- Offer Profile

- We strive for quality in everything we do

At Habasit, we focus on improving the quality, reliability, and productivity of our customers’ industrial processes through our unmatched expertise and a vast portfolio of products. We are a team of professionals with deep industry experience and application knowledge.

Habasit is the world leader for fabric-based conveyor belts, plastic modular belts and chains, power transmission belts, and monolithic and timing belts used in a wide range of industries.

Solutions

Solutions for Food and Beverage

-

Habasit sets value on your food processing belts to have the right design and characteristics to keep your lines running at peak performance.

Ensuring food safety in your processes

Habasit’s unmatched quality, range, and customization options ensure the optimal solution for a wide range of food processing and packaging, and beverage applications. Hygiene is paramount in this industry, so you can count on us to meet or beat the regulations relevant to your industry.

Our HACCP hygienic design principles for food conveyor and processing belts give you safe food production, excellent cleanability, and efficient conveying at every stage. Plus, you benefit from reliable operation and reduced maintenance and downtime. Our Habasit belting specialists are here to provide you with reliable technical support at all times.

Solutions for the Construction Industry

-

Customers in the construction industry around the globe rely on Habasit’s vast belting experience and capabilities to deliver customized solutions for their applications.

First-class quality, performance, and reliability

When it comes to belting solutions, companies in the construction and heavy industry sectors put their trust in Habasit, relying on our extensive industry expertise and over 30 years of experience to deliver high-performing, strong, and reliable belts. As your belting partner, we provide professional technical

support and advice at every stage. Our durable belts feature high abrasion resistance, excellent grip, outstanding reliability even for very heavy loads, as well as long belt lifetimes. Whatever your specific application needs, we can provide the belting solution to match, making a positive contribution to your long-term success.

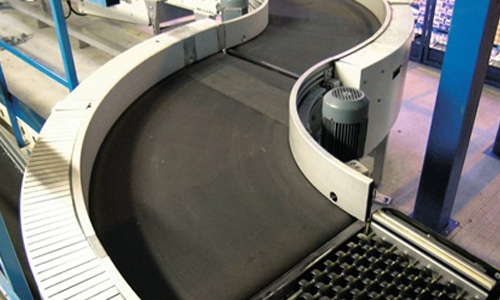

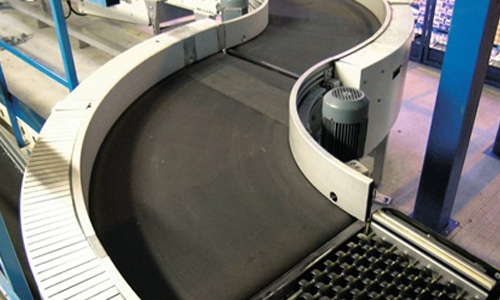

Solutions for the Material Handling Industries

-

Habasit is one of the few belt suppliers to provide solutions for material handling across the entire spectrum, allowing us to give you the solutions you need, not just what we have available.

Your reliable supplier

Sourcing all your belting-related products and services from the same supplier reduces purchasing and logistics complexity as well as costs. It also makes your life easier. Thanks to our expertise, we can offer an unbiased opinion on the best solution for every application.

Our offering extends from traditional lightweight fabric.

belts, to plastic modular belts and chains, to timing belts. With Habasit, you get the solutions you need from start to finish for materials handling applications in a wide range of logistics industries. From new designs to retrofits, and from installation to repair, we’ll provide you with expert technical support at every stage.

Solutions for Packaging

-

Drawing on our years of global experience, we’ll help you meet your challenges with optimal solutions that come with improved productivity and reduced maintenance costs as part of the package.

Meeting the challenges of packaging

Choosing the right belt is key to every successful operation involving packaging machinery. Thanks to our thorough understanding of packaging application requirements, totally customer-focused approach, and extensive range of belts and accessories, you can rely on Habasit to meet your most demanding needs.

As a world-leading belt manufacturer and solution provider, we offer high-quality feeder belts, machine tapes, power transmission belts, conveyor belts, plastic modular belts, and timing belts. Our application engineers, technicians, and joining specialists are available to you at all times with professional advice and support.

Solutions for the Paper Industry

-

Production processes in the paper printing, board converting, and hygienic paper product industry require a vast range of different belts. With energy costs continuously increasing, Habasit ensures both high efficiency as well as energy and cost savings.

Adapting to the paper industry market

Profound industry know-how, ongoing research and innovation, and contact with leading machine manufacturers worldwide enable Habasit to develop solutions that respond to the latest market needs while meeting your requirements for high performance and

reliability at an attractive price/value ratio.

We also know how important highly accurate speed, minimized machine downtime, and fast and easy installation are to you. Whatever your challenges, we can offer the tailor-made solutions you need to meet them.

Solutions for the Textile Industry

-

Our proven breadth of industry knowledge and extensive belting offering cover yarn processing, textile printing, and nonwovens. Because we understand the pressures you face, every solution from Habasit delivers a long service life, high reliability, reduced energy consumption, and an optimal price/value ratio.

Top-quality belting for the textile industry

In the highly competitive textile industry, access to expert technical advice and a comprehensive range of high-quality belting is essential. Habasit has the experienced engineers and world-class solutions you seek for all types of yarn processing, textile printing, and nonwovens applications.

Our focus is on high reliability, reduced energy consumption, and an optimal price to value ratio. We work closely with leading machine manufacturers and end-users to ensure state-of-the-art developments that deliver the high performance, fast installation, and reduced maintenance you require.

Solutions for the Automotive Industry

-

Driven by quality

The automotive industry’s large production volumes and high quality standards demand continuous system innovation. With industrial belting involved throughout the production process, Habasit is the partner you need for expert technical advice and high-quality solutions to meet your specific application requirements.

Our extensive range of conveyor and processing belts, timing belts, modular belts, and power transmission belts for the automotive industry has been developed through years of close cooperation with our customers. We understand your challenges, and we share your focus on quality, efficiency, safety, and value.

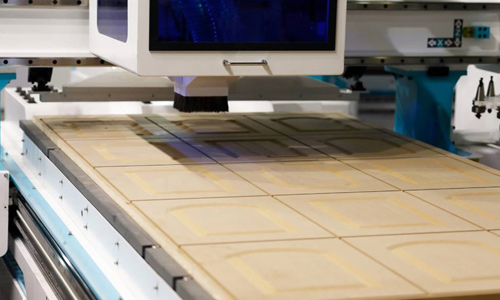

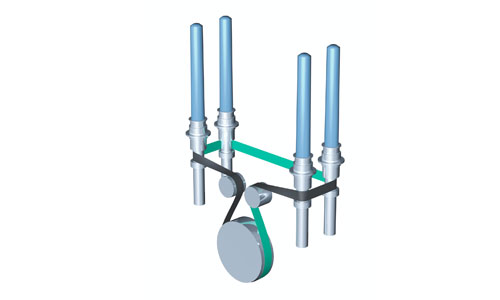

Industrial Automation

-

Tailor-made solutions for industrial automation

With industrial automation on the raise, Habasit is the ideal partner for all your belting needs. Our broad global experience and deep industry expertise keep us at the forefront of developments, with an ever-expanding range of innovative solutions and products, and a team of highly skilled specialists to advise and support you at every stage.

Our belting experts will help you select the optimal belt style, type and material for your application, providing a cost-effective, reliable and high-quality customized solution to meet your most complex requirements. Please contact us – we’re here to assist you.

Waste Treatment and Recycling

-

Sustainable solutions for waste treatment and recycling

You can rely on Habasit’s expert consultation and support to achieve optimal solutions for your waste treatment and recycling belting needs. Whether for handling plastic, paper, cardboard, glass, metal or aluminum, Habasit offers a complete range of belting products and services.

Our solutions provide high abrasion-, impact, temperature and chemical resistance, as well as excellent sanitation properties, while increasing belt service life and performance. Our high-quality materials and robust designs are also suitable for metal detectors, NIR-scanners and X-rays.

