- Offer Profile

-

Eaton is a power management company with 2016 sales of $19.7 billion.

For more information, visit www.eaton.com.

We provide energy-efficient solutions that help our customers effectively manage electrical, hydraulic and mechanical power more efficiently, safely and sustainably. Eaton is dedicated to improving the quality of life and the environment through the use of power management technologies and services. Eaton has approximately 96,000 employeesand sells products to customers in more than 175 countries.

Automation

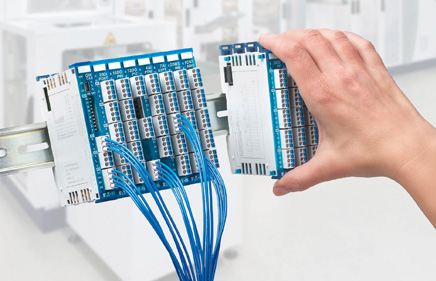

SmartWire-DT®: The Communication and Connection System for Your Entire System

-

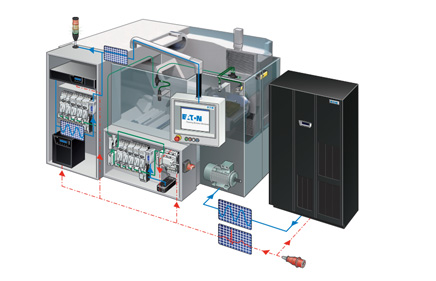

With SmartWire-DT, Eaton has heralded in a new era of connectivity between individual switchgear and controllers. SmartWire-DT not only replaces the control circuit wiring for all the components inside a machine's control panel, but also extends this flexibility to elements such as sensors. This way, SmartWire-DT makes it perfectly possible for a system's central controller and moving components to communicate with each other continuously and directly. In addition, the fact that this eliminates the need for previously required PLC inputs/outputs and control wiring saves signifi-cant space, making the use of more compact control panels possible.

The SmartWire-DT communication system can be used anywhere where switchgear, sensors, and actuators are at work. And the advantages it holds over competing solutions quickly become clear during installation, operation, and further expansion down the line. Large data volumes, a length of up to 600 m, and flexible options for connecting to field buses from virtually any PLC manufacturer are just a few of the characteristics that make SmartWire-DT the ideal system for an extremely wide range of applications.

XV HMI/PLC: Systematic Visualization and Control

- With the XV HMI-PLC touch panels Eaton is offering customers in the machine and system building sector a systematically coordinated range that can be integrated perfectly into different performance classes. The smart implementation of the PLC runtime into a slim and efficient embedded platform strategy in combination with powerful processors creates a state-of-the-art, scalable and cost-efficient automation concept. The openness of the system is demonstrated in the use of the CODESYS programming standard and the possibility to access over 100 protocols as an HMI. Display sizes from 3.5" to 15", device versions in plastic, metal or stainless steel, as well as the possibility of use with particularly robust infra-red touch technology make a wide range of solutions possible.

Unique on the market: XV panels with an onboard SmartWire-DT master interface. This offers potential savings affecting all aspects of a project, from hardware planning to software creation, to wiring and commissioning.

XP500 Industrial Touch Panel PC

-

The XP500 series from Eaton, developed especially for the requirements of mechanical and plant engineering, enhances the field of automation with contemporary control interfaces and command methods familiar from consumer electronics. The Projected Capacitive Touch (PCT) technology provides a more intuitive user interface. This includes multitouch functionality, allowing users to press functional buttons on the screen either with multiple fingers on one hand or using two hands.

The devices are being launched onto the market with the following three widescreen display sizes: 10.1", 15.6", and 21.5". Their slim design, featuring a non-reflective glass front, delivers a modern look. In addition, their heavy-duty, scratch-resistant front and open device design make these panel IPCs ideal for use in virtually any industrial branch in the field of machine building and plant engineering.

XN300 - Modular I/O System

-

The ultra-compact, slice-card-based XN300 modular I/O system features a high channel density plug-in connection system and can be combined with HMI PLC products in order to create the ideal system solution for your applications.

