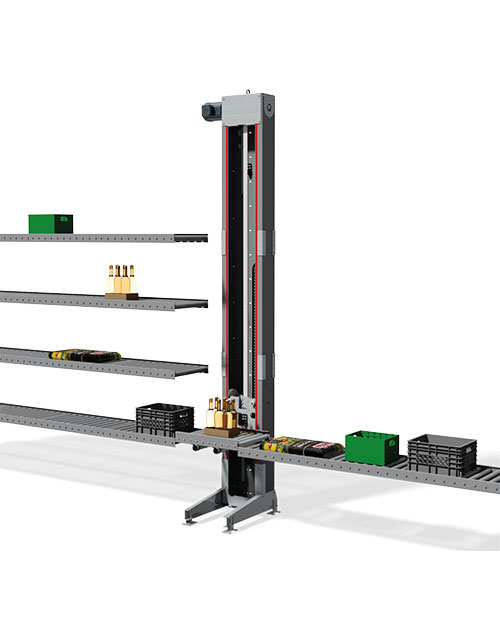

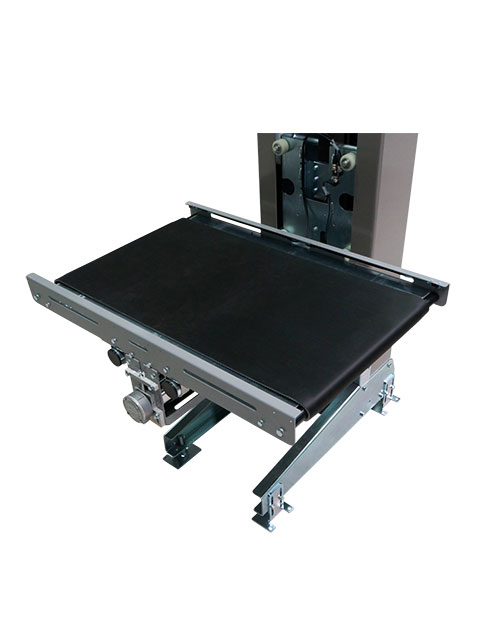

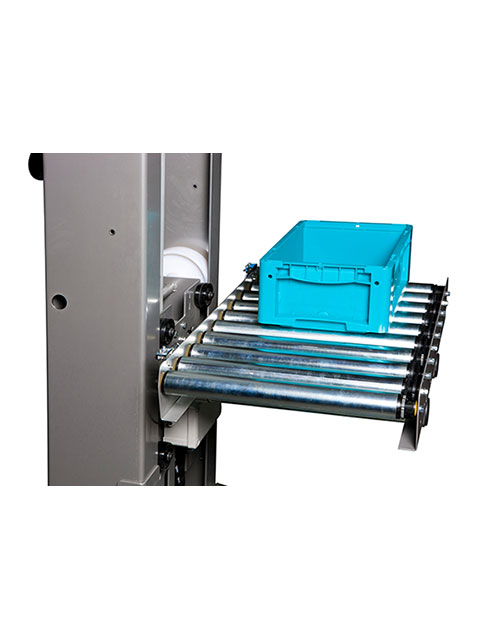

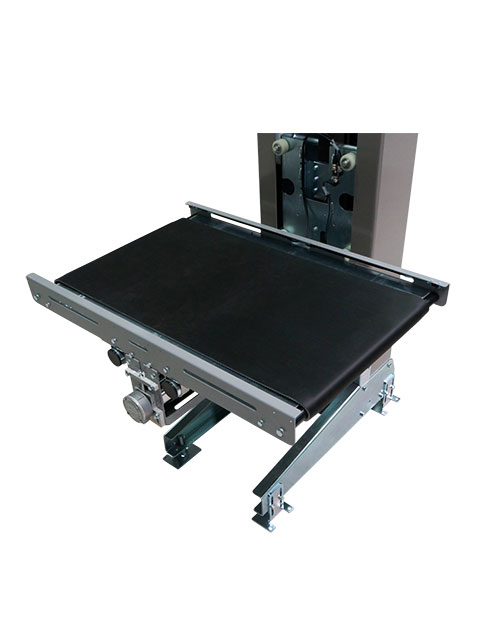

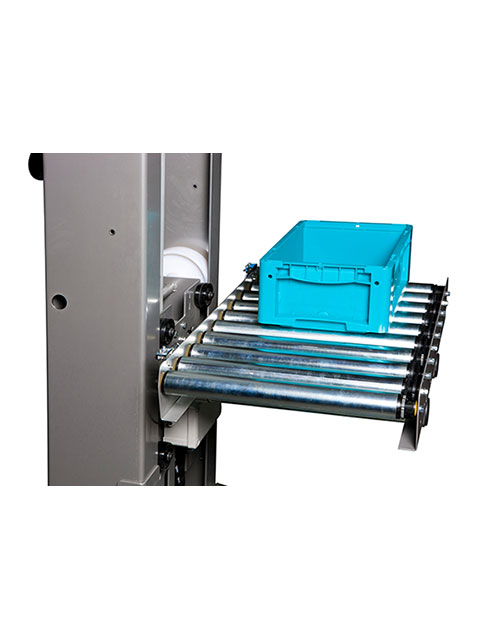

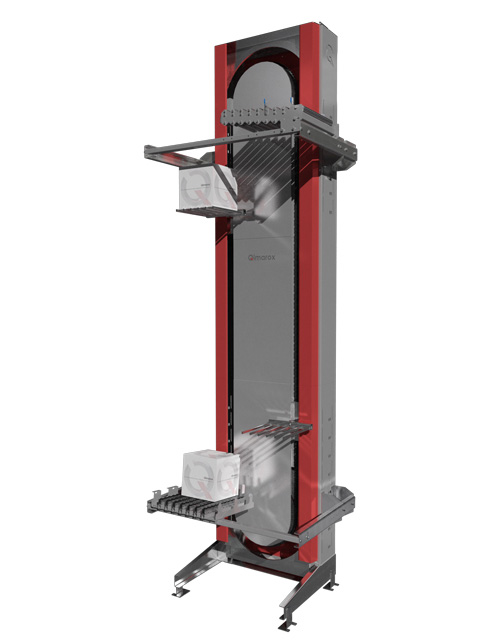

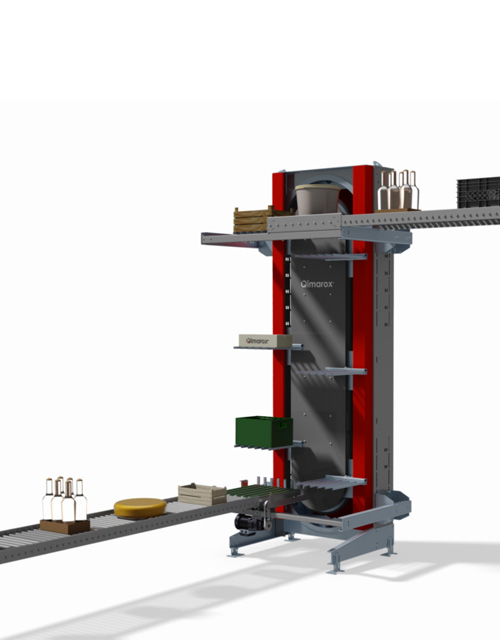

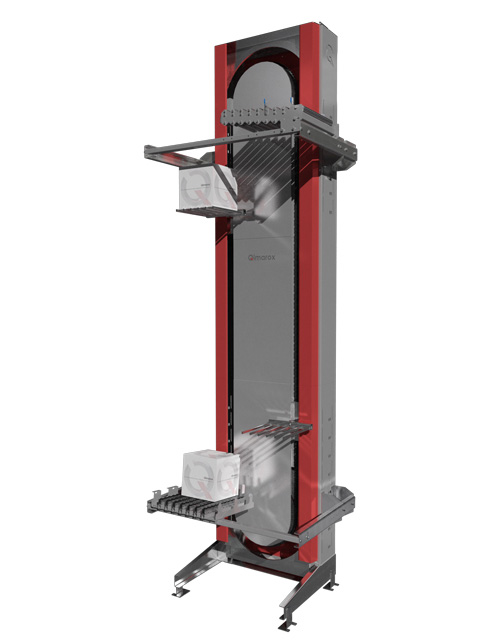