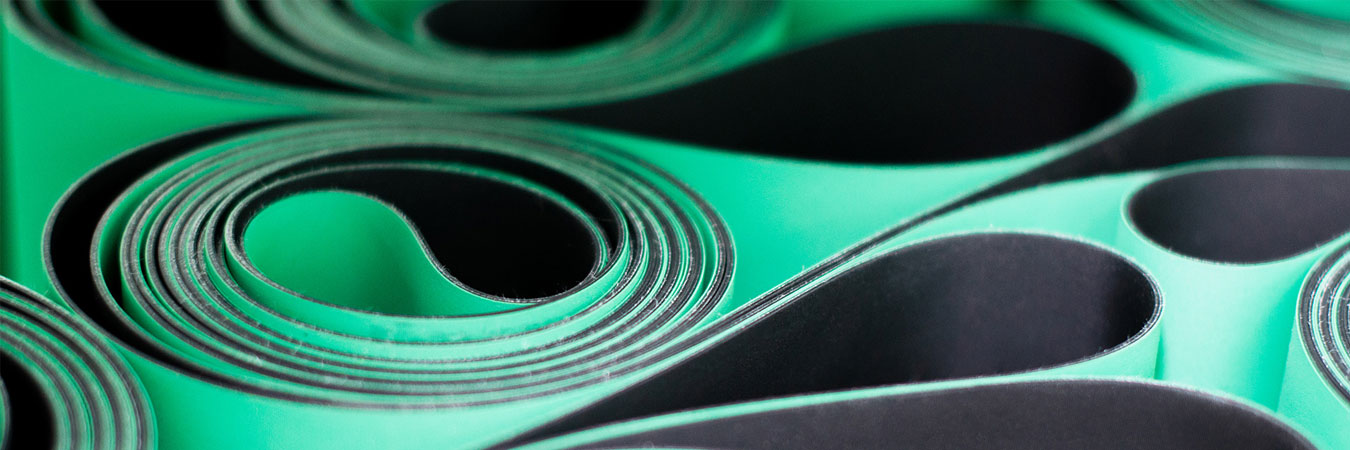

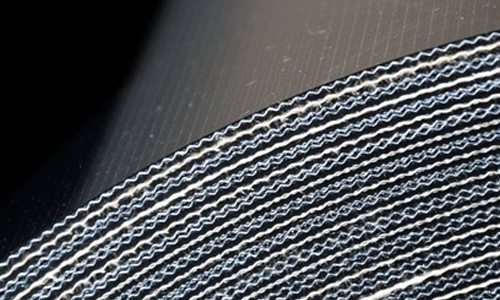

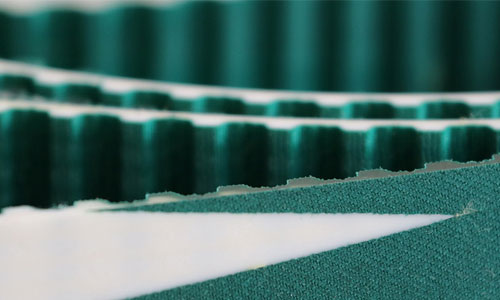

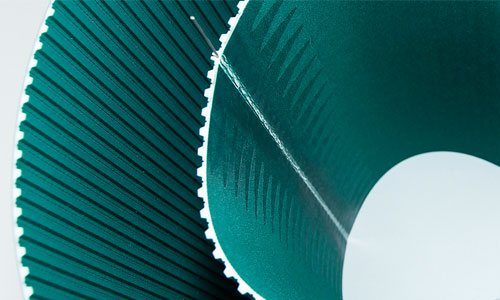

Fabric Belts

-

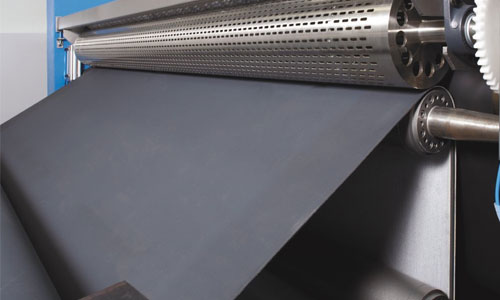

Swiss-quality, world-class-performance fabric belts

Fabric-based conveyor and processing belts are used in a vast number of industries and applications. Habasit’s wide-ranging offering extends from lightweight conveyor belts to specialized processing belts, and from power transmission belts to machine tapes.

Every Habasit solution is made with high precision and sets the performance benchmarks in the belting industry. We ensure the reliability and flexibility of our solutions through combining top-quality raw materials with state-of-the-art manufacturing and our extensive engineering experience.

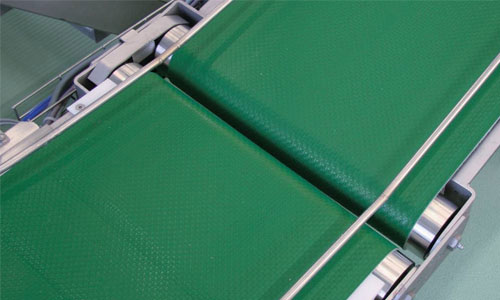

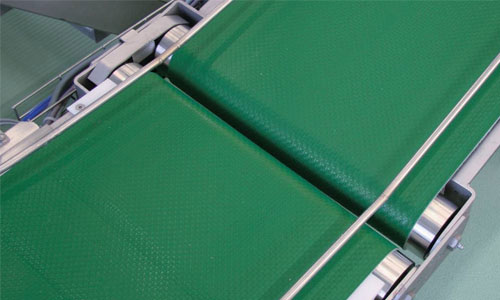

Light Conveyor Belts

- The all-rounders for light conveying

Light conveyor belts are used in almost every industry, from airport and distribution, to electronics and agriculture, to gypsum board and wood panel production. They handle general conveying applications such as induction, transfer and check-out, as well as sorting, metering, inspection, packaging, and many others.

Habasit light conveyor belts come in a range of chemical and abrasion resistant materials, with antistatic and low-noise features combined with energy-saving or anti-flame treatments, to support your most demanding applications.

Heavy Conveyor Belts

- The workhorses for arduous processing tasks

Industries around the world, from airports and distribution centers, to marble, stone, and metal processors, to glass, tire and plastics manufacturers, use heavy conveyor belts for numerous applications including cutting, punching, and stamping; check-in, acceleration and accumulation; and incline loading and unloading.

Habasit offers a wide variety of belts optimized for various requirements such as cut- and wear resistance, oil- and impact resistance, high rigidity, permeability, flame retardance, adhesive or non-adhesive surfaces, resistance against temperature variations, or various other properties to match the application requirements.

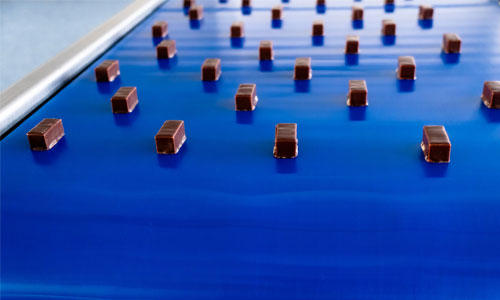

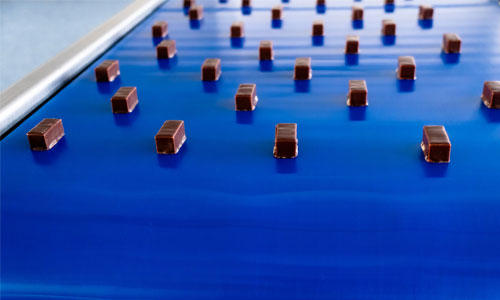

Food Belts

- A complete menu of food conveyor and processing belts

The food industry includes many different sub-industries, and production and processing steps. Food companies face numerous challenges, not least very high safety standards, plus oily, fatty and wet conditions at different temperatures. Conveying and processing belts are indispensable. Fortunately, Habasit has the right belting solution to meet your requirements.

Our food belts offer excellent release properties even for very sticky foodstuffs, wear- and abrasion resistant coatings, and sophisticated chemical resistance to cope with common cleaning agents and food ingredients. The belts deliver outstanding performance and a superior service life. Habasit solutions are suitable for direct food contact and comply with applicable food regulations.

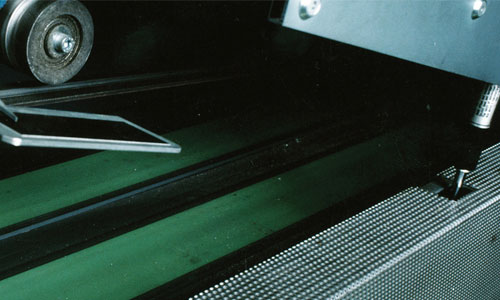

Processing Belts

- Motion for manufacturing and processing

Belting is the essential enabler wherever industrial automation is required. Whatever your industry and application needs, Habasit can draw on our expert capabilities to create a fully customized, reliable and durable solution.

Looking for general conveying and goods processing? Induction and transfer? Calibrating, polishing, packaging, or other special applications? We can meet your needs with belts offering abrasion-, cut- and oil resistance, high grip and stability, ozone- and UV resistance, high temperature resistance, and many other features.