All this is combined with a sleek design an a convenient installation concept that makes handling easier and allows users to pre-assemble their I/O stations and the components they will be connecting. Moreover, the plug-in terminal system and the way in which signals are clearly identified make commissioning easier and round off the system‘s characteristics.

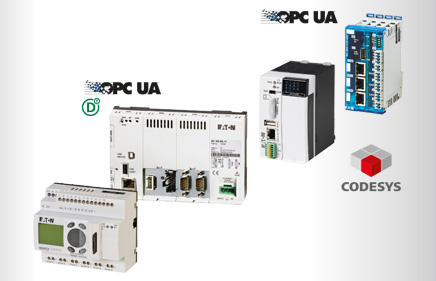

Modular and Compact PLCs

-

The XC300 is a powerful and flexible modular PLC. In combination with the XN300 I/O slices and the innovative XV300 touch panels it enables compact and modern automation concepts. The XC300 PLC can be seamlessly integrated into existing automation solutions and new concepts based on Industry 4.0.

The compact PLCs XC152 facilitate cost-effective solutions of automation tasks using their computing power, the SmartWire-DT interface as well as a whole range of further interfaces.

Both PLCs – the XC300 and the XC152 - feature the possibility to exchange data with OPC clients via the Ethernet interface and an integrated web server.

The compact class with the EC4P controllers offer the performance of a PLC in the housing of the renowned easy control relay. This enables the convenient creation of solutions for small and medium-sized control tasks.

easyE4 control relay

-

Moeller® series

Whatever your application, the easyE4 control relay allows for control systems that are efficient, flexible and easy to implement. The new easyE4 range is significantly more compact than the previous easy500, easy700 and easy800 series.Thanks to the flexible expansion with up to 11 modules to a maximum of 188 inputs/outputs, as well as the large voltage range, the easyE4 is ideally suited for industrial and building applications. For additional flexibility, the intuitive easySoft programming software comes with four programming languages as standard, including function block diagram (FBD) and structured text (ST). New helpful function blocks, such as the automatic e-mail notification, as well as the possibility of creating own function blocks facilitate the programming for each user.

The powerful XV-102-A0-35TQRB-1E4 touch panel with resistive touch interface is available for convenient visualization of easyE4 projects. The Galileo software is used to create the visualization. In conjunction with the easyE4, compact and powerful automation solutions are implemented via the integrated communication interfaces (Modbus TCP) of the easyE4 touch panel. Thanks to the integrated web server, visualization is also possible on mobile devices.

Safe Monitoring and Processing

-

Machines and plants contain potentially dangerous motion sequences that require a technical solution to make them safe. Safety devices such as emergency-stop pushbuttons, guard doors, light curtains and operating elements for safe setting must be controlled and monitored, and the installation may have to be switched to a safe state. For these tasks, Eaton is offering two safety logic series, the ESR5 electronic safety relay and the easySafety control relay.

Whether on a simple or complex machine, the required protection of personnel and process can be ensured using these Eaton safety products that have been approved by TÜV Rheinland:

GALILEO – Visualization at a Whole New Level

-

Eaton's GALILEO is a powerful and comprehensive visualization program that can be used to configure any XV or XP touch panel.

GALILEO is an intuitive and powerful engineering environment that not only takes little time to master, but that also meets virtually every requirement involved in on-site machine operation. The visualization software, developed by Eaton, is designed to meet the needs of any industry while providing comprehensive configuration options for all XV devices and PC runtime solutions. As part of this approach, GALILEO puts its full functionality at the disposal of design engineers at all times, avoiding nested variable and screen limitations.

GALILEO-WEB as part of GALILEO enables a web visualization based on HTML5 – with only one click! Remote devices like PC’s, Tablet’s or Smartphones can then easily access the XV300 visualization.

Command and Signalling

In Great Shape: The Ergonomic Control Circuit Devices RMQ-Titan®

-

Modern styling has been combined with an optimum range of functions. The perfect outfit for use at machines and on panels. The ergonomically shaped button elements are matched to the shape of a fingertip for even more comfortable operation.