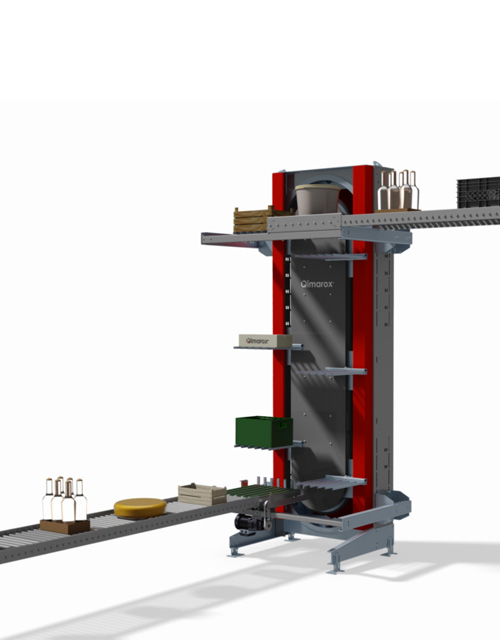

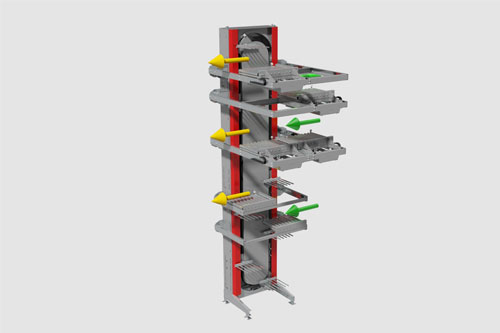

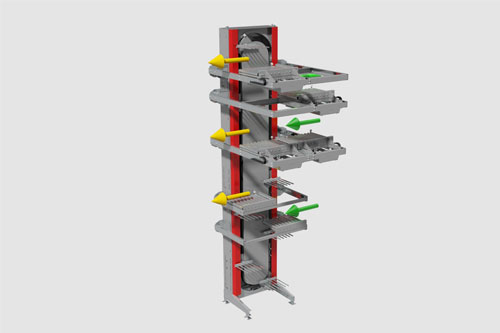

Vertical conveyor Prorunner mk1

-

Discontinuous vertical conveyor

The Prorunner mk1 is a compact and robust discontinuous product lift that requires minimal maintenance and is attractively priced.