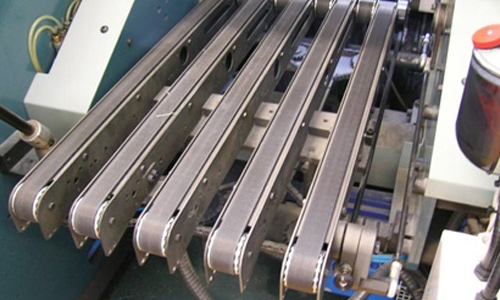

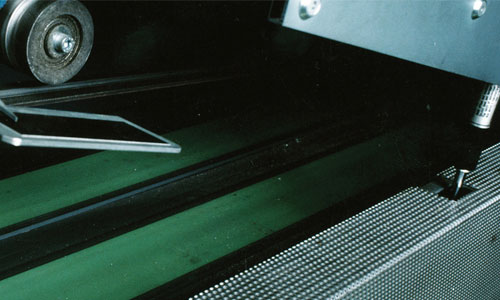

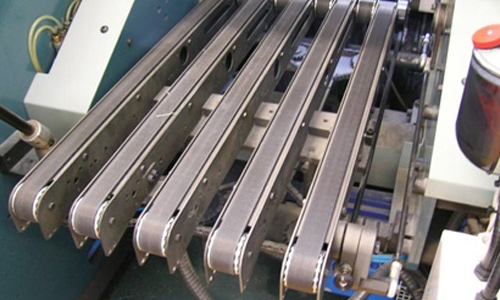

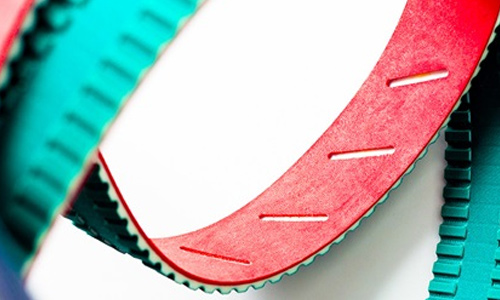

Folder-Gluer Belts

- Essential for box making applications

Habasit folder-gluer belts offer excellent folding precision and high machine performance. With a choice of polyamide or polyester composite for the traction layer, plus proven NBR rubber covers, Habasit’s comprehensive range is suitable for applications extending from box folding to tube winding.

Habasit folder-gluer belts provide excellent reversed bending properties, high abrasion resistance, and outstanding dimensional stability. Their constant and safe grip provides precise folding and the belts leave no marking on the transported goods.

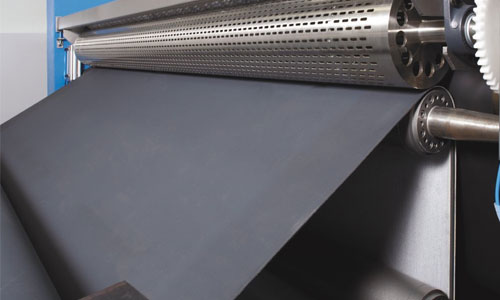

Elastomer Covered Conveyor Belts

- Strong belts for demanding applications

Habasit’s elastomer covered conveying and processing belts manufactured with NBR or EPDM rubber offer reliable and durable solutions for applications in demanding production processes and harsh environmental conditions.

The belts feature high abrasion- and temperature resistance, a consistent coefficient of friction, and a long belt life. Elastomer covered belts are suitable for a wide range of applications in various industries, including materials handling, paper manufacturing, paper and board converting, and packaging.

Machine Tapes

- Multipurpose solutions for printing and paper applications

When you need top-quality machine tapes to convey, speed up, slow down, position, or fold paper material in your applications, you can count on Habasit. Our machine tapes draw on years of experience, ongoing research, and close contacts with the printing and paper industry.

Habasit's Hamid, polyamide and polyurethane machine tapes are manufactured with abrasion resistant NBR covers or other application-oriented surface materials. These highly effective belting solutions are extremely reliable, have constant grip, and offer a long service life.

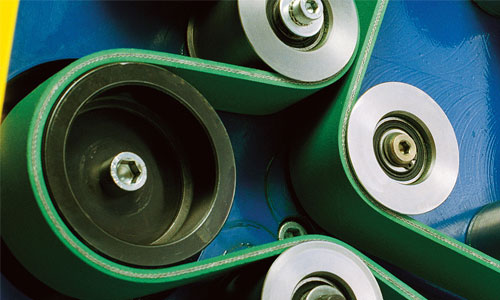

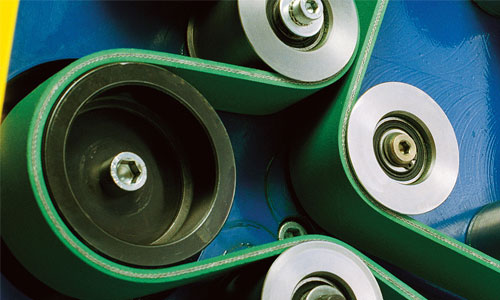

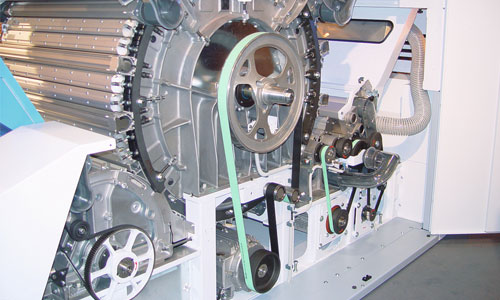

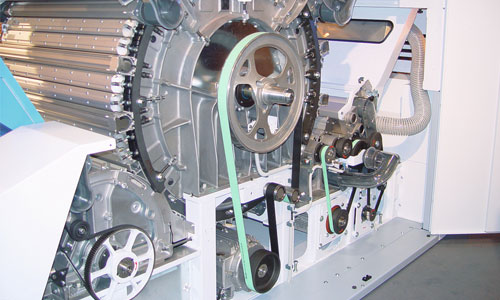

Power Transmission Belts

- Reliable belts that get things moving

Habasit’s fully synthetic, high-quality power transmission belts are equipped with a strong and resilient traction layer made of polyamide, polyester, or aramid. Wear-, oil- and grease-resistant friction covers made of NBR rubber provide a high degree of consistent friction between belt and pulleys.

The versatility and energy-saving properties of these maintenance-free belts make them a key component in all areas of power transmission technology. Their long service life and little or no unexpected machine downtime make them a reliable solution across a variety of industries.

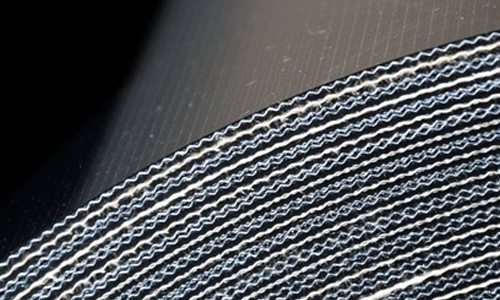

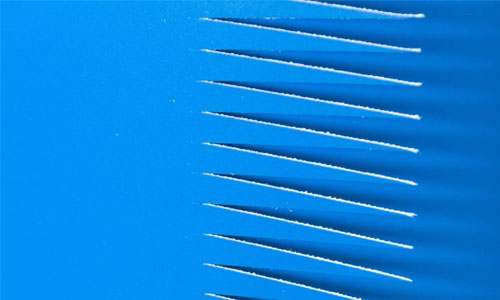

Spindle Tapes

- Champions in the textile industry

Habasit has been setting the benchmark for spindle tapes for decades, and today our spindle tapes are used in the textile industry all around the world. Drawing on our extensive range, you can find the most suitable spindle tape for your specific application, no matter how demanding.

Our polyamide and polyester spindle tapes offer a long service life and cost savings. By preventing fiber accumulation, cleaning is no longer necessary and production is uninterrupted. Moreover, Habasit tapes provide constant spindle speed and uniform yarn quality.

Tobacco Belts

- End-to-end solutions for the tobacco industry

Habasit’s TPO and TPEE tobacco belts ensure efficient and trouble-free flow through every manufacturing stage. We have the customized solutions you need all along the line, from green leaf processing to primary processing, cigarette production, and logistics.

Our tobacco belts provide lateral flexibility, excellent longitudinal stability, hydrolysis resistance, and anti-stick properties resistant to moisture absorption. You can count on their high abrasion resistance and anti-slip surfaces for steep incline applications.

Treadmill Belts

- State-of-the-art treadmills

Are you looking for PVC or TPU belts for high-use applications in fitness centers and hotels, or for installation in home gyms? Habasit’s extensive range includes waxed treadmill belts as well as maintenance-free types for commercial and institutional treadmill units.