RMQ-Titan pilot devices can be flexibly used in a wide range of applica-tions thanks to their IP67/IP69K degree of protection.

The Emergency-STOP buttons1) for the worldwide usable control circuit device product range RMQ-Titan are available as palm switches/mushroom actuators with a diameter of 38, 45 or 60 mm.

RMQ-Titan pilot devices have been granted numerous national approvals and ship classifications, meaning they are ready for use anywhere in the world.

The new Small E-Stop is the perfect addition to Eaton’s RMQ-Titan emergency-stop range. It features an entirely new, innovative lighting concept based on a patented 360° illuminated ring, it enhances visibility and thereby contributes to improved safety.

Control circuit devices RMQ-Titan are ingeniously simple to connect with SmartWire-DT.

Implement Efficient Signaling and See Your Equipment's Availability Soar

-

Signal towers are just as essential to the smooth and safe operation of machines and systems as they are at airports and supermarkets. More-over, the tasks they have to perform are as varied as the locations where they have to be used. This is why Eaton has designed its signal towers in such a way as to be able to accommodate extremely versatile light and acoustic modules. On top of this, their high IP66 degree of protection ensures that they can be used virtually anywhere. Ship classifications and CCC are currently pending.

In terms of signaling systems, light intensity and signal strength are as crucial to a system's efficiency as are the speed and ease with which complete towers can be assembled and disassembled, e.g., in order to transport a machine.

Moreover, this efficiency can be increased even further by effectively inte-grating signal towers into an automation solution. Within this context, a SmartWire-DT connection not only significantly reduces wiring complexity, but also considerably enhances a system's communication capabilities. Intelligent switchgear can send alarm messages through the system – when, for example, overloading is imminent – in order to avoid stops and down-times. Following these signals, signal towers can output their own clearly recognizable signals, thus ensuring higher machine and system availability.

Movements Safely Under Control Detect Positions Mechanically, Optically and Inductively

-

Wherever exact positioning is required, safety/position switches from Eaton with positively opening contacts are used.

Safety components are able to reliably monitor and protect protective guards, doors and covers. The RS Titan safety position switches and non-contact safety switches from Eaton’s Moeller series stand out for their robust design and for the safety they provide. Compliance with various standards makes the devices ideal for integration into machine development processes in line with international requirements.

The LS Titan position switches of the Eaton Moeller series can be used to safely, accurately and reliably detect positions. They enable smooth and safe operation and can be optimally adapted to any application. Position switches also contribute to higher standards of process and personal safety.

The MCS pressure switches of the Eaton Moeller series are control devices that measure the pressure of a medium and then convert this information into an electrical signal. They are used to monitor the pressure of liquids and gases. The MCS pressure switches have two adjustable operating points (on and off operating point).

Timing Relay DILET, ETR, Measuring Relay and Monitoring Relay EMR

-

Eaton's large portfolio of measuring and monitoring relays provides maximum safety for your application. By monitoring currents, voltages, unbalances and insulation resistance values, any anomalous events are identified early on, thereby preventing extended machine downtime. And our temperature and level relays similarly make control tasks easier and safer to handle. There are 35 different relay types in total, which can all be combined with one another and boast state-of-the-art technology and design. The new EMR6 devices are replacing the previous EMR4/EMR5 series, and also offer additional functions. Thanks to their comprehensive approvals and certifications, the EMR6 measuring and monitoring relays can be used across a wide range of applications and geographical locations.

Motor Control

Contactors DIL - efficiently and flexibly combinable

-

The contactor series covers the entire performance range from mini-contactor relay with 7 A up to a vacuum contactor at 2600 A. The combination with electronic overload relays or bimetal relays provides motor starters for the most varied of applications. All circuit breakers fulfil the demands for world-wide use and are compliant to UL/CSA, CCC and shipping classifications. The motor protection systems are also ATEX certified. The contactors are becoming more efficient, particularly due to the Eco types for 15.5, 38, 72, 170 and 570 A, as well as through the many innovations with the motor starter, for example, such as SmartWire-DT.