Vertical conveyor Prorunner mk1 - Small footprint

The Prorunner mk1 is a discontinuous vertical conveyor with a small footprint that excels in robustness and requires minimal maintenance. Its steel structure is extremely stable under all circumstances.

By using a flat belt the Prorunner mk1 is completely silent in its movement. Moreover, a flat belt of this type almost has no maintenance. No lubrication and tension in comparison to chain driven system is needed anymore. Due to the small footprint the machine can be used in almost any factory lay-out.

Efficient vertical transport (Vertical conveyor)

The lift can easily hoist boxes, trays, boxes, crates, boxes or bags weighing up to 100 kg. The Prorunner mk1 is ideally suited for applications where maximum capacity of approximately 420 movements per hour is needed. Its compact design makes it a vertical conveyor with small footprint.

All this together makes the Prorunner mk1 an extremely efficient and economical solution for your vertical transportation.

The vertical conveyor Prorunner mk1 has the following specifications:

- Lowest infeed/outfeed position of the mk1: 360 mm / 14 inch

- Highest infeed/outfeed position of the mk1: 14,100 mm / 552 inch

- Max. Column height: 14,300 mm / 47 feet

- Drive: SEW 0,55 kW

- Max. Product weight: 100 kg / 220 lbs

- Max. Product size: 910 x 610 mm / 36 x 24 inch

- Max. Throughput: 420 p/hour

- Required surface: 500 x 900 mm / 20 x 35 inch

Due to its modular design, the Prorunner mk1 adapts easily to its operating environment. A standard roller conveyor (possibly driven) is included standard as a product carrier. This can optionally be replaced by a belt conveyor or other specific carrier. It is possible to install a custom conveyor without having to modify the construction. In this way, the elevator will optimally connect to the conveyor system in your production or distribution environment.

Customised infeed and outfeed heightsThe infeed and outfeed heights may be freely chosen and are in principle not bound to a maximum height. It is also possible to use the Prorunner mk1 to supply multiple infeed or outfeed conveyors, so that the elevator can act as a vertical sorter.

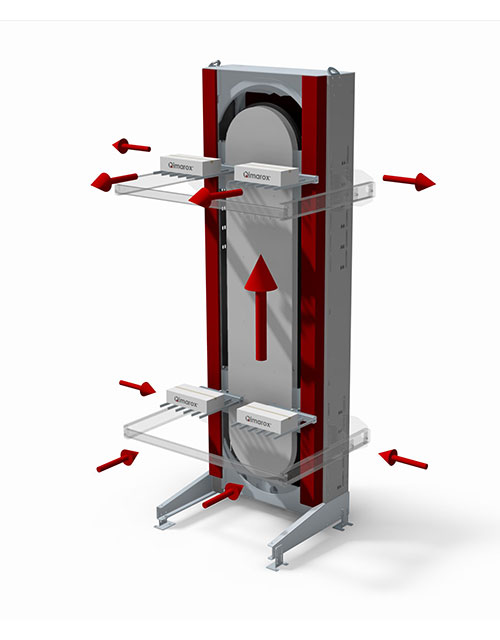

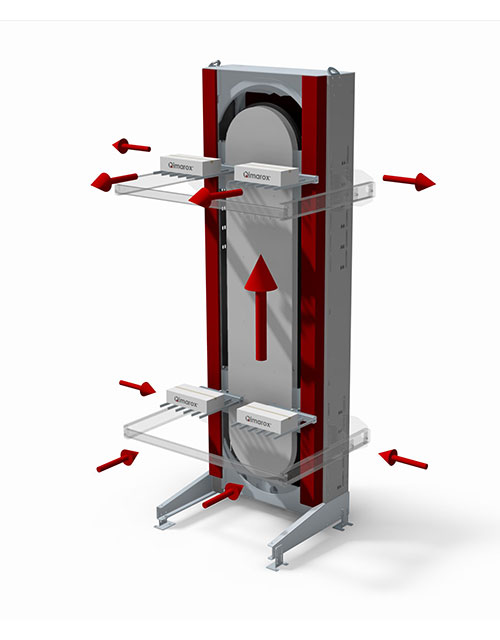

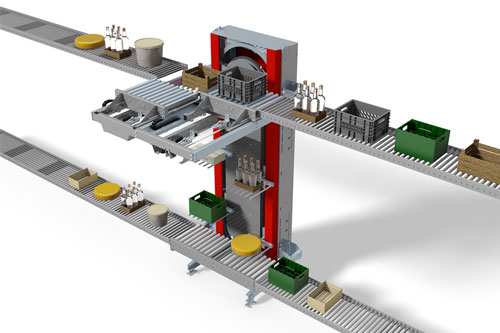

Vertical conveyor prorunner mk5

-

The Prorunner mk5 is a fully module based continuous product lift that can be easily assembled in almost any configuration. This system incorporates only highly reliable components that offer an extremely long service life. Maintenance is restricted to an absolute minimum.

