ASA

Videos

Loading the player ...

- Offer Profile

- ADVANCED SYSTEM AUTOMATION

The full range of material flow from a single source.

Whether it be conveyor systems, robotic systems, or system automations, we are your expert partner when it comes to improving the efficiency of your manufacturing systems’ internal logistics, since advanced automation systems are the key factor determining your competitiveness.

Product Portfolio

FOR EACH TASK, THE OPTIMAL SOLUTION!

-

Regardless of the branches of industry and products involved

To us, every application represents both a challenge and an opportunity. Regardless of what you need, whether it be an entire system or merely subsystems, we will help you find simple, cost-effective solutions for your materials-flow tasks, solutions that will improve your productivity. We will be pleased to share with you our knowledge and experience in the field of manufacturing processes and automation in order that you will see the full range of choices in the area of economical, sustainable manufacturing operations immune to rapid obsolescence. Automotive

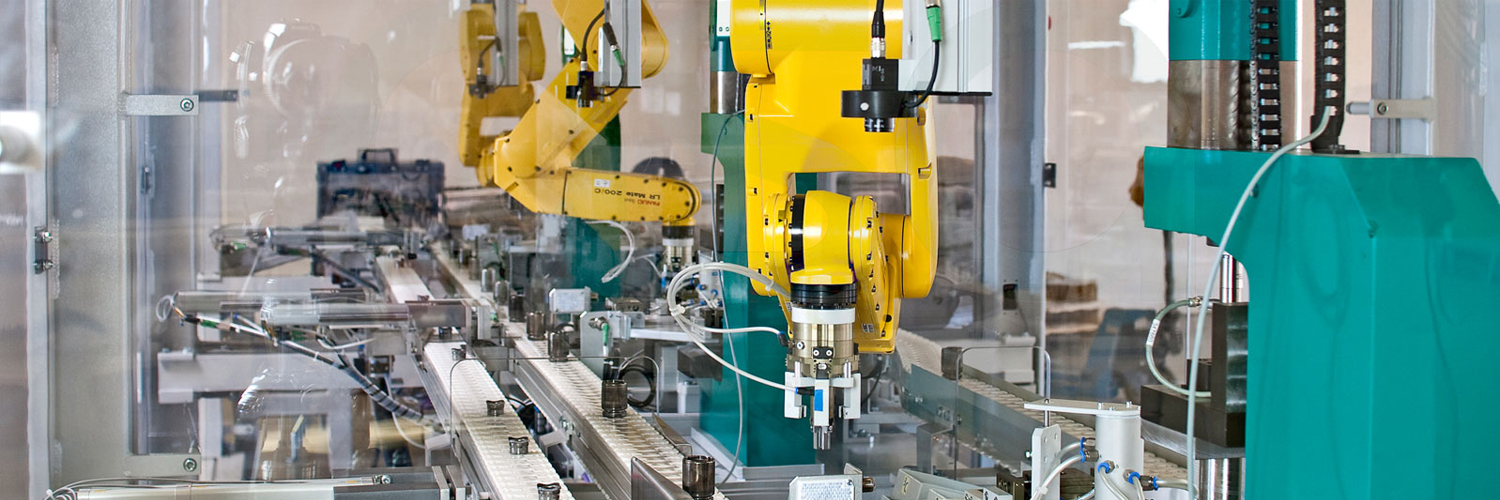

MANUFACTURING OPERATIONS WITHIN SECONDS

- This linked system for the unmanned fabrication and assembly of pistons for passenger-car brake calipers met all requirements, such as achieving a certain, high throughput, high reliability, and excellent finished-product quality levels.

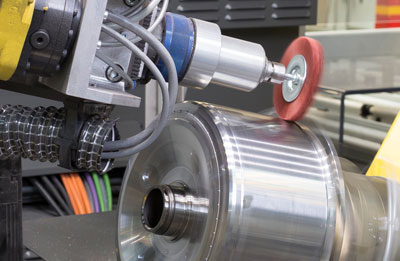

INDUSTRY 4.0 IN DEBURRING TECHNOLOGY

- A pair of collaborative robots manufacturing rotor bearings for hybrid drives for the automotive industry. In addition to deburring, our solution also gauges, inspects, and documents each and every bearing.

