- Offer Profile

- Conception, construction, production, start-up, service and training – FEHLMANN incorporates all of these values under one roof. For you, as the customer, this adds up to highly precise milling machines that are convincing due to their well-thought out ergonomics, compelling reliability and compact construction.

Machining centres in portal design

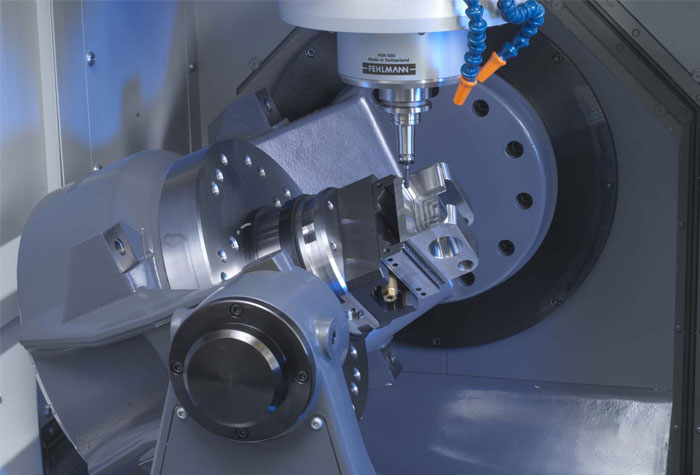

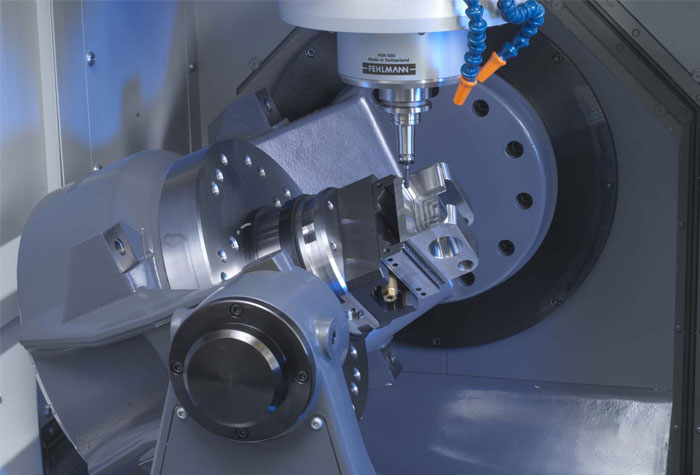

NEW - VERSA® 945

-

Highest level of precision and dynamics

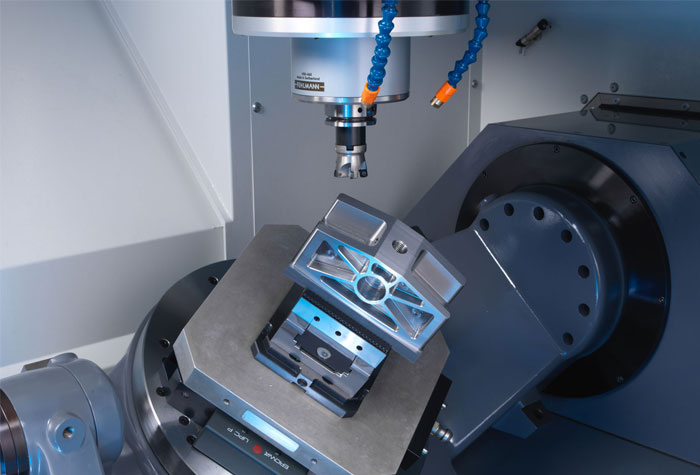

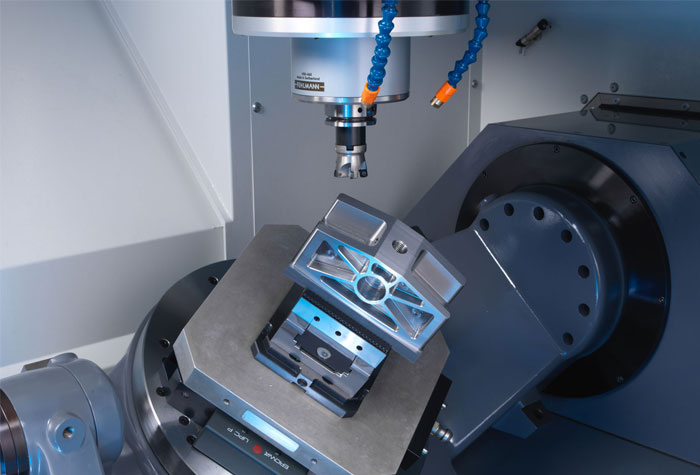

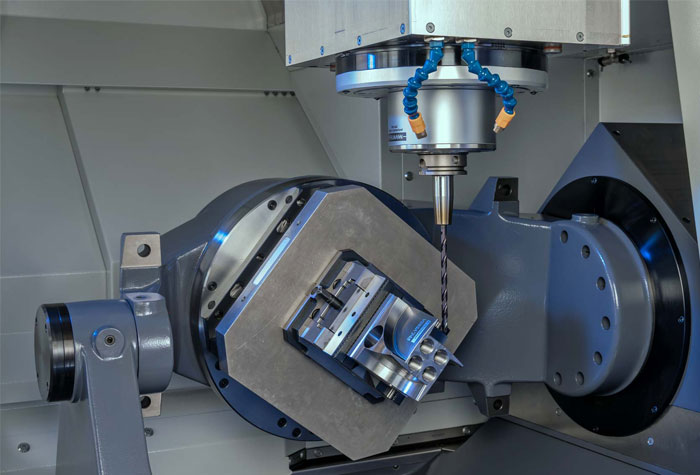

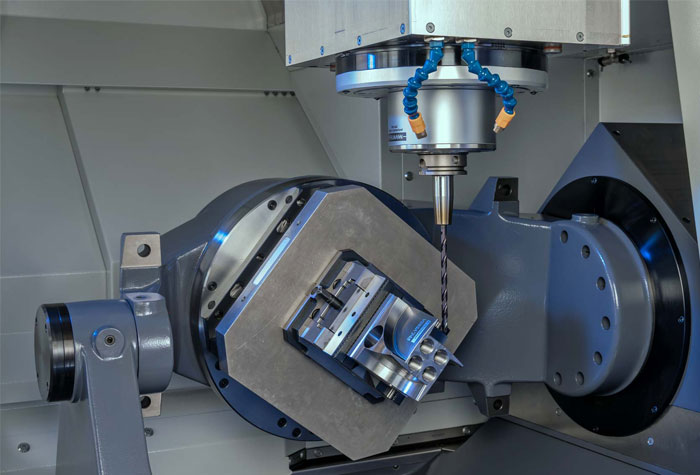

For 5-sided and 5-axis machining - with the VERSA 945, workpieces up to Ø 650 mm can be precisely machined in 5 axes. The largest machine in the VERSA family also combines the latest technology with proven features.

The rotary tilting table is driven with torque motors and integrated along the X-axis - perfectly designed for quick 5-axis simultaneous milling, as well as highly precise 5-axis milling with positioning. The grey cast iron base, thermo-symmetrical set-up and the fact that only 2 axes on the tool side are used for cutting, result in maximum rigidity and precision, as well as excellent dynamic accuracy.