All our belts have been developed based on scientific analyses of market needs and thorough lab tests, including power consumption measurements, belt life tests, friction tests, wear and tear tests, and noise measurements. Every belt type is extensively field-tested before release onto the market.

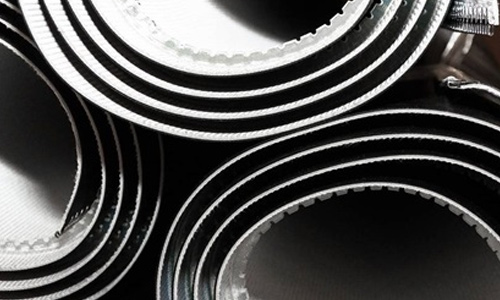

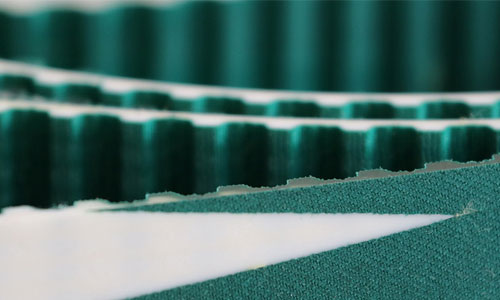

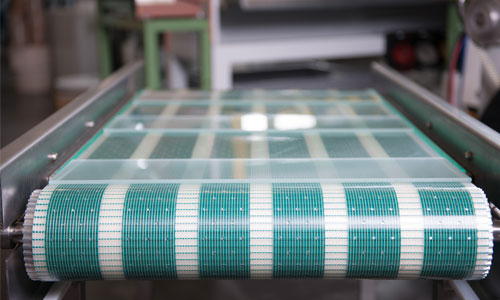

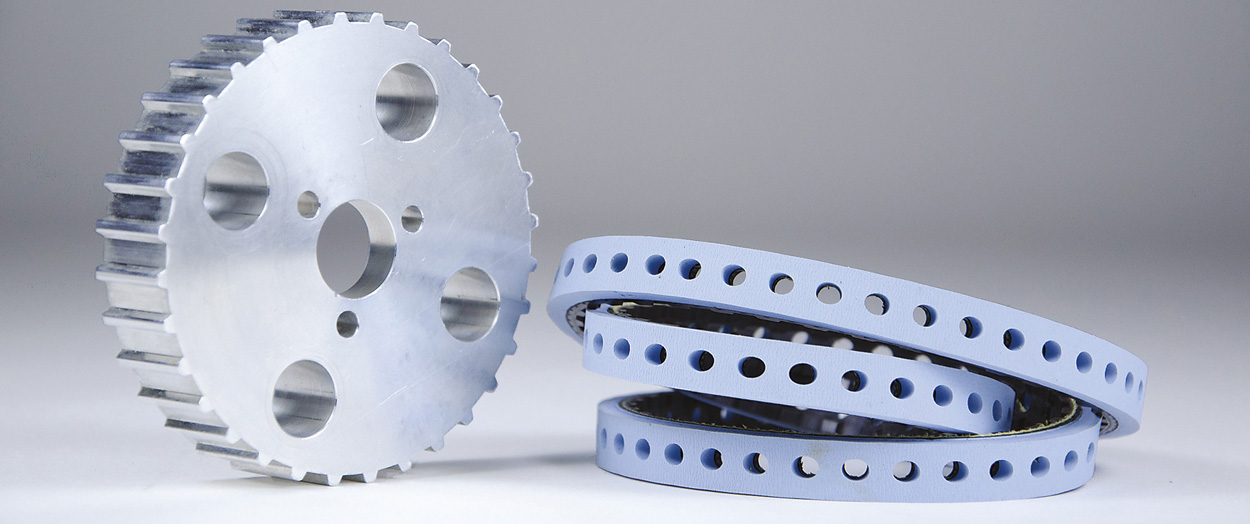

HabaSYNC Timing Belts

-

Swiss precision you can rely on

HabaSYNC timing belts support conveying and linear movement applications where optimal performance depends on precise product placement and component positioning. High-quality materials coupled with our state-of-the-art manufacturing processes and years of experience ensure innovative solutions tailored to your needs.

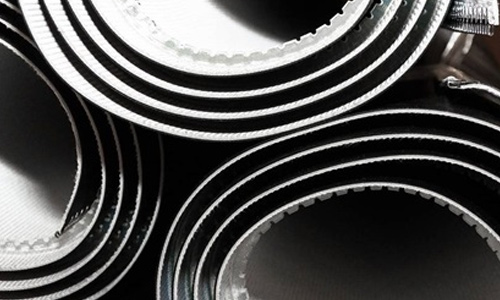

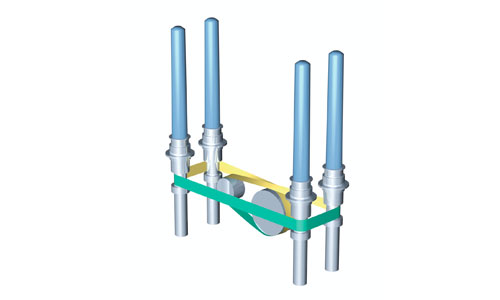

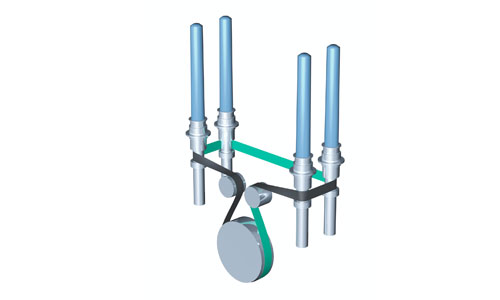

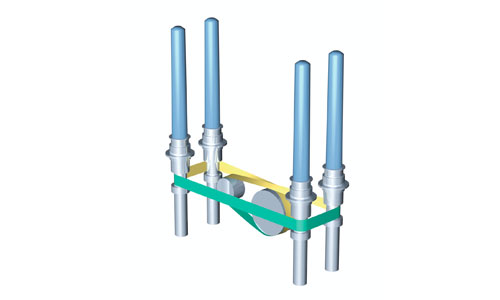

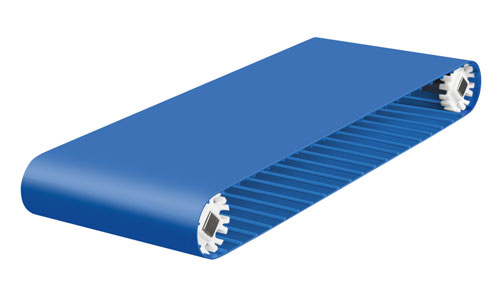

Open-End Timing Belts

- Highly durable and dimensionally accurate open-end timing belts

Featuring exact tooth pitches and very small tolerances, HabaSYNC open-end timing belts guarantee parallel and linear synchronicity for a wide range of different conveyor applications. The belts provide precise positioning and gentle product conveyance, while supporting improved efficiency due to tighter product spacing on the belt.

Open-end timing belts can be joined endless to any length, either in the workshop or directly on the conveyor. If required, friction-reducing, wear resistant polyamide fabric can be added on the tooth side, and abrasion resistant polyamide fabric on the conveying side.

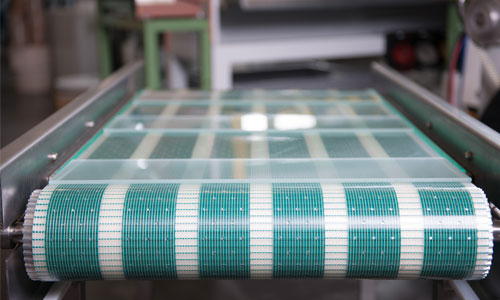

Wide Timing Belts

- The widest timing belt on the market

When you need a wide-surface belt for synchronous conveying and precise product positioning, Habasit has the right solution. Our HabaSYNC wide timing belts are available in widths of up to 609 mm / 24 inches, and offer easy maintenance and reliable processing performance.

Habasit’s wide timing belts come with multiple TPU options. The range extends from food-grade TPU with superior hydrolysis resistance, to TPU with increased chemical- and abrasion resistance for the automotive industry. Whatever your requirement, we can meet it.