The specifications for the continous vertical conveyor Prorunner mk5 are:

- Lowest infeed/outfeed position of the mk5: 676 mm / 21 inch

- Highest infeed/outfeed position of the mk5: 19,200 mm / 760 inch

- Max. column Height: 20,000 mm / 66 feet

- Drive System: SEW 0.37 kW

- Max. product weight: 50 kg per carrier / 110 lbs per carrier

- Max. product size: - 600 mm x 610 mm x H / 23.5 inch x 24 inch x H

- Throughput: 1 carrier for 200 products per hour (add further carriers for higher capacities)

- Configuration: B3 or C2 for elevating, 6G or 7F for descending (more options become available with a different type of carrier)

- Securyfence Safety Fencing H=2120 mm (83.47")

- Pitch Product Carrier 75 mm (2.95")

- Infeed Conveyor: gravity roller conveyor / powered roller conveyor optional

- Outfeed Conveyor: gravity roller conveyor / powered roller conveyor optional

Prorunner mk5 - Modular continuous vertical conveyor

The vertical conveyor Prorunner mk5 is a continuous product lift with the surprisingly low price tag of a discontinuous conveyor. The module-based Prorunner mk5 can easily reach a throughput of 2,000 products per hour and the vertical conveyor is particularly versatile for material handling. The modular buildup of our vertical conveyors makes shipment volumes smaller and shipment costs cheaper. Our Prorunner mk5’s can be used to effortlessly and quickly transport a wide variety of products to a second or higher floor aswell as back to the ground floor.

This energy-efficient product lift can be used to effortlessly and quickly transport a wide variety of products. Products like boxes, cases, trays or bags can be transported to and from any height you require. The product is always carried in an upright position without the risk of product deformation.

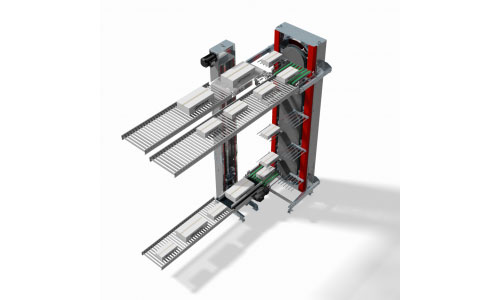

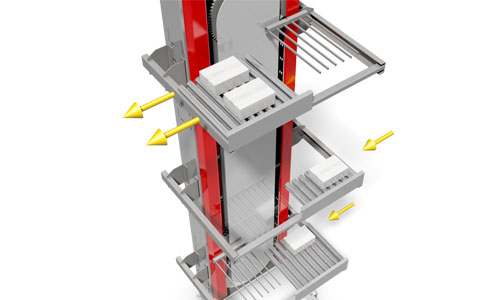

Vertical Conveyor Prorunner PR12

-

The Prorunner PR12 (Vertical conveyor for AMR and products up to pallet size)

The PR12 is a discontinuous vertical conveyor with a small footprint built for AGV and/or medium sized products. The machine has good positioning accuracy, stiffness and a high capacity. The PR12 is the perfect choice to transport Automated Guided Vehicles or products. The machine column can even be fitted with a secondary carrier which is individually driven. This doubles the capacity. Each carrier can be fitted with a roller conveyor or a platform for an AGV.

The PR12 is a discontinuous vertical conveyor with a small footprint built for AMR and products up to pallet size. The machine has good positioning accuracy, stiffness and a high capacity. The PR12 is the perfect choice to transport Automated Guided Vehicles or products. The machine column can even be fitted with a secondary carrier which is individually driven. This doubles the capacity. Each carrier can be fitted with a roller conveyor or a platform for an AMR.

The specifications for the discontinuous vertical conveyor Prorunner PR12 are:- Lowest infeed/outfeed position of the PR12: 200 mm /8 inch

- Highest infeed/outfeed position of the PR12: 23.300 mm / 919 inch

- Max. Column height: 24.000 mm / 79 feet

- Drive: Servo motor with resolver and mechanical brake

- Max. Product weight: 150 kg / 330 lbs per carrier (can be increased by 75 kg / 165 lbs by choosing for a HD* edition - max. 225 kg / 495 lbs per carrier)

- Max. Product size: 850 x 700 mm / 33 x 28 inch

- Max. speed = 2 meter a second / 6.5 feet p/s

- Required surface single carrier: 966 x 1125 mm / 13 ft²

- Required surface double carrier: 1.125 x 1.932 / 23 ft²

Continuous vertical conveyor Prorunner mk5-XL

-

Continuous vertical conveyor to handle bigger products

The Prorunner mk5-XL is a fully module based continuous vertical conveyor that can be easily assembled in almost any configuration. The continuous vertical conveyor system incorporates highly reliable components that offer an extremely long service life. Maintenance is restricted to an absolute minimum.