Of course, standard as well as customised automation solutions are also available.Uncompromising Precision

The FEHLMANN VERSA 945 has been designed for maximum precision through and through. The cooled slide components, as well as the cooled machine structure, reliably prevent undesirable thermal growth. The X axis with the tilting rotary table is supported along the entire bed length for perfect stability. The stable swivel bridge with counter-bearing also contributes to the high rigidity of the FEHLMANN VERSA 945.

Features and Highlights

- 5-axis machining for workpieces up to Ø 650 mm

- Excellent accessibility and optimal visibility into the machining area. Manual part loading from the front. The door extends right into the machine roof, allowing for comfortable crane loading from the top.

- Tool changer with chain magazine has a capacity for 48 tools in the

basic version and can be upgraded to 80 tools. The optional rack magazine

accommodates, depending on tool holder, from 224 to 400 additional tools

(scalable) and can be installed easily and in a space-saving manner on the

left side of the machine.

- High rigidity with minimum thermal growth and optimal vibration damping

due to the machine base made of gray cast iron, with three-point support

system.

- Perfect dynamic accuracy due to weight-optimized moving parts made of

spheroidal cast iron.

- Standardized as well as customized automation with a robot may be retrofitted at any time, as the right side of the machine remains accessible.

- Perfect operability from the front with ergonomic configuration of all

operating elements.

- Wide variety of automation options are available, including individually customized solutions.

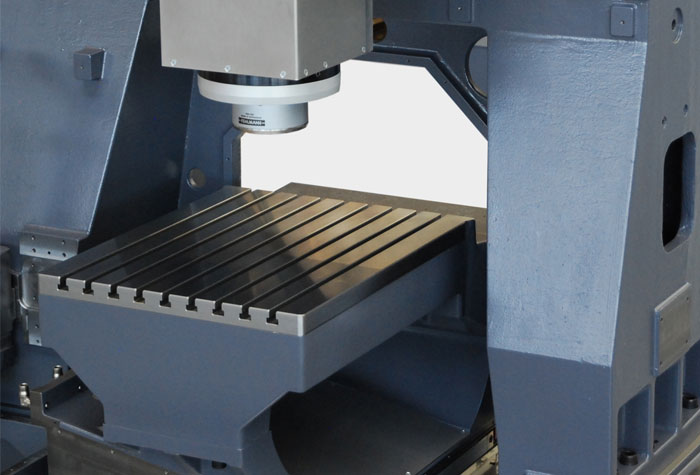

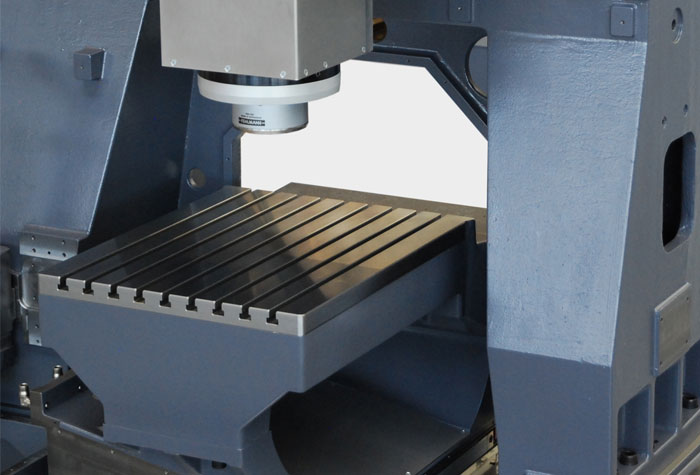

NEW - VERSA® 943

-

Highest level of precision and dynamics

This 3-axis machining center with a fixed table offers a generously-sized clamping area of 870 x 760 mm. Workpieces up to 1000 kg can be machined with high precision and dynamics.

The VERSA 943 combines the latest technology with proven features.The grey cast iron base, thermo-symmetrical set-up and the fact that only 2 axes are used for cutting result in maximum rigidity and precision, as well as excellent dynamic accuracy.

Of course, standard as well as customised automation solutions are also available.Uncompromising Precision

The FEHLMANN VERSA 943 has been designed for maximum precision through and through. The cooled slide components, as well as the cooled machine structure, reliably prevent undesirable thermal growth. The X axis is supported along the entire bed length for perfect stability.

Features and Highlights

- Clamping area of 870 x 760 mm, workpieces up to 1000 kg.

- Excellent accessibility and optimal visibility into the machining area. Manual part loading from the front. The door extends right into the machine roof, allowing for comfortable crane loading from the top.

- Tool changer with chain magazine has a capacity for 48 tools in the

basic version and can be upgraded to 80 tools. The optional rack magazine

accommodates, depending on tool holder, from 224 up to max. 400 additional

tools (scalable) and can be installed easily and in a space-saving manner on

the left side of the machine.

- High rigidity with minimum thermal growth and optimal vibration damping

due to the machine base made of gray cast iron, with three-point support

system.

- Perfect dynamic accuracy due to weight-optimized moving parts made of

spheroidal cast iron.

- Standardized as well as customized automation with a robot may be retrofitted at any time, as the right side of the machine remains accessible.

- Perfect operability from the front with ergonomic configuration of all

operating elements.

- Wide variety of automation options are available, including individually customized solutions.

VERSA® 745

-

Highest level of precision and dynamics

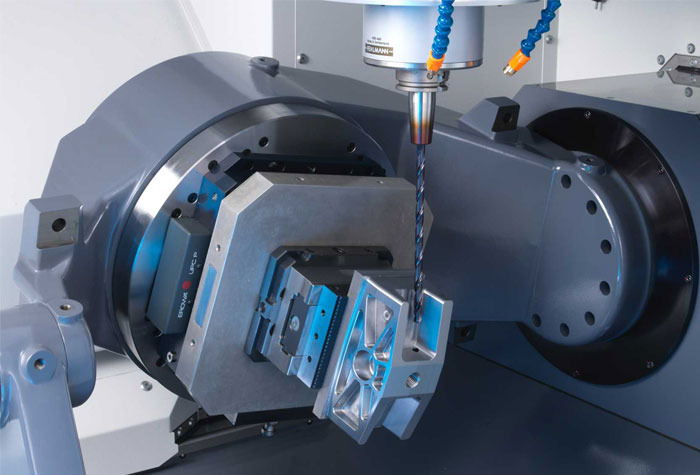

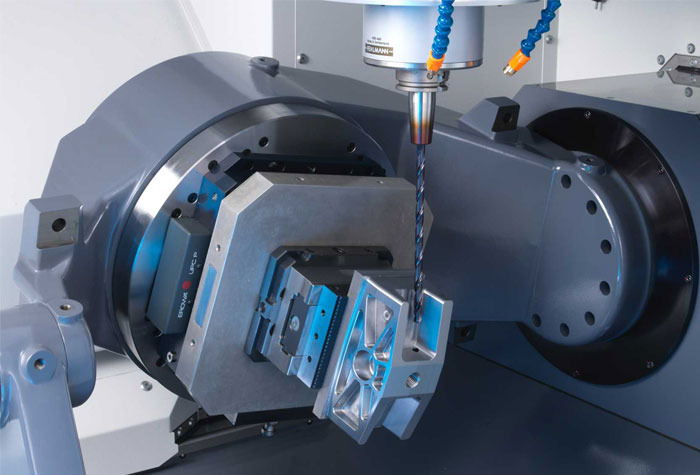

For 5-sided and 5-axis machining - with the VERSA 745, workpieces up to Ø 500 mm can be precisely machined in 5 axes.