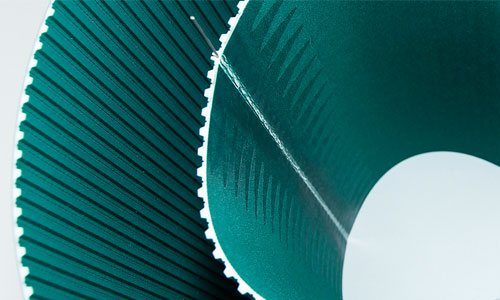

Flex Timing Belts

- The truly endless timing belts

Manufactured in endless lengths with helically wound cords, HabaSYNC flex timing belts provide double the tensile strength of joined endless timing belts. This makes them ideal for synchronized conveying and precise positioning of heavy loads, as well as for high power transmission applications, especially where chemical- and wear resistance are required.

Flex timing belts are available in a wide range of pitches and materials, and are manufactured with a variety of cord options. Diverse Habasit TPU matrix materials provide resistance to abrasion, hydrolysis, UV light, ozone, oil, grease and some acids and caustic solutions, making our seamless HabaSYNC flex timing belts ideal for different industries and applications.

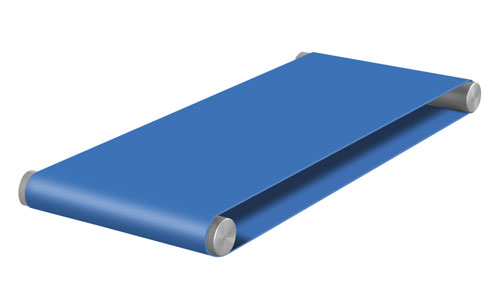

Flat belts

- HabaSYNC flat belts offer maintenance-free operation, low-noise running, and significant cost savings in comparison with roller chains and cable tension systems. Available in different thicknesses with a variety of strengths provided by reinforcement cords, plus a choice of TPU matrix materials, these belts are ideally suited for applications based on linear movement with a winding function, such as lifts and elevators.

Engineered cast belts

- HabaSYNC cast timing belts are the right solution when complex, fully customized and precise belt construction is required. Cast belts are molded using thermoset elastomers and a wide variety of cords. The molds can be adjusted to create not only standard shapes but also belts with integrated profiles and special surfaces to perfectly match your application needs.

Timing belt covers

- Habasit offers a wide range of covers for HabaSYNC timing belts of different sizes, materials, and surface structures. We have a solution to fit your specific application needs and handle your product efficiently, effectively and reliably.

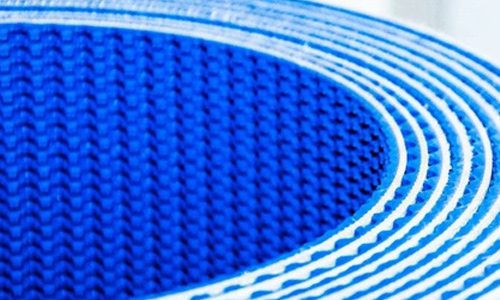

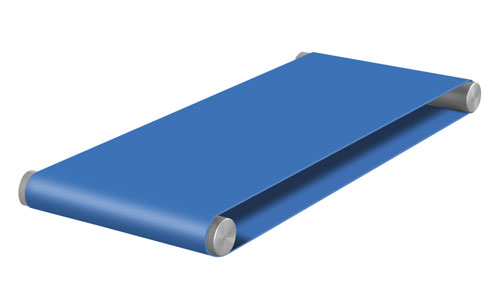

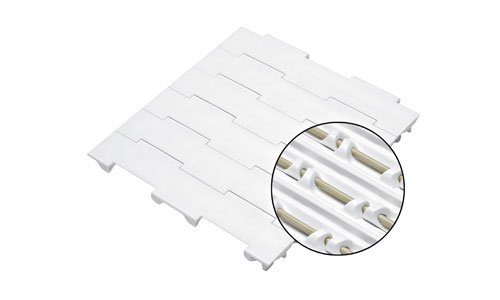

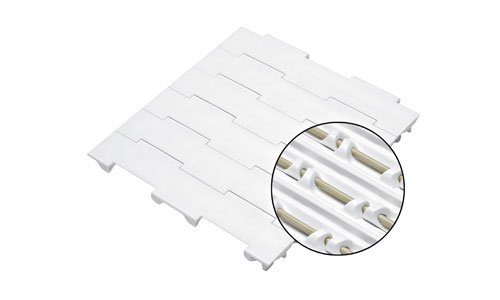

Monolithic Belts

-

The hygienic solution for wet food applications

Monolithic belts are designed to work in wet applications, mainly in the food industry, as well as in materials handling and other areas. The fully extruded monolithic belt design produced by our advanced manufacturing technology satisfies the most demanding hygiene requirements, while delivering exceptional performance, reliability, and cost-efficiency.

Habasit’s food-grade monolithic belts are FDA/USDA/USDA Dairy approved and conform to EC regulations. The belt materials are impenetrable to water, oil, grease, and other fluids. They are chemical- and abrasion resistant, and offer a range of surface structures to match different application requirements.

Habasit Cleandrive

- Aramid reinforced monolithic TPU conveyor belts

Habasit Cleandrive aramid reinforced monolithic TPU conveyor belts are recognized for their safe and hygienic food processing performance. Their significant advantages include a uniform surface without sink marks, and embedded cords that guarantee true belt length without creep. The belts’ advanced technology and design meet the most stringent hygiene requirements while delivering exceptional performance, reliability, and cost-efficiency.

Habasit Cleandrive belts reduce the design work required when constructing a conveyor. Their zero-tension belt design eliminates the need for special active sprocket engagement, which both reduces complexity and cost, and extends the belt lifetime due to less abrasion. The premium TPU material offers extraordinary hydrolysis and microbiological resistance. The belts’ closed smooth surface is essential for wet applications.

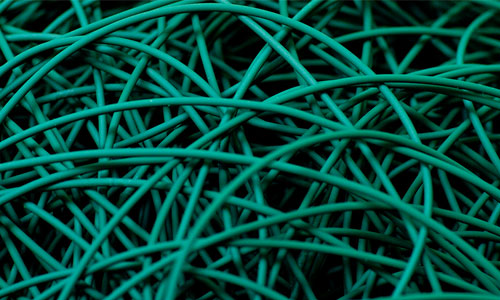

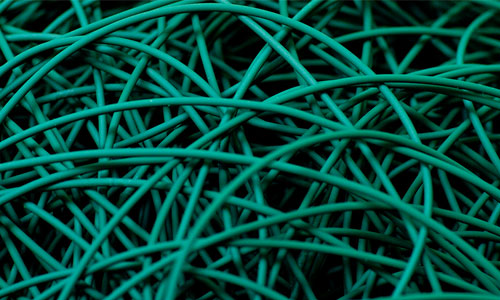

Extruded Belts

- Habasit round belts and V- and T-shaped belts

Habasit’s extruded belts include round belts from 2 mm to 20 mm in diameter, as well as V-and T-shapes in various designs and sizes. The round belts are highly flexible, directionally adjustable, and multi-directional for angular gears. They can be used for conveying as well as for driving applications.

Trapezoidal and other shaped belts are tailor-made to suit specific industry and application needs or machine designs, and are used on linear conveyors and in diverter applications. Our food-approved extruded belts provide excellent chemical resistance and high wear properties.

Monolithic Flat Belts

- Homogenous design, varied uses

Monolithic flat belts are designed for light conveying and are used in a wide range of applications. Since they improve process- and equipment hygiene, they are mainly found in cutting, separating, and weighing applications in the food industry, and are also used for materials handling. The belts also serve as side skirts, accessories for fabricated belts (e.g. as special cleats or sidewalls), and as covers for timing belts.

Habasit's monolithic flat belts are made with TPU in various hardnesses, thicknesses and widths. They offer a choice of over 15 different surface structures, which is why they can cope with almost any application. They are available in several colors: black, blue, green, transparent, and white. The belt design complies with the most demanding hygiene requirements and regulations for the food processing industry.