The specifications for the Prorunner mk5-XL are:

• Lowest infeed/outfeed position of the mk5: 812 mm / 32 inch

• Highest infeed/outfeed position of the mk5: 17,300 mm / 680 inch

• Max column height: min. aprox. 18 mtr / 705 inch

• Drive System: SEW 0,55 - 4,0 kW

• Max. product weight: 50 kg per carrier / 110 lbs per carrier

• Max. product size: - 900 mm x 610 mm x H / 35 inch x 24 inch x H

• Throughput: 1 carrier for 200 products per hour (add further carriers for higher capacities)

• Configuration: B3 or C2 for elevating, 6G or 7F for descending (more options become available with a different type of carrier)

• Securyfence Safety Fencing H=2120 mm (83.47")

• Pitch Product Carrier 75 mm (2" 61/64)

• Infeed Conveyor: gravity roller conveyor / powered roller conveyor / belt conveyor / shuttle roller conveyor

• Outfeed Conveyor: gravity roller conveyor / powered roller conveyor / belt conveyor / shuttle roller conveyorContinuous vertical conveyor - Prorunner mk5-XL

The Prorunner mk5-XL is designed for when you want to handle bigger products than the regular Prorunner mk5 can handle. This continuous product lift is still module-based and it offers a maximum capacity of 2,000 products per hour. The modular buildup of our vertical conveyors in general offers another benefit, which is that the shipment volumes are smaller and therefore shipment costs are cheaper. Our continuous vertical conveyor Prorunner mk5-XL is used to effortlessly and quickly transport a wide variety of (bigger) products vertically.

The Prorunner mk5-XL is also an energy-efficient product lift, which can be used to quickly transport products up or down. It is also possible to have products to be transported up while also bringing another batch of products down. Products like boxes, cases, trays or bags can be transported to and from a height up to 17.3 meters / 56 ft 10 inch. The products are always carried in an upright position so there is no risk of product deformation.

The Prorunner mk5-XL is capable to lift bigger products! Like already mentioned above, our continuous vertical conveyor can be used for both ascending and descending product flows at the same time! This versatile vertical conveyor is even suitable to function as a vertical sorter by adding retractable conveyors at the in and outfeed.

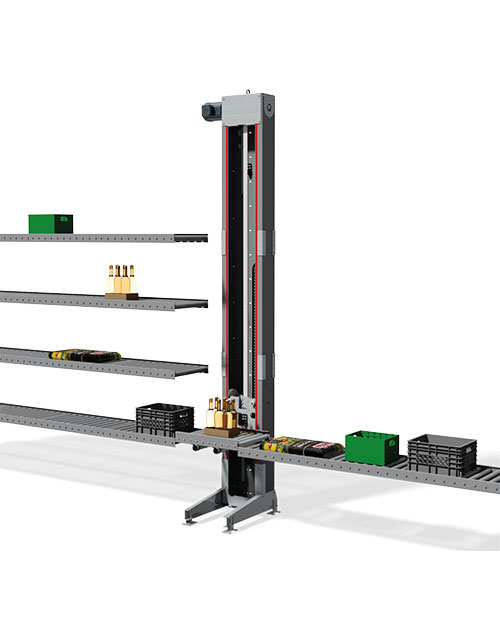

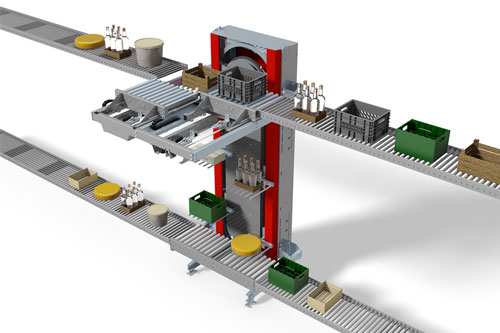

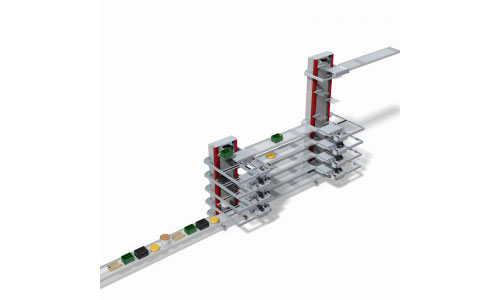

VERTICAL SORTING

- By adding retractable conveyors to our unique Prorunner mk5 vertical conveyor it’s now possible to build a vertical sorter. Products can enter or discharge at any level.