The rotary tilting table is driven with torque motors and integrated along the X-axis - perfectly designed for quick 5-axis simultaneous milling, as well as highly precise 5-axis milling with positioning. The grey cast iron base, thermo-symmetrical set-up and the fact that only 2 axes on the tool side are used for cutting, result in maximum rigidity and precision, as well as excellent dynamic accuracy. Of course, standard as well as customised automation solutions are also available.Features and Highlights

- 5-axis machining for workpieces up to Ø 500 mm

- Excellent accessibility and optimal visibility into the machining area. Manual part loading from the front. The door extends right into the machine roof, allowing for comfortable crane loading from the top.

- Tool changer with chain magazine has a capacity for 42 tools in the basic version and can be upgraded to 74 tools. The optional rack magazine accommodates, depending on tool holder, from 112 to 600 additional tools (scalable) and can be installed easily and in a space-saving manner on the left side of the machine.

- High rigidity with minimum thermal growth and optimal vibration damping due to the machine base made of gray cast iron, with three-point support system.

- Perfect dynamic accuracy due to weight-optimized moving parts made of spheroidal cast iron.

- Standardized as well as customized automation with a robot may be retrofitted at any time, as the right side of the machine remains accessible.

- Perfect operability from the front with ergonomic configuration of all operating elements.

- Wide variety of automation options are available, including individually customized solutions.

VERSA® 743

-

3-axis machining center - highest level of precision and dynamics

This 3-axis machining center with a fixed table and Heidenhain CNC control offers a generously-sized clamping area of 770 x 650 mm. Workpieces up to 1000 kg can be machined with high precision and dynamics. The machining center VERSA 743 combines the latest technology with proven features.

The grey cast iron base, thermo-symmetrical set-up and the fact that only 2 axes are used for cutting result in maximum rigidity and precision, as well as excellent dynamic accuracy. Of course, standard as well as customised automation solutions are also available for our machining centers.Features and Highlights

- Clamping area of 770 x 650 mm and travels of 500 x 650 x 420 mm for workpieces up to 1000 kg.

- Excellent accessibility and optimal visibility into the machining area. Manual part loading from the front. The door extends right into the machine roof, allowing for comfortable crane loading from the top.

- Tool changer with chain magazine has a capacity for 42 tools in the basic version and can be upgraded to 74 tools. The optional rack magazine accommodates, depending on tool holder, from 112 up to max. 600 additional tools (scalable) and can be installed easily and in a space-saving manner on the left side of the machine.

- High rigidity with minimum thermal growth and optimal vibration damping due to the machine base made of gray cast iron, with three-point support system.

- Perfect dynamic accuracy due to weight-optimized moving parts made of spheroidal cast iron.

- Standardized as well as customized automation with a robot may be retrofitted at any time, as the right side of the machine remains accessible.

- Perfect operability from the front with ergonomic configuration of all operating elements.

- Wide variety of automation options are available, including individually customized solutions.

VERSA® 825

-

Highest productivity for precise 5-axis machining of complex work pieces.

The FEHLMANN VERSA® 825 is ideally suited for dynamic HSC milling as well as for machining of tough materials.The tilting rotary table is integrated longitudinally into the X-axis, thus allowing tilt operation that is wholly unaffected by the linear axes.

Automation can be easily retrofitted at a later date and in no way constrains the access to the working area.Features and Highlights

- Travels X 875 mm, Y 700 mm, Z 450 mm, A +/- 115°, B 360°

- Motor spindle FEHLMANN HSK A-63

with powerful max. spindle torque 120 Nm - Highest geometrical precision and thermal stability

- Best surfaces with perfect dimensional accuracy

- Practice-orientated accessibility, also when loaded automatically by robot

- Swivel range of +/- 115°

- Heidenhain CNC control TNC 640 with best dynamic setup

- Generous tool changer scalable with 44, 80, 250 and 346 tools

VERSA® 823

-

Ideal for the machining of precision mechanical engineering components and mould assemblies weighing up to 1000 kg.

The FEHLMANN VERSA® 823 allows for precision and dynamic high-performance machining of work pieces weighing up to 1000 kg max. Highest geometric accuracy is achieved through the solid, strong ripped grey cast iron construction. All energy transmitting machine elements are cooled, thus preventing thermal deformations of the machine structure even under heaviest load. Automation can be easily integrated at any time without creating constraints to the accessibility of the working area.

Features and Highlights

- Travel X 820 mm, Y 700 mm, Z 450 mm

- Large clamping area of 1200 x 750 mm

- Motor spindle FEHLMANN HSK A-63

with powerful max. spindle torque 120 Nm - Highest geometrical precision and thermal stability

- Best surface and perfect dimensional accuracy

- Practice-oriented accessibility, also when loaded automatically by robot

- Heidenhain CNC-control TNC 640 with best dynamic setup

- Generous tool changer, loadable with 44, 80, 250 and 346 tools scalable

- Variety of standard automation options, as well as individual customized solutions

VERSA® 645 linear

-

Highly dynamic 5-axis machining

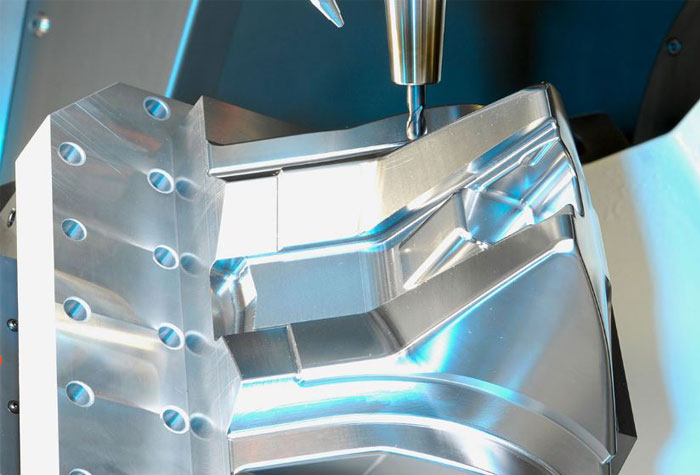

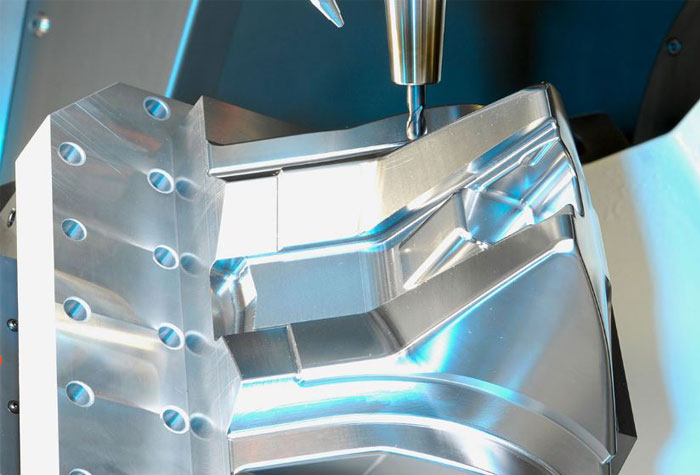

Machining simple or complex precision parts — whether 5-axis with positioning or 5-axis simultaneous milling, the FEHLMANN VERSA 645 linear masters any demanding complex task with flying colours — accurately and reliably.

The FEHLMANN VERSA 645 linear allows for machining workpieces highly dynamically in five axes and with maximum precision. Thanks to the intelligently designed drive concept compromises between precision and dynamic machining are a thing of the past: linear drives permit high acceleration and dynamics without compromising maximum precision.