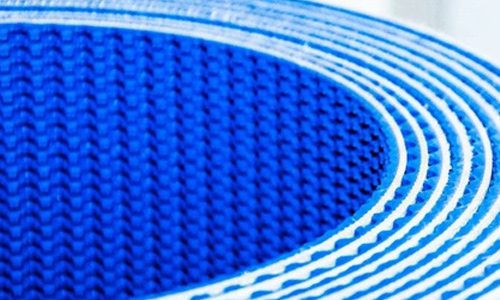

Seamless and Grabber belts

-

Tailored solutions for optimal performance

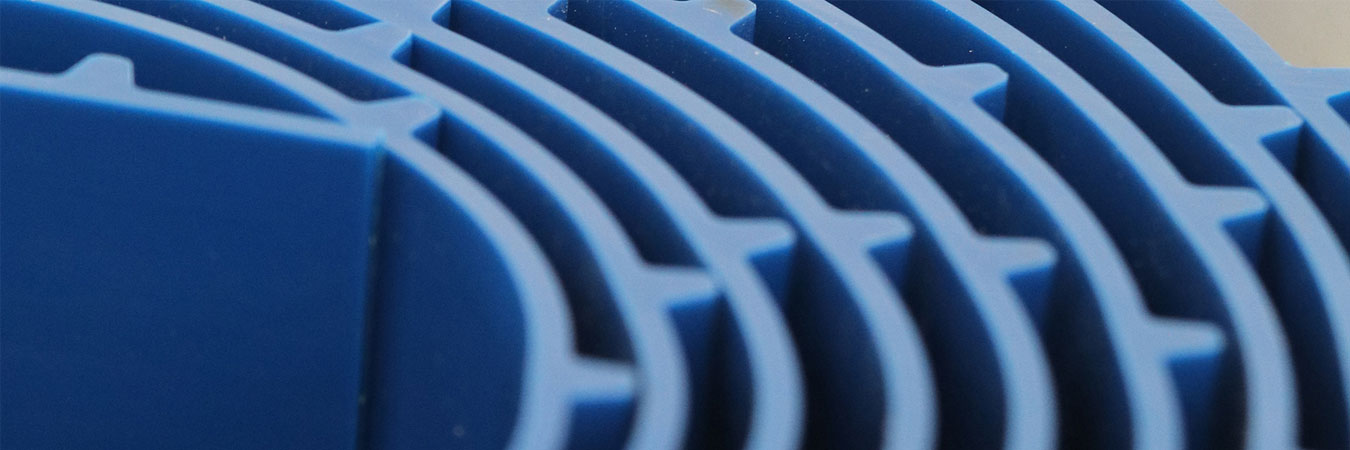

The Habasit seamless belt portfolio consists of woven endless and knitted endless belts, as well as synchronous and non-synchronous endless substrates. The belts can be coated with no splice or seam, providing uniform physical properties during the entire belt service life. Our manufacturing processes and ideal combination of materials ensure optimal design for your specific application requirements. Habasit seamless belts offer reduced lifecycle costs, as well as smooth and vibration-free operation, especially at high speeds. HabasitLINK Plastic Modular Belts

-

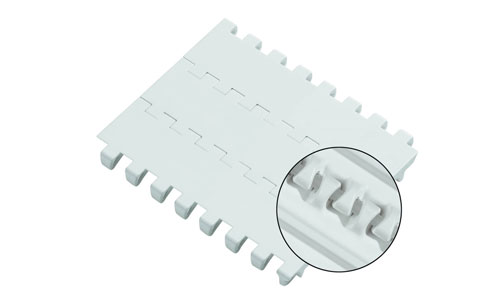

The many advantages of plastic modular belts

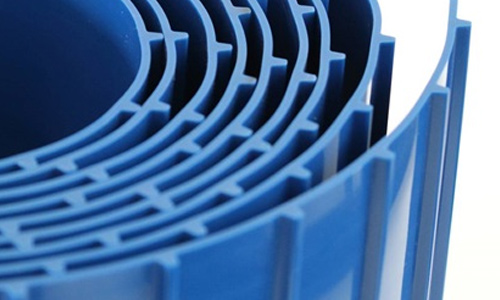

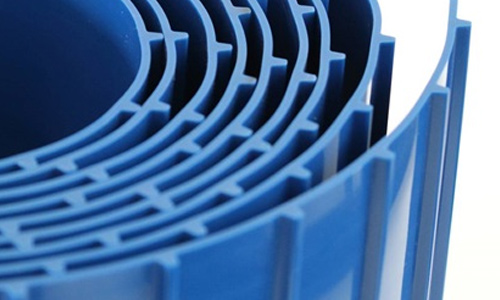

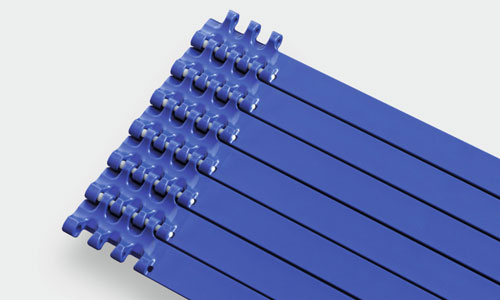

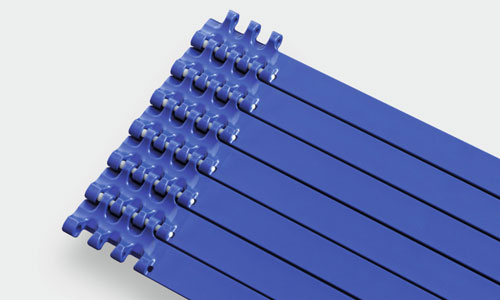

The HabasitLINK range of plastic modular belts has over 20 years of a proven industry performance. Our current portfolio contains over 150 different belt styles in a wide range of material and color combinations.

HabasitLINK plastic modular belts come equipped with many advantages from long life time and high strength to quick repair and maintenance.Why HabasitLINK?

Positive drive and tracking

Plastic modular belts do not need any pre-tensioning and are not affected by mistracking issues often caused by a poor conveyor design or heavy contamination. The positive drive given from sprockets avoids any possible belt slippage and guarantees smooth operations resulting in much less maintenance and downtime.Resistance to extreme conditions

Plastic modular belts work safely and reliably in a wide range of conditions and temperature ranging from -70°C to +240°C. HabasitLINK product range has a solution for wide temperature variations, humidity, aggressive chemical agents, cutting operations, product impact, high speed and abrasive environments.Quick repair and maintenance

It is unusual for a plastic modular belt to require maintenance or repair, but, should it become necessary, the belt is easily opened using simple tools such as a screwdriver. It can be repaired and re-closed in a short period of time without the need to replace the full belt. Downtime is reduced to a minimum and, as modular belts do not need lubrication, no additional maintenance is required.