Vertical Sorter – Prorunner mk5

- Based on the Prorunner mk5 vertical conveyor it’s possible to add retractable conveyors to the lift column. This makes it possible to have products entering or discharging at any floor level while still just using one vertical movement In this way products e.g. can be elevated and lowerated at the same time: The Prorunner mk5 Vertical Sorter

VERTICAL SORTER PRORUNNER MK1

- At lower throughput also an Prorunner mk1 vertical conveyor can be used as a vertical sorter by adding additional stopping positions to the vertical movement. With this you can have multiple feeding lines discharging to one central conveyor. If you have different products coming on one central conveyor you can also sort them out vertically by adding more discharge levels to the system.

BUFFERING

- If buffering of product is needed but floor space is limited our Prorunner mk5 can be used as a buffer system by simply adding more carriers to the vertical movement.

Buffering – Prorunner mk5

-

The Prorunner mk5 vertical conveyor can be used as a buffering system by adding more carriers and to put the vertical movement in a start-stop motion. This solution makes it possible to store more products on a small floor space before entering the next process step or to store products if the downstream process is disrupted.

Buffer system – Prorunner mk5

-

The possibility to add retractable conveyors to the vertical movement gives you high flexibility to create your own system. If one vertical conveyor is used to bring products in and one to take products out you can build a buffer system to prepare orders or to accumulate products for multi-palletizing.

PALLET HANDLING

- Qimarox can supply various modules for pallethandling. These modules can be used in combination with our pallet lifts or palletising modules but also as stand-alone units.

Loaded pallet stacker Prorunner mk10-PS

-

Stacking loaded pallets

Based on our successful Prorunner mk10 pallet lift the loaded Pallet Stacker is a very versatile unit to stack loaded pallets on top of each other.

Based on our successful Prorunner mk10 pallet lift the Loaded pallet stacker Prorunner mk10-PS is a very versatile unit to stack loaded pallets on top of each other. Stacking loaded pallets is very common in logistic operations to limit the number of fork lift movements or to use within an automated truck loading system. When using a pallet doubler the logistics handling is lowered significantly and transportation cost can be lowered.

The specifications of the pallet stacker Prorunner mk10-PS are:

• Lowest infeed/outfeed position of the mk10-PS: 0 mm / 0 inch (Floorlevel)

Advantages:

• Highest infeed/outfeed position of the mk10-PS: 1,000 mm / 40 inch

• Max. lifting weight: 1000 kg / 2200 lbs

• Max. pallet size: 1,650 x 1,400 mm / 65 x 55 inch

• Max. infeed throughput: 100 single pallets p/hour

• Max. outfeed throughput: 50 stacked pallets p/hour- Minimal footprint

- Infeed / discharge to all sides

- Suitable for vertical sorting (multiple floors)

- Pallets, racks, etc. up to 2000 kg

- Sturdy, low maintenance machine

- Quiet

- Solid steel construction

- Standard equipped with drop-down safety

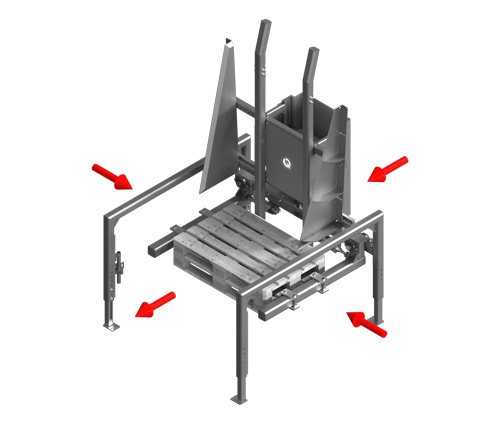

Pallet Dispenser PD1 for empty pallets

- The Qimarox Pallet Dispenser is suitable for stacking and/or de-stacking of empty pallets.

Pallet Dispenser PD1 - for empty pallets

The Qimarox Pallet dispenser PD1 is suitable for stacking and/or de-stacking empty pallets. By using pneumatic movements these are being carried out effectively and controlled, which guarantees an optimal operation. This machine is suitable for both two-way and four-way pallets, regardless of the wooden or plastic material of the pallet.

Most logistic operations require empty pallets to be singled out and offered to the automated process like palletizing. By suppling empty pallets tot he system automatically the overall efficiency increases as there is less risk that the palletizer comes to an standstill.

The specifications of the pallet dispensder PD1 are:

Min. pallet size: 800 x 800 mm /32" x 32" inch

Advantages of the Qimarox Pallet Dispenser:

Max. pallet size: 1200 x 1200 mm / 48" x 48" inch

Throughput (incl. pallet transport): 200 p/hour

Maximum pallet stack height: 2,500 mm / 98" inch

Lifting power: 400 kg / 880 Lbs.- Pneumatic movements

- Suitable for several pallet types

- Underlying pallet transport possible to/from three sides

- Automatic filling by pallet transport possible

- Suitable for stacking and de-stacking

- Suitable for any type of pallet transport

Pallet Dispenser PD2 for empty pallets

-

Pallet dispenser PD2 - empty pallet handling

The Qimarox empty Pallet Dispenser PD2 is suitable for stacking and/or de-stacking empty pallets of different sizes. By using pneumatic movements these are being carried out effectively and controlled, which guarantees an optimal operation. This machine is suitable for both two-way and four-way pallets, regardless the wooden or plastic material of the pallet.