The fact that only two axes on the tool side are used for cutting, results in high rigidity and precision and, thus, in an immaculate surface finish. The tilting rotary table is integrated into the machine concept in a longitudinal direction, thereby guaranteeing a swiveling area unaffected by the linear axes (no kinetic coupling effect). It also disposes of direct drives with cooled torque motors and high-accuracy angular measurement systems, which grant maximum dynamic precision even during simultaneous multi-axis machining.

Uncompromising Precision

The FEHLMANN VERSA 645 linear has been designed for maximum precision through and through. The cooled slide components, as well as the cooled machine structure, consistently prevent undesirable thermal growth. The X axis with the tilting rotary table is supported along the entire bed length for perfect stability. The stable swivel bridge with counter-bearing also contributes to the high rigidity of the FEHLMANN VERSA 645 linear.

Features and Highlights

- Excellent accessibility and optimal visibility into the machining area.

Manual part loading is done from the front. The door extends right into the

machine roof, allowing for comfortable crane loading from the top.

- The tool changer with chain magazine has a capacity for 50 tools in the

basic version and can be upgraded to 86 tools. The optional rack magazine

accommodates up to 400 additional tools scalable and can be installed easily

and in a space-saving manner on the left side of the machine.

- High rigidity with minimum thermal growth and optimal vibration damping

due to the machine base made of gray cast iron, with three-point support

system.

- Perfect dynamic accuracy due to weight-optimized moving parts made of

spheroidal cast iron.

- Standardized or even customized automation with robot may be retrofitted

at any time, as the right side of the machine remains accessible.

- Can also easily be combined with a FEHLMANN VERSA 825 automation system

at any time – due to an intelligent symmetrical concept, which leaves the

right machine side accessible for automation.

- Perfect operability from the front with ergonomical configuration of all

operating elements.

- Wide variety of pallet types up to individual customized solutions.

- Excellent accessibility and optimal visibility into the machining area.

Manual part loading is done from the front. The door extends right into the

machine roof, allowing for comfortable crane loading from the top.

VERSA® 643 linear

-

Precise and highly dynamic 3-axis machining

Instead of the integrated tilting rotary table, the 3-axis version features a table size of 620 × 500 mm - perfectly suited for high-precision and high-dynamic 3-axis machining. Guarantees long tool life, optimal surface finish and high accuracy.

The FEHLMANN VERSA 643 linear allows for machining workpieces highly dynamically in three axes and with maximum precision. Thanks to the intelligently designed drive concept compromises between precision and dynamic machining are a thing of the past: linear drives permit high acceleration and dynamics without compromising maximum precision.

Spacious enough for flexible 3-axis precision machining

The table, with a generous size of 620 x 500 mm and a capacity of up to 400 kg, allows for multiple clamping as well as multiple clamping devices.Uncompromising Precision

The FEHLMANN VERSA 643 linear has been designed for maximum precision through and through. The cooled slide components, as well as the cooled machine structure, consistently prevent undesirable thermal growth. The X axis is supported along the entire bed length for perfect stability.

Features and Highlights

- Excellent accessibility and optimal visibility into the machining area. Manual part loading is done from the front. The door extends right into the machine roof, allowing for comfortable crane loading from the top.

- The tool changer with chain magazine has a capacity for 50 tools in the basic version and can be upgraded to 86 tools. The optional rack magazine accommodates up to 400 additional tools scalable and can be installed easily and in a space-saving manner on the left side of the machine.

- High rigidity with minimum thermal growth and optimal vibration damping due to the machine base made of gray cast iron, with three-point support system.

- Perfect dynamic accuracy due to weight-optimized moving parts made of spheroidal cast iron.

- Standardized or even customized automation with robot may be retrofitted at any time, as the right side of the machine remains accessible.

- Can also easily be combined with a FEHLMANN VERSA 825 automation system at any time – due to an intelligent symmetrical concept, which leaves the right machine side accessible for automation.

- Perfect operability from the front with ergonomical configuration of all operating elements.

- Wide variety of pallet types up to individual customized solutions.

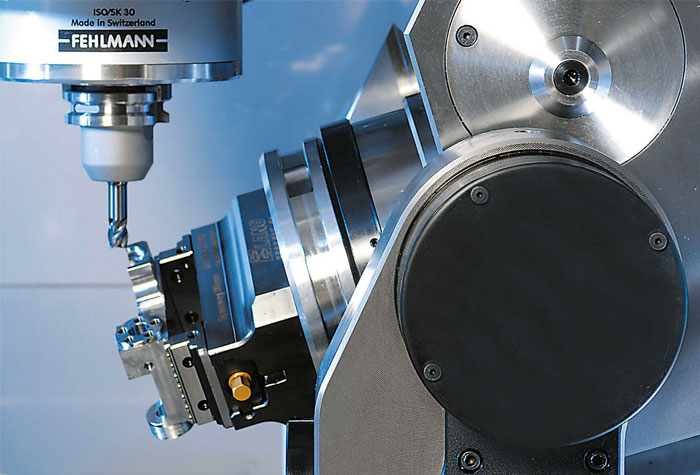

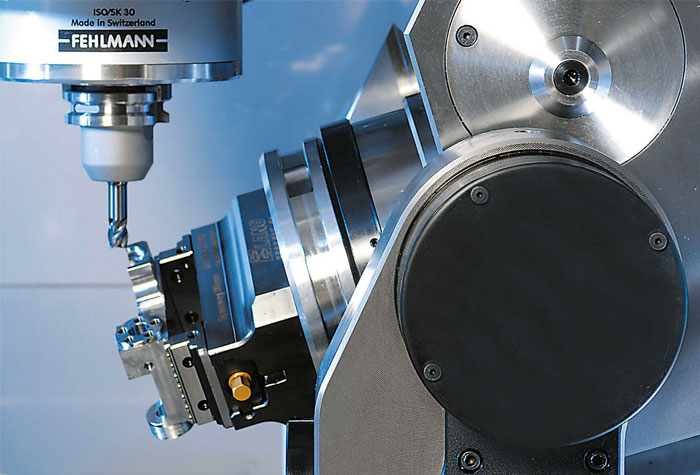

Machining centres

PICOMAX® 95

-

Milling of 5-axis small cubic parts as well as bulky 3-axis workpieces from hard-to-mill materials

Ideally suited for manufacturing of precision parts, machining of tough materials and milling of hardened tooling steel.

This machine copes with all kinds of tasks as a result of the optimized machine construction and the HSK-A63 motor spindle, which combine rigidity, torque and dynamism.

5-axis machining without foregoing the stability and precision of a 3-axis machine - all possible with the PICOMAX®95. This machine can be fitted with a fully controlled, integrated 4th or 5th axis at any time on the generous working table. Good accessiblity and ergonomics consistently guarantee ease of access to all machine features. The compact , but also generous, tool changer of the PICOMAX®95 is equipped with a magazine of 48 or 80 tool pockets.

The freely configurable automation can also be retrofitted. The side entry allows accessibility to the machining area at all times.Characteristics and Highlights

- Travel: X 800mm, Y 500mm, Z 610mm

- Large clamping area (length x width 1600 x 550 mm)

- Fehlmann HSK-A63 motor spindle with active spindle coolant

- Practice-orientated accessibility

- Digital drive technology

- Universal, versatile Heidenhain CNC-control

- Perfect surfaces and high precision

- Generous tool changer with chain magazine for up to 48 or 80 tool pockets

- Fully integrated and controlled 4/5 axis can be added anytime

PICOMAX® 75

-

Powerful solution for 5- to 3-axis precision machining.