MANUAL WORKPLACES

- Partially automated, manual, workplaces for assembling brake calipers where the piston-insertion process and caliper-closure operations, along with ergonomy and occupational safety, played major roles.

PISTON LABELLING

- This robotic system equipped with a machine-vision system labels pistons with accurately oriented and emplaced labels having defined adhesions.

Food & Packaging

PICK & PLACE CYCLES OF SECONDS

- This high-speed pick&place system demonstrates that even difficult-to handle products, such as items consisting of half-baked dough, may be safely packed in boxes in record time and by a six articulated-arm robots and the boxes intralogistically transported to a labeling station and palletized.

SPACE-SAVING SPIRAL CONVEYOR

- This spiral conveyor allows space-saving bridging of large height differences within conveyor systems while maintaining constant, high, transport rates, where the items conveyed may be either individual products, packages, cartons, or even containers

PALLETIZING CARTONS FOR SAFE TRANSPORT

- This system arranges cartons in a transport-safe pattern and palletizes them in several layers using grippers of our own design.

SPACE-SAVING SANDWICH CONVEYOR

- The design of this innovative sandwich conveyor for gently conveying products in tight quarters allows conveying vastly differing types of products having vastly differing dimensions on one and the same system. The conveyor is capable of operating at inclinations of up to 70° to the horizontal.

HYGIENIC BOX TRANSPORT

- This stainless-steel conveyor system for hygienically transporting boxes demonstrates how individual wine boxes may be conveyed to collective packagings, as well as the various chain conveyors, lateral guide rails, product separators, etc., involved.

ERECTING BOXES WITHIN SECONDS

- This dual-cell, box-erection station, which is equipped with a pair of articulated-arm robots, erects 40 folding plastic boxes in parallel every minute, a rate that could not be more than briefly sustained by a human operator. Thanks to the employment of articulated-arm robots, station uptime is better than that of conventional systems employing linear handling mechanisms.

NEW BIG BAG CLOSING SOLUTION

- New: An ATEX-certified bag-closure machine closes big bags without exposing handling personnel to hazardous substances during filling operations. Its air intake and exhaust Systems have been designed such that no contamination by particulates of areas outside the cell occurs, which also contributes to creating a more-healthy working environment.

Pharma

PACKAGING SYRINGES IN A CLEANROOM

- In this cell, products are gently gripped, oriented, and transferred to the next manufacturing stage.

GROUPING COMPULA PACKAGINGS

- Three collaborative robots group bags containing dental supplies at a rate of 30 bags/ minute.

Chemistry

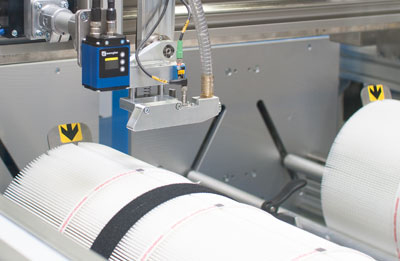

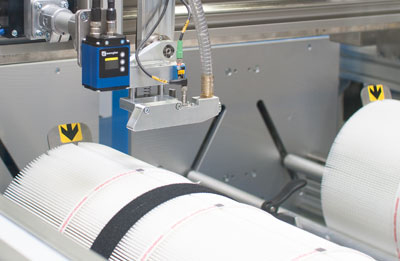

CASSETTE-FILTER ASSEMBLY

- Even cassette filters involving floppy and intricate components maz be assembled in record time.

TUBULAR-FILTER ASSEMBLY

- Final assembly of filters, involving bonding processes and visual quality controls.

Other Branches

CUSTOMIZED INDUSTRIAL DESIGN

- In the case of this cell, the product’s basic structure is very precisely measured on a coordinate-measuring machine. In addition to ergonomic and safe-operation aspects, the cell’s design and color scheme reflected the product’s atypical character and luxurious image.

3D-CONVEYANCE OF TOBACCO CANS

- 3D-conveyance of tobacco cans employing various chain conveyors, lateral guide rails, an elevator, various longitudinal separator tracks, flipping units, etc.