Most logistic operations require empty pallets to be singled out and offered to the automated process like palletizing. By suppling empty pallets tot he system automatically the overall efficiency increases as there is less risk that the palletizer comes to an standstill. By using the Qimarox pallet dispensers you can easily handle all kind of different pallet types; like EURO, CHEP, GMA and Australian standard pallets.

The specifications of the pallet dispensder PD2 are:

Min. pallet size: 800 x 800 mm /32" x 32" inch

Advantages of the Qimarox Pallet Dispenser PD2:

Max. pallet size: 1200 x 1200 mm / 48" x 48" inch

Throughput (incl. pallet transport): 200 p/hour

Maximum pallet stack height: 2,500 mm / 98" inch

Lifting power: 400 kg / 880 Lbs.- Pneumatic movements

- Suitable for several pallet types

- Underlying pallet transport possible to/from three sides

- Automatic filling by pallet transport possible

- Suitable for stacking and de-stacking

- Suitable for any type of pallet transport

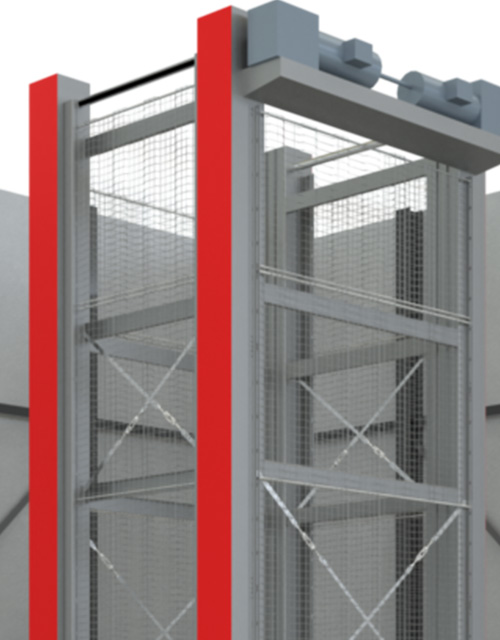

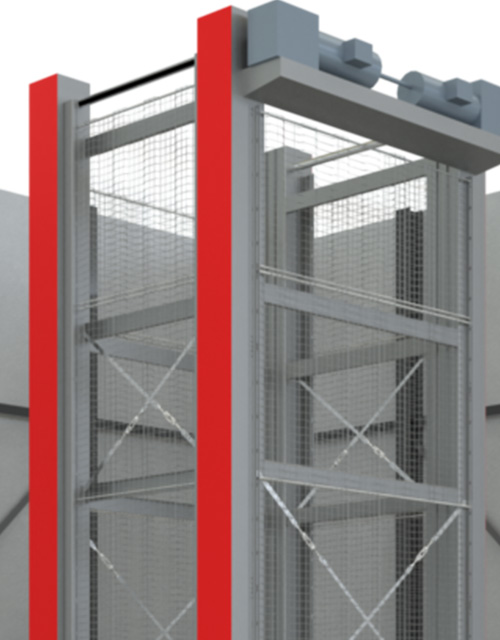

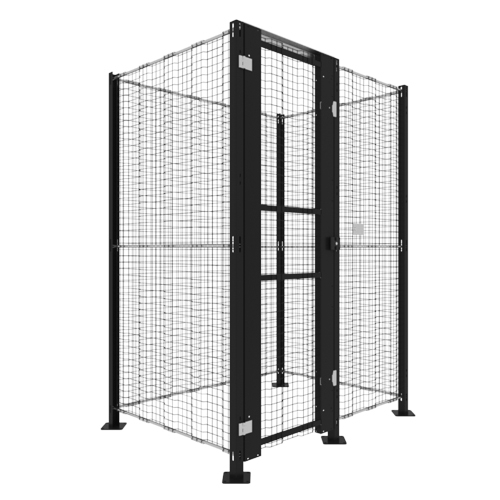

SAFETY FENCING

- Flexible fencing system, designed to be easy to erect and adjust, for use in guarding and fencing off machinery and zones.

Safety fence Mesh Panels – Securyfence

-

Securyfence consists of profiled mesh panels that are screwed to the posts via tubes. The standard sizes don’t fit? You can easily cut and saw the mesh panels and tubes to fit on the spot.

Safety fence mesh panels - Securyfence

Securyfence safety fencing consists of profiled mesh panels that are screwed to the posts via tubes. The standard sizes don’t fit? You can easily cut and saw the mesh panels and tubes to fit on the spot. Installing safety fencing was never this easy.

The mesh panels offer an excellent view of the machine, so you can take immediate action if necessary. Thanks to the profiling, the mesh panels are extra sturdy and therefore able to take a knock or two.