Versatile, productive and compact.

The PICOMAX 75 impresses with high precision, best rigidity and optimum energy efficiency.

Tool magazine with loading from front during machining, a compact, space-saving design, as well as Fehlmann-typical, outstanding ergonomics are just a few features of this novelty.

Machine construction, Z-axis travel, geometry and control unit have been designed for 5-axis machining with FEHLMANN dividing and swiveling units. Up to 5 axes are fully integrated in the control system. This combination ensures best access and precision in 5-, 4- and 3-axis machining.Characteristics and Highlights

- Designed from the beginning for 5-axis working

- Compact, well-thought-out design for perfect accessibility and best operating ergonomics for 5-, 4-, and 3-axis milling, guarantees highest precision.

- Automatic tool changer with 50 places (optional 80 places) loadable from operator side during machining.

- Energy-optimized design and power units for saving energy and operating costs.

- Power units switch off automatically when they are not in use.

- Latest generation, fully digital, universal contouring control unit Heidenhain iTNC 530.

- High rigidity due to new stability-optimized design, vertical column, stable carriage, ball-screw axis drives and digital three-phase drives with AC motors.

- High-precision glass scales with compressed air for direct position measurement as standard.

- Powerful FEHLMANN motor spindles with high torque.

- Maximum spindle speed 14,000 / 20,000 / 30,000 / 36,000 rpm

- Axis travel X 600 mm, Y 400 mm, Z 610 mm

- Maximum feed rate (with interpolation) on all axes 30,000 mm/min

- Machine can be automated without impairing accessibility

- Fehlmann Swiss Made – everything from a single source!

Milling-/drilling machines

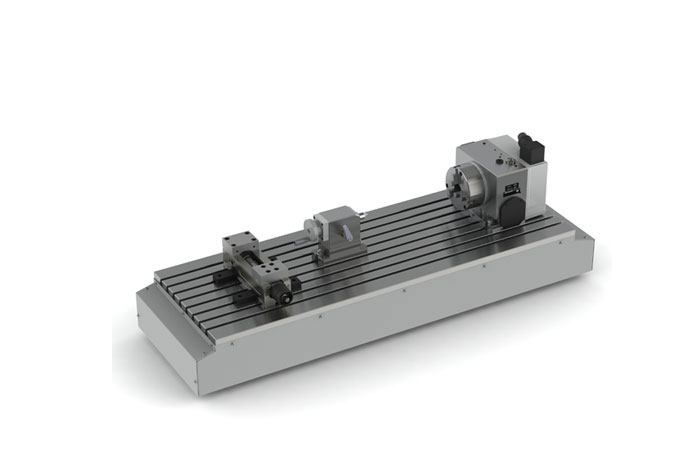

PICOMAX® 56L TOP

-

The CNC machining center PICOMAX 56 in L version - even more flexible and versatile

Modernizing conventional machiningThe TOP machine for manual and CNC operation with the innovative FEHLMANN operating concept: handy, fast and economical.

The machining center PICOMAX 56 L TOP (Touch Or ProgramTM) is equipped with an entirely new operating concept, combining both CNC controlled 3-axis machining, as well as manual operation, using a drilling lever and handwheels.

Specifically designed to execute milling, drilling and threading tasks on single parts in a quick, reliable and efficient way without any time-consuming programming. After a very short initial training period, operators are able to efficiently operate the machining center PICOMAX 56 L TOP, even without previous programming knowledge.

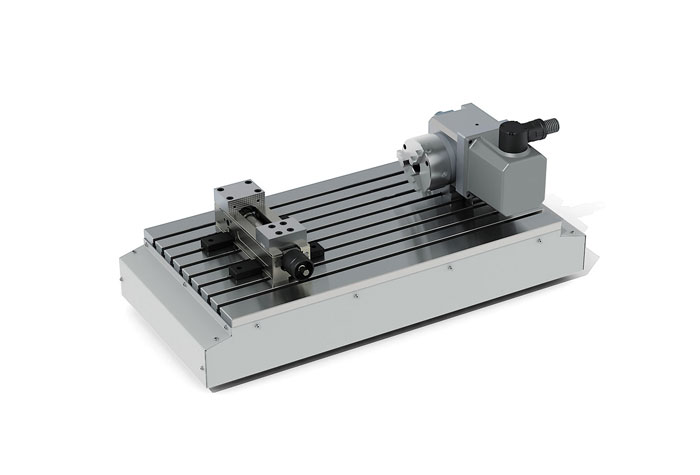

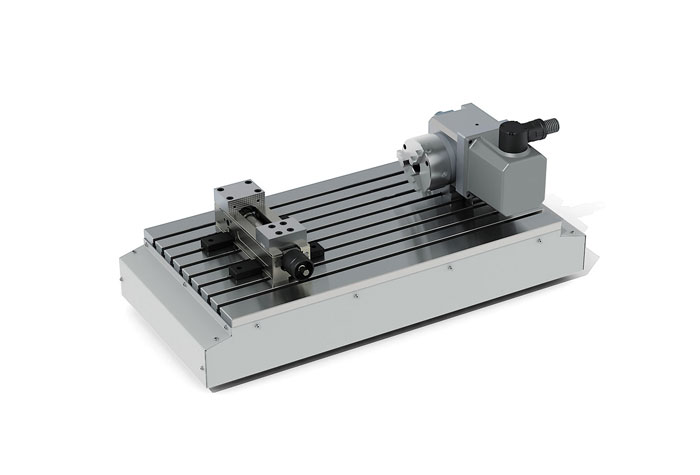

Machining center with larger clamping surface

The L Version has extended X travel of 800 mm, compared to the standard model, and a clamping surface of 1400 x 480 mm. Extra long workpieces can be machined in a single step without repositioning. More possibilities are available for 4-axis machining with a dividing unit. Thanks to the increased distance between the dividing unit and tail stock, longer workpieces can also be machined efficiently.

Even the basic model of this machining center (CNC) "made in Switzerland" offers the features of a modern, highly productive milling machine, such as: fully digital Heidenhain controls TNC 620, a Fehlmann cooled and high-torque motor spindle for universal milling up to 12'000 rpm, Z/S interpolated thread cutting, 3D milling, boring, etc.

Furthermore the PICOMAX 56 L TOP is upgradeable with various functional machine options, such as a FEHLMANN dividing unit for 4-axis operation, an automatic tool changer with 20 or 30 pockets and more.Characteristics and Highlights

- Can be used as a full CNC machining center or as a conventional "manual" machine. For economical milling and drilling of small batches and single parts, without time-consuming programming.