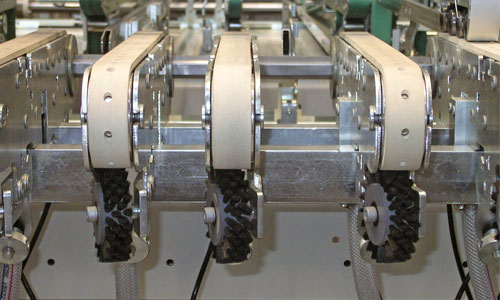

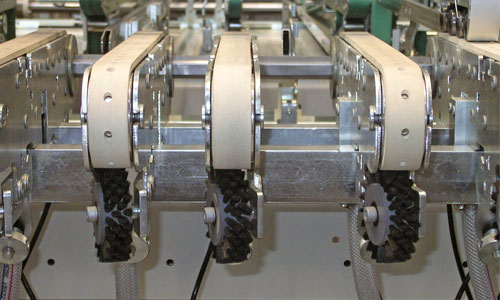

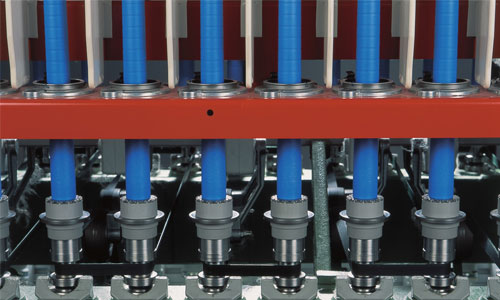

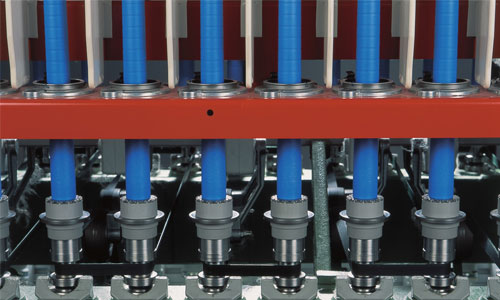

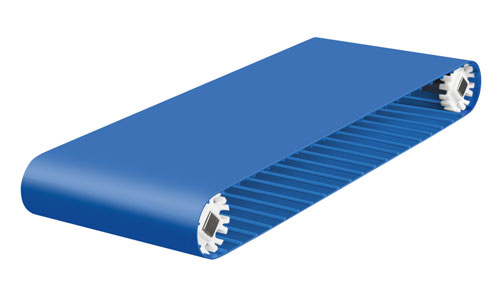

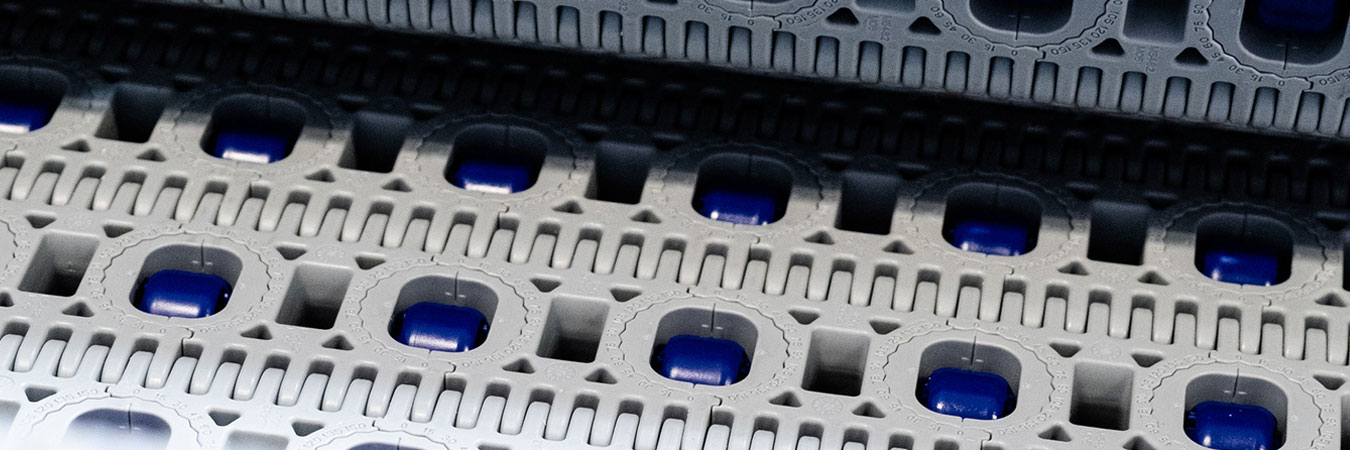

HabasitLINK Micropitch

-

Smallest longitudinal transfer

HabasitLINK Micropitch modular belts were the first plastic modular belt able to face transfer diameter as small as 6 mm.

The Micropitch series delivers reliable belt tracking on small knife edge transfers, combined with a superior sprocket engagement and maximum application flexibility.

HabasitLINK Spiral Belts

- Engineered for reliable operations and hassle-free maintenance

The HabasitLINK spiral belts deliver high airflow and their rounded surfaces prevent product marking. The range of solutions includes belts with multiple collapse factors to optimize the machine footprint and a wide material portfolio to handle the required temperature range.

Our spiral belts have been running in thousands of systems worldwide and are a proven technology used every day in a broad range of applications.

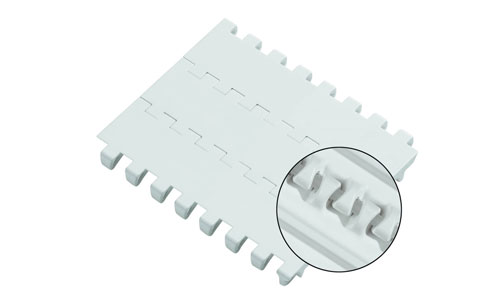

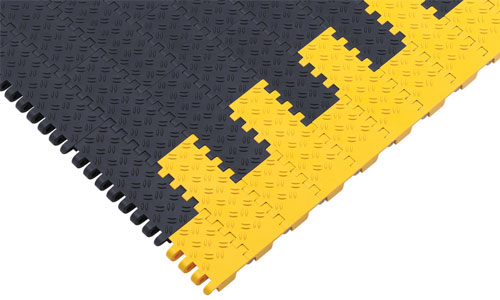

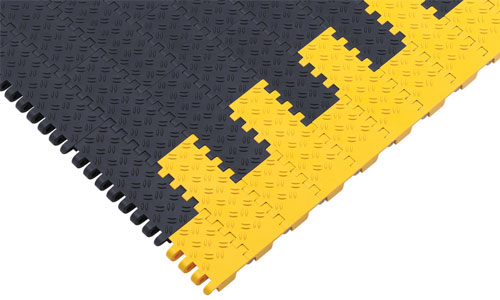

Habasit HyCLEAN

- Tomorrow’s sanitation standards today

The creation and maintenance of optimal hygiene conditions is one of the greatest challenges faced by the food industry today. As a result, hygienic design and ease of cleaning are important prerequisites for equipment and components used in hygiene-sensitive food processes.

Conveyor belts have a key role to play as they are often in direct contact with food. The Habasit HyCLEAN plastic modular belt products have been developed to improve hygiene conditions and cleaning procedures in food processing areas.

Super HyCLEAN

- The future of hygiene is now

Super HyCLEAN is a brand new concept in the HabasitLINK plastic modular belting range. The products have been designed for applications where the highest hygienic standards are required, with special focus on poultry and fish processing.

The innovative hygienic design reduces the deposit of organic debris and, at the same time, it allows quick, easy and efficient cleaning operations, reducing the overall sanitation costs and the risk of product cross-contamination.

Plastic Modular Industry Solutions

Plastic Modular Belts for Bakery and Confectionery

- Modular solutions for bakery and confectionery

HabasiLINK plastic modular belts for food industry applications are made with food-safe materials and comply with relevant food industry regulations.

They are engineered with a number of features for more efficient operations, such as dynamic open hinge design for ease of cleaning or the micropitch range for tight transfers.

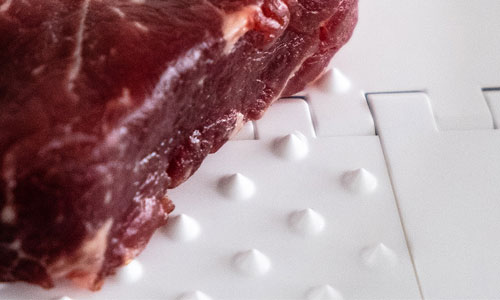

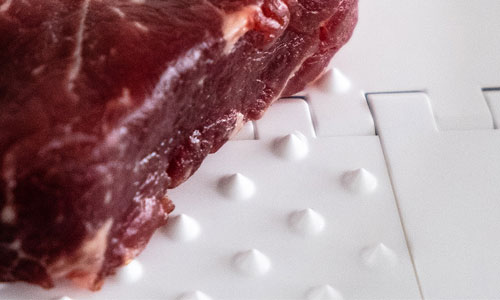

Plastic Modular Belts for Meat, Poultry and Fish

- Enhancing hygiene in meat, poultry, and fish

HabasiLINK plastic modular belts for food industry applications are made with food-safe materials and comply with relevant food industry regulations.

They are engineered with a number of features for more efficient cleaning, such as dynamic open hinge design.

Plastic Modular Belts for Tire Industry

- Robust solutions for the tire industry

The tire production process requires a wide range of solutions from rubber mixing to the creation of a green tire and the final product.

HabasitLINK modular belt range covers processes at every turn of the tire manufacturing, from high temperature applications to handling of the finished tires.

Plastic Modular Belts for Automotive Industry

- From press shop to the final vehicle

HabasitLINK solutions for the automotive industry cover the full process from the press shop to the final vehicle. The robust and high-quality modular belts are widely used in the press shop, body shop, paint shop, on skid conveyors, in the final assembly, water test, and final inspection.

HabasitLINK installations span from small and narrow conveyors to wide and long conveying lines and they do not require lubrication in order to work reliably.

Whatever your car assembly application, we can match your needs

Conveyor Chains

-

Flexible chain solutions for every need

Reliable and cost-efficient chain conveyor solutions are required in numerous applications across many industries. Our HabaCHAIN range offers more than 60 different types of high-quality chains, including straight-running and radius/side-flexing versions. Fully compatible with industry standards, our chains run on most systems and sprockets on the market today, making retrofits easy, with no need for conveyor modifications.