Safety fencing mesh panels

Safety fences are used in different situations, but the main goal is always the same. The goal of a safety fence is to keep people in or out a certain area. Our fencing is made for machines. Our fences protect work personnel from entering dangerous areas.

Securyfence is a modular system, which means you can choose from a wide range of sizes. All components are available from stock. You can choose from six widths, ranging from 225 to 1495 millimetres, and 2 heights: 1023 or 2123 millimetres.

Benefits:

- Quick to assemble

- Simple to customise

- Extra sturdy thanks to profiling

- Modular system

- Good transparency

- Available in stainless steel

- Dimensions meet all CE and NEN standards

- Patented system

Safety fencing Hinged doors – Securyfence

-

Securyfence hinged doors offer easy access to protected machines or shielded areas. The hinged doors are available in two widths.

If you use Securyfence as area guard, the hinged doors can be locked with a lock and key. In the event of a machine guarding system, each hinged door must of course be secured with a door switch, which we can also supply. If you already have your own door switches, we can supply you with the correct mounting materials.

Benefits:

- Quick to assemble

- Simple to customise

- Extra sturdy thanks to profiling

- Modular system

- Good transparency

- Available in stainless steel

- Dimensions meet all CE and NEN standards

- Patented system

Safety Fencing Sliding Doors – Securyfence

-

With Securyfence sliding doors, you can create an opening in your machine guard or area guard in even the most confined of spaces.

With Securyfence sliding doors for safety fencing, you can create an opening in your machine guard or area guard in even the most confined of spaces. Although the sliding doors are available in two widths, you can of course tailor them to any size. Like all other components, our doors are therefore built entirely modularly.

Sliding doors are a great alternative for situations where there is no space for a hinged door. Just like the hinged doors, the sliding doors can be locked with a lock and key. If you plan to use the Securyfence as a machine guard, we can supply you with the necessary door switches. Already have your own door switches? Then we will provide you with the correct mounting materials.

Benefits:

- Quick to assemble

- Simple to customise

- Extra sturdy thanks to profiling

- Modular system

- Good transparency

- Available in stainless steel

- Dimensions meet all CE and NEN standards

- Patented system

Stainless Steel – Securyfence

-

All standard Securyfence components are available from stock. Order today, get it tomorrow. Would you like a guard in stainless steel? These two are available from stock.

All standard Securyfence components are available from stock, also in stainless steel. Order today, get it tomorrow. You can have your new guard set up in only two days.

In addition to the standard model, the Securyfence is also available in every RAL colour, as well as galvanised. This means that there will always be a guard that will fit the look and feel of your company, while meeting the most safety stringent requirements.

Benefits:

- Quick to assemble

- Simple to customise

- Extra sturdy thanks to profiling

- Modular system

- Good transparency

- Available in stainless steel

- Dimensions meet all CE and NEN standards

- Patented system

APPLICATIONS

- See other applications for Qimarox components here. There are some very creative solutions to be discovered. See what our solutions can do for you.

Hanging vertical conveyer

- If you need products to be transported from one floor to another and you want to save floor space it’s also possible to have your vertical conveyor hanging on the first floor. This will save cost as the overall column height can be lower. The lower floor will remain completely free if the roller conveyor is mounted at higher level as well.

Extra product flow with retractable conveyor

- In a standard Prorunner mk5 vertical conveyor application products are either transported up or down. With a small, standard option, it’s also possible to add an extra product flow. By adding two retractable conveyors this can be achieved without any change to the vertical conveyor itself.

Combi-solution

- In this solution a Prorunner mk1 vertical conveyor and a Prorunner mk5 vertical conveyor are combined to handle both large and small products. If the system needs to handle large products only the Prorunner mk1 is activated. If handling of smaller products is needed – at higher throughput – the belt of the Prorunner mk1 is used as an indexing belt conveyor to feed the Prorunner mk5 vertical conveyor.

Prorunner mk5 2=1

-

In this example solution we combine two feeding conveyors to be discharged at one level. By extending the carrier and picking up the two products at different positions without the use of retractable conveyors as normally used in this type of situation.

The system can also work in opposite direction if needed.

Conveyor bridge

- If a passage is needed to make it possible for forklifts or truck to pass you can build a simple conveyor bridge by the use of two vertical conveyors. The Qimarox vertical conveyors occupy a minimal floor space so this solution can be implemented in almost every factory lay-out. These vertical conveyors solutions are so easy to integrate that it can be installed in excising product lines very quickly.

One vertical conveyor is used to bring products up to the needed level and by using standard roller conveyors to product is transported over the passage. A second vertical conveyor is used to bring products down at the end of the roller conveyor. Both vertical conveyors can be operated by the same control system.

Prorunner mk1-Twin Vertical Conveyor

- If you need your larger products to be vertically transported it’s possible to have two standard Prorunner mk1 vertical conveyors connected and have this set equipped with a larger conveyor. This gives you the possibility to handle longer products but still use a minimal amount of floor space.