- FEHLMANN TOP-functions, an entirely innovative operating concept, allowing the machine to be used both for CNC controlled 3-axis machining, as well as for manual operation - using drilling lever and handwheels

- Extra-long workpieces can be machined in one single step, without re-positioning

- Several fixtures can be mounted simultaneously on the 1400 x 480 mm clamping surface

- 4-axis machining of extra-long workpieces

- Efficient and economical machining of complex parts using the Heidenhain TNC 620 and the graphically supported cycles

- Space-saving and clearly laid out, due to ergonomic and compact construction

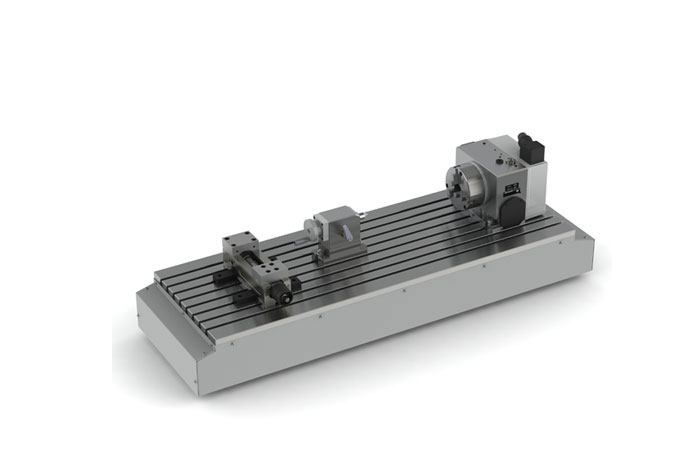

PICOMAX® 56L mill

-

For simple conventional as well as CNC machining - L-version with larger clamping surface for even more flexibility

Modernizing conventional machining.

Mill version also for vocational training, with 3 handwheels and basic functions for conventional milling, drilling and threading.

The precision milling machine PICOMAX 56 L is also available in the mill version.

Specially optimized for simple, conventional milling tasks – thus allowing for optimal entry into modern cutting technology. Operates like a full-fledged conventional milling and drilling machine, without the necessity of programming knowledge.

Larger clamping surface

The L Version has extended X travel of 800 mm, compared to the standard model, and a clamping surface of 1400 x 480 mm.

Extra long workpieces can be machined in a single step without repositioning. More possibilities are available for 4-axis machining with a dividing unit. Thanks to the increased distance between the dividing unit and tail stock, longer workpieces can also be machined efficiently.

Even the basic model of this FEHLMANN machine "made in Switzerland" offers the features of a modern, highly productive milling machine, such as: fully digital Heidenhain controls TNC 620, a Fehlmann cooled and high-torque motor spindle for universal milling up to 12'000 rpm, Z/S interpolated thread cutting, 3D milling, boring, etc.

Furthermore, the PICOMAX 56 L mill is upgradeable with various functional machine options, such as a FEHLMANN dividing unit for 4-axis operation, an automatic tool changer with 20 or 30 pockets and more.

Also perfectly suited for modern vocational training

From the basics of milling to advanced CNC applications, the mill version of the PICOMAX 56 L is also ideally suited for modern, practice-oriented training - for both conventional and CNC machining. With the FEHLMANN mill functions and the three mechnaical handwheels, the controls function as a simple digital display. This allows basic conventional milling knowledge to be taught up close and with maximum operator safety, thanks to the safety door.

The simple and logical operation, a modern and compact machine concept, the technical features and a high degree of flexibility make the PICOMAX 56 L mill the perfect machine for training.Characteristics and Highlights

- Manual and CNC operation, for manual machining without giving up the advantages of a CNC machine - switch to CNC mode at any time at a push of a button

- FEHLMANN mill functions, a simplified operating concept which enables single parts and small series to be milled, drilled and thread-cut rapidly and precisely. The mill package includes three labeled, parallel-active mechanical-electronic handwheels for the X, Y and Z axes, as well as the basic functions for conventional milling, drilling and tapping, without any programming knowledge.

- Extra-long workpieces can be machined in one single step, without re-positioning

- Several fixtures can be mounted simultaneously on the 1400 x 480 mm clamping surface

- 4-axis machining of extra-long workpieces

- Efficient and economical machining of complex parts using the Heidenhain TNC 620 and the graphically supported cycles

- Space-saving and clearly laid out, due to ergonomic and compact construction

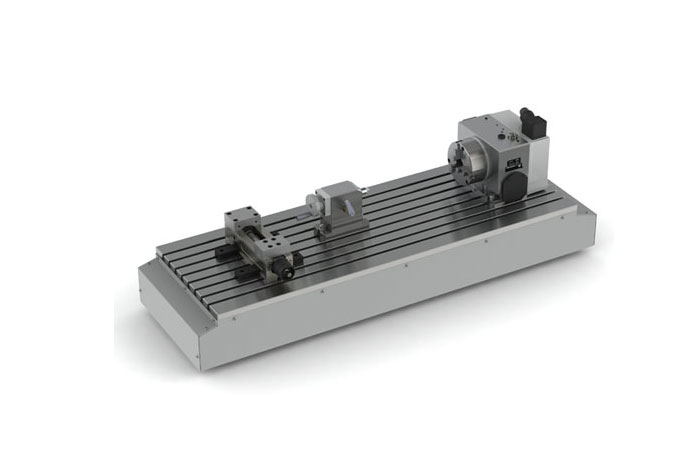

PICOMAX® 56 TOP

The TOP machine for manual and CNC operations, the PICOMAX® 56 TOP

Modernizing conventional machining.

The TOP machine for manual and CNC operation with the innovative FEHLMANN operating concept: handy, fast and economical.

The precision milling and drilling machine PICOMAX 56 TOP (Touch Or Program™) is equipped with an entirely new operating concept, combining both CNC controlled 3-axis machining, as well as manual operation, using a drilling lever and handwheels.

Specifically designed to execute milling, drilling and threading tasks on single parts in a quick, reliable and efficient way without any time-consuming programming. After a very short initial training period, operators are able to efficiently operate the machine, even without previous programming knowledge.

Even the basic model of this FEHLMANN milling machine "Made in Switzerland" offers the features of a modern, highly productive milling machine, such as: fully digital Heidenhain CNC control TNC 620, a cooled and high-torque motor spindle made by Fehlmann for universal milling up to 12'000 rpm, Z/S interpolated thread cutting, 3D milling, boring, etc...

Furthermore, the milling machine PICOMAX 56 TOP is upgradeable with various functional machine options, such as a FEHLMANN dividing unit for 4-axis operation, an automatic tool changer with 20 or 30 pockets, etc.Characteristic and Highlights

- Manual CNC milling machine, for economical milling and drilling of small batches and single parts.

- FEHLMANN TOP functions, the entirely innovative operating concept, allowing the machine to be used both for CNC controlled 3-axis machining, as well as manual operation - using drilling lever and handwheels

- Efficient and fast, even without programming knowledge

- Using the Heidenhain TNC 620 and the graphically supported cycles, complex parts are machined very economically

- High-performance and versatility with excellent cost/performance ratio

- Space saving and clearly laid out, due to ergonomic and compact construction

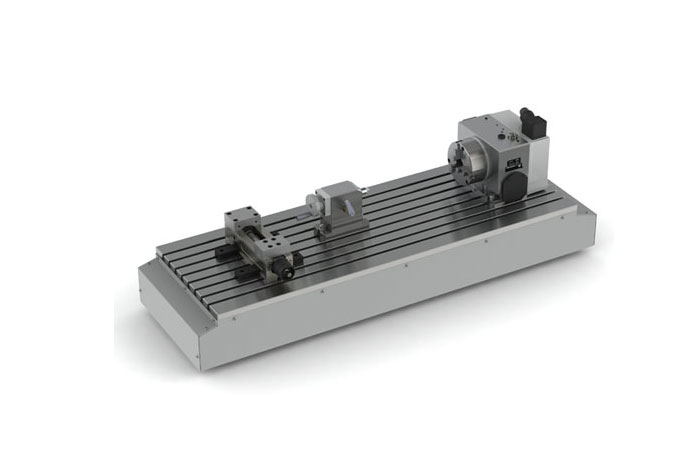

PICOMAX® 56 mill

Conventional and CNC milling machine in one

Combination of manual and CNC machining - modernizes the conventional workplace.