Motor-protective circuit breaker PKZ and PKE

-

Motor-protective circuit breakers PKZ have been manufactured by Eaton since 1932. Our ideas and developments have decisively influenced the trends in the protection of motors since then. The results are progressive concepts and marketable product innovations that again and again assume the role international trendsetting, pioneering products, e.g. such as the motor-protective circuit breaker PKE.

The fuseless motor-protective circuit breakers PKZ combine short-circuit protection and overload protection in a single device. This enables a short recovery time. PKZM0, PKZM01, PKZM4 and PKE feature the same range of accessories. They can be easily combined with contactors DILM and soft starters DS7.

Motor Starter Combinations

-

Eaton offers a comprehensive portfolio for starting the motor with the motor start system xStart: From protective to soft starting devices and motor protection using bimetal relays, to motor-protective circuit breakers with electronic wide-range overload protection. All of these standard components can be easily combined using simple mechanical and electronic connectors. Three-phase commoning links offer comfortable assistance for motor current wiring. SmartWire-DT also replaces the control current wiring and integrates comprehensive communication options into the system.

Soft Starter

-

With its DS7 devices for currents of up to 200 A and S801+/S811+ devices for currents of up to 1,700 A, Eaton offers two different soft starter series with different strengths: DS7 units are ideal for standard applications, while S811+ models make a compelling case with their powerful range of functionalities.

The right drive for each application

-

From starting motors in simple machines to speed control for complex applications, Eaton has the right drive control technology for your needs. The PowerXL family not only offers optimized device series, but also a comprehensive product range designed for energy-efficient use in a broad variety of applications.

The PowerXL family includes:

- DB1 Cold Plate Drives for frequency control In the smallest space

- DE1 Variable Speed Starters which close the gap between conventional motor starters and variable frequency drives.

- DC1 Variable Frequency Drives that are particularly well-suited for simple applications involving pumps, fans, or material handling systems.

- DA1 Variable Frequency Drives for demanding applications.

- DG1 Variable Frequency Drives - „The Next Generation“ in the PowerXL family.

- 9000X Variable Frequency Drives which are ideal for sophisticated applications.

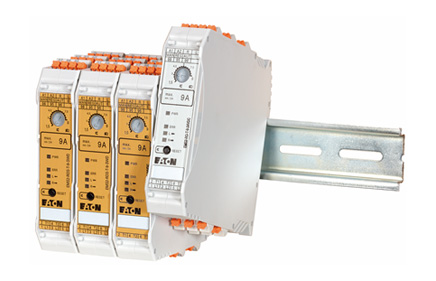

EMS2 electronic motor starters

-

The EMS2 electronic motor starter from Eaton's Moeller seriesTM combines all the functions of a conventional motor starter in a single, highly compact device. With a width of only 22.5 mm, it can be used in any application where motors up to 3 kW need to be driven. The EMS2 electronic motor starter can handle DOL and reversing starts, while offering wide-range overload protection and an emergency-stop function (Sil3). The SmartWire-DT interface replaces the conventional control wiring and also provides additional information.

Power Management

Safe Switching, Isolating and Control with Rotary Switch T and Switch Disconnector P

-

The high-performance, robust and compact T rotary switches and P switch-disconnectors are used in industry, trade and building engineering applications. The degree of protection IP65 with the switch mounts and the switch front enables use in harsh environments. Ten basic switch types in four different construction types, in a whole range of standard switches and across a wide performance range are available. Customised circuits can also be implemented in addition to the standard configurations. The possibilities are almost unlimited. A comprehensive accessory range complements the switch range and rounds off the range of applications. All contacts feature double breaking contacts.

With the metal extension shafts our reliable P1 and P3 switches can be mounted in electrical cabinets of up to 600 mm deep and with several Handle and Shaft options a solution can be found for every application. Also the most common types are available as a complete switch/shaft/handle package.