HabaCHAIN products are available in a wide selection of problem-solving materials delivering key features that include low friction, enhanced chemical resistance, high temperature resistance, and anti-static and magnetic properties. Industries served include automotive; bakery; beverage and canning; materials handling; meat, poultry and fish; packaging, pharmaceuticals, snack foods, textiles and tissue. HABIPLAST

-

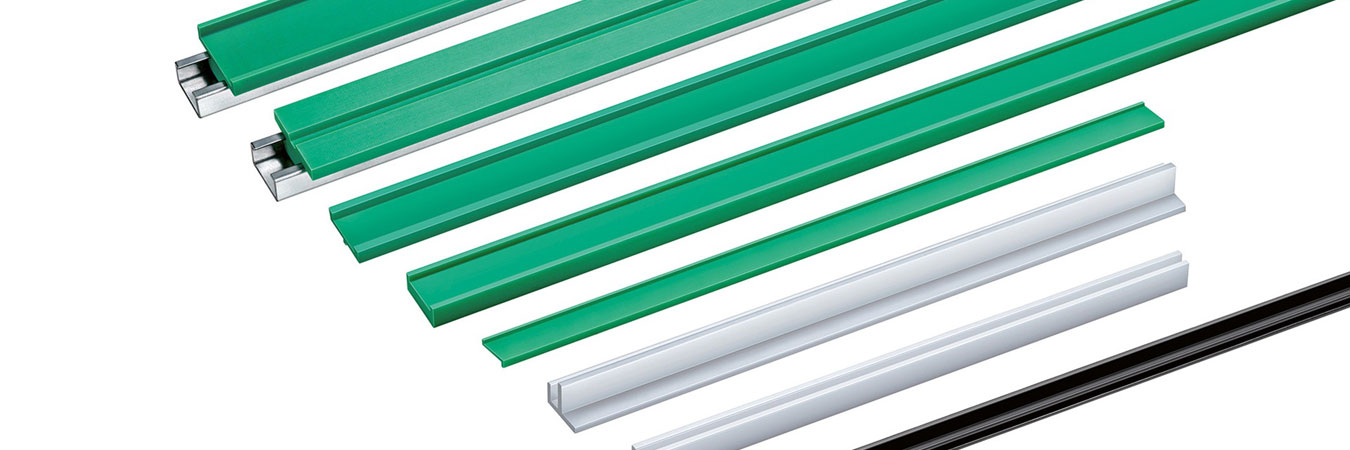

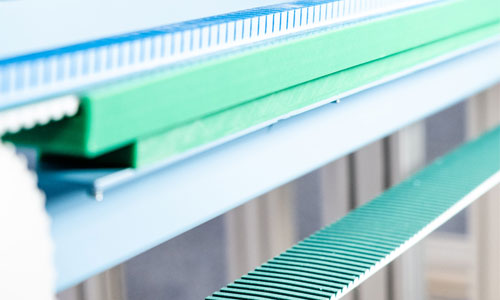

HabiPLAST keeps everything in line on your line

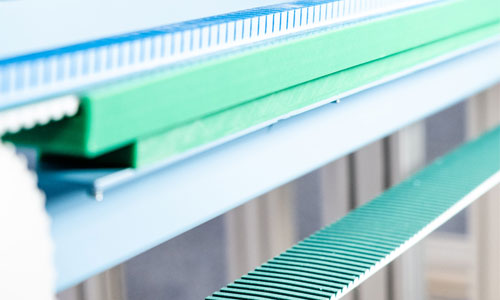

Wear strips and guides are essential belting accessories in numerous industries, from bottling, packaging and chemicals to pharmaceuticals, ceramics, food processing and paper. Whether added to modular belts, conveyor chains, or timing belts, our comprehensive range of HabiPLAST plastic accessories ensures a fully customized and efficient solution to meet your toughest application challenges.

Using only the highest quality materials, our wear strips and guides for belts, chains and goods, as well as our custom-machined plastic parts, offer important mechanical features including high impact resistance, tensile strength at high temperatures, and energy absorption under high stress levels.

Guides for Plastic Modular Belts, Chains and Goods

- Guides keep your production on track

HabiPLAST profiles represent the best solution not only to support and guide HabasitLINK plastic modular belts, HabaCHAIN plastic and metal chains, but also to guide goods along the conveyor.

The wide range of standard extruded profiles allows the finding of a suitable and “easy to assemble” solution for the most common conveyor structures. Customized machined profiles are also available for any special application.

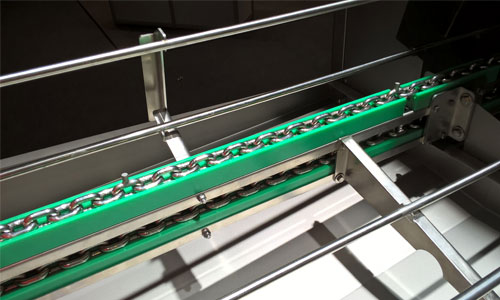

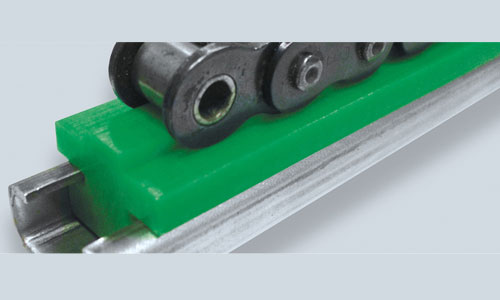

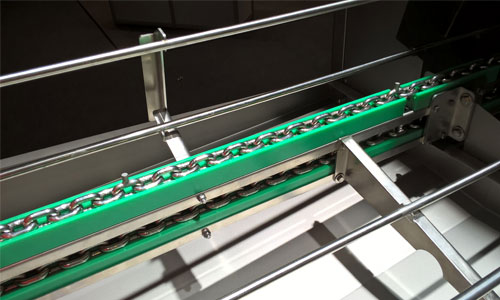

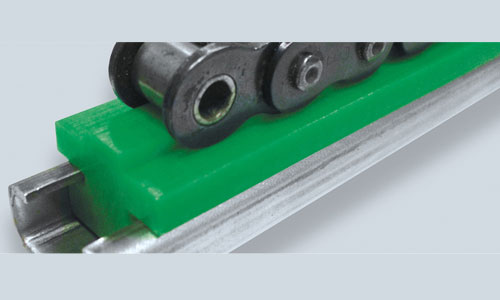

Guides for Roller Chains

- Guides keep your production on track

HabiPLAST offers a wide standard range of guides for steel roller chains.

They are specifically designed and manufactured to improve the overall performance of the machinery where roller chains are installed.

Guides for Round and V-belts

- Guides keep your production on track

HabiPLAST guides are the best solution for improving performance and reducing maintenance of round and V-belts.

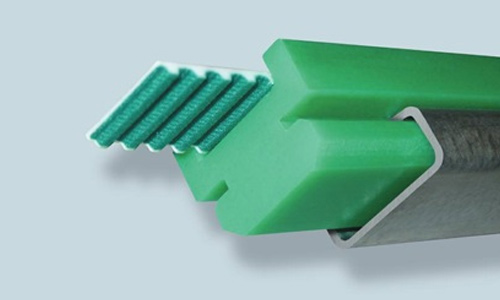

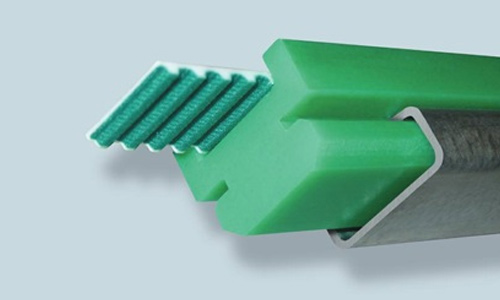

Guides for Timing Belts

- Guides keep your production on track

HabiPLAST timing belt support guides enable HabaSYNC timing belts to run smoothly across a low friction surface.

All HabiPLAST guides for timing belts can also be supplied with metallic profiles.

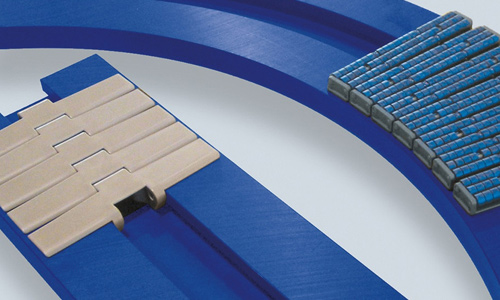

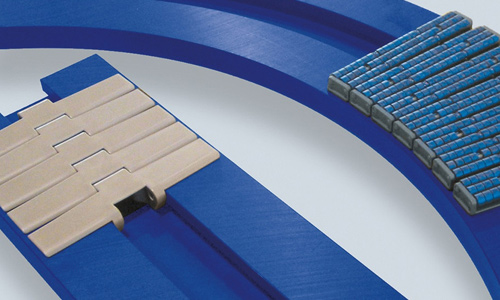

Chain Tracks

- Chain tracks for different needs

In addition to extruded and machined profiles and guides, HabiPLAST offers a complete range of corner and straight tracks that are designed for use with plastic and metal chains.

Alongside the standard tab and bevel tracks, there is also a magnetic version that makes chain removal both quicker and easier.

Accessories

- Accessories to aid application performance

Metal rails in stainless steel, galvanized steel and aluminum alloy, as well as plastic fixing clamps can be supplied as required.

They are used as installation supports for a wide range of HabiPLAST products.