Mill version also for vocational training, with 3 handwheels and basic functions for conventional milling, drilling and threading.

The precision milling machine PICOMAX 56 is also available in the mill version.

Specially optimized for simple, conventional milling tasks – thus allowing for optimal entry into modern cutting technology. Operates like a full-fledged conventional milling and drilling machine, without the necessity of programming knowledge.

This '"made in Switzerland" machine already offers various equipment features of a modern, powerful milling machine in the basic version, i.e.: fully digital CNC Heidenhain control TNC 620, FEHLMANN liquid-cooled and high-torque motor spindle for universal milling up to 12,000 rpm, as well as Z/S-interpolated thread cutting, 3D-milling, boring, etc..

Furthermore, the combination of manual and CNC milling machine PICOMAX 56 mill is upgradeable with various functional machine options, such as a FEHLMANN dividing unit for 4-axis operation, an automatic tool changer with 20 or 30 pockets, etc.

Also perfectly suited for modern vocational training

From the basics of milling to advanced CNC applications, the mill version of the PICOMAX 56 is also ideally suited for modern, practice-oriented training - for both conventional and CNC machining. With the FEHLMANN mill functions and the three mechanical handwheels, the controls function as a simple digital display. This allows basic conventional milling knowledge to be taught up close and with maximum operator safety, thanks to the safety door.

The simple and logical operation, a modern and compact machine concept, the technical features and a high degree of flexibility make the manual and CNC milling machine PICOMAX 56 mill the perfect machine for training.Characteristics and Highlights

- Manual and CNC milling machine, for manual machining without giving up the advantages of a CNC machine - switch to CNC mode at any time at a push of a button

- FEHLMANN mill functions, a simplified operating concept which enables single parts and small series to be milled, drilled and thread-cut rapidly and precisely. The mill package includes three labeled, parallel-active mechanical-electronic handwheels for the X, Y and Z axes, as well as the basic functions for conventional milling, drilling and tapping, without any programming knowledge.

- Using the Heidenhain TNC 620 controls and the graphically supported cycles, complex parts are machined very economically

- Robust, handy and versatile

- Space saving and clearly laid out, due to ergonomic and compact construction

PICOMAX® 21-M

-

Robust and very user-friendly precision coordinate drilling and milling machine.

Ideal for training purposes, as well as for the production of single pieces and small series.

The integrated motorised table allows ultra-rapid and precise positioning not just manually, but also automatically, for bolt hole circles, dot patterns and rectangular pockets. Entries are made simply and comfortably via the digital readout’s touch screen display.

Glass scales and ball screws guarantee for long-lasting high production quality.Detailed Information

Flexibility- Milling, drilling, thread cutting, boring Large clamping surface cuts down on set-up times (availability of simultaneous chucking options) Versatile machine accessories, including sinus table and manual dividing attachments Manual or automatic positioning

- Simple, rapid and intuitive touch screen operation on digital readout With lightning speed - the manual tool change system Perfect work piece accessibility Mechanical handwheels A complete work station (integrated tool cabinet) Reduction of non-productive time Requires little space

Precision / quality- Jig-boring machine precision, positioning tolerances below 0.01mm Direct path measuring systems, scraped machine geometry Quality assurance using state-of-the-art devices In-house development, production and assembly at Fehlmann/Switzerland

PICOMAX® 21-D

The PICOMAX 21-D fulfills even the highest requirements for maximum precision and handiness for state-of-the-art workshops. It is used for drilling, thread cutting and milling operations in the demanding prototype and tool production, as well as for training purposes. This machine forms a solid basis for an up-to-date machine fleet. The proven machine concept is continuously being further developed and refined and contributes to the efficient and precise production of mechanical components on more than 10'000 shop floors world-wide every day.Detailed Information

Flexibility- Milling, drilling, thread cutting, boring

- Large clamping surface cuts down on set-up times (several chucking options at a time)

- Versatile machine accessories, including sinus table and manual dividing attachments

- Also available with simple control unit

Operation- With lightning speed - the manual tool change system

- Perfect work piece accessibility

- Mechanical handwheels

- A complete work space (integrated tool cabinet)

- Reduction of non-productive times

- Requires little space

Precision / quality- Jig-boring machine precision, positioning tolerances below 0.01mm

- Direct path measuring systems, scraped machine geometry

- Quality assurance using state-of-the-art devices

- In-house development, production and assembly at Fehlmann/Switzerland

Automation

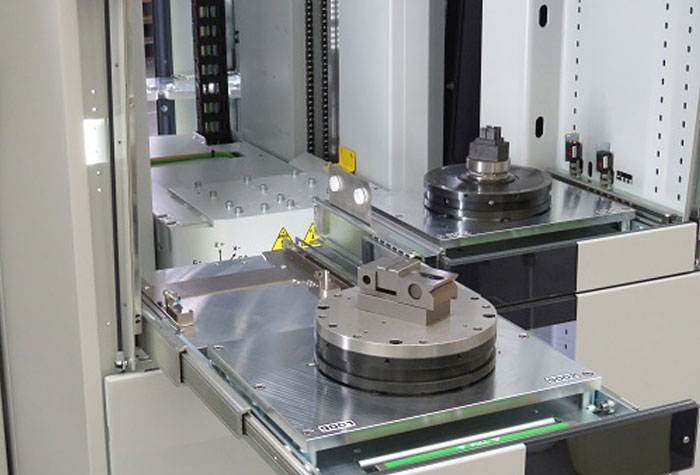

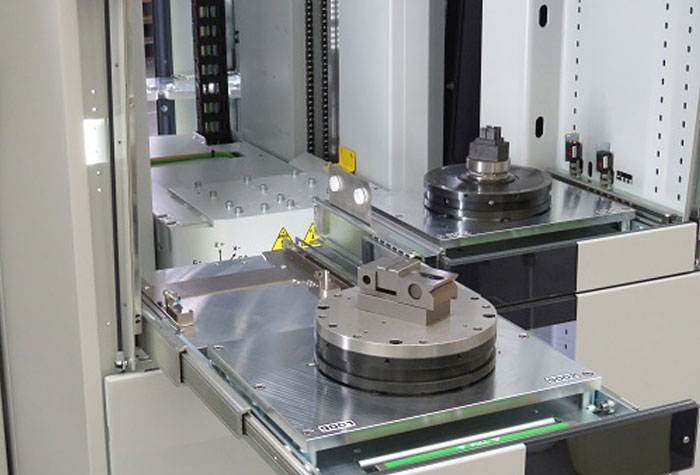

VERSA® 945 / 943 Automation

- If an 8- or 16-hour shift per day is no longer sufficient... More and more frequently, 'time to market' has become one of the most important 'survival' criteria for today's tool room shops and parts producers. New products are developed and produced in short periods of time. With the help of the latest information technology of the FEHLMANN MCM™ (Milling Center Manager), parts can be loaded and unloaded quickly and reliably - in an operator friendly way. Apart from the high quality of the part, key factors are the unlimited availability, the accessibility of the system during day shifts, as well as the safety of the process during night shifts (unattended operation with little or no staff). The FEHLMANN MCM™ offers you valuable support - proven time and again - measuring up to today's automation requirements and based on today's industrial standards. As the MCM is an in-house development by FEHLMANN, you can put trust and safety in the support of the entire system in our hands.