Provide, Log, and Visualize Main Switch Energy Data

- Eaton NZM circuit-breakers and P switch-disconnectors are used as main switches for a wide variety of machines. On top of this, NZM circuit-breakers provide reliable short-circuit and overload protection. But they also offer much more: Their field bus interfaces make it possible to send advance warnings and transmit diagnostic data, as well as energy consumption values. Critical current warnings make it possible to take countermeasures and prevent overload tripping. Diagnostic data provides information regarding the cause behind faults and malfunctions and makes it possible to obtain trend analyses designed to identify load peaks. Moreover, NZM circuit-breakers make it easy to tackle today's focus on energy consumption by measuring and communicating operational data. This data, in turn, can be easily integrated into the BreakerVisu visualization and logging system in a user-friendly manner.

Protection for All Applications – Safety up to 125 A

-

Industry, system builders and the trade sector worldwide place their trust in Eaton products and solutions. Tested quality, approvals and shipping register classifications vouch for the functional scope and reliability of xEffect industrial miniature circuit breakers being suitable for world markets. In conjunction with the versatile complete range of modular installation devices and accessories, the user is provided with more options for solving complex technical problems.

Eaton offers a comprehensive range of residual current devices for residual current protection of persons against electrical shock and to protect installations against fire.

SASY 60i busbar system provides highest efficiency in the control panel

-

SASY 60i – safety and reliability in a single product: SASY 60i is a comprehensive UL-certified solution for switching, controlling, protecting, and distributing power that is designed for use with motor-protective circuit-breakers and molded-case circuit-breakers.

More specifically, the SASY 60i modular busbar system has been designed for efficient power distribution in control panels. And thanks to its busbar adapter, feeder and outgoing circuit-breakers can be quickly and easily mounted directly on its busbar system while saving space.On top of this, the SASY 60i system's double-T profiled DIN busbars reduce the amount of work required in order to prepare contact points. In addition, they combine an extremely high rated peak withstand current with a small number of busbar supports, meaning that they take full advantage of every inch of control cabinet space available. The large surface of the busbar profile allows optimum heat dissipation.

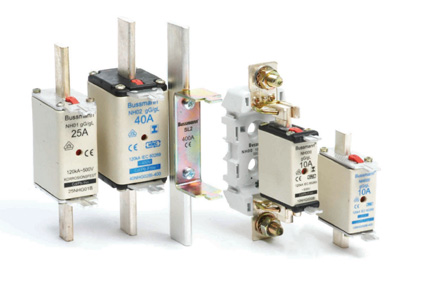

One range

Complete circuit protection-

Bussmann’s range of NH DIN style fuse links and bases offers unrivalled choice and performance for industrial applications.

Available in a comprehensive range of voltage, current and sizes. The fuses’ dual indication system saves time and money as the operated fuses can be quickly identified and replaced. The insulated metal gripping lugs enhance the safety of the fuses as the lug is voltage free.

It’s a range that sets the standard for protecting electrical systems.

CS Sheet Steel Wall-Mount Enclosures –Safe and Reliable Enclosure Technology for People Who Value Their Time

- Eaton's second generation of CS sheet steel enclosures is characterized by maximum ruggedness and can be used anywhere where a high level of protection is required, both to effectively protect against direct contact with live parts and to protect all installed components from damaging external factors such as liquids. The enclosures' IP66 degree of protection (UL/CSA types 1, 4, 12) – achieved with a continuous CNC foamed polyurethane gasket – prevents water, oil, and dirt from entering them. This, together with other characteristics, makes the

CS series of enclosures a perfect match for sub-distribution systems in control systems for industrial buildings, as well as for machine building environments. In addition, these heavy-duty steel sheet enclosures meet the requirements set forth in IEC/EN 62208, i.e., they are approved for use in switchgear assemblies as defined in IEC/EN 61439-2.

Backup power solutions for machines and production lines

-

Eaton’s Uninterruptible Power Supplies (UPS) help you minimise production downtime and data loss caused by voltage dips, power outages or surges, minimising ramp-up times and related costs. Our UPSs also contribute to the continuous operation of all critical operational safety systems.

High productivity and availability of machinery as well as energy monitoring and reduction requirements are key priorities. Our broad range of machine level power quality and energy management products and solutions help machine operators’ track, manage and secure power safely and efficiently.