VERSA® 745 / 743 Automation

- If an 8- or 16-hour shift per day is no longer sufficient... More and more frequently, 'time to market' has become one of the most important 'survival' criteria for today's tool room shops and parts producers. New products are developed and produced in short periods of time. With the help of the latest information technology of the FEHLMANN MCM™ (Milling Center Manager), parts can be loaded and unloaded quickly and reliably - in an operator friendly way. Apart from the high quality of the part, key factors are the unlimited availability, the accessibility of the system during day shifts, as well as the safety of the process during night shifts (unattended operation with little or no staff). The FEHLMANN MCM™ offers you valuable support - proven time and again - measuring up to today's automation requirements and based on today's industrial standards. As the MCM is an in-house development by FEHLMANN, you can put trust and safety in the support of the entire system in our hands.

VERSA® 825 / 823 Automation

- If an 8- or 16-hour shift per day is no longer sufficient... More and more frequently, 'time to market' has become one of the most important 'survival' criteria for today's tool room shops and parts producers. New products are developed and produced in short periods of time. With the help of the latest information technology of the FEHLMANN MCMTM (Milling Center Manager), parts can be loaded and unloaded quickly and reliably - in an operator friendly way. Apart from the high quality of the part, key factors are the unlimited availability, the accessibility of the system during day shifts, as well as the safety of the process during night shifts (unattended operation with little or no staff). The FEHLMANN MCMTM offers you valuable support - proven time and again - measuring up to today's automation requirements and based on today's industrial standards. As the MCM is an in-house development by FEHLMANN, you can put trust and safety in the support of the entire system in our hands.

VERSA® 645 / 643 linear Automation

- If an 8- or 16-hour shift per day is no longer sufficient... More and more frequently, 'time to market' has become one of the most important 'survival' criteria for today's tool room shops and parts producers. New products are developed and produced in short periods of time. With the help of the latest information technology of the FEHLMANN MCMTM (Milling Center Manager), parts can be loaded and unloaded quickly and reliably - in an operator friendly way. Apart from the high quality of the part, key factors are the unlimited availability, the accessibility of the system during day shifts, as well as the safety of the process during night shifts (unattended operation with little or no staff). The FEHLMANN MCMTM offers you valuable support - proven time and again - measuring up to today's automation requirements and based on today's industrial standards. As the MCM is an in-house development by FEHLMANN, you can put trust and safety in the support of the entire system in our hands.

PICOMAX® 95 Automation

- If an 8- or 16-hour shift per day is no longer sufficient... More and more frequently, 'time to market' has become one of the most important 'survival' criteria for today's tool room shops and parts producers. New products are developed and produced in short periods of time. With the help of the latest information technology of the FEHLMANN MCMTM (Milling Center Manager), parts can be loaded and unloaded quickly and reliably - in an operator friendly way. Apart from the high quality of the part, key factors are the unlimited availability, the accessibility of the system during day shifts, as well as the safety of the process during night shifts (unattended operation with little or no staff). The FEHLMANN MCMTM offers you valuable support - proven time and again - measuring up to today's automation requirements and based on today's industrial standards. As the MCM is an in-house development by FEHLMANN, you can put trust and safety in the support of the entire system in our hands.

PICOMAX® 75 Automation

- If an 8- or 16-hour shift per day is no longer sufficient... More and more frequently, 'time to market' has become one of the most important 'survival' criteria for today's tool room shops and parts producers. New products are developed and produced in short periods of time. With the help of the latest information technology of the FEHLMANN MCMTM (Milling Center Manager), parts can be loaded and unloaded quickly and reliably - in an operator friendly way. Apart from the high quality of the part, key factors are the unlimited availability, the accessibility of the system during day shifts, as well as the safety of the process during night shifts (unattended operation with little or no staff). The FEHLMANN MCMTM offers you valuable support - proven time and again - measuring up to today's automation requirements and based on today's industrial standards. As the MCM is an in-house development by FEHLMANN, you can put trust and safety in the support of the entire system in our hands.

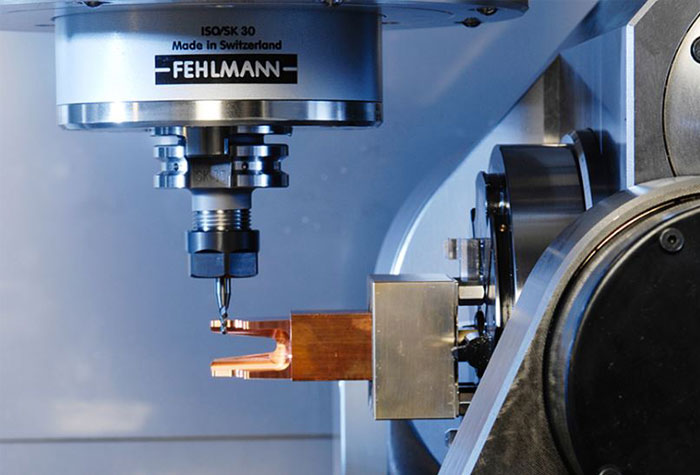

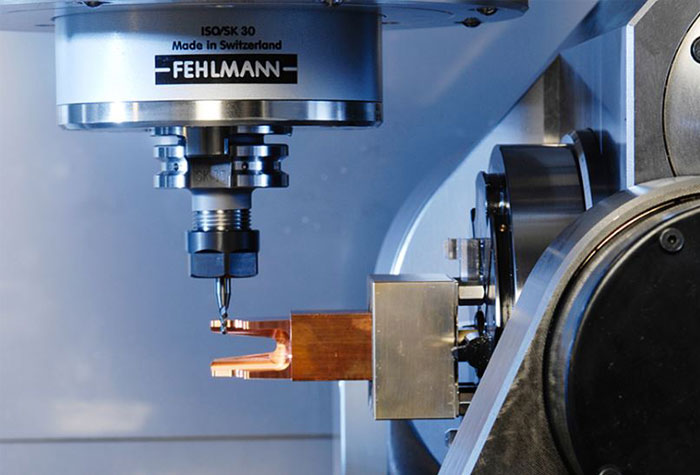

Milling and Grinding

Milling and Grinding Centers

Versatile and economical – one machine for two processes

The decision whether to use hard milling or coordinate grinding requires the evaluation of costs, machining time and desired precision. FEHLMANN solves this question with the new VERSA 645 linear and VERSA 945 with a coordinate grinding function - both processes are perfectly combined on one machine. You can decide case-by-case and with great flexibility how to achieve the desired surfaces most economically.Advantages of combining hard milling and grinding:

- Versatile and economical – one machine for two processes

- Time-savings with one-time clamping of workpiece for milling and grinding. No more re-clamping necessary

- Shorter machining times thanks to two processes on same machine

- Multi-use of precision: make a one-time investment in high precision and benefit twice, thanks to the combination of milling and grinding

- Increased efficiency due to high process reliability

- Parts can be precisely pre-milled before grinding, ensuring a perfectly pre-finished part. Elimination of varying offsets caused, for example, by warpage during hardening

- Consistent excellent surface quality and contour accuracy - due to choice of most suitable machining strategy and automatic dressing of grinding tool

- Simple programming - grinding functions such as pendulum stroke and dressing can be easily integrated into the